A Ce3+, Mn2+ double-doped apatite structure nitrogen oxide white light phosphor and its preparation method and application

A nitrogen oxide and phosphor technology, which is applied in the field of apatite structure nitrogen oxide white light phosphor and its preparation, can solve the problems of difficult control of luminescence ratio and difficult realization of color regulation, and achieve good industrialization prospects and application prospects , good thermal stability, and the effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

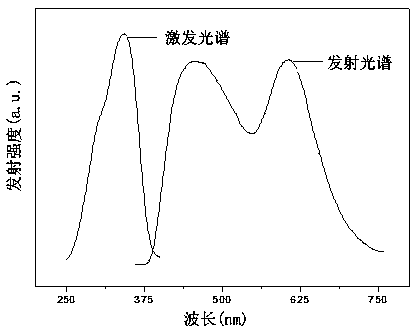

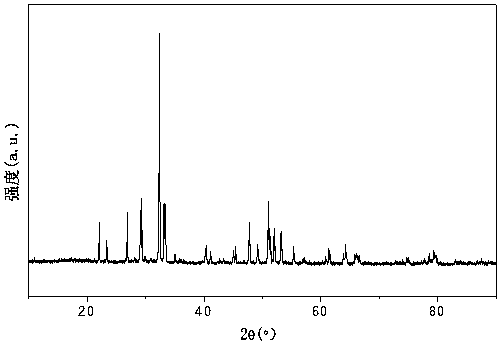

[0028] Example 1: Mg 1.94 Y 2.94 Si 3 o 11 N: 0.06Ce 3+ , 0.06Mn 2+ Phosphor powder preparation

[0029] Its preparation method is as follows:

[0030] According to the molar ratio of each element in the molecular formula, weigh the corresponding mass of MgO 0.391g, Y 2 o 3 1.6597g, SiO 2 0.6759g, Si 3 N 4 0.1754g, CeO 2 0.0516g, MnCO 3 0.0345g, and the purity of the above raw materials is above 99%. Grind the above-mentioned raw material mixture in an agate mortar evenly, put it into a corundum crucible, and raise the temperature to 900°C at a heating rate of 10°C / min in a reducing atmosphere containing 5v% hydrogen gas, and bake for 6 hours. Cool to room temperature. The pre-fired sample was taken out and ground again, then raised to 1400°C at a rate of 10°C / min, kept at a constant temperature for 6 hours, and cooled to room temperature. After the obtained sintered product is crushed, it is finely ground with a ball mill and sieved to obtain a solid powder ...

Embodiment 2

[0033] Example 2: Mg 1.77 Ca 0.2 Y 2.97 Si 3 o 11 N: 0.03Ce 3+ , 0.03Mn 2+ Phosphor powder preparation

[0034] Its preparation method is as follows:

[0035] According to the molecular formula, weigh the corresponding mass of MgO 0.3567g, CaCO 3 0.1001g, Y 2 o 3 1.6766g, SiO 2 0.6759g, Si 3 N 4 0.1754g, CeO 2 0.0258g, MnCO 3 0.0172g, and the purity of the above raw materials is above 99%. Grind the above-mentioned raw material mixture in an agate mortar evenly, put it into a corundum crucible, and raise the temperature to 1000°C at a heating rate of 15°C / min in a reducing atmosphere containing 5v% hydrogen gas, and roast for 6 hours. Cool to room temperature. The pre-fired sample was taken out and ground again, then raised to 1500°C at a speed of 15°C / min, calcined for 8 hours, and cooled to room temperature. After the obtained sintered product is crushed, it is finely ground with a ball mill and sieved to obtain a solid powder with a particle size of 3 t...

Embodiment 3

[0038] Example 3: Mg 1.94 Y 2.44 La 0.5 Si 3 o 11 N: 0.06Ce 3+ ,0.06Mn 2+ Phosphor powder preparation

[0039] Its preparation method is as follows:

[0040] Weigh the corresponding mass of MgO 0.391g and Y respectively according to the molecular formula 2 o 3 1.3774g, La 2 o 3 0.4073g 、SiO2 2 0.6759g, Si 3 N 4 0.1754g, CeO 2 0.0516g, MnCO 3 0.0345g, and the purity of the above raw materials is above 99%. Grind the above-mentioned raw material mixture in an agate mortar evenly, put it into a corundum crucible, and raise the temperature to 1000°C at a heating rate of 10°C / min in a reducing atmosphere containing 5v% hydrogen gas, and bake for 8 hours. Cool to room temperature. The pre-fired sample was taken out and ground again, then raised to 1450°C at a speed of 10°C / min, calcined for 8 hours, and cooled to room temperature. After the obtained sintered product is crushed, it is finely ground with a ball mill and sieved to obtain a solid powder with a pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com