Water-based ultrathin steel structure fire-resistant coating based on aluminum phosphinate and preparation method and application thereof

A technology of diethylphosphinic acid and fire retardant coating, applied in the direction of fire retardant coating, coating, etc., can solve the problems of poor weather resistance and poor durability, and achieve the improvement of durability and weather resistance, excellent fire resistance performance and good quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Based on the water-based ultra-thin fireproof coating for steel structures based on aluminum diethylphosphinate, its composition and weight percentage are as follows:

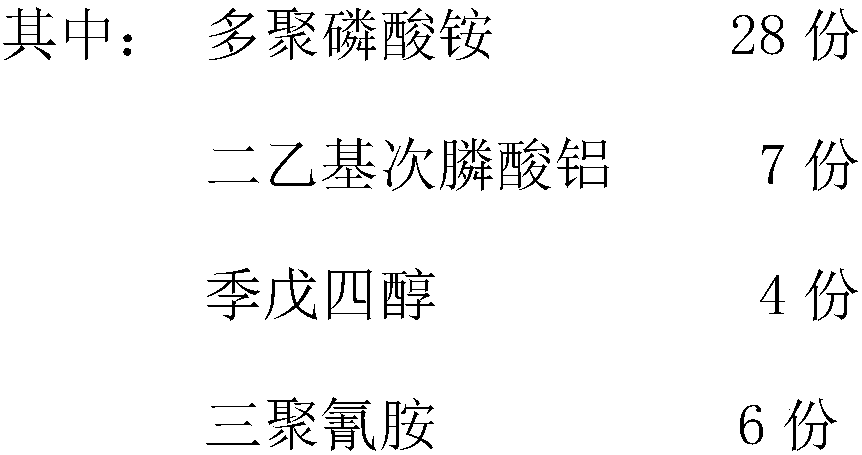

[0020] ① Flame retardant system 55 parts

[0021] in:

[0022] ②Film-forming system 40 parts

[0023] in:

[0024] ③Flame retardant synergistic system 5 parts

[0025] Titanium dioxide 5 parts

[0026] ④ 60 parts of water

[0027] First, 55 parts by weight of the flame retardant system and 5 parts by weight of the flame retardant synergistic system are ground uniformly in a ball mill and passed through a 150-mesh sieve, and then added to 40 parts by weight of the film-forming system and 60 parts by weight of water. After high-speed stirring and dispersing evenly, the water-based steel structure fireproof coating based on aluminum diethylphosphinate of the present invention with a solid content of 50% is obtained.

[0028] According to GB14907‐2002 "Steel Structure Fireproof Coating Performance ...

Embodiment 2

[0030] Based on the water-based ultra-thin fireproof coating for steel structures based on aluminum diethylphosphinate, its composition and weight percentage are as follows:

[0031] ① Flame retardant system 45 parts

[0032]

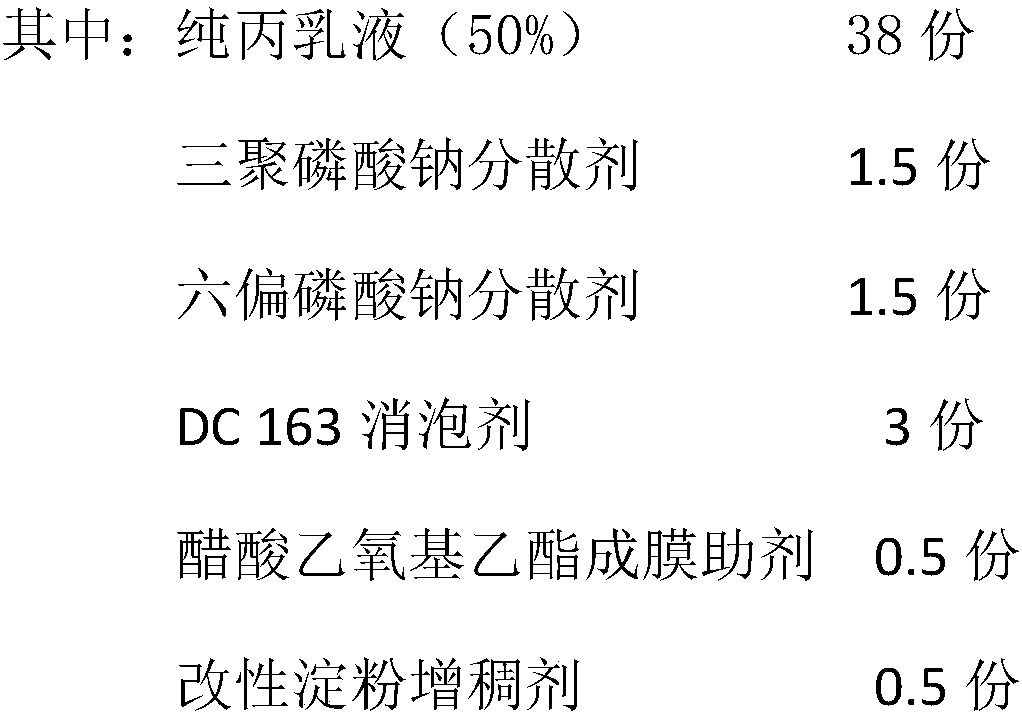

[0033] ②Film-forming system 45 parts

[0034]

[0035] ③Flame retardant synergistic system 10 parts

[0036] Of which: Halloysite 7 parts

[0037] 3 parts titanium dioxide

[0038] ④30 parts of water

[0039] First, grind 45 parts by weight of the flame retardant system and 10 parts by weight of the flame retardant synergistic system in a ball mill to pass through a 150-mesh sieve, then add them to 45 parts by weight of the film-forming system, and add 30 parts by weight of water. After high-speed stirring and dispersing evenly, the water-based steel structure fireproof coating based on aluminum diethylphosphinate of the present invention with a solid content of 60% is obtained.

[0040] According to GB14907‐2002 "Steel Structure Fireproof Co...

Embodiment 3

[0042] Based on the water-based ultra-thin fireproof coating for steel structures based on aluminum diethylphosphinate, its composition and weight percentage are as follows:

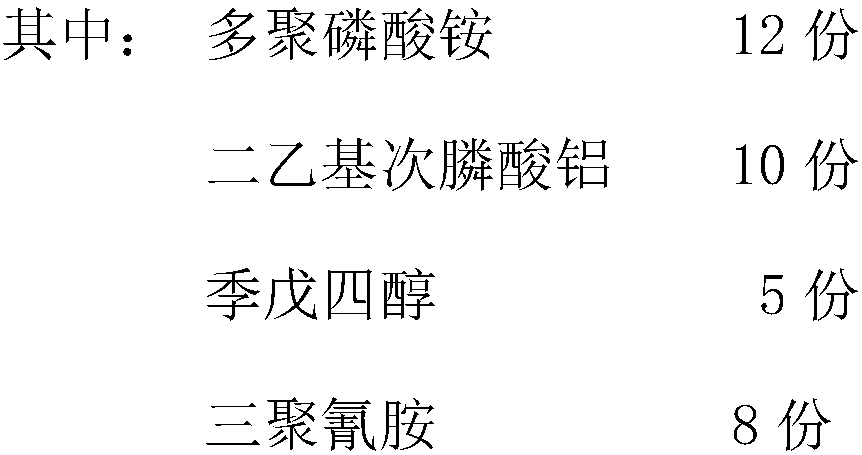

[0043] ① Flame retardant system 35 parts

[0044]

[0045] ②Film-forming system 50 parts

[0046]

[0047]

[0048] ③Flame retardant synergistic system 15 parts

[0049] Of which: silicon dioxide 3 parts

[0050] 3 parts titanium dioxide

[0051] Kaolin 9 parts

[0052] ④ 8 parts of water

[0053] First, grind 35 parts by weight of the flame retardant system and 15 parts by weight of the flame retardant synergistic system in a ball mill to pass through a 150-mesh sieve, then add them to 50 parts by weight of the film-forming system, and add 8 parts by weight of water. After high-speed stirring and dispersing evenly, the water-based steel structure fireproof coating based on aluminum diethylphosphinate of the present invention with a solid content of 70% can be obtained.

[0054] According ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com