Multi-emission-peak LED (light emitting diode) white light fluorescent powder and preparation method thereof

A multi-emission and fluorescent powder technology, which is applied in the direction of luminescent materials, chemical instruments and methods, and the use of gas discharge lamps, etc., can solve the problem of affecting the light efficiency of the light source, the low conversion efficiency of red and green powder, and the low color rendering index of white light, etc. problems, to achieve the effect of simplifying the process flow, good industrialization prospects and application prospects, and good color rendering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

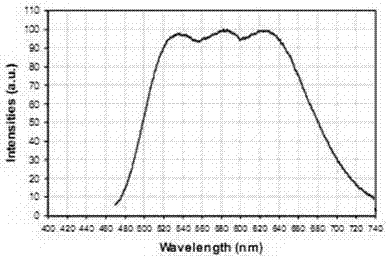

Image

Examples

Embodiment 1

[0017] (1) According to the chemical formula Sr 1.94 SiO 4 :(Eu 2+ 0.02 , Eu 3+ 0.04 ) Weigh SrCO 3 , SiO 2 and Eu 2 o 3 , and weigh 1% of the mass of the chemical formula SrF 2 As a co-solvent, grind for 360min in a ball mill with a revolution of 30r / min and an autorotation of 700r / min;

[0018] (2) Dry the above mixture and put it into a crucible, place it in a high-temperature tube furnace, and pass H into the tube furnace 2 / N 2 Reducing atmosphere (H 2 volume content 5%), with 5 o The heating rate of C / min raises the furnace temperature to 800 o C kept for 2 hours, then increased to 1400 o C sintering for 3 hours, close the furnace, and the sintered product is cooled to room temperature with the furnace in a reducing atmosphere;

[0019] (3) Take the sintered material out of the furnace and crush it. Wash 5 times with deionized water, and at 135 o Dry in C oven for 5 hours to obtain Sr 1.94 SiO 4 :(Eu 2+ 0.02 , Eu 3+ 0.04 ) alkaline earth metal si...

Embodiment 2

[0022] (1) According to the chemical formula Ba 1.96 SiO 4 :(Eu 2+ 0.02 , Eu 3+ 0.02 ) Weigh BaCO 3 , SiO 2 、Eu 2 o 3 , and weigh BaF which accounts for 2.5% of the mass of the chemical formula 2 As a co-solvent, grind for 45min in a ball mill with a revolution of 350r / min and an autorotation of 60r / min;

[0023] (2) Dry the above mixture and put it into a crucible, place it in a high-temperature tube furnace, and pass H into the tube furnace 2 / N 2 Reducing atmosphere (H 2 volume content 5%). to 5 o The heating rate of C / min raises the furnace temperature to 850 o C is maintained for 4 hours, and then increased to 1500 o C, sinter for 8 hours, close the furnace, and cool the sinter to room temperature with the furnace in a reducing atmosphere;

[0024] (3) Take the sintered product out of the furnace and pulverize it. Washed three times with deionized water, and at 105 o Dry in C oven for 10 hours to get Ba 1.96 SiO 4 :(Eu 2+ 0.02 , Eu 3+ 0.02 ) Alkal...

Embodiment 3

[0027] (1) According to the chemical formula Sr 1.87 Ba 0.1 SiO 4 :(Eu 2+ 0.01 , Eu 3+ 0.02 ) Weigh SrCO 3 、BaCO 3 , SiO 2 、Eu 2 o 3 , and weigh 2% of the mass of chemical formula NH 4 F is used as a co-solvent, and is ground in a ball mill for 150 min with a revolution of 150 r / min and an autorotation of 150 r / min;

[0028] (2) Dry the above mixture and put it into a crucible, place it in a high-temperature tube furnace, and pass H into the tube furnace 2 / N 2 Reducing atmosphere (H 2 volume content 5%). to 5 o The heating rate of C / min raises the furnace temperature to 850 o C is maintained for 4 hours, and then increased to 1500 o C, sintered for 6 hours. After closing the furnace, the sintered product is cooled to room temperature with the furnace in a reducing atmosphere;

[0029] (3) Take the sintered product out of the furnace and pulverize it. Wash 4 times with deionized water, and at 120 o Dry in C oven for 7 hours to get Sr 1.87 Ba 0.1 SiO 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com