Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98 results about "Black ferric oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ferric oxide black (Fe3O4), also known as iron (III) oxide, is a coloring agent for tablets and capsules used in the pharmaceutical industry. Iron oxides are also commonly used in the cosmetics industry. Iron oxides for use in pharmaceutical manufacturing may also be synthetic.

Preparing and applications of ferric oxide-alumina compound nanophase defluoridation material

InactiveCN101229504AReduce dosageImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionSorbentAlumina composite

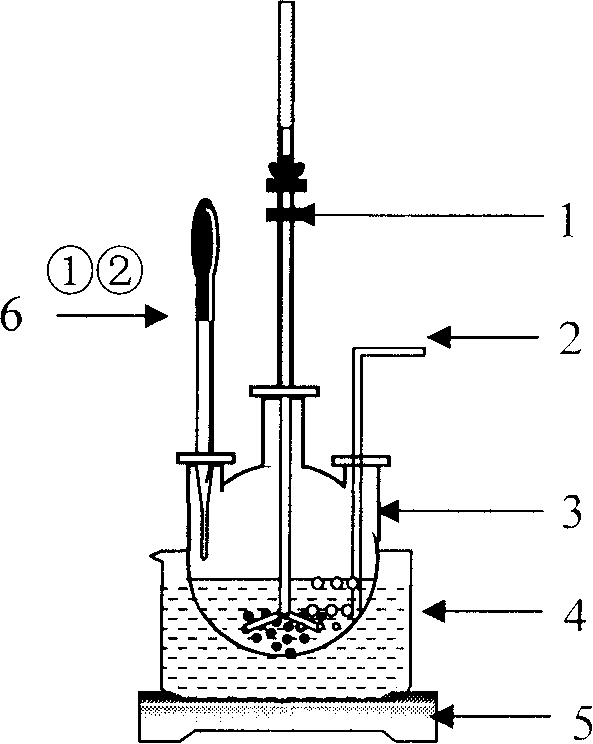

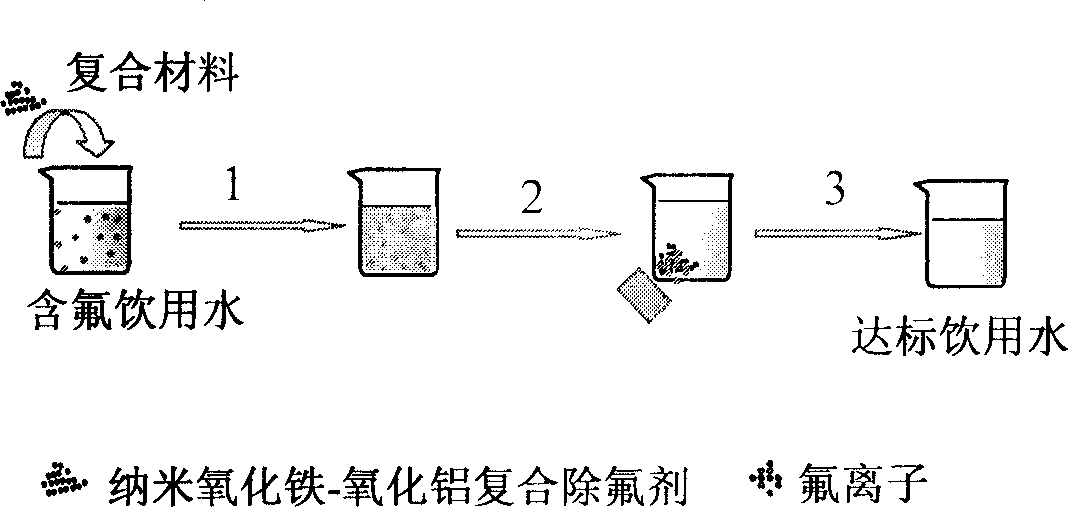

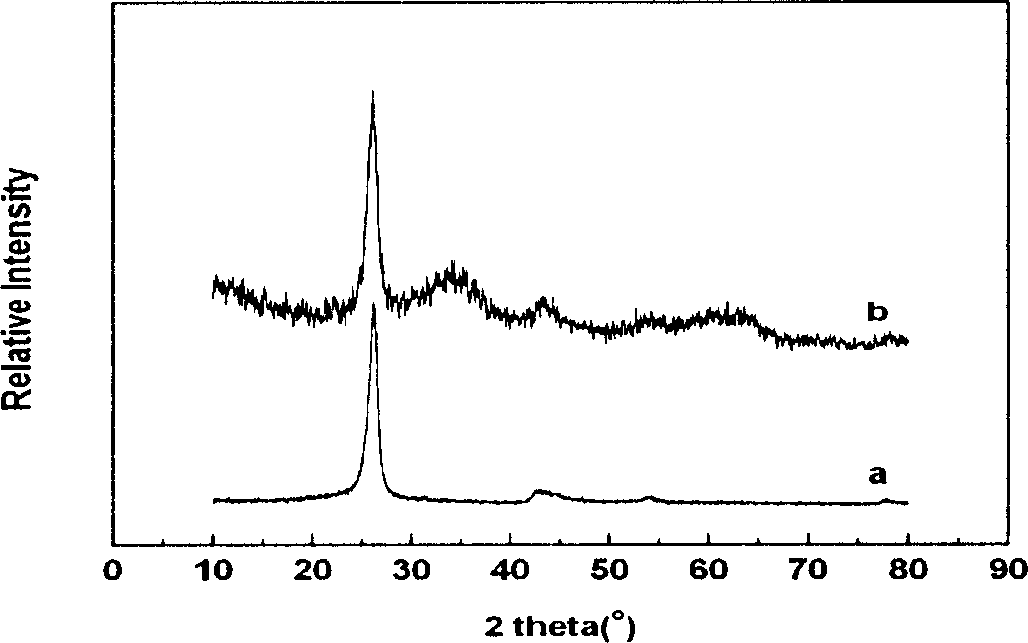

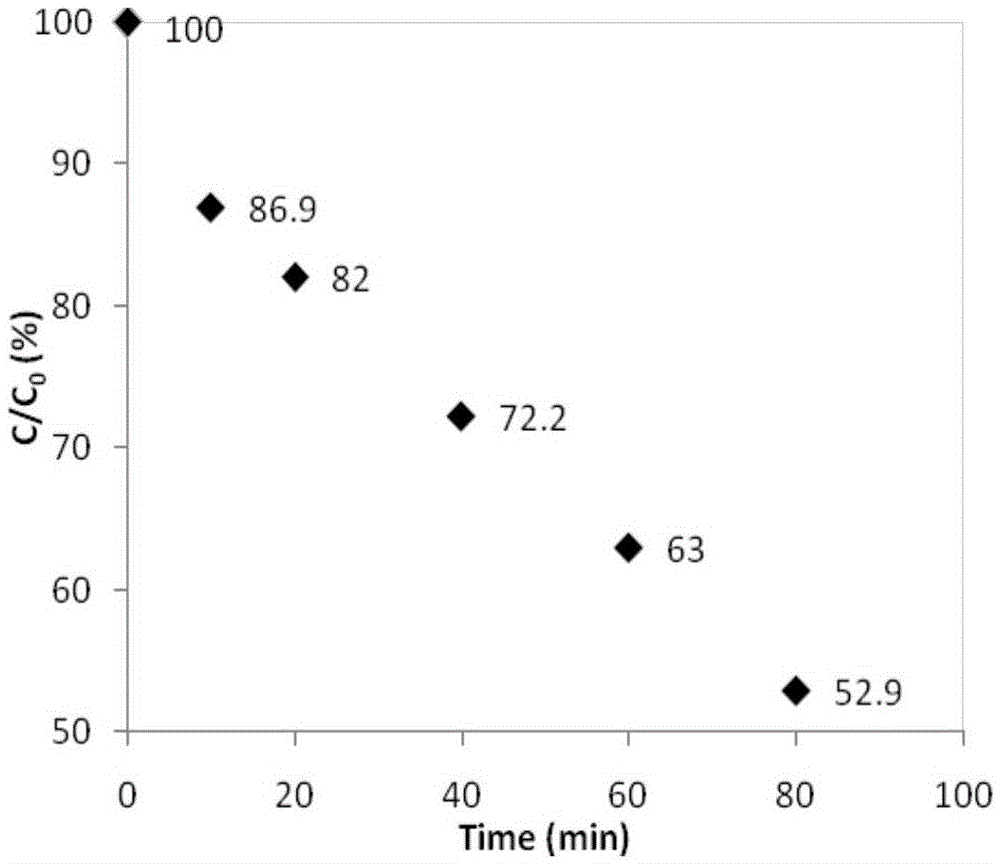

The invention pertains to the field of chemical analysis test equipment, relating to a novel composite material of nano iron oxide-alumina which is used as an sorbent for removing fluoride from water to remove the fluoride from the large amount of drinking water; the fluorin content after the treatment is lower than the content of national standard; compared with the traditional defluorinating agent, the invention has the advantages of simple structure, low cost, high sorption capacity and fast removing speed. As a novel magnetic nano material, the defluorinating agent can realize the separation of extraction agent and base solution under the condition of external magnetic field. The surface of the nano iron oxide is coated with a layer of Al(OH)3; F<-> and Al<3+> in the water to form a complex compound which settles down to realize the effect of defluorination; 1L of water sample only consumes the defluorinating agent of 0.1g; to high fluorin content water with concentration of 20mg / L, the concentration after defluorination can be less than 1mg / L, which can well meet requirement with the reproducibility of analysis result RSD being less than 7 percent.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Colorized reflection heat insulation coating and color card thereof

ActiveCN102181217AModulation shortcutHigh Solar ReflectanceReflecting/signal paintsMulticolor effect coatingsHigh reflectivityMaterials science

The invention discloses a colorized reflection heat insulation coating. Carbon black, iron oxide red, organic yellow, phthalocyanine green, phthalocyanine blue, and other conventional common pigments are replaced by the pigments, namely nickel iron chromite black, nickel iron chromite red, cobalt blue, titanium yellow and cobalt green, so that the colorized reflection heat insulation coating can meet the demand of the external wall decoration on colors and has high reflectivity to solar energy and a good heat insulation effect. The invention also provides a color card by which a colorized coating is formed by mixing the nickel iron chromite black, the nickel iron chromite red, the cobalt blue, the titanium yellow and the cobalt green, a user can quickly mix the coating of the corresponding colors according to the pigment formula corresponding to each color in the color card, and the color card is convenient to use.

Owner:NIPPON PAINT GUANGZHOU

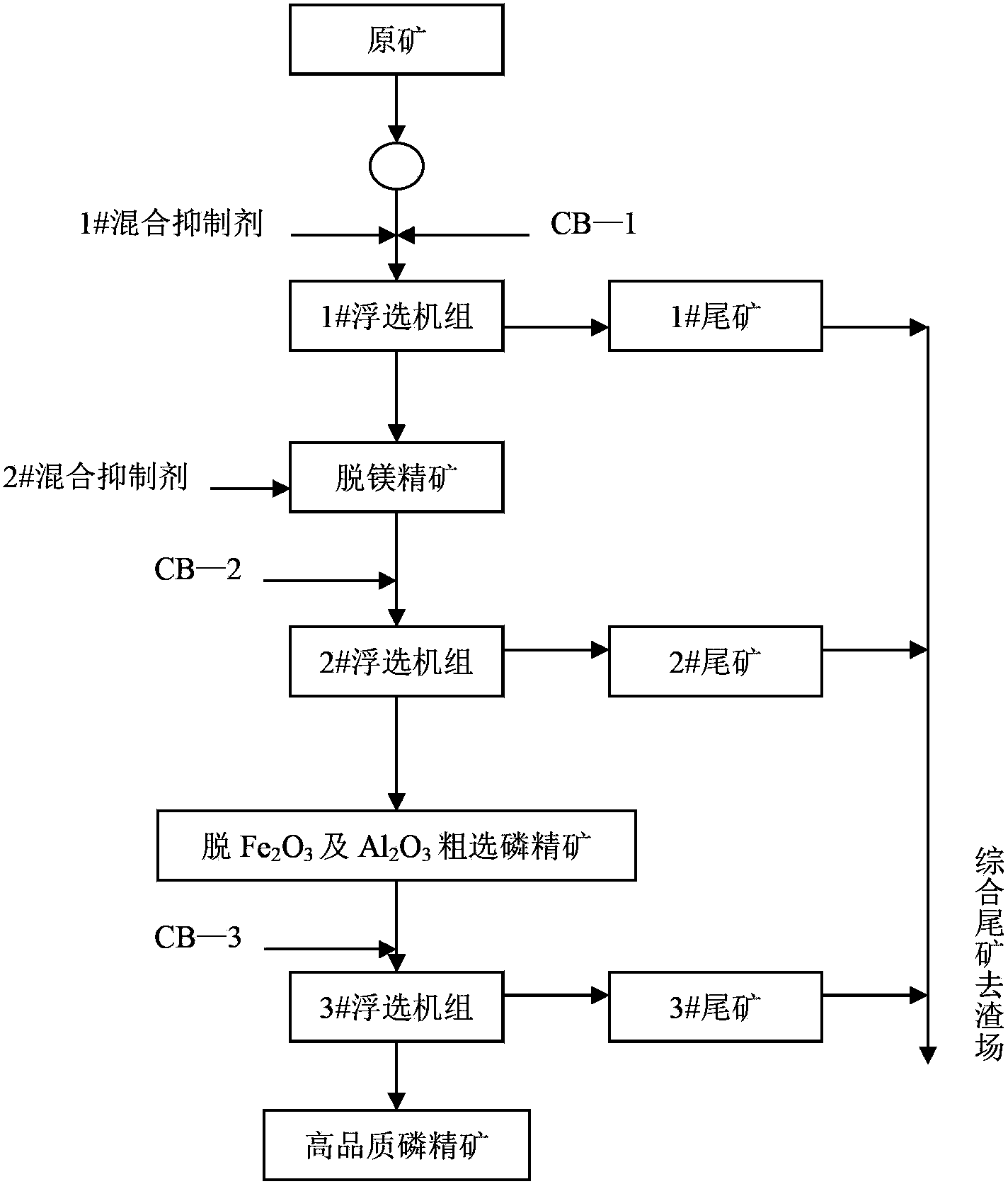

Method for simultaneously removing magnesium oxide, ferric oxide and aluminum oxide sesquioxide in middle-grade and low-grade phosphate ores by adopting double-reverse floatation process

The invention relates to a method for simultaneously removing magnesium oxide, ferric oxide and aluminum oxide sesquioxide in middle-grade and low-grade phosphate ores by adopting a double-reverse floatation process. The method adopts the double-reverse floatation process to remove MgO, Fe2O3 and Al2O3 so as to realize continuous production of an industrialization device. The method comprises the following process steps of: levigating raw phosphate ore, wherein more than or equal to 85 percent of raw phosphate ore is minus 200 messes in size, and the solid content of ore pulp is 20-45 percent; adding a No.1 mixed inhibitor in the ore pulp, introducing the regulated ore pulp into a floatation machine, adding a collecting agent CB-1, aerating, and collating, so as to obtain magnesium removal phosphate concentrate; adding a No.2 mixed inhibitor in the magnesium-removal phosphate concentrate, adding a collecting agent CB-2, aerating, and collating, so as to obtain crude phosphate concentrate without ferric oxide and aluminum oxide; and adding a collecting agent CB-3 into the crude phosphate concentrate without ferric oxide and aluminum oxide, aerating, and collating, so as to obtain high-grade phosphate concentrate. The method can simultaneously remove the content of magnesium oxide, ferric oxide and aluminum oxide from the concentrate, thus obviously improving the quality of the phosphate concentrate and lowering the production cost in follow-up acid making process.

Owner:KUNMING CHUAN JINNUO CHEM IND

Regeneration process of high temperature gas desulfurizer

InactiveCN101805641ANo obvious sintering occursGentle regeneration conditionsSulfur preparation/purificationCombustible gas purificationReaction rateOxygen

The invention relates to a regeneration process of a high temperature gas desulfurizer, belonging to the field of preparation and use of gas desulfurizer. The invention is characterized in that by utilizing the regeneration heat-absorbing reaction of a ferric oxide based desulfurizer under an atmosphere containing sulfur dioxide, temperature runaway sintering of the desulfurizer caused by acute heat release of the regeneration reaction of the ferric oxide based desulfurizer under an atmosphere containing trace oxygen is avoided, thereby improving the regeneration reaction rate, recovering theelemental sulfur resource, realizing the desulfurizing / regeneration cycle process of the ferric oxide based desulfurizer, and simultaneously realizing cycle of the regeneration gas by introducing theregenerated gas into a regeneration reactor. The regeneration rate of the ferric oxide high temperature gas desulfurizer can reach more than 80%, and the regenerated products are all elemental sulfur. The invention has simple operation, stable desulfurizing performance of the regenerated desulfurizer and considerable application value, economic benefit and social benefit, and is developed mainly aiming at the ferric oxide based high temperature gas desulfurization and purification.

Owner:TAIYUAN UNIV OF TECH

Porous ferric oxide-titanium oxide-activated carbon complex fiber membrane and preparation method

InactiveCN106345314AThe process is simple and easy to controlLow costSemi-permeable membranesMembranesFiltrationTitanium oxide

The invention belongs to the technical field of functional fiber materials, and provides a porous ferric oxide-titanium oxide-activated carbon complex fiber membrane and a preparation method thereof. The porous ferric oxide-titanium oxide-activated carbon complex fiber membrane is formed by porous fibers formed by three phases: ferric oxide, titanium dioxide and activated carbon, and has the characteristics of photocatalysis, adsorption and filtration. Meanwhile, the invention also provides a preparation method of a nanocrystalline iron oxide / titanium oxide / activated carbon complex fiber membrane with the characteristics of high photocatalysis and adsorption, and a three-phase complex nanofiber membrane is obtained through an electrostatic spinning method and hot pressed sintering processing, and is controllable in structure, simple in preparation process and easy for large-scale production; the fiber membrane can be applied in organic and heavy metal wastewater treatment, is high in treatment efficiency, and can be recycled.

Owner:JIANGSU UNIV

Method for preparing magnetic compound material of ferric oxide cladded carbon nanotube

InactiveCN1670251AImprove performanceMeet the needs of developmentMetallic material coating processesTransformerCarbon nanotube

The invention discloses a method for preparing magnetic composite material of a carbon nanometer tube covered with di-iron trioxide. The invention makes the carbon nanometer tube reflux in the nitric acid, to introduce several function groups such as carboxyl group, hydroxyl group and carbonyl group in the tube wall, which can adsorb iron ions in the solution. Then the iron ions adsorbed in the tube wall react with the hydroxide ion in the ammonial solution, which coated the hydroxide ion on the tube, and the tube can be coated with di-iron trioxide by calcining. The invention provides a simple way to get composite material, good performance soft magnetic material, which is facilitating to industrial production, and may be used in the areas of high-density magnetic recording material, wave-absorbing material, ink for electrophotographic copying, broad-cellulae transformer, noise filter, voltage transformer for communicating and so an.

Owner:DONGHUA UNIV

Method for extracting ferric oxide, aluminum oxide and scandium oxide through neutralization of cobaltous hydroxide nickel smelting slag and waste titanium dioxide acid

The invention relates to a method for extracting ferric oxide, aluminum oxide and scandium oxide through neutralization of cobaltous hydroxide nickel smelting slag and waste titanium dioxide acid. The method comprises the following steps: firstly, performing neutralization on cobaltous hydroxide nickel smelting slag with the waste titanium dioxide acid and water in a certain ratio, adding a flocculant to remove silicon, filtering so as to obtain filtrate, performing reextraction of Al, Fe and Sc in the obtained filtrate by using an extraction agent respectively so as to obtain aluminum salt, ferric salt and Sc(OH)3, performing high-temperature roasting on the ferric salt and the aluminum salt, thereby obtaining oxides with relatively high purity, and roasting the Sc(OH)3, thereby obtaining the scandium oxide. The method has the beneficial effects that valuable metals such as iron and aluminum are extracted by using the cobaltous hydroxide nickel smelting slag, and the rare earth metal scandium is recycled, so that the comprehensive utilization rate of metals in ore can be increased, environment pollution can be reduced, and high economic benefits and environment benefits can be created.

Owner:万华化学(烟台)电池材料科技有限公司

Method for preparing photocatalyst for porous pucherite nanosheet modified by ferric oxide

ActiveCN103962146AHigh activityEasy to centrifuge and reuseMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsVisible light radiationPhenol

The invention discloses a method for preparing a compound photocatalyst for modified porous pucherite nanosheet, and belongs to the field of inorganic nano photocatalytic materials. The degradation rate of the porous pucherite nanosheet loaded with ferric oxide to rhodamine B can reach 99% in 90 minutes under the irradiation of visible light, and the degradation rate is 27 times higher than the porous pucherite nanosheet not modified by the ferric oxide. The compound photocatalyst can effectively degrade colorless organic pollutant such as phenol. Under the irradiation of visible light, the removal rate to phenol in 2 hours can reach more than 96%, and the degradation rate is 31 times higher than the porous pucherite nanosheet not modified by the ferric oxide. According to the invention, the prepared compound photocatalyst not only can perform efficient photocatalytic degradation on poisonous and harmful chemical substances under the irradiation of visible light, but also can conveniently perform precipitation separation recycle in a liquid phase reaction, the preparation method is simple, the material cost is low, and good application prospect is achieved.

Owner:WENZHOU UNIVERSITY

Novel magnetic iron/lanthanum composite arsenic removal adsorbing material and preparation method thereof

ActiveCN107913662AEasy to elutePromote regenerationOther chemical processesWater contaminantsAir atmosphereSorbent

The invention discloses a novel magnetic iron / lanthanum composite arsenic removal adsorbing material and a preparation method thereof. The composite adsorbing material is prepared by the steps: by taking a ferric iron salt, a trivalent lanthanum salt and a ligand terephthalic acid as a precursor and taking N,N-dimethyl formamide (DMF) as a medium solvent, carrying out a solvothermal reaction to obtain a bimetallic-organic framework material; and calcining the coordination product in an air atmosphere to further obtain the composite magnetic adsorbent composed of ferric oxide (Fe2O3) and lanthanum oxide carbonate (La2O2CO3).The composite magnetic adsorbent synthesized in the invention can effectively utilize strong adsorption property of lanthanum on arsenate and utilize magnetic separationperformance of the ferric oxide, and more importantly has outstanding advantages of being easy to recover, recyclable and the like. The novel magnetic iron / lanthanum composite arsenic removal adsorbing material disclosed by the invention provides a selection for removing arsenic and other heavy metals in drinking water, domestic sewage and industrial wastewater and has important actual application value.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI +1

Preparation method for ferric oxide-modified titanium dioxide high-efficiency visible photocatalyst

ActiveCN105478121ASimple methodLow costWater/sewage treatment by irradiationWater treatment compoundsAtmospheric pollutionCalcination

The invention discloses a preparation method for a practical ferric oxide-modified titanium dioxide high-efficiency visible photocatalyst, which belongs to the field of treatment of environmental wastewater. The objective of the invention is mainly to overcome the disadvantages of low visible light absorption properties of titanium dioxide, a great number of steps for preparation of ferric oxide-modified titanium dioxide (Fe2O3 / TiO2) and the like. The preparation method provided by the invention only employs commercial P25 and ferriferrous oxide (Fe3O4) nanoparticles as raw materials and carries out calcination by using a gradient heating program so as to allow Fe3O4 powder to be directly converted into ferric oxide (Fe2O3) and to be fully fused with P25, and thus, the high-efficiency Fe2O3 / TiO2 visible photocatalyst is prepared. The method provided by the invention is extension and further expansion of preparation technology for metal oxide doped titanium dioxide and is provided to overcome the disadvantages of poor solar energy utilization capability, difficulty in mass production and the like of photocatalysts. The prepared Fe2O3 / TiO2 visible photocatalyst can be extensively applied to the fields of purification of atmospheric pollution and waste water, etc.

Owner:JIANGSU UNIV

Antifouling polyurethane coating

InactiveCN105482677AIncrease elasticityHigh tensile strengthAntifouling/underwater paintsPaints with biocidesSilanesButanediol

The invention discloses an antifouling polyurethane coating. The antifouling polyurethane coating comprises the raw materials of perfluoroalkyl ethyl alcohol, polytetrahydrofuran ether glycol, polycarbonate diol, diphenylmethane diisocyanate, isophorone diisocyanate, 1,4-butanediol, stannous octoate, stannous oleate, amino silane, nano titanium dioxide, nano zinc oxide, nano calcium carbonate, nano ferric oxide, talc powder, a modified antifouling agent, a dispersant, ethyl cellulose, a leveling agent, propylene glycol, a film forming assistant, and deionized water. The antifouling polyurethane coating disclosed by the invention, is strong in adhesive force with a substrate, excellent in antifouling performance, and good in heat resistance, weather resistance and water resistance.

Owner:ANHUI ANDA HUATAI NEW MATERIALS CO LTD

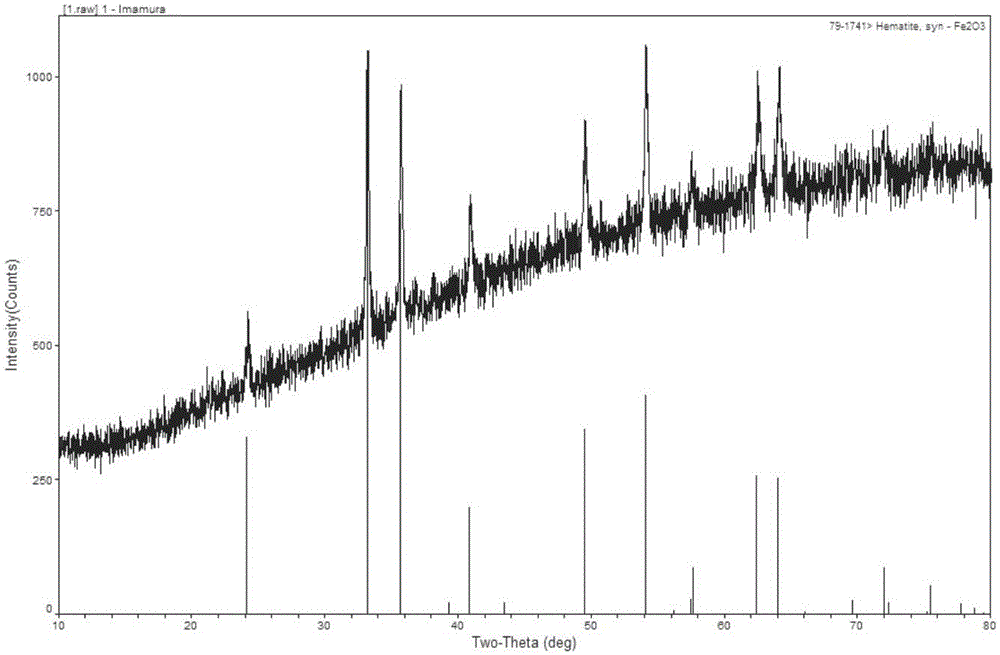

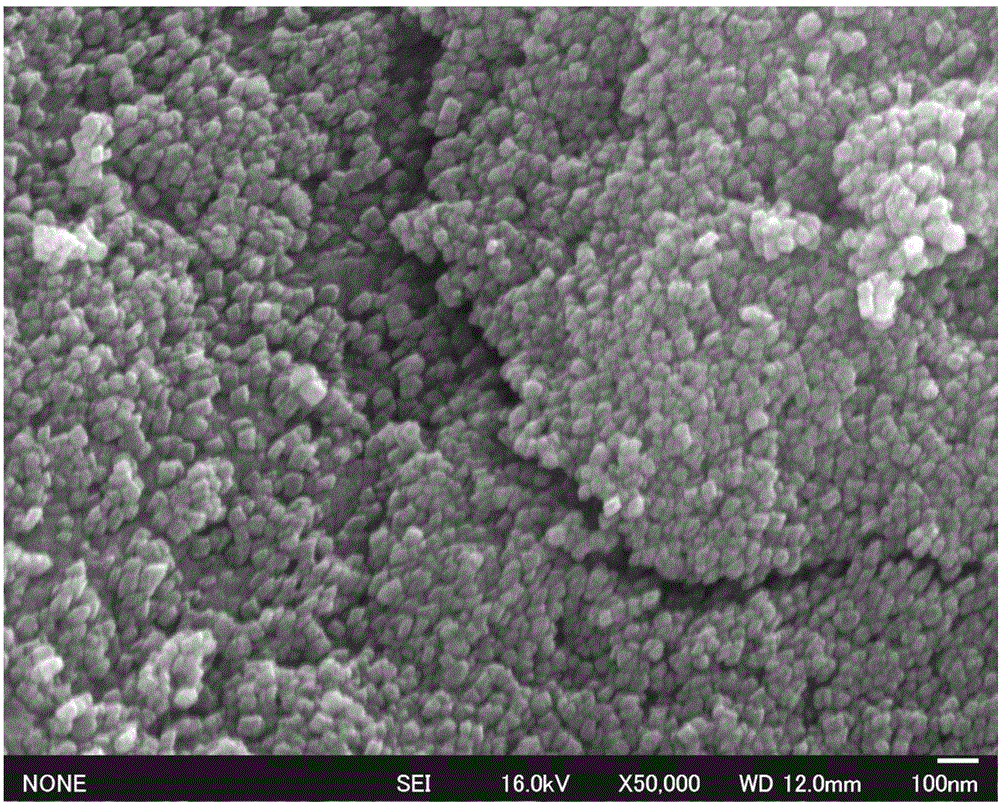

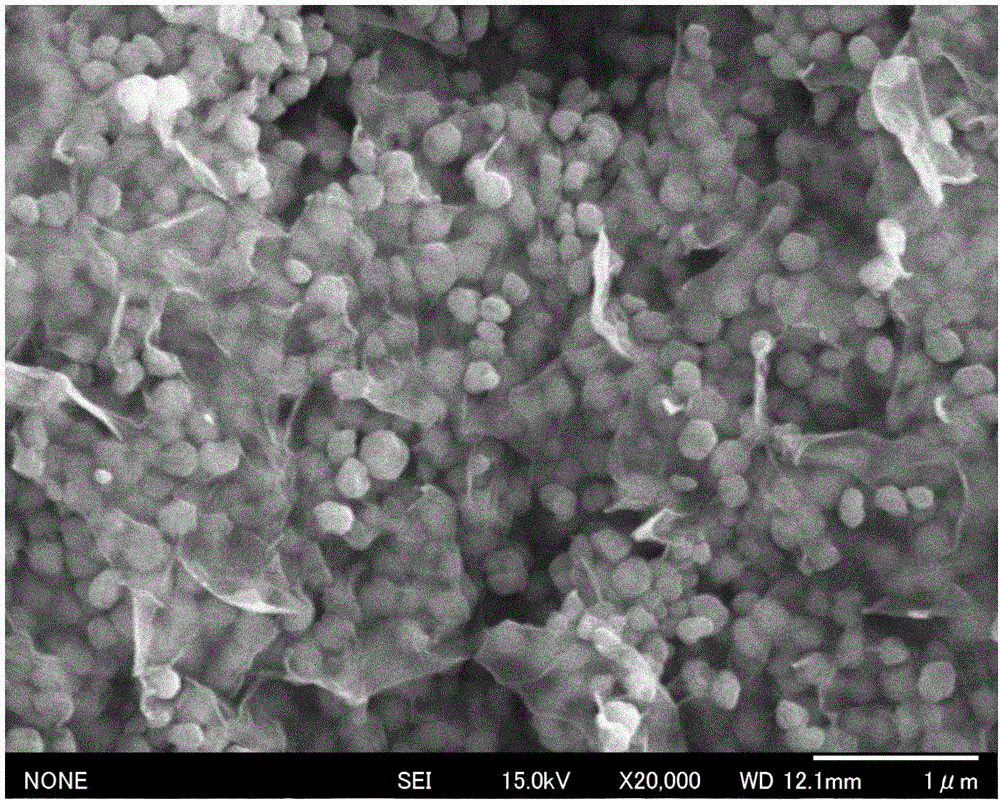

Preparation method for rice grain-shaped alpha-Fe2O3 (alpha-ferric oxide) nanometer powder

InactiveCN104150541AUniform rice grainLarge specific surface areaMaterial nanotechnologyFerric oxidesSurface-active agentsRice grain

The invention discloses a preparation method for rice grain-shaped alpha-Fe2O3 (alpha-ferric oxide) nanometer powder, and belongs to the technical field of the preparation of nanometer materials. The method comprises the following steps: firstly, Fe2(SO4)3 (ferric sulfate) and NaOH (sodium hydroxide) are used as raw materials, hexadecyl trimethyl ammonium bromide (C19H42BrN) is used as a surface active agent, a hydrothermal method is used for preparing needle-shaped FeOOH powder, then after the temperature of the FeOOH powder rises from a room temperature to 1000 DEG C at the temperature rising rate of 10 DEG C / min in a muffle furnace, the FeOOH powder is directly cooled, and the rice grain-shaped alpha-Fe2O3 nanometer powder is obtained. The alpha-Fe2O3 which is prepared according to the method presents a more uniform rice grain shape, the specific surface area is large, and the method can have potential application in the field of photocatalysis and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Preparation method of flake ferric oxide

InactiveCN101913657AImprove the mixing effectActs as a crystal form guideFerric oxidesWater bathsRust

The invention discloses a preparation method of flake ferric oxide, which comprises the following steps: dissolving ferric trichloride hexahydrate, a composite fused salt and an additive in dilute sulphuric acid to prepare solution of a precursor; drying at 100 to 150 DEG C for 24 to 36 hours till no water exists, grinding to obtain precursor powder, and sintering at 900 to 1,200 DEG C for 2 to 6 hours; and obtaining a flake ferric oxide product by stirring in water bath, washing, filtering and drying. In the invention, the precursor is prepared by wet-method crystallization rather than the conventional dry-method mixing, so the agglomeration problem of the product is solved effectively; an aluminum oxide or zinc oxide additive is introduced for crystal form guiding; and the product is hexagonal flakes with flat and smooth surfaces, the particle dispersing performance of the product is high, the average particle size is 20 to 60 mu m, the thickness is uniformly distributed around 0.4 mu m, and the diameter-to-thickness ratio is 50 to 150. The prepared flake ferric oxide product can be wieldy used in anticorrosion coatings, high-quality pearl pigments and cosmetics as an inorganic rust-resisting material.

Owner:CENT SOUTH UNIV

Preparation method of ferric oxide and zinc oxide nanometer composite material

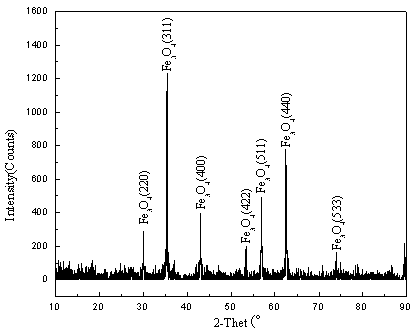

InactiveCN102133531AShorten the timeEnhanced photocatalytic performanceMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsBlack ferric oxideIron oxide

The invention discloses a preparation method of a ferric oxide and zinc oxide nanometer composite material, which is used for solving the technical problem of long reaction time of the traditional preparation method of the ferric oxide and zinc oxide nanometer composite material. In the technical scheme, a ferric oxide and zinc oxide nanometer composite material with regular shape and high crystallinity is prepared at lower temperature within shorter time by adopting a microwave assisted hydrothermal method; and compared with a method adopted in the background art, the reaction time for preparation is shortened to 0.5-1 hour from 24 hours, the time is shortened by more than 20 times, and meanwhile, the photocatalytic performance is improved by 3.5 times.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Iron Oxide Precipitaion from Acidic Iron Salt Solutions

InactiveUS20080206127A1Reduce usageZinc oxides/hydroxidesCalcium/strontium/barium nitratesZinc hydroxideIron salts

Improved methods for treating metallurgical compositions involve reacting a metallurgical composition with an aqueous nitric acid solution. The reaction is performed at a pressure or at least about 220 psig and at a temperature of at least 100° C. The metallurgical composition comprises iron and one or more non-ferrous metals. The reaction dissolves at least a portion of the non-ferrous metal compositions into the solution which is in contact with solid ferric oxide. The reaction can be repeated on the isolated solids to increase the purity of ferric oxide in the solids. Zinc can be removed from mixed metal solutions obtained from furnace dust by adding base to precipitate zinc hydroxide.

Owner:METALOX INT

Method for preparing graphene-ferric oxide-graphene composite structure battery negative electrode material

ActiveCN106848220AImprove conductivityIncrease tightnessCell electrodesWater bathsBlack ferric oxide

The invention discloses a method for preparing a graphene-ferric oxide-graphene composite structure battery negative electrode material. The method comprises the following steps: preparing graphene loaded Fe2O3 through a first-step pyrolysis method; covering a graphene layer on the surface of Fe2O3 through a water bath method; and finally forming a graphene-ferric oxide-graphene sandwich structure. According to the structure, the electrical conductivity and charge and discharge stability of the ferric oxide can be obviously improved. Meanwhile, the equipment used in the method is simple and easy to realize.

Owner:SHAANXI UNIV OF SCI & TECH

Catalyst for surface sulfation of ferric oxide, as well as preparation method and application thereof

InactiveCN103785420ALow priceEfficient redox processPhysical/chemical process catalystsDispersed particle separationSulfationBlack ferric oxide

The invention discloses a preparation method of a catalyst for surface sulfation of ferric oxide. The method comprises the following steps: (1) preparing ferric oxide; (2) performing sulfation treatment on the surface of the ferric oxide to obtain a ferric oxide catalyst of which the surface is sulfated. The ferric oxide catalyst with the enhanced surface acidity and the proper oxidation-reduction capacity is synthesized for the first time through performing sulfating process on the surface of the ferric oxide, so that the NOx purification activity of middle and high temperature sections in NH3 selectively reducing NOx (namely NH3-SCR) reaction is obviously improved, an operation temperature window is obviously broadened, and the catalyst has the extremely excellent SO2 poisoning resistance performance and is very applicable for catalytic elimination of a stationary source and a mobile source NOX.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

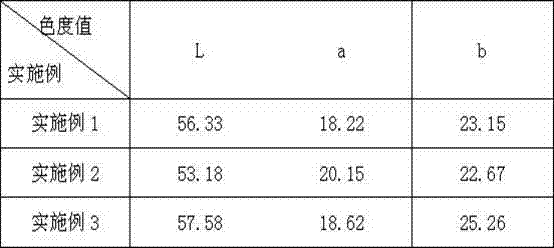

Preparation method of aluminum iron oxide red ceramic pigment

The invention discloses a preparation method of an aluminum iron oxide red ceramic pigment. The method comprises the following steps: putting a mixture of 70% to 80% of calcined aluminum hydroxide, 20 to 30% of ferric oxide and a sodium salt as a mineralization agent by weight percent into a ball miller in a crossing manner to carry out a ball-milling treatment for 25 to 40 hours, wherein the adding amount of the sodium salt accounts for 1% to 5% of the total weight of calcined aluminum hydroxide and ferric oxide, and high-aluminum balls are adopted as ball-milling materials; calcining the material mixture in a kiln at the high temperature of 1050 to 1100 DEG C for 6 to 15 hours; and finally crushing the obtained material to reach the granularity of less than 50 mu m. According to the method, the price of the raw materials is low, so that the cost is saved; and on the premise that the calcining temperature for aluminum iron oxide red in the body kiln reaches 1250 DEG C, the produced architectural ceramic is less in color aberration change, good in stability and bright in forming color, thereby commendably satisfying the aesthetic requirements of people in daily life.

Owner:石家庄高砂新材料有限公司

Preparation method of thallous iodide

InactiveCN108217716AHigh product purityEmission reductionGallium/indium/thallium compoundsSlagIodide

The invention discloses a preparation method of thallous iodide, and belongs to the technical field of metal compounds. The preparation method is characterized in that ash slag of sulfuric acid, wastewater of sulfuric acid and iodide are used as raw materials to prepare; the ash slag of sulfuric acid is prepared from Fe2O3 (ferric oxide), Fe3O4 (ferroferric oxide), TlF (thallium fluoride) and TlF3 (thallium trifluoride); the sulfur acid waste water contains HF (hydrogen fluoride) and Tl<+>. The preparation method of the thallous iodide has the advantages that the production cost is reduced, and the purer product can be obtained.

Owner:GUANGZHOU UNIVERSITY

Ferric oxide desulfurizer and preparation method thereof

ActiveCN104058491AHigh mechanical strengthDispersed particle separationWater/sewage treatmentCarbonationBlack ferric oxide

The invention provides a preparation method of ferric oxide desulfurizer. The preparation method includes the following steps that at the temperature of 50 DEG C to 75 DEG C, solid soluble ferrite and a carbonate compound aqueous solution are mixed, stirred and rolled in a mixing mode and react for 20 minutes to 30 minutes, so that a reaction mixture is obtained; at the temperature of 50 DEG C to 75 DEG C, the reaction mixture and hydroxide are mixed, stirred and rolled in a mixing mode and react for 20 minutes to 30 minutes, so that insoluble ferric salt is obtained; insoluble ferric salt is formed through physical vacuum extrusion, and the ferric oxide desulfurizer is obtained after drying. The invention further provides the ferric oxide desulfurizer. Ferric oxide serves as an active component of the ferric oxide desulfurizer, and the content of the ferric oxide ranges from 28% to 35%. The preparation method of the ferric oxide desulfurizer is simple in process and short in production period, and the prepared ferric oxide desulfurizer is high in sulfur capacity and mechanical strength, capable of saving energy and environmentally friendly.

Owner:YUEYANG HAIDA ENVIRONMENTAL PROTECTION TECHCO

Method for detecting content of ferric oxide in silicon carbide

ActiveCN104280382AShort test timeAvoid the risk of being carbonized and reducedPreparing sample for investigationAnalysis by thermal excitationMaterials scienceInductively coupled plasma emission spectroscopy

The invention discloses a method for detecting the content of ferric oxide in silicon carbide. The method comprises the following steps: A, preparing a to-be-detected solution; and B, building a standard working curve by a ferric standard solution, testing the to-be-detected solution obtained in the step A to obtain the concentration of ferric ions in a filtrate, and calculating to obtain the content of Fe2O3 in the silicon carbide. The method for detecting the content of the ferric oxide in the silicon carbide is different from a conventional silicon carbide sample melting method and a method for detecting Fe2O3 in the silicon carbide by virtue of an inductively coupled plasma emission spectrometer (ICP-OES); hydrochloric acid, HF acid and ammonia water do not need to be used for treating samples in the early stage; a platinum vessel does not need to be used for preparing the samples; the sample preparing time is greatly reduced; the acid damage and the risk that a platinum crucible is carbonized and reduced can be avoided; the environmental pollution damage is greatly reduced; in addition, high-purity SiO2 auxiliary products are obtained; the value of the method for detecting the content of the ferric oxide in the silicon carbide is greatly improved.

Owner:北京远大信达科技有限公司

Ferric oxide supported activated carbon as well as synthesis method and application thereof

ActiveCN110075802AHigh removal rateImprove pore structureOther chemical processesWater/sewage treatment by sorptionFiberSynthesis methods

The invention belongs to the field of water treatment and discloses ferric oxide supported activated carbon as well as a synthesis method and an application thereof. The synthesis method comprises steps as follows: the activated carbon is soaked in a water solution of a ferric source, ultrasonic treatment is performed, then, evaporation to dryness and roasting are performed, and the ferric oxide supported activated carbon is obtained. By means of the synthesis method, Fe supporting, Fe-O-C bond production and formation of filamentary structures in pores are brought. The activated carbon has alarge specific surface area, organic pollutants are more sufficiently adsorbed in the pores of the activated carbon, the extracellular electron transfer rate of attached-growth microorganisms is increased, and formation of biomembranes is promoted. The activated carbon can reduce disinfection byproducts and pathogenic microorganisms in finished water and also has the function of inhibiting generation of disinfection byproducts and regrowth of the pathogenic microorganisms in follow-up pipeline networks of tap water.

Owner:GUANGZHOU UNIVERSITY

Preparation and application of amphiphilic magnetic palladium-loaded nano-ferric oxide and emulsion thereof

InactiveCN102527407AAvoid Surfactant Removal ProcessSimplify separabilityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsBlack ferric oxideOrganic synthesis

The invention discloses a preparation method of a Pickering emulsion by utilizing amphiphilic magnetic palladium-loaded nano Fe3O4 particles, and a method of carrying out an organic synthetic reaction in the Pickering emulsion. The preparation method is characterized by comprising the following steps: modifying nano Fe3O4 particles by using alkyl carboxylic acid and salts thereof to enable the particles to have amphiphilic property; loading palladium to the particles, thus preparing amphiphilic palladium-loaded nano FeO4 particles with catalytic activity; preparing the Pickering emulsion in oil-water phase, and applying the Pickering emulsion to a Suzuki reaction; adsorbing all magnetic nano-particles by using a magnet after the reaction is completed; and automatically separating the emulsion into an oil phase and a water phase to facilitate the separation and reclamation of a catalyst. According to the preparation method, a complicated process of removing a surfactant in a conventional emulsion is avoided, and a process of reclaiming nano-particles by adopting a filter mode is avoided, so that breaking emulsion separation, catalyst reclamation and other operations are simplified.

Owner:JIANGNAN UNIV

Polyhedral ferric oxide and preparation method thereof

InactiveCN107758748AImprove gas sensing performanceReduce contact resistanceMaterial nanotechnologyFerric oxidesCalcium Chloride HexahydrateContact resistance

The invention discloses polyhedral ferric oxide and a preparation method thereof. Ferric oxide is polyhedral and has a size ranging from 50nm to 800nm. The polyhedral ferric oxide is mainly prepared from ferric chloride hexahydrate by the following steps: adding ferric chloride hexahydrate and urea into a mixed solution of deionized water and ethanol according to a mass ratio; adding the uniformlystirred solution into an inner container of an autoclave, then putting the autoclave into an oven, heating the autoclave to 150-170 DEG C, and keeping the temperature for 8-12 hours; taking out the autoclave, naturally cooling the autoclave to room temperature, taking out a reaction product, washing and centrifuging the reaction product, and drying the reaction product to obtain a ferric oxide material with a polyhedral structure. According to the preparation method provided by the invention, a non-spherical ferric oxide material prepared by a hydrothermal method can be widely applied to various fields, particularly used as a gas sensitive material, and can effectively and greatly reduce the contact resistance between particles and improve the gas sensitive performance of the material.

Owner:HEFEI UNIV

High manganese and high aluminous steel covering slag containing ferric oxide and application thereof

The invention discloses high manganese and high aluminous steel continuous casting covering slag containing ferric oxide and application thereof. The covering slag comprises, by mass, 22%-32% of CaO, 19%-29% of Al2O3, 10%-16% of SiO2, 2%-8% of MnO, 6%-12% of Na2O, 2%-6% of Li2O, 4%-12% of BaO, 7%-13% of F, 2%-10% of Fe2O3, 1.3%-2.3% of (CaO+BaO) / Al2O3 and 0.2%-0.9% of Fe2O3 / SiO2. By adding a proper amount of the Fe2O3 in a controlled mode, the covering slag with the low viscosity and good crystallization property is obtained. The covering slag is applied to the high manganese and high aluminous steel slab continuous casting production process, the slag-steel reaction happening in the continuous casting process can be effectively restrained, the crystallization property and lubricating property of the covering slag in the continuous casting process are changed to be more stable, the effect that the high manganese and high aluminous steel continuous casting process can be executed smoothly is guaranteed, and the surface quality of a poured high manganese and high aluminous steel casting blank is excellent.

Owner:CENT SOUTH UNIV

Preparation method of ferric oxide-doped nanowire ordered array photo-anode

InactiveCN107099817AImprove photoelectric propertiesImprove the efficiency of hydrogen production by photolysis of waterNanotechnologyElectroforming nanostructuresNanowireHydrogen

The invention discloses a preparation method of a ferric oxide-doped nanowire ordered array photo-anode and belongs to the technical field of catalysis. The preparation method comprises the following steps of: preparing a hydroxyl ferric oxide nanowire ordered array containing doping elements by means of an aluminum oxide ordered template and an electrochemical synthesis method; and then calcining a sample to obtain an ion-doped ferric oxide nanowire ordered array. The prepared ferric oxide-doped nanowire ordered array is of a polycrystal structure, is regular in arrangement and uniform in size, has a relatively good photocatalytic performance, and has a wide application prospect as the photo-anode in photolysis of water of producing hydrogen in the future.

Owner:HEFEI UNIV OF TECH

Process for water supply deep treatment of catalyzing ozone oxydation by hydroxy ferric oxide as catalyst

InactiveCN1275883CLarge specific surface areaGenerate efficientlyMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFiltrationDigestion

The invention is a drinking water advanced treatment method by ozone oxidation with iron oxide hydroxide as catalyst, relating to a drinking water treatment process of eliminating organic substances by ozone oxidation catalyzed by solid catalyst. The surface water is processed by coagulation, deposition, filtration, etc, and enters in an ozone contact tower, a catalyst bed, and a bio-activated carbon filter bed in turn to eliminate the organic substances, and finally enters in the network pipe after sterilized. The catalyste has the advantages of high catalyzing efficiency and completely weak digestion of metallic ions. The invention adopts a drinking water treatment process combining catalytic ozone oxidation and bio-activated carbon, improving the ability of ozone oxidation to eliminate organic substance in the water, the biochemical degrability of organic substances in the water, and ozone utilization ratio, and also helps eliminate metallic ions in the water. It has the advantages of low cost and high oxidizing efficiency.

Owner:HARBIN INST OF TECH

Method for coproducing tricalcium phosphate and ferric oxide by virtue of phosphated waste residues

ActiveCN104386662AAvoid emissionsReduce pollutionFerric oxidesAlkali metal chloridesTri calcium phosphateBlack ferric oxide

Owner:GUIZHOU RES INST OF CHEM IND

Method for electrolyzing ferric oxide by using deep eutectic solvent to prepare ferroferric oxide

InactiveCN104233361ALow costWide variety of sourcesElectrolysis componentsElectrolysisHydrometallurgy

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com