Sweet corn low-sugar composite type beverage and preparation method thereof

A sweet corn and beverage technology, applied in the field of sweet corn low-sugar compound beverage and its preparation, can solve the problems of restricting the development of fruit juice industry and the conflict of fruit consumption channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

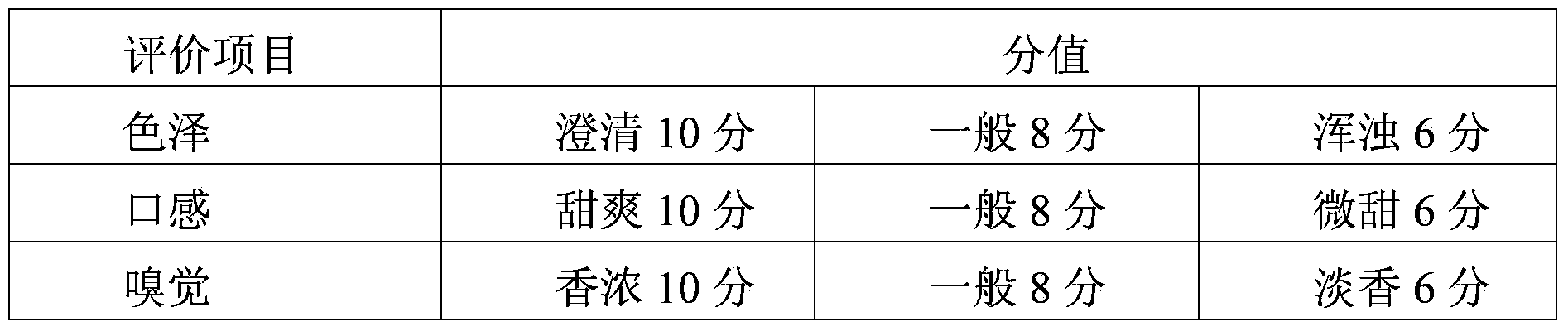

Examples

Embodiment 1

[0024] Embodiment 1, the preparation of sweet corn low-sugar compound beverage

[0025] 1) Sweet corn pretreatment

[0026] Weigh 50g of sweet corn, add 250mL of water to wash, and pass through an 85-mesh sieve; repeat washing twice and drain the water to obtain clean sweet corn.

[0027] 2) Ingredients

[0028] Weigh 10g of kudzu root, 10g of poria cocos, and 15g of wild chrysanthemum, mix them with cleaned sweet corn, and put them in a stainless steel container; add 1500mL of pure water to it (neglect the water attached to the cleaned sweet corn).

[0029] 3) Extraction and filtration

[0030] Soak and extract the above materials in a water bath at 75°C for 2.5 hours; take out the materials, perform vacuum filtration (vacuum degree 100kPa) to remove solid residues, and collect the filtrate as the extraction solution.

[0031] 4) deployment

[0032] Using xylitol as the sugar source, the final sugar content reached 9% (Brix).

[0033] 5) Filling and sterilization

[003...

Embodiment 2

[0045] Embodiment 2, the preparation of sweet corn low-sugar composite beverage

[0046] 1) Sweet corn pretreatment

[0047] Weigh 500g of sweet corn, add 2500mL of water to wash, and pass through a 85-mesh sieve; repeat washing twice and drain the water to obtain clean sweet corn.

[0048] 2) Ingredients

[0049] Take 100g of kudzu root, 100g of poria cocos, and 150g of wild chrysanthemum, mix them with cleaned sweet corn, and put them in a glass container; add 10L of pure water to it (neglect the water attached to the cleaned sweet corn).

[0050] 3) Extraction and filtration

[0051] Soak and extract the above materials in a water bath at 80°C for 1.5 hours; take out the materials, perform vacuum filtration (vacuum degree 100kPa) to remove solid residues, and collect the filtrate as the extraction solution.

[0052] 4) deployment

[0053] Using xylitol as the sugar source, the final sugar content of the preparation solution was 8% (Brix).

[0054] 5) Filling and steril...

Embodiment 3

[0059] Embodiment 3, the preparation of sweet corn low-sugar composite beverage

[0060] 1) Sweet corn pretreatment

[0061] Weigh 400g of sweet corn, add 2000mL of water to wash, and pass through an 85-mesh sieve; repeat washing twice and drain the water to obtain clean sweet corn.

[0062] 2) Ingredients

[0063] Weigh 100g of kudzu root, 150g of poria cocos, and 200g of wild chrysanthemum, mix them with cleaned sweet corn, and put them in a glass container; add 10L of pure water to it (neglect the water attached to the cleaned sweet corn).

[0064] 3) Extraction and filtration

[0065] Soak and extract the above materials in a water bath at 75°C for 2.0 hours; take out the materials, perform vacuum filtration (vacuum degree 100kPa) to remove solid residues, and collect the filtrate as the extraction solution.

[0066] 4) deployment

[0067] Using xylitol as the sugar source, the final brix content of the preparation solution was 7.5% (Brix).

[0068] 5) Filling and ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com