Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

117 results about "Aluminium diethyl phosphinate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium diethyl phosphinate is a chemical compound with formula Al(C₄H₁₀O₂P)₃. It decomposes above 300 °C.

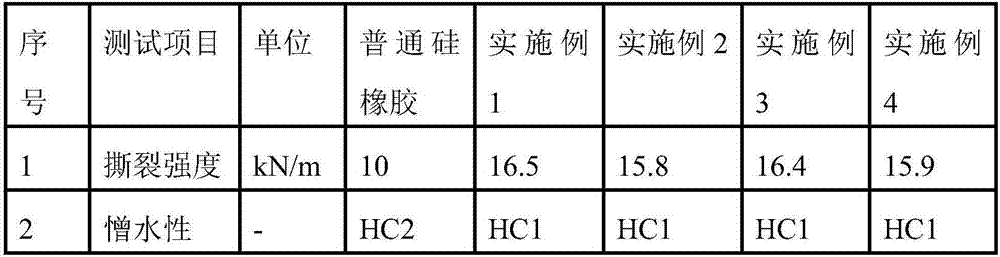

Aging-resistant and low-temperature-resistant EPDM (ethylene-propylene-diene monomer) rubber cable material

InactiveCN104610663AHigh strengthGood air aging resistanceRubber insulatorsPlastic/resin/waxes insulatorsCalcium silicateElastomer

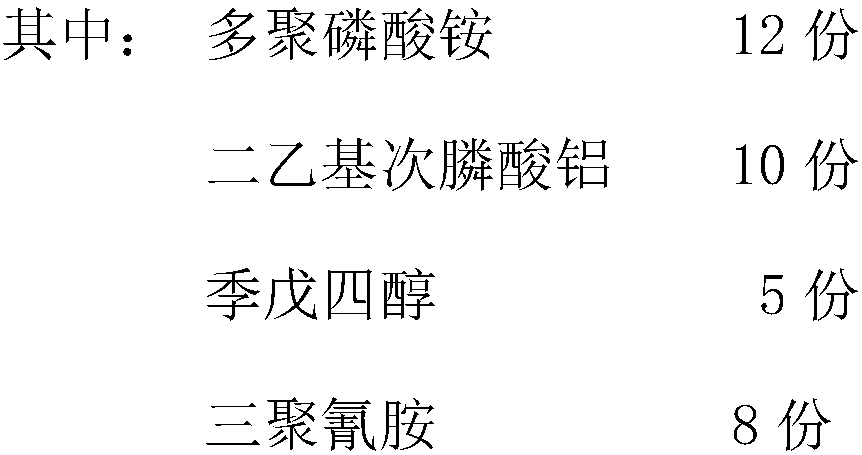

The invention discloses an aging-resistant and low-temperature-resistant EPDM (ethylene-propylene-diene monomer) rubber cable material. The material comprises raw materials as follows: EPDM rubber, natural rubber, an ethylene-butene elastomer, superfine talc powder, nano calcium carbonate, modified superfine desulfurization ash, active calcium silicate, zinc methacrylate modified nano silicon nitride, pre-dispersed hollow phenolic microspheres, reinforcing fibers, zinc oxide, stearic acid, dicumyl peroxide, sulfur, N,N'-meta phenylene bismaleimide, diphenylmethane bismaleimide, DIPDIS, coumarone-indene resin, APP (ammonium polyphosphate), ADP, an MPE (metallocene polyethylene) elastomer, N-(4-anilino phenyl maleimide and 2-mercapto benzimidazole. The aging-resistant and low-temperature-resistant EPDM rubber cable material is high in strength, good in aging resistance and low-temperature resistance, excellent in insulating property and flame retardation and long in service life.

Owner:无为县华祥电缆材料有限公司

Composite flame retardant for polyesters and application method thereof

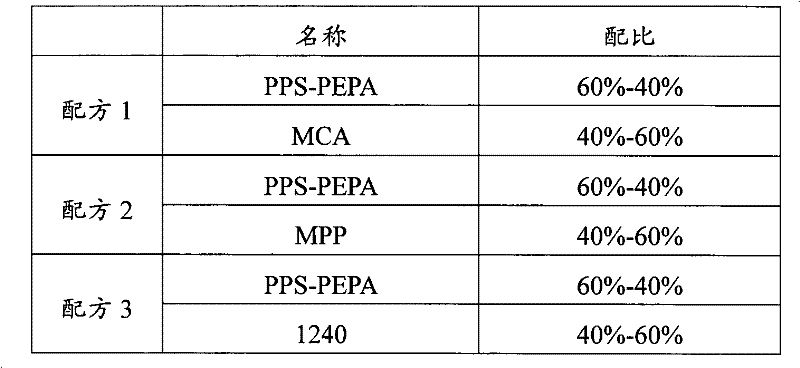

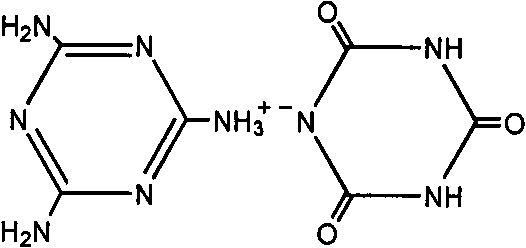

The invention relates to a composite flame retardant for polyesters and an application method thereof. The flame retardant is prepared through compounding any one of melamine cyanurate (MCA), melamine polyphosphate (MPP) and aluminium diethyl hypophosphite (1240) with bis(1-oxyphospha-2,6,7-trioxa bicyclo[2.2.2]octyl-4-methyl) phenyl thiophosphate (PPS-PEPA) in any weight preparation. The flame retardant disclosed by the invention has the advantages of multielement synergy, good material compatibility, high flame retardancy, environmental friendliness, and capability of reducing the application costs and the like.

Owner:BEIJING KEYING JINGYI TECH

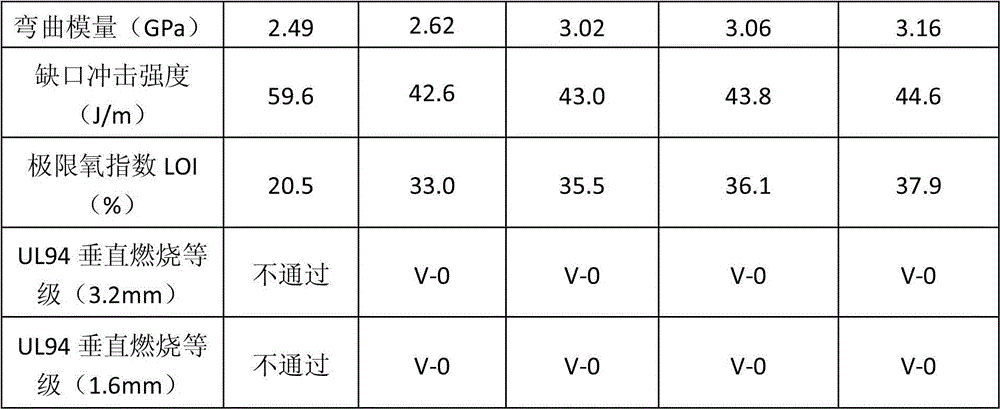

Flame-retardant chain-extended polybutylene terephthalate composition and preparation method thereof

ActiveCN102911485AReduce dosageObvious flame retardant synergistic effectPolytetramethylene terephthalateEpoxy

The invention discloses a flame-retardant chain-extended polybutylene terephthalate (PBT) composition and a preparation method of the PBT composition. The composition comprises the following raw materials by weight: 85%-90% of PBT, 9%-12% of aluminum diethylphosphinate, 0.4%-3% of polysiloxane containing an epoxy group in the side group, and 0.3%-0.7% of processing agent, wherein the processing agent is an antioxidant and an anti-dripping agent. According to the invention, the adopted polysiloxane containing the epoxy group in the side group and aluminum diethylphosphinate have obvious flame retardant synergistic effects on PBT. When the flame retardant property reaches to UL94V-0@1.6mm, the dose of aluminum diethylphosphinate is reduced by about 20% and the total flame retardant dose is reduced by about 12%. Under the premise of same flame retardant level, the mechanical properties of the composition provided by the invention is greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

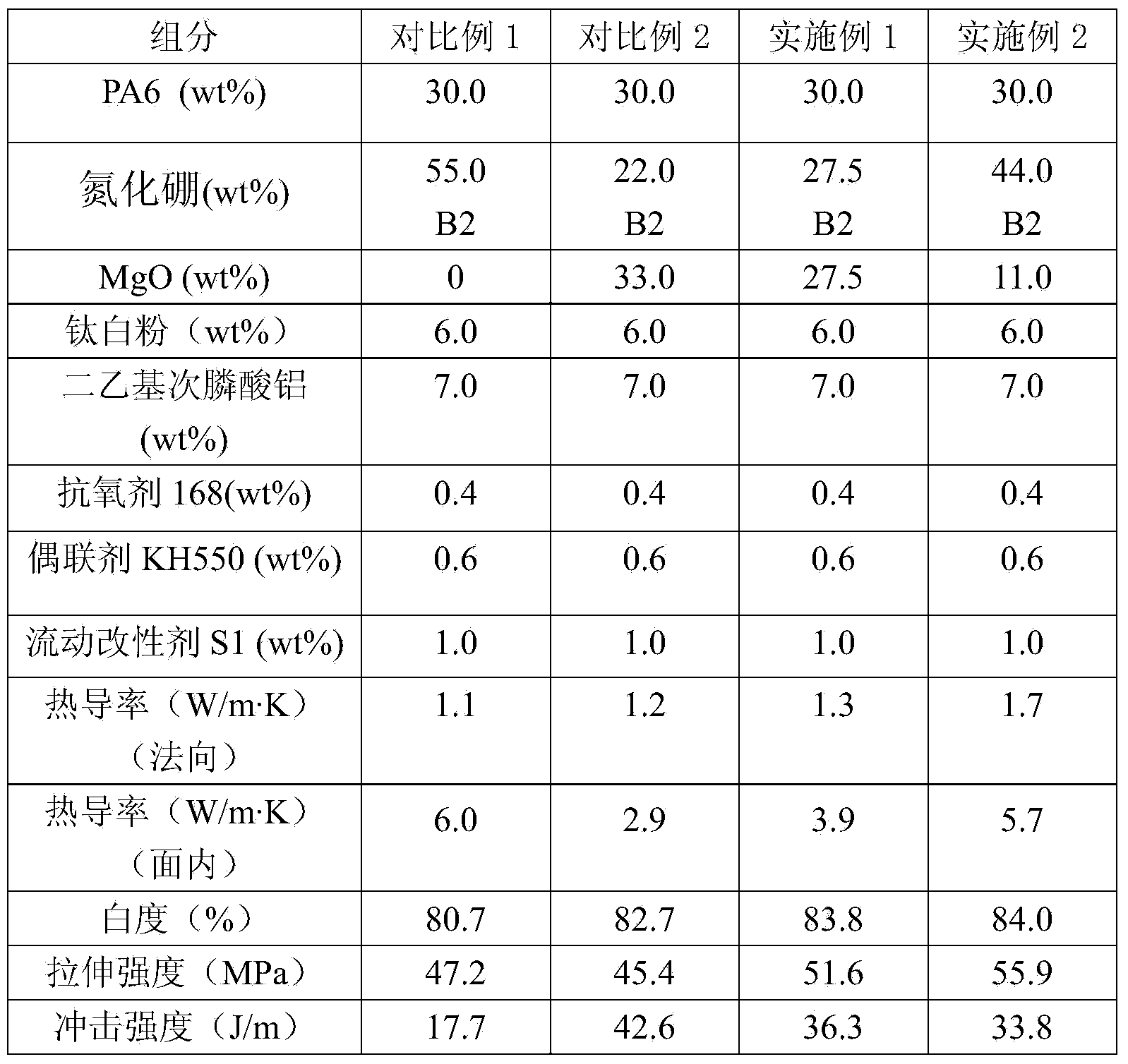

High-whiteness, halogen-free, flame-retardant, thermal conductive and insulated PA 6 (polyamide 6)-based composite material and preparation method thereof

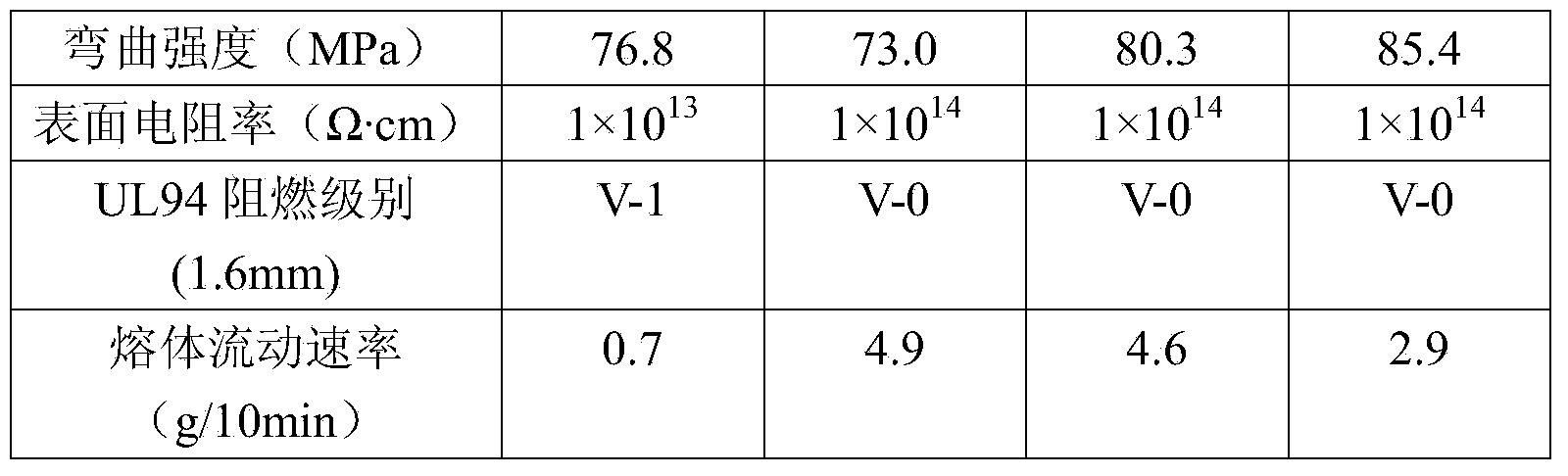

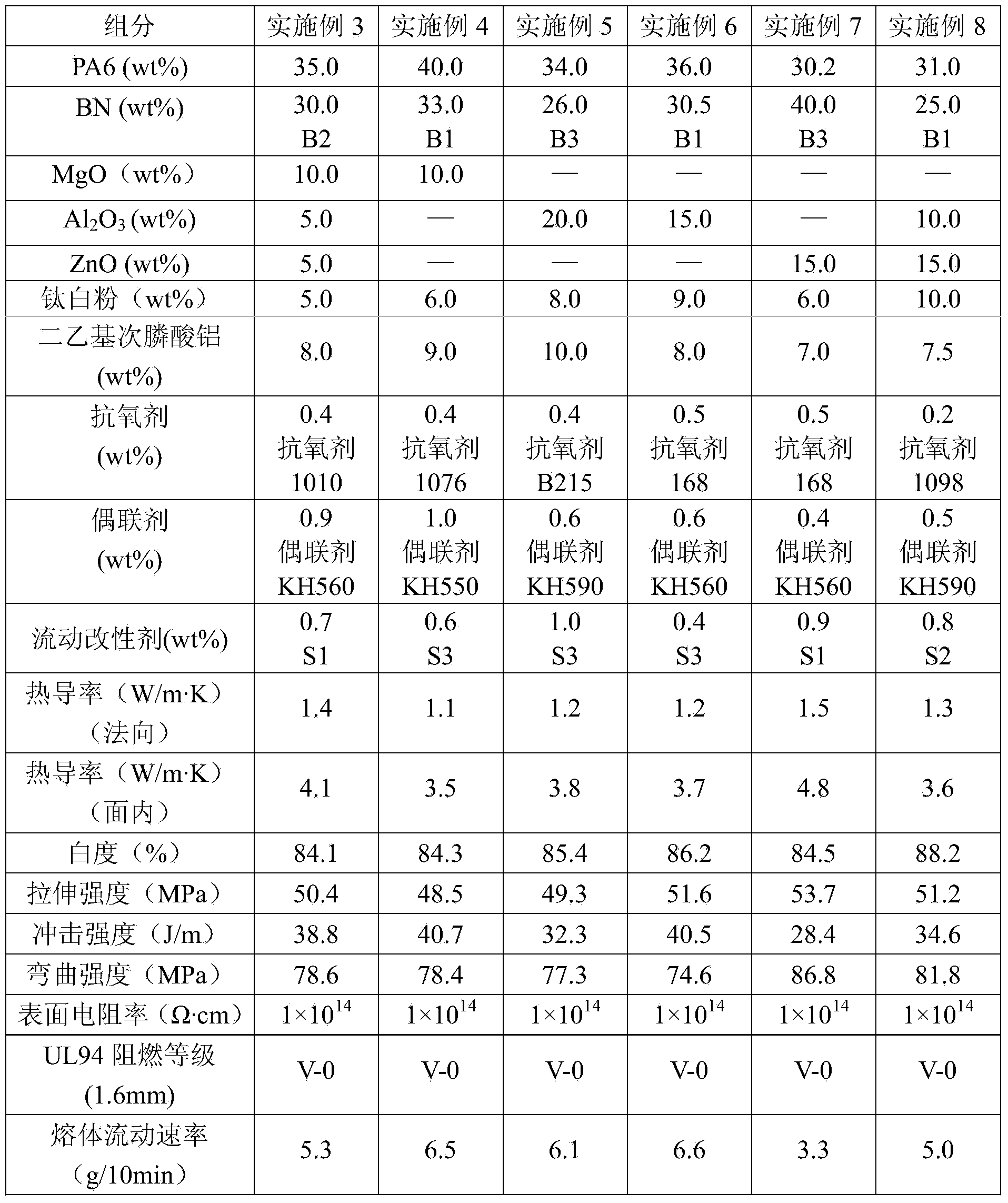

The invention discloses a high-whiteness, halogen-free, flame-retardant, thermal conductive and insulated PA 6 (polyamide 6)-based composite material and a preparation method thereof. The raw material formula is composed of the following components according to percentage by mass: 30-40% of polyamide 6, 40-55% of thermal conductive fillers, 5-10% of titanium dioxide, 7-10% of aluminum diethyl phosphinate, 0.4-1.0% of coupling agent, 0.4-1.0% of flow modifier and 0.2-0.5% of antioxidant, wherein the thermal conductive fillers are composed of a filler with a layered structure and a granular filler, the filler with the layered structure is boron nitride, and the length-width ratio is (10:1) to (15:1); the particle size range of the granular filler is 10-40 microns. The vertical combustion of a 1.6 mm sample strip of the PA6-based composite material disclosed by the invention passes UL94V-0 level, the normal thermal conductivity is higher than 1.1 W / m.K, and the high-whiteness, halogen-free, flame-retardant, thermal conductive and insulated PA 6-based composite material has the advantages of high whiteness, good flame retardancy, high thermal conductivity, insulation, good processing fluidity, and the like.

Owner:SOUTH CHINA UNIV OF TECH

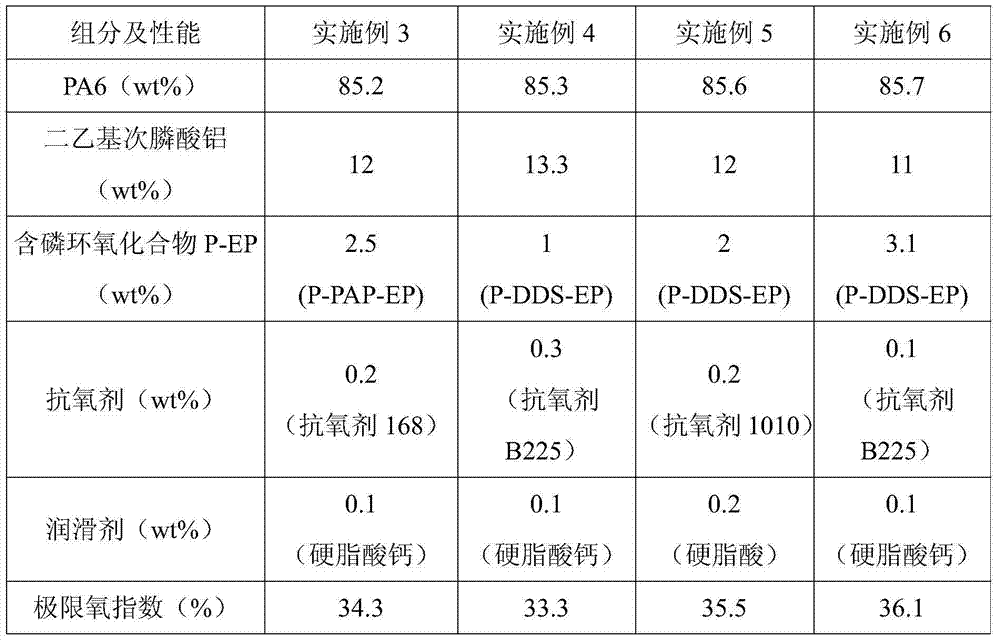

Flame-retardant chain-extending nylon 6 composition and preparation method thereof

InactiveCN103897385AImprove flame retardant performanceImprove mechanical propertiesEpoxyAntioxidant

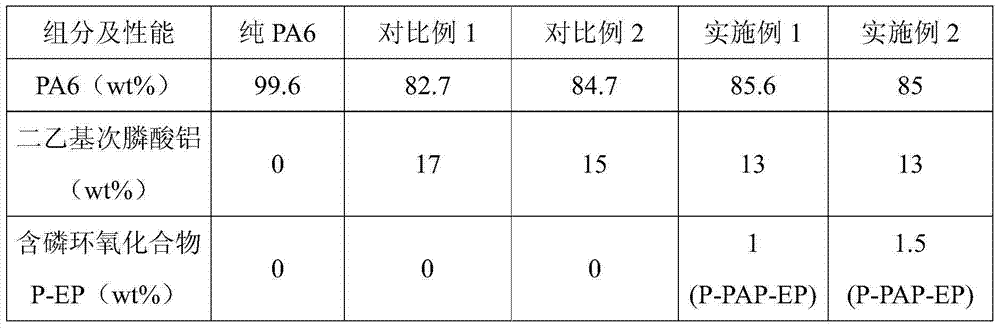

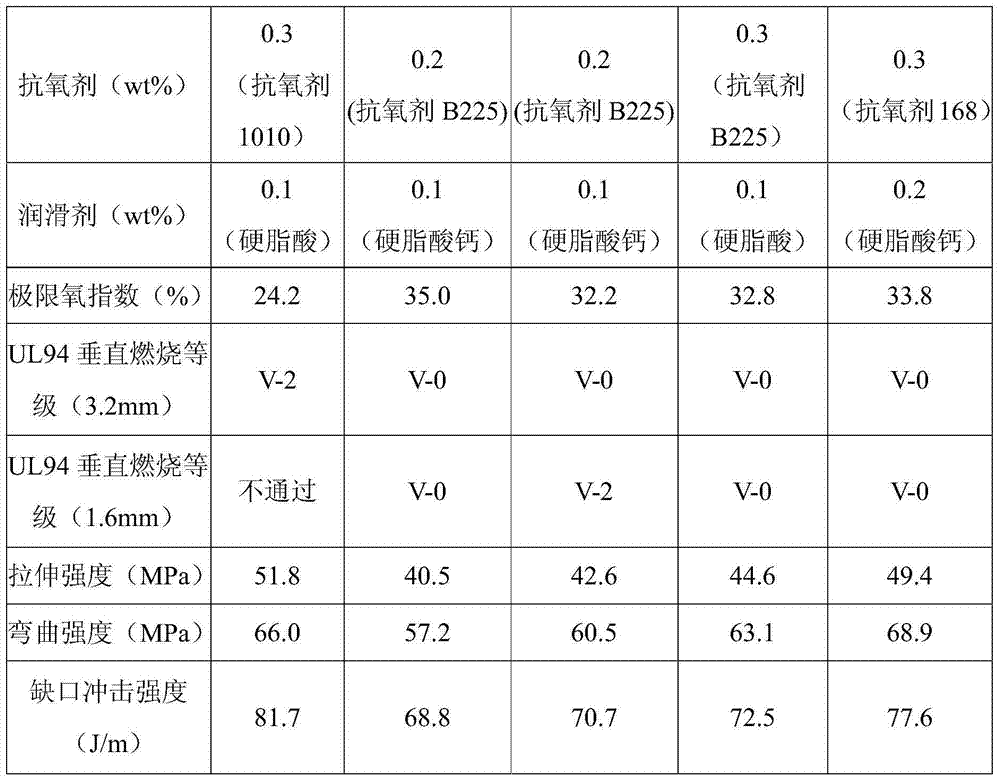

The invention discloses a flame-retardant chain-extending nylon 6 composition and a preparation method thereof. The raw material formula of the flame-retardant chain-extending nylon 6 composition comprises the following components by mass percent: 85-85.7% of nylon 6, 14-14.5% of composite flame retardant, 0.1-0.3% of antioxidant and 0.1-0.2% of lubricating agent, wherein the composite flame retardant is a mixture of aluminum diethylphosphinate and a phosphorous epoxy compound P-EP; the phosphorous epoxy compound P-EP accounts for 7-22% of the mass percent of the composite flame retardant. The flame-retardant chain-extending PA6 composition disclosed by the invention has a good synergistic flame-retardant effect on PA6 by using the composite flame retardant of the phosphorous epoxy compound P-EP and the aluminum diethylphosphinate, and has a chain-extending and viscosifying action on PA6, the total dosage of the flame retardant rating achieving UL-94V-0@1.6mm is lower than the dosage of independent aluminum diethylphosphinate flame retardant, and the mechanical property is obviously improved.

Owner:SOUTH CHINA UNIV OF TECH +1

Heat-resistant and flame-retardant nylon tube

InactiveCN105482448AImprove the disadvantage of high water absorptionImprove water absorptionPolymer scienceMagnesium borate

The invention discloses a heat-resistant and flame-retardant nylon tube. The heat-resistant and flame-retardant nylon tube is prepared from nylon 66, nylon 6, polymethylhydrosiloxane, epoxy resin, titanate coupling agent modification nano-zinc oxide, modification needle-like wollastonite, an amination carbon nano-tube, nano-silicon dioxide, red phosphorus, melamine cyanurate, organic nano-montmorillonite, glass fibers, magnesium borate whiskers, basic zinc carbonate nanofibers, ethylene-propylene-diene monomer, ethylene-bis-stearamide, calcium pimelate, zinc pimelate, silane coupling agent, aluminum diethylphosphinate and lanthanum stearate. The heat-resistant and flame-retardant nylon tube is good in heat resistance and flame retardancy, high in strength and excellent in impact resistance, and a nylon tube formed by the heat-resistant and flame-retardant nylon tube is good in overall performance and long in service life.

Owner:安徽都邦电器有限公司

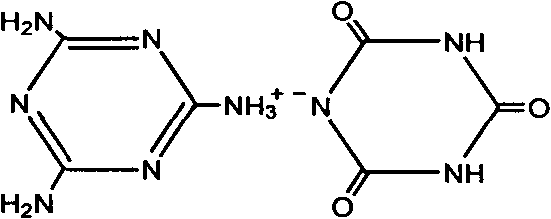

Halogen-free flame retardant polyamide moulding compositions with increased glow wire and fire resistance

ActiveUS20160304715A1Improve electrical performanceImprove the immunityNitrogenTemperature resistance

The present invention relates to halogen-free flame retardant compositions essentially comprising polyamide polymers (preferred is PA6), at least an Hypophosphorous acid metal salt (preferred is Aluminium hypophosphite), at least an organic phosphinate metal salt (preferred is Aluminium Di Ethyl Phosphinate), at least a Nitrogen based flame retardant agent (preferred is Melamine Cyanurate), at least an organic polyhydric polymer (preferred is EVOH) and optionally further conventional components. Such compositions are highly flame retarded at low thickness and have high Glow Wire temperature resistance.

Owner:ITALMATCH KEMIKALS SPA

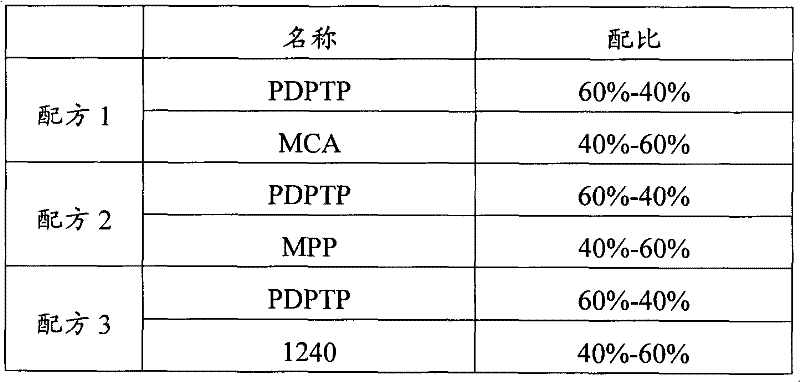

Halogen-free flame retardant composition for polyesters and application method thereof

The invention relates to a halogen-free flame retardant composition for polyesters and an application method thereof. The flame retardant composition is prepared through compounding any one of melamine cyanurate (MCA), melamine polyphosphate (MPP) and aluminium diethyl hypophosphite (1240) with PDPTP (polyphenyl thiophosphoric acid) in any weight preparation. The flame retardant disclosed by the invention has the advantages of multielement synergy, good material compatibility, high flame retardancy, environmental friendliness and the like.

Owner:贝塞尔中创(北京)技术有限公司

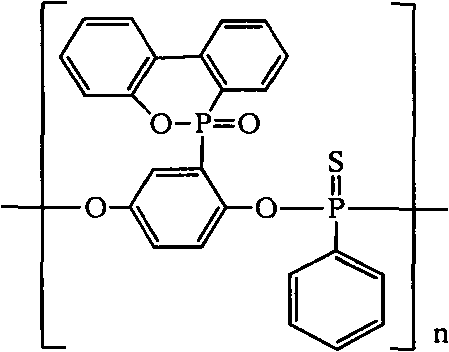

Novel nitrogen-phosphorus system halogen-free flame-retardant nylon 6 and preparation method thereof

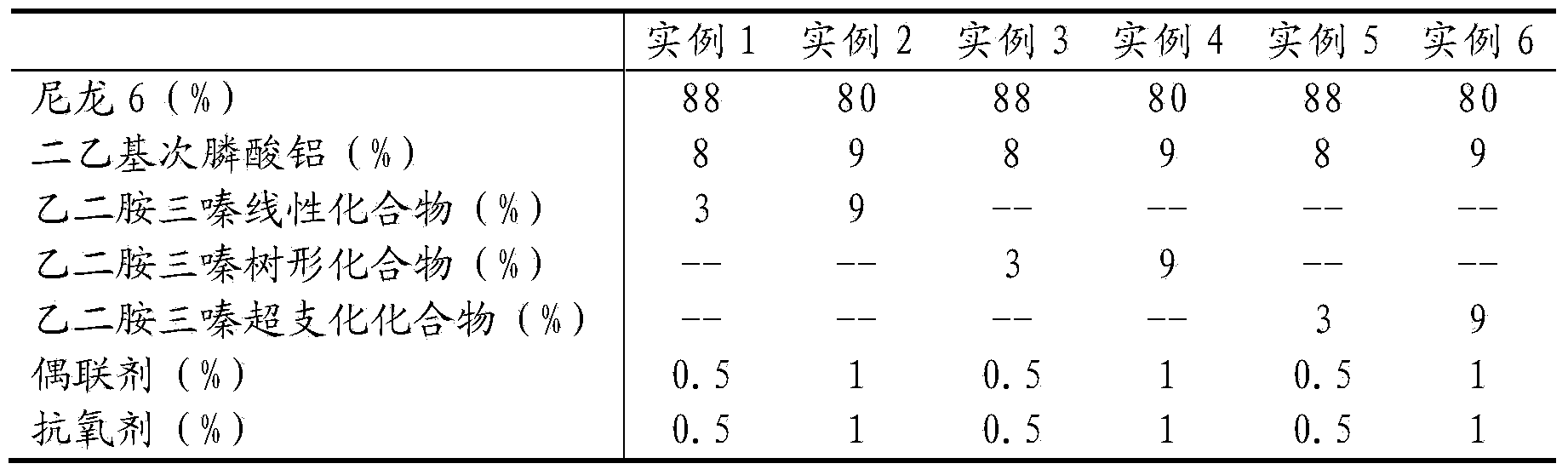

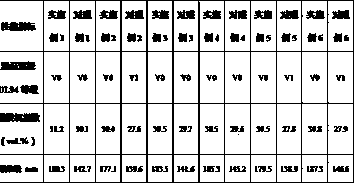

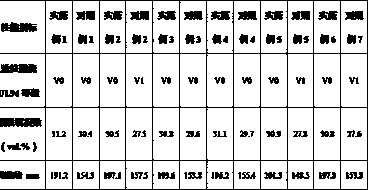

ActiveCN104177824AComply with processing conditionsImprove thermal stabilityNylon 6Thermal stability

The invention belongs to the technical field of preparation of flame-retardant composite materials through melt blending, and in particular relates to novel nitrogen-phosphorus system halogen-free flame-retardant nylon 6 and a preparation method thereof. The preparation method comprises two steps: 1, mixing diethyl aluminum phosphinate, a macromolecular charring agent, a coupling agent, an antioxidant and nylon 6 resin, and stirring uniformly; and 2, preparing the nitrogen-phosphorus system halogen-free flame-retardant nylon 6 by performing high-temperature melt blending on the mixture obtained in the step 1. According to the novel nitrogen-phosphorus system halogen-free flame-retardant nylon 6 and the preparation method thereof, an organic nitrogen-containing flame retardant is not used, the used macromolecular charring agent has high thermostability which accords with a processing condition of nylon 6, the macromolecular charring agent is added into the nylon 6 resin, and the diethyl aluminum phosphinate is compounded with the macromolecular charring agent, so that the thermostability and flame-retardant effect of the composite material are improved, the usage amount of the diethyl aluminum phosphinate is effectively reduced, and the cost is reduced.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Anti-aging flame-retardant power cable

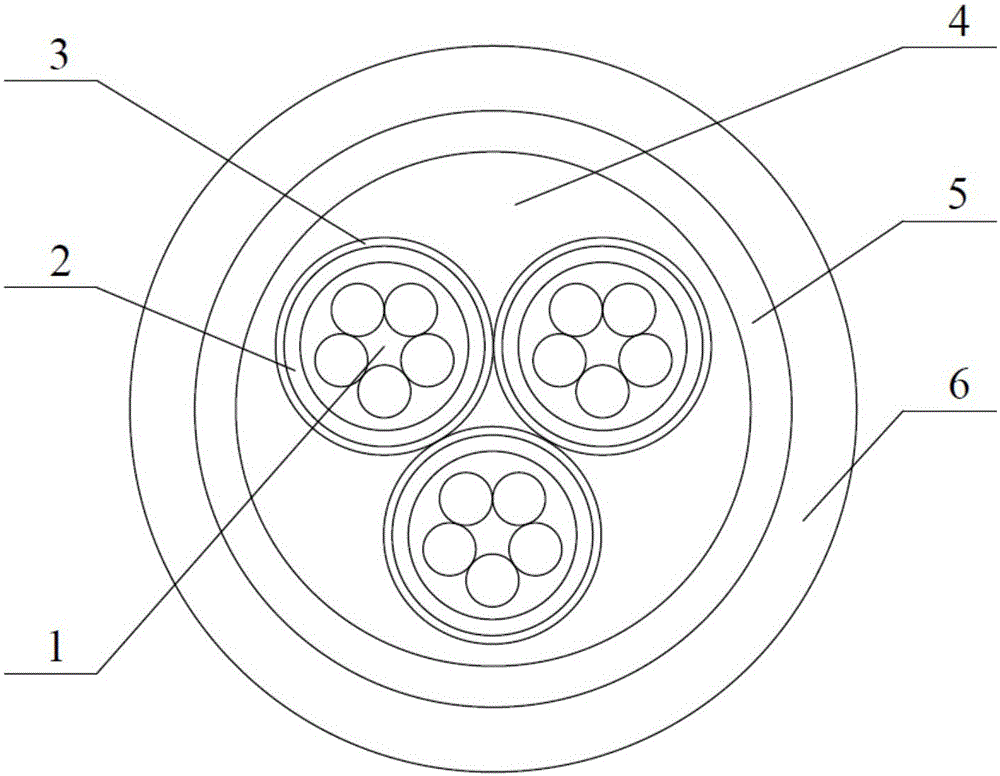

ActiveCN105825944AAchieve co-vulcanizationImprove performanceFibre typesInsulated cablesCalcium silicateElastomer

Disclosed in the invention is an anti-aging flame-retardant power cable. The cable comprises conductors. A plurality of wires are twisted mutually to form a bundle and then a wrapping layer and an insulating layer coats the outside of the bundle successively to form one conductor. The gap among the N conductors is filled with flame-retardant filling materials to form a cable core. Besides, an aluminum-plastic composite isolation layer and a fireproof sheath layer coats the outside of the cable core successively. The fireproof sheath layer is prepared by using a modified natural rubber composite material, wherein raw materials of the modified natural rubber composite material consist of natural rubber, terpolymer EP rubber, an ethylene-butene elastomer, a polyacrylonitrile fiber, stearic acid, zinc oxide, dicumyl peroxide, sulphur, active calcium silicate, calcined attapulgite, modified montmorillonite, graphene oxide, expansible graphite, ammonium polyphosphate, diethylphosphinic acid aluminium salt, an accelerant, an anti-aging agent, triphenyl phosphate, hexakis (4-formacylphenoxy) cyclotriphosphazene, pentaerythritol, perfluorooctanamide, octadecylamine, and bis(diisopropyl)thiophosphoryl disulfide.

Owner:ANHUI HAIYUAN SPECIAL CABLE

Special halogen-free flame-retardant synergistic masterbatch for modification of nylon resin and preparation method of halogen-free flame-retardant synergistic masterbatch

ActiveCN110591341AEffective protectionImprove thermal protection performanceAcrylonitrilePolytetrafluoroethylene

The invention relates to the technical field of modification and processing of plastics, in particular to special halogen-free flame-retardant synergistic masterbatch for modification of nylon resin and a preparation method of the halogen-free flame-retardant synergistic masterbatch. Multiple-compounded coated aluminum diethylphosphinate is adopted as a phosphorous-based flame retardant of the functional masterbatch, and the functional masterbatch comprises the compositions: in percent by mass, 55.0-65.0% of multiple-compounded coated aluminum diethylphosphinate, 20.0-30.0% of anhydrous zinc borate, 8.0-10.0% of nylon 6 resin, 3.0-5.0% of star-shaped nylon, 0.5-1.0% of styrene-acrylonitrile copolymer-coated polytetrafluoroethylene, 0.5-1.0% of a dispersant and 0.3-0.5% of a lubricant. Whenthe prepared functional masterbatch is compared with traditional flame-retardant functional masterbatch, the heat resistance and thermal stability of aluminum diethylphosphinate are improved significantly, aluminum diethylphosphinate is adaptive to a high processing temperature of nylon resin, so that the flame retardant effect of aluminum diethylphophinate on nylon resin is improved more effectively.

Owner:江苏万纳普新材料科技有限公司

Acrylic acid-polyaniline composite modified polyurethane coating

InactiveCN105602440AImprove corrosion resistanceGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsGlycerolFire resistance

The invention discloses an acrylic acid-polyaniline composite modified polyurethane coating which is prepared from modified polyurethane emulsion, waterborne acrylic emulsion, waterborne polyaniline emulsion, diphenylmethane diisocyanate, nano-zinc oxide, nano-zinc phosphate, aluminum oxide, wollastonite, boron nitride, barium sulfate, aluminum triphosphate, diethyl aluminum phosphinic acid, calcium chloride, N-methyl pyrrolidone, a defoaming agent, a dispersing agent, a wetting agent, a flatting agent, glycerol, 8-hydroxyquinoline, epoxy resin, a silane coupling agent, polyethylene wax and water. The acrylic acid-polyaniline composite modified polyurethane coating is good in water resistance and corrosion resistance, excellent in heat resistance and weather resistance, high in strength, high in adhesive force with a base material and long in service life, and has the certain fire resistance.

Owner:ANHUI ANDA HUATAI NEW MATERIALS CO LTD

Polyurethane thermal-insulation composite board

InactiveCN105860504AImprove wear resistanceGood oil resistanceSynthetic resin layered productsConstructions elementsPolyesterHexamethylphosphoramide

The invention discloses a polyurethane thermal-insulation composite board which comprises a polyurethane thermal-insulation layer and back lining layers arranged on the inner and lower surfaces of the polyurethane thermal-insulation layer, wherein the polyurethane thermal-insulation layer is prepared from a high-performance polyurethane rigid foam material. The high-performance polyurethane rigid foam material is prepared from polyester polyol, diphenylmethane diisocyanate, hexamethylene diisocyanate, polyacrylate, styrene-butadiene rubber, cyclohexylamine, triethylenediamine, stannous octoate, a foaming agent, hydroxy silicone oil, a flame retardant, expanded perlite, attapulgite, pentaerythritol and sorbitol. The flame retardant is prepared from red phosphorus, nano magnesium hydroxide, ammonium polyphosphate, aluminum diethyl hypophosphite, piperazidine pyrophosphate and hexametapol. The polyurethane thermal-insulation composite board disclosed by the invention has the advantages of high strength, favorable impact resistance, excellent flame retardancy and long service life.

Owner:ANHUI GUANGYAN NEW MATERIAL TECH

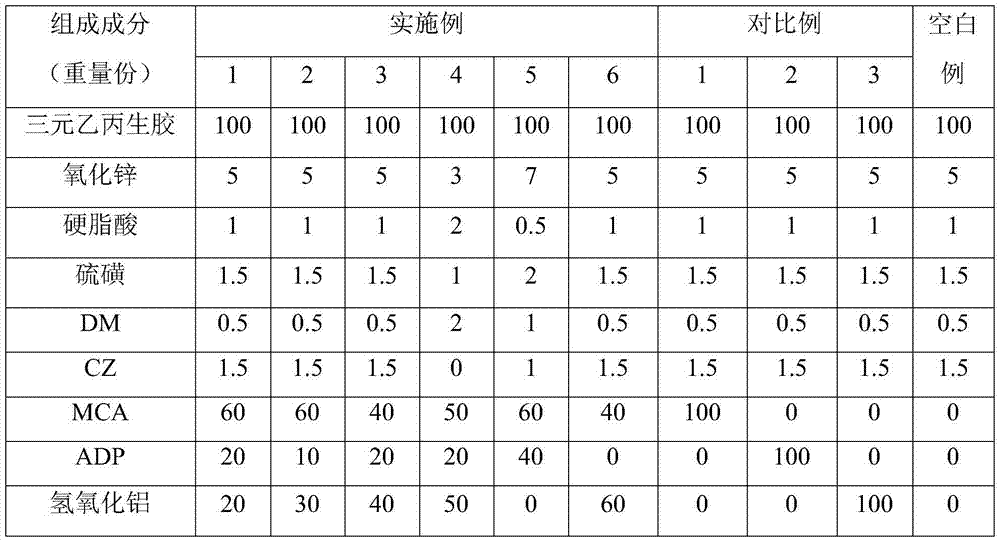

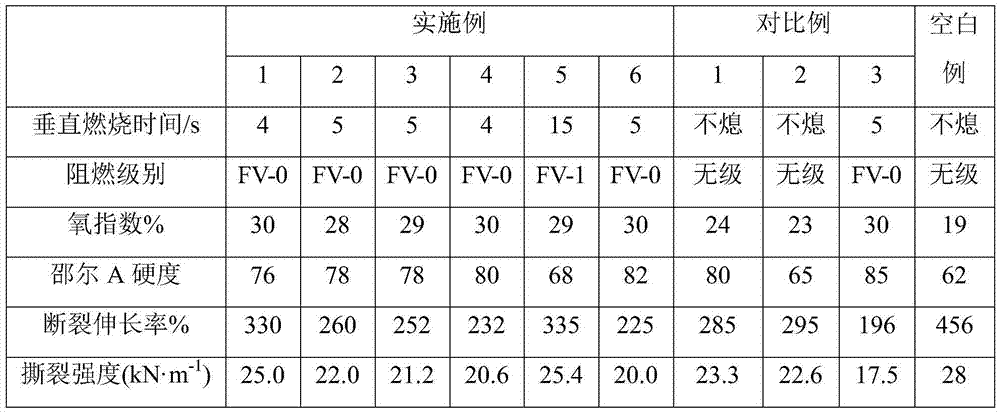

Intumescent halogen-free flame-retardant agent, halogen-free flame-retardant ethylene propylene diene monomer composition, halogen-free flame-retardant ethylene propylene diene monomer, and applications of halogen-free flame-retardant ethylene propylene diene monomer

ActiveCN106967230AImprove flame retardant performanceHigh elongation at breakEthylene-propylene-diene-monomerPolymer chemistry

The present invention relates to the field of flame-retardant agents, particularly to an intumescent halogen-free flame-retardant agent, a halogen-free flame-retardant ethylene propylene diene monomer composition containing the intumescent halogen-free flame-retardant agent, a halogen-free flame-retardant ethylene propylene diene monomer obtained by mixing and vulcanizing the halogen-free flame-retardant ethylene propylene diene monomer composition, and applications of the halogen-free flame-retardant ethylene propylene diene monomer, wherein the intumescent halogen-free flame-retardant agent contains the mixture of melamine cyanurate and aluminum diethylphosphinate and / or aluminum hydroxide. According to the present invention, the intumescent halogen-free flame-retardant agent has good flame-retardant property, and the prepared halogen-free flame-retardant ethylene propylene diene monomer has high elongation at break.

Owner:CHINA PETROLEUM & CHEM CORP +1

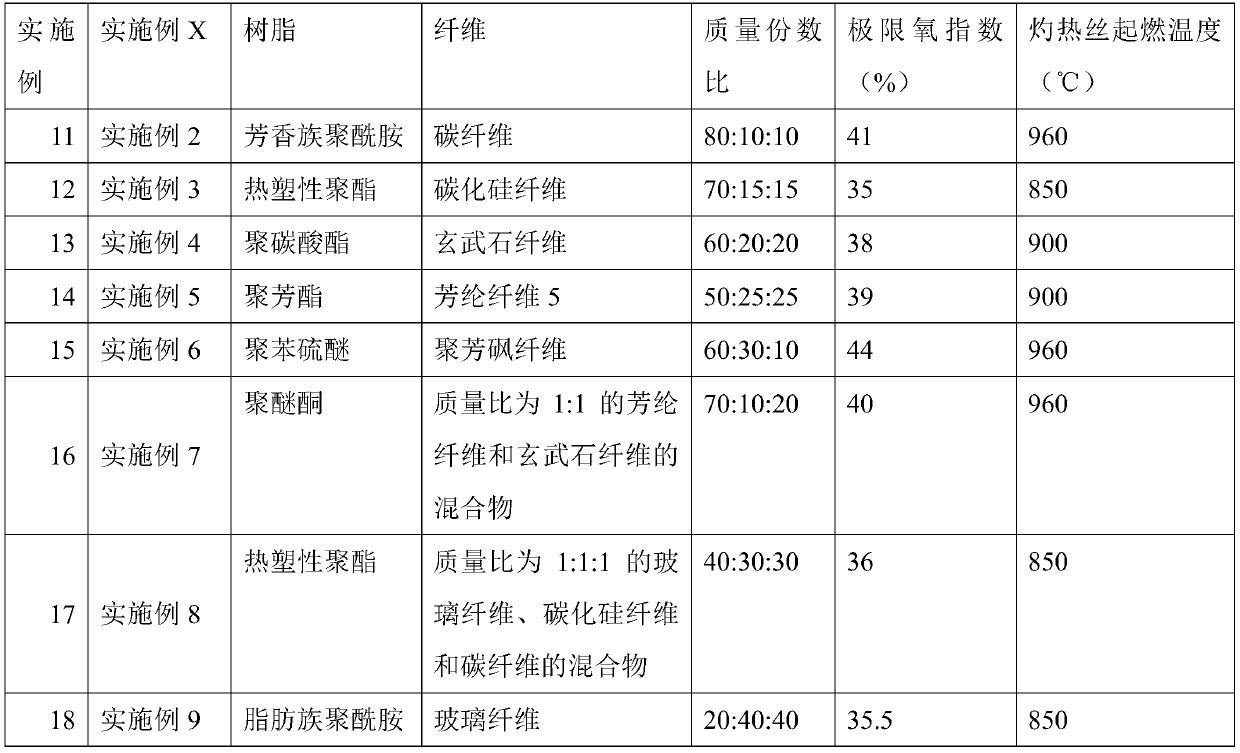

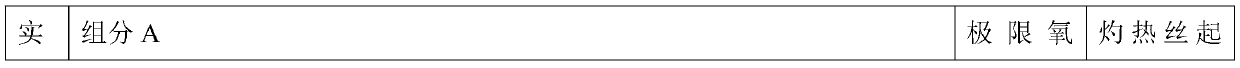

Halogen-free flame retardant composition and application thereof

The invention relates to a halogen-free flame retardant composition and application thereof. The halogen-free flame retardant composition at least comprises a component A, a component B, a component Cand a component D, wherein the component A is one or more of 2-carboxyethyl phenyl phosphinates; the component B is one or more of aluminum diethyl phosphinate, zinc diethyl phosphinate, aluminum methyl ethyl phosphinate, aluminum methyl propyl phosphinate, aluminum dipropyl phosphinate and aluminum ethyl propyl phosphinate; the component C is one or more of melamine cyanuric acid, melamine polyphosphate, melamine trithiocyanate, melamine hypophosphite and ammonium polyphosphate; and the component D is one or more of montmorillonite, kaolin, molybdenum disulfide, graphite-like carbon nitride,graphene and graphene oxide. The application process is as follows: resin, fibers and the halogen-free flame retardant composition are subjected to melt blending to prepare flame-retardant polymer materials. The halogen-free flame retardant composition disclosed by the invention is simple to prepare, low in cost, free of halogen elements, lasting in flame-retardant effect, capable of continuouslyretarding flame in the whole stage of flame development and good in application prospect.

Owner:湖南美莱珀科技发展有限公司

Flame-retardant composition and application thereof, PBT composite material and preparation method of PBT composite material

ActiveCN112812366AImprove mechanical propertiesImprove flame retardant performancePhosphorous acidPolymer science

The invention relates to a flame-retardant composition and application thereof, a PBT (polybutylene terephthalate) composite material and a preparation method of the PBT composite material. The flame-retardant composition is prepared from the following components in percentage by weight: 55 to 65 percent of aluminum diethylphosphinate, 15 to 26 percent of melamine polyphosphate, 10 to 15 percent of melamine cyanurate, 4 to 8 percent of organic modified montmorillonite and 0 to 5 percent of aluminum phosphite. When the flame-retardant composition and main materials such as PBT are melted and mixed to prepare the flame-retardant material, the prepared flame-retardant material can be decomposed to form a coke layer in the combustion process, the coke layer has the function of a heat-insulating oxygen-blocking protective layer, and meanwhile, the nitrogen-containing compound in the flame-retardant composition also has the functions of foaming and coke enhancement, and aluminum phosphite can achieve synergistic flame-retardant and whitening effects, so that the prepared flame-retardant material is good in flame retardance and can maintain good mechanical properties.

Owner:ZHEJIANG XINHUA CHEM

Method for treating aluminum diethyl phosphinate wastewater.

InactiveCN106007054AEfficient degradationEfficient removalWater contaminantsMultistage water/sewage treatmentAluminium phosphatePhosphenic acid

The invention belongs to the technical field of wastewater treatment, in particular to a method for treating aluminum diethyl phosphinate wastewater. The method provided by the invention comprises the following steps: a) carrying out a heating reaction between the aluminum diethyl phosphinate wastewater and oxidants in the presence of an activated carbon supported metal catalyst to obtain oxidized wastewater, wherein the oxidants comprise hydrogen peroxide and sodium persulfate, and iron element and copper element are supported on the carrier activated carbon of the activated carbon supported metal catalyst; b) mixing the oxidized wastewater with a dephosphorizing precipitant to obtain treated wastewater. The method has the advantages that valence variation of iron and copper supported on the catalyst is fully utilized to catalyze hydrogen peroxide to generate OH<-> and activate sodium persulfate to generate SO<4->., and the two radicals are coupled mutually to oxidize aluminum diethyl phosphinate and degradation products thereof, so that aluminum diethyl phosphinate in the aluminum diethyl phosphinate wastewater is degraded effectively, and phosphorus in the aluminum diethyl phosphinate wastewater is further removed efficiently.

Owner:GUANGDONG UNIV OF TECH

High-strength high-toughness modified silicone rubber material

The invention discloses a high-strength high-toughness modified silicone rubber material, which comprises silicone rubber, ethylene-propylene-diene terpolymer rubber, hydrogenated butadiene-acrylonitrile rubber, chlorosulfonated polyethylene rubber, fluororubber, butyl rubber, hydroxyl-terminated polybutadiene, methacrylic acid, vinyltriethoxysilane, low density polyethylene, liquid paraffin, dibutyl sebacate, nanometer silica, silicon carbide, zinc oxide, magnesium oxide, nylon, graphite powder, zinc stearate, chlorinated paraffin, aluminum diethylphosphinate, tetraethoxysilane, dibutyltin dilaurate, a high strength modification auxiliary agent and a high-toughness modification filling material. The silicone rubber material is excellent in high-strength high-toughness performance.

Owner:天长市荣盛有机硅科技有限公司

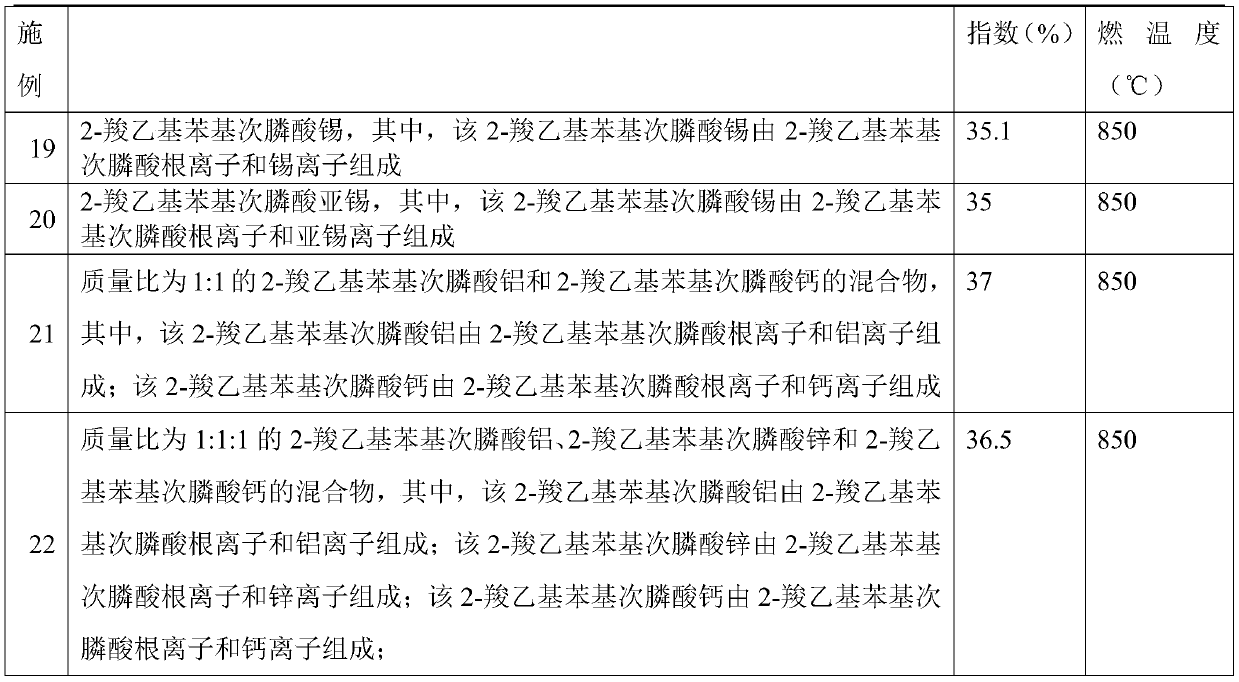

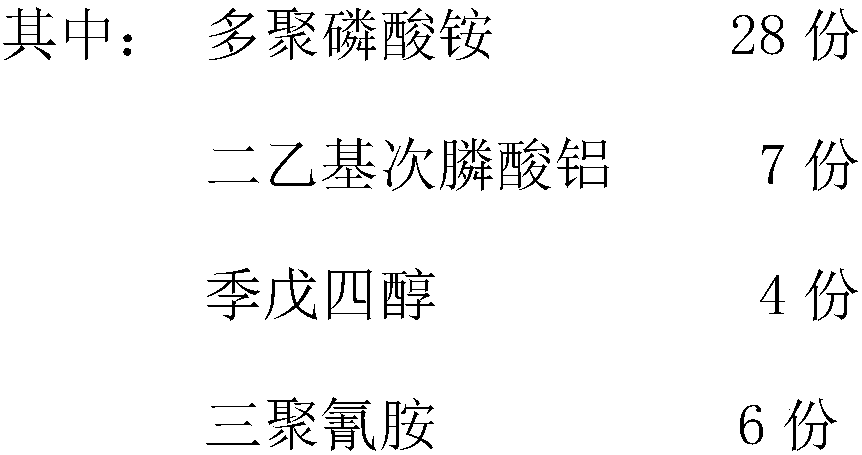

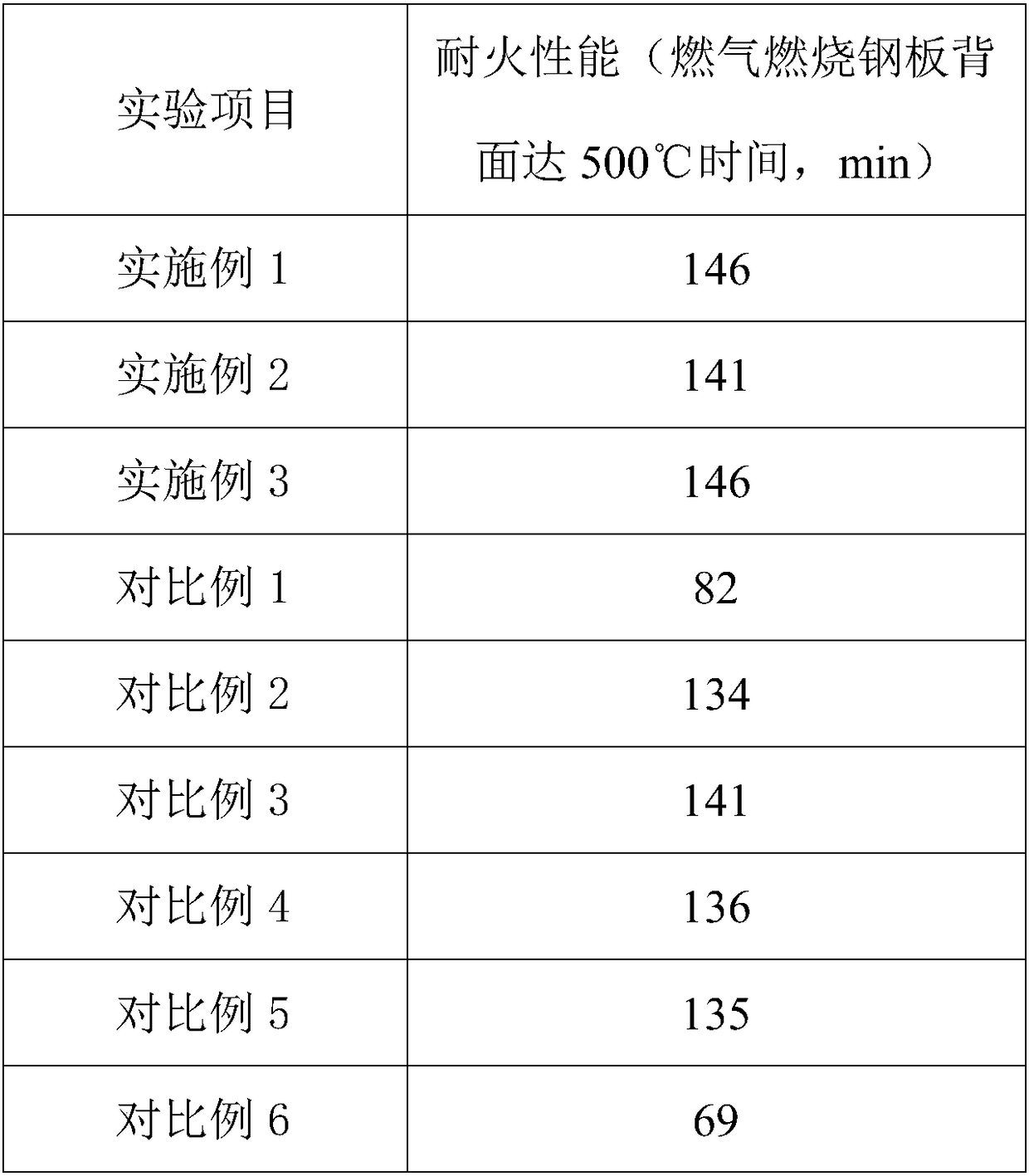

Water-based ultrathin steel structure fire-resistant coating based on aluminum phosphinate and preparation method and application thereof

The invention relates to water-based ultrathin steel structure fire-resistant coating based on aluminum phosphinate and a preparation method and application thereof. The fire-resistant coating is prepared from 35-55 parts by weight of a flame-retardant system, 40-50 parts by weight of a film-forming system, 5-15 parts by weight of a flame-retardant synergetic system and a suitable amount of water.The water-based ultrathin steel structure fire-resistant coating based on the aluminum phosphinate is capable of creatively using the aluminum phosphinate as an important component in an ammonium polyphosphate expansive-type flame-retardant system, a combustion charcoal layer of the water-based ultrathin steel structure fire-resistant coating based on the aluminum phosphinate is better in quality, the fire resistance is excellent, the durability and weather ability are greatly improved, and the water-based ultrathin steel structure fire-resistant coating based on the aluminum phosphinate is very low in VOC content. In production and coating processes and a using process, a person cannot be injured basically, and the environment cannot be polluted.

Owner:SOUTH CHINA UNIV OF TECH

Modified silicon rubber sheath material and preparation method thereof

InactiveCN107325555AImprove mixing modificationGood oil resistanceRubber insulatorsFiberPolymer science

A modified silicone rubber sheath material provided by the invention and a preparation method thereof, the raw materials of which are made of silicone rubber, fluororubber, fluorosilicone rubber, heptadecafluorodecyltrimethoxysilane, polyvinylidene fluoride, and a crosslinking agent , butyl titanate, stearic acid, aluminum diethylphosphinate, modified nanofibers, polyacrylonitrile organic fibers, flame retardants, anti-ultraviolet agents, stabilizers and toughening agents, among which, modified nanofibers The fiber is isocyanate triethoxysilane modified titanium boride nanofiber. The modified silicone rubber sheath material thus prepared not only improves the mechanical strength of the cable sheath, but also endows it with better oil stain resistance and corrosion resistance.

Owner:ZHEJIANG DIHENG IND CO LTD

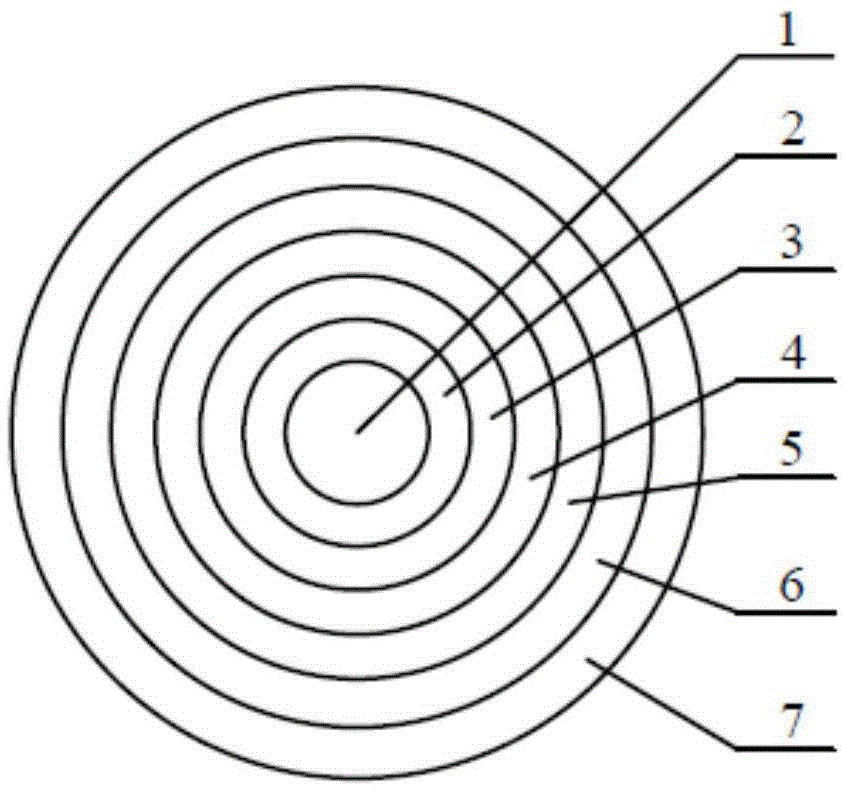

High-strength impact-resistant power cable

ActiveCN105632636AEasy to processImprove toughnessClimate change adaptationPower cables with screens/conductive layersElastomerElectrical conductor

The invention discloses a high-strength impact-resistant power cable. The cable comprises a conductor, wherein the exterior of the conductor is coated with a conductor wrapping layer; the exterior of the conductor wrapping layer is coated with an insulating layer; the exterior of the insulating layer is coated with an insulating wrapping layer; the exterior of the insulating wrapping layer is coated with a metal shielding layer; the exterior of the metal shielding layer is coated with a shielding wrapping layer; the exterior of the shielding wrapping layer is coated with a sheath layer; the sheath layer is prepared from a modified unsaturated polyester composite material; and the modified unsaturated polyester composite material comprises the raw materials of unsaturated polyester resin, an ethylene-butylene elastomer, phenylethylene, polyacrylonitrile fibers, basalt fibers, ammonium polyphosphate, diethyl aluminium hypophosphite, expandable graphite, hexa p-formyl phenoxy cyclotriphosphazene, methyl ethyl ketone peroxide, cobalt iso-octoate, calcined attapulgite, modified imvite, graphene oxide, octadecylamine and a defoaming agent. The high-strength impact-resistant power cable provided by the invention is high in strength, high in flexibility, excellent in impact resistance and long in service life.

Owner:ANHUI HAIYUAN SPECIAL CABLE

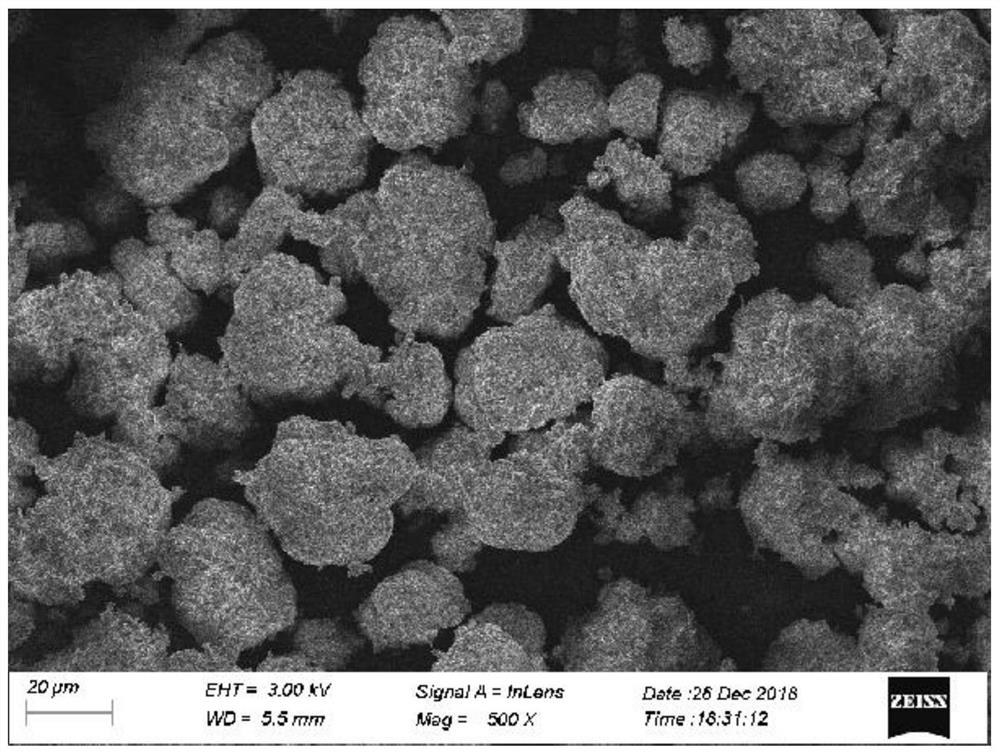

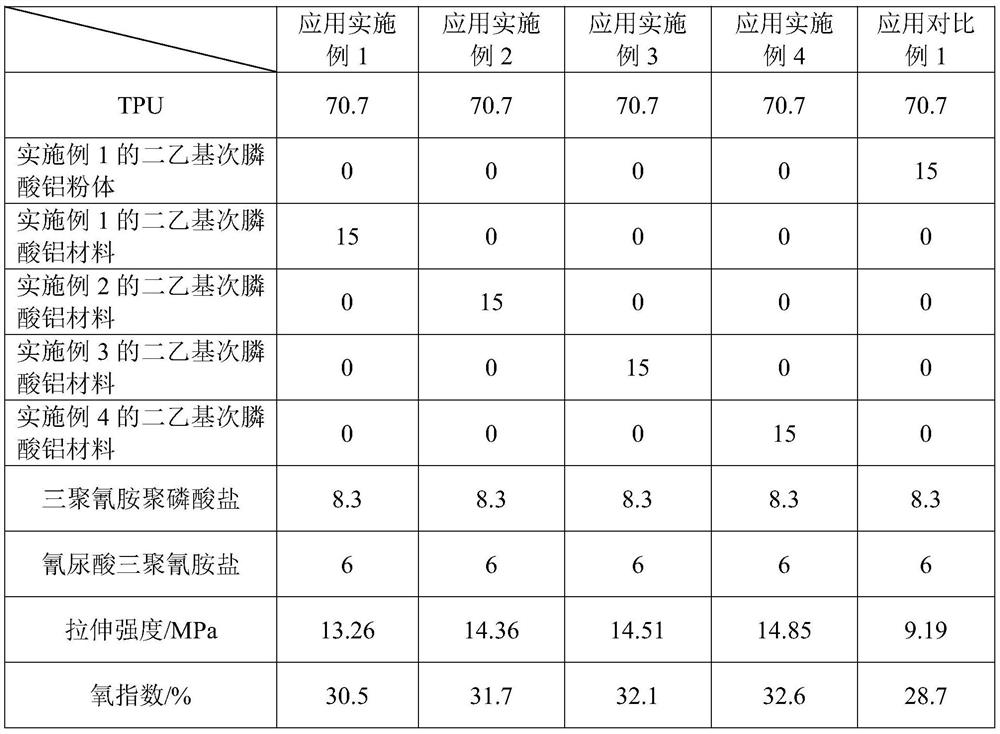

Aluminum diethyl phosphinate material and preparation method thereof

ActiveCN111808133ALarge specific surface areaReduce pollutionGroup 5/15 element organic compoundsPhosphinic AcidsMaterials science

The invention relates to an aluminum diethyl phosphinate material and a preparation method thereof. The preparation method comprises the steps that a mixed acid solution and a turbid liquid containingan aluminum source are provided, wherein the mixed acid solution comprises dialkyl phosphinic acid and a crystallization assisting agent; the mixed acid solution and the turbid liquid are mixed and react to obtain aluminum diethyl phosphinate particles, the multiple aluminum diethyl phosphinate particles are stacked to form powder of a porous structure, and the powder has D95 particle size distribution of 5-30 microns; putting the powder into a mixing machine to be mixed; and a coupling agent is added into the mixing machine in a spraying mode and mixed with the powder, the coupling agent andthe powder are combined to obtain the diethyl aluminum phosphinate material, and the bulk density of the diethyl aluminum phosphinate material is 0.45 g / cm < 3 > to 0.70 g / cm < 3 >. The diethyl aluminum phosphinate material can be uniformly dispersed in a polymer in the use process, so that the polymer material has excellent flame retardancy and mechanical properties, and dust pollution is small.

Owner:ZHEJIANG XINHUA CHEM +1

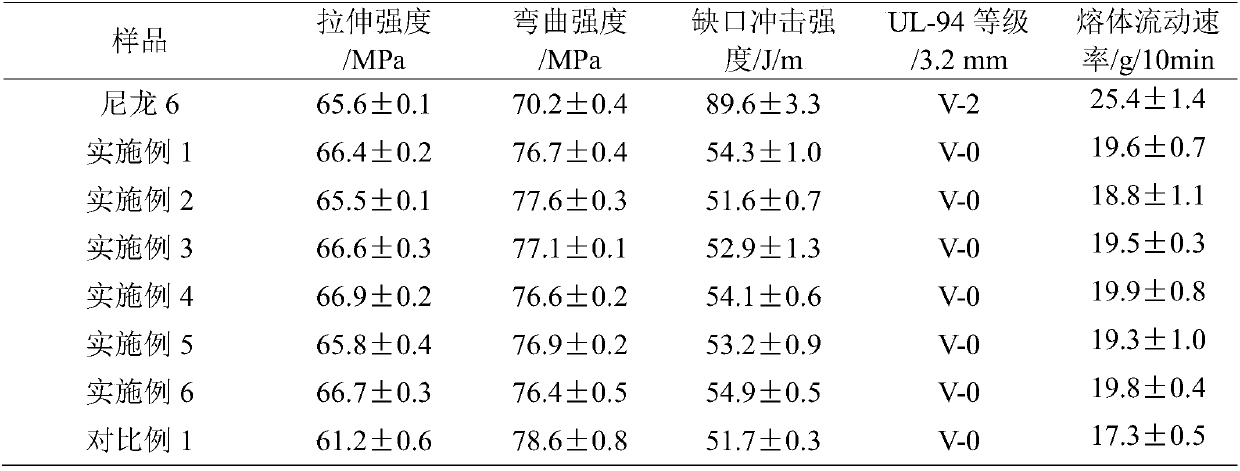

Phosphate-glass synergistic-effect halogen-free flame-retardant nylon-6 composition and preparation method thereof

The invention discloses a phosphate-glass synergistic-effect halogen-free flame-retardant nylon-6 composition and a preparation method thereof. The phosphate-glass synergistic-effect halogen-free flame-retardant nylon 6 composition is prepared from, by weight, 88.4%-90.1% of nylon-6, 9.0%-11.0% of diethyl phosphonic acid aluminum, 0.3%-1.0% of melamine modified phosphate glass, 0.1%-0.3% of an antioxygen and 0.1%-0.2% of a lubricant. The phosphate-glass synergistic-effect halogen-free flame-retardant nylon-6 composition is good in flame retardant performance, dosage of diethyl phosphonic acidaluminum can be dropped by up to 30.8% when flame retardant rating reaches UL-94V-0@3.2mm and the total amount of a flame retardant is decreased by 26.9%; compared with a flame retardant system adopting diethyl phosphonic acid aluminum independently, the phosphate-glass synergistic-effect halogen-free flame-retardant nylon-6 composition system has the advantages that melt flow rate is by 14.5%, and tensile strength is increased by 9.0%.

Owner:SOUTH CHINA UNIV OF TECH

Flame-retardant and antistatic epdm (ethylene-propylene-diene monomer) material

InactiveCN108659356AGood compatibilityGood physical and mechanical propertiesPolymer sciencePolyethylene glycol

The invention discloses a flame-retardant and antistatic epdm (ethylene-propylene-diene monomer) material. The flame-retardant and antistatic epdm material is prepared from EPDM rubber, nitrile rubber, polyethylene glycol terephthalate, silicon dioxide, graphene, nanometer titania, nano-particles of polyacenic semiconductor material, zinc oxide, magnesium oxide, stearic acid, dicumyl peroxide, sulphur, trimethylolpropane triacrylate, acrylonitrile grafted epdm, an accelerant, an anti-aging agent, a flame retardant, octadecyl methyl dihydroxyethyl ammonium bromide and polyoxyethylene stearate;the flame retardant is a mixture of aluminum diethyl phosphonate, melamine pyrophosphate, aluminum hydroxide, carbon microspheres and ammonium polyphosphate. The flame-retardant and antistatic epdm material is high in strength, excellent in heat resistant and flame retardant property and good in antistatic property.

Owner:李侠

Environment-friendly flame-retardant polyolefin protective film, and preparation method thereof

InactiveCN108912435AMaintain glossWill not cause badFilm/foil adhesivesEnvironmental resistancePolymer science

The invention provides an environment-friendly flame-retardant polyolefin protective film. The environment-friendly flame-retardant polyolefin protective film comprises, by weight, 100 parts of polyolefin resin, 3 to 12 parts of a composite flame retardant, 1 to 5 parts of a color master batch, and 1 to 2 parts of a processing auxiliary agent; wherein the polyolefin resin is composed of 50 to 100wt% polyethylene resin and 0 to 50wt% of polypropylene resin; the composite flame retardant comprises an eight bromo ether flame retardant and antimony oxide at a weight ratio of 2-4:1. The composite flame retardant also comprises 1 to 5wt% of aluminium hypophosphite and / or aluminum diethylphosphinate. A preparation method comprises following steps: the above ingredients are mixed to be uniform, are subjected to heating melting using an extrusion film blowing machine so as to obtain polyolefin film through film blowing, and then gluing and drying are carried out so as to obtain the protective film. The environment-friendly flame-retardant polyolefin protective film can be used in metal product protection.

Owner:广州市寅源新材料股份有限公司

PA6 flame retardant plastic

The invention provides a PA6 flame retardant plastic, and relates to a plastic. The PA6 flame retardant plastic is prepared from aluminum hydroxide and a diethyl aluminum phosphinate composite environmental-protection flame retardant agent, and comprises, by weight, 100 parts of a PA6 resin, and 40-75 parts of a composite environmental-protection flame retardant agent for PA6, or a halogen-free flame retardant PA6 comprises, by weight, 80-100 parts of PA6, 30-60 parts of aluminum hydroxide, 5-20 parts of diethyl aluminum phosphinate composite, 30-60 parts of glass fiber, and 0.5-3% of a silane coupling agent. The PA6 flame retardant plastic of the present invention has characteristics of low cost, no halogen, environmental protection, stable color, high mechanical property, and good flame-retardant effect.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

High-flame-retardance polyurethane and preparation method thereof

InactiveCN108219440AImprove flame retardant performanceWell mixedBuilding insulationsPolyesterDiethylenetriamine

The invention discloses high-flame-retardance polyurethane, and belongs to the technical field of polyurethane preparation. The high-flame-retardance polyurethane is prepared from the following raw materials including polyurethane, polycaprolactone diols, alkyd resin, polyester acrylic resin, trimethylolpropane triacrylate, polyacrylic acid, chlorinated rubber, organic silicon resin, azodicarbonamide, diethylenetriamine, benzotriazole, zinc borate, aluminum triphosphate, nitrocotton, sodium molybdate, nanometer aluminum oxide, magnesium hydrate, chlorinated paraffin, mica iron oxide, hydroxypropyl silicone oil, aluminum diethyl phosphonate, sodium metaborate, chlorinated paraffin, emulsified asphalt, dicumyl peroxide, antimonous oxide, nanometer boron nitride, silane coupling agents HK-560and flame-retardance modifying agents through the steps of base material preparation, modifying material preparation, mixing of materials such as base materials and modifying materials and the like.The prepared polyurethane has excellent flame-retardance performance.

Owner:安徽天择化工有限公司

Additive for plastic and application of additive, and flame-retardant polymer molding composition formed by additive

The invention discloses an additive for plastics, application thereof, and a flame-retardant polymer molding composition composed of the same. Specifically, the additive comprises: A. diethyl aluminum phosphinate; and B. homologues, the molar content of which in the total additive is 0.001-0.78%. The homologues are ethyl butyl aluminum phosphinate, butyl butyl aluminum phosphinate, ethyl hexyl aluminum phosphinate, butyl hexyl aluminum phosphinate and / or hexyl hexyl aluminum phosphinate. The additive for plastics provided by the invention can be added into a polymer, has small corrosion to the screw of a mixing assembled unit during processing and small damage to surrounding polymers. Compared with plastic additives with a high content of homologues, the additive provided by the invention has a high effective P content and good flame retardant performance, thus greatly broadening the application range of the plastic additive in the market.

Owner:ZHUHAI WANTONG CHEM

Anti-corrosion and heat-proof modified silicone rubber material

The invention discloses an anti-corrosion and heat-proof modified silicone rubber material. The anti-corrosion and heat-proof modified silicone rubber material is prepared from the following raw materials: silicone rubber, phenolic resin, EPDM (Ethylene-Propylene-Diene Monomer) rubber, chloroprene rubber, amino-terminated liquid butadiene-acrylonitrile rubber, butyl rubber, hydroxyl-terminated polybutadiene, methacrylic acid, vinyl triethoxy silane, sodium stearate, isocyanate, low-density polyethylene, liquid paraffin, styrene, zinc borate, nano alumina powder, nano graphite, magnesium hydroxide, antimonous oxide, diethyl aluminum phosphinate, tetraethoxysilane, dibutyltin dilaurate, an anti-corrosion modification assistant and heat-proof modification filler. The anti-corrosion and heat-proof modified silicone rubber material disclosed by the invention has excellent corrosion resistance and heat resistance.

Owner:天长市荣盛有机硅科技有限公司

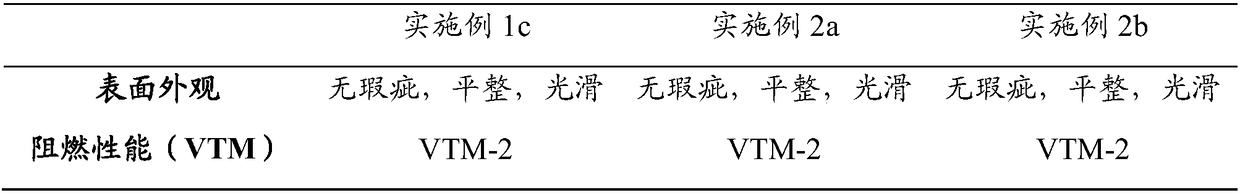

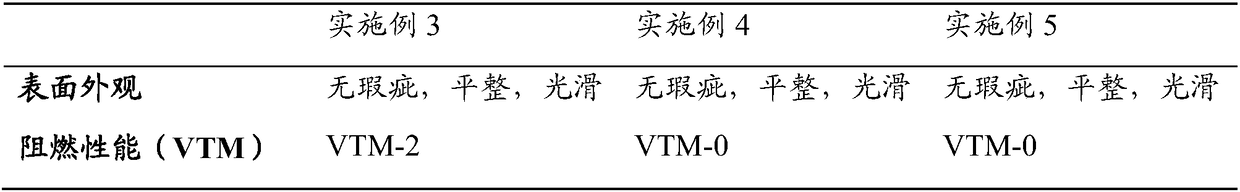

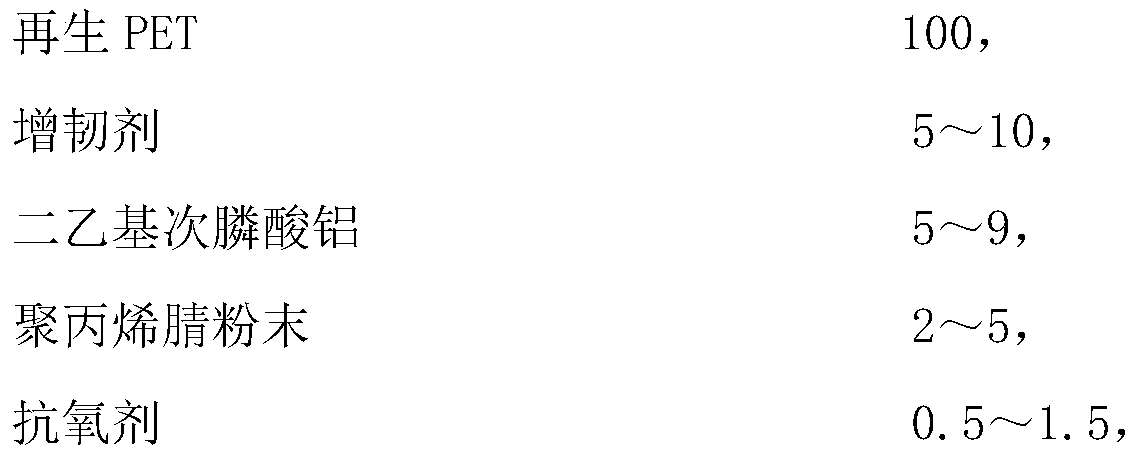

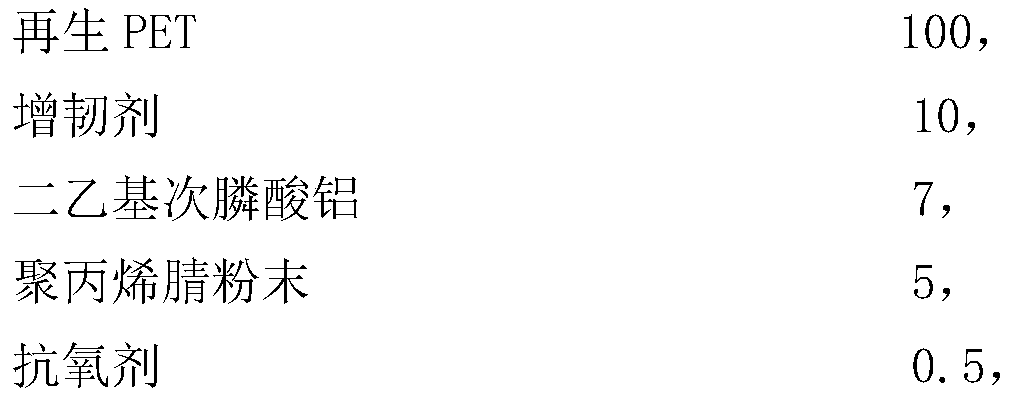

Special halogen-free flame-retardant recycled PET (polyethylene terephthalate) sheet material for coil packaging and preparation method thereof

The invention relates to a special halogen-free flame-retardant recycled PET (polyethylene terephthalate) sheet material for coil packaging, prepared from, by weight, 100 parts of recycled PET, 5-10 parts of a toughener, 5-9 parts of aluminum diethyl phosphinate, 2-5 parts of polyacrylonitrile powder, and 0.5-1.5 parts of an antioxidant material. A preparation method of the special halogen-free flame-retardant recycled PET sheet material for coil packaging is also provided; the preparation method includes the steps of 1) drying the recycled PET; 2) mixing the dried recycled PET with the toughener, aluminum phosphinate, polyacrylonitrile powder and the antioxidant to obtain a mixture; 3) subjecting the mixture to melt extrusion with a twin-screw extruder in vacuum for granulating. A recycled PET sheet prepared with the special halogen-free flame-retardant recycled PET sheet material for coil packaging has the advantages of high tensile strength, excellent flame retardance, good impact resistance and good processing mobility and is suitable for the field of coil packaging.

Owner:武汉融科包装材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com