Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Will not produce" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

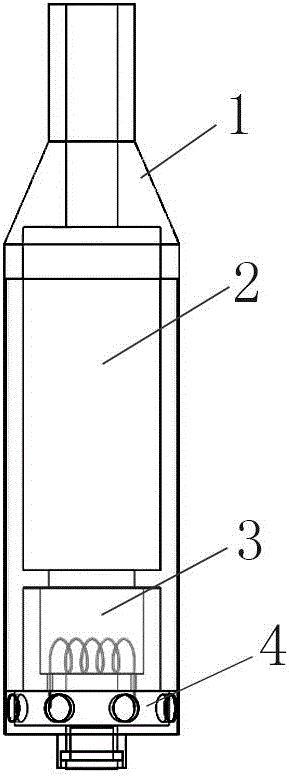

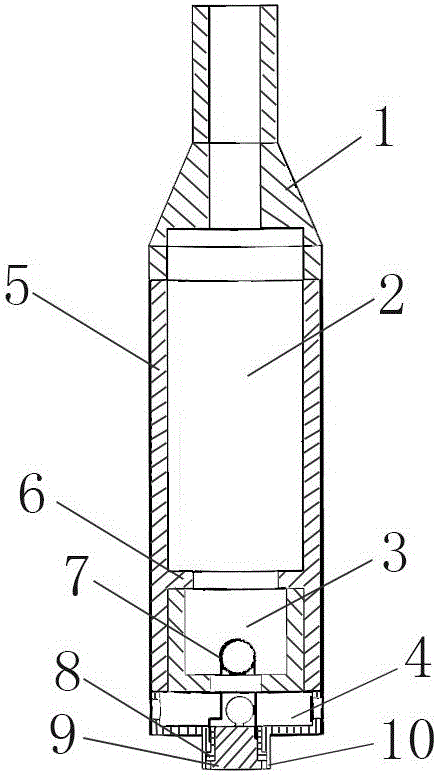

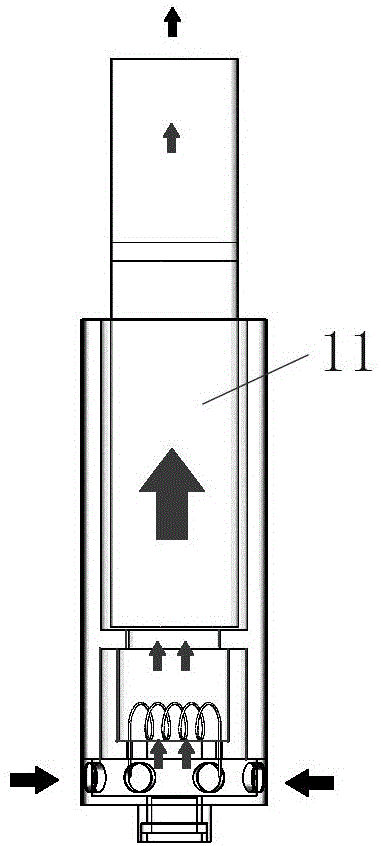

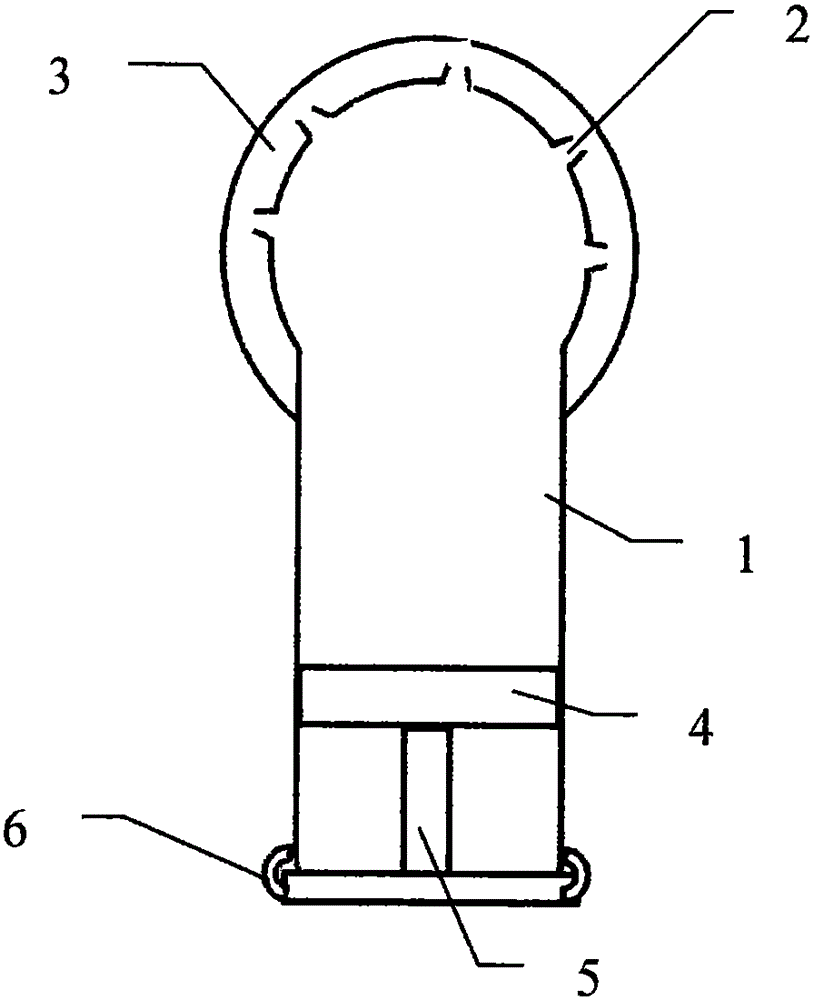

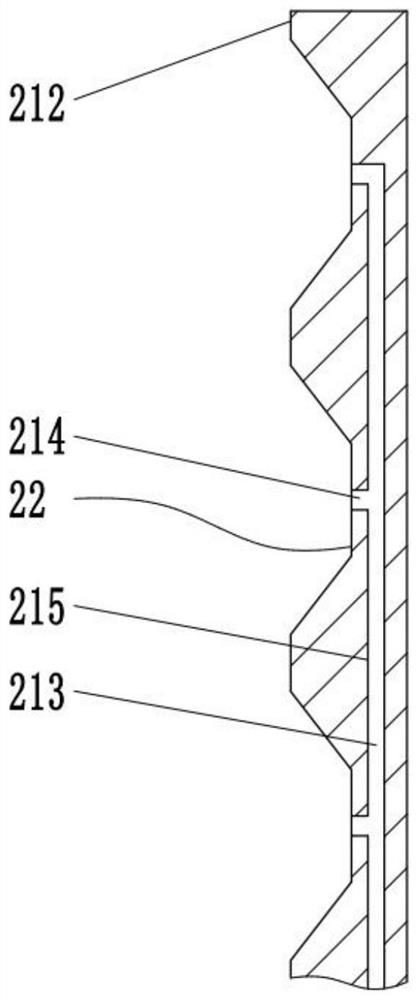

Electronic smoke atomizer based on hot airflow non-contact heating

The invention discloses an electronic smoke atomizer based on hot airflow non-contact heating. During use, low-temperature cigarettes or smoke cartridges are heated by hot airflow, and a heating assembly is not directly contacted with the low-temperature cigarettes or smoke cartridges. During electrification, the heating assembly generates high temperature, so that temperature of the whole heating cavity is instantaneously raised; when air is continuously sucked through a smoke nozzle, fresh air enters from an air hole of a battery connecting assembly, is instantaneously heated to a high temperature through the heating assembly and forms continuous high-temperature airflow, the high-temperature airflow flows to an atomizing cavity, and the low-temperature cigarettes or smoke cartridges arranged in the atomizing cavity are heated; and according to the effect of the hot airflow, flavor components in the low-temperature cigarettes or electronic smoke atomized oil in the smoke cartridges can be sublimated and atomized. According to the atomizer, the electronic smoke atomized oil can be atomized by virtue of the hot airflow generated by less electric quantity, and the condition that the electronic smoke atomized oil is cracked to generate hazardous substances due to extremely high temperature is avoided.

Owner:张志雄 +2

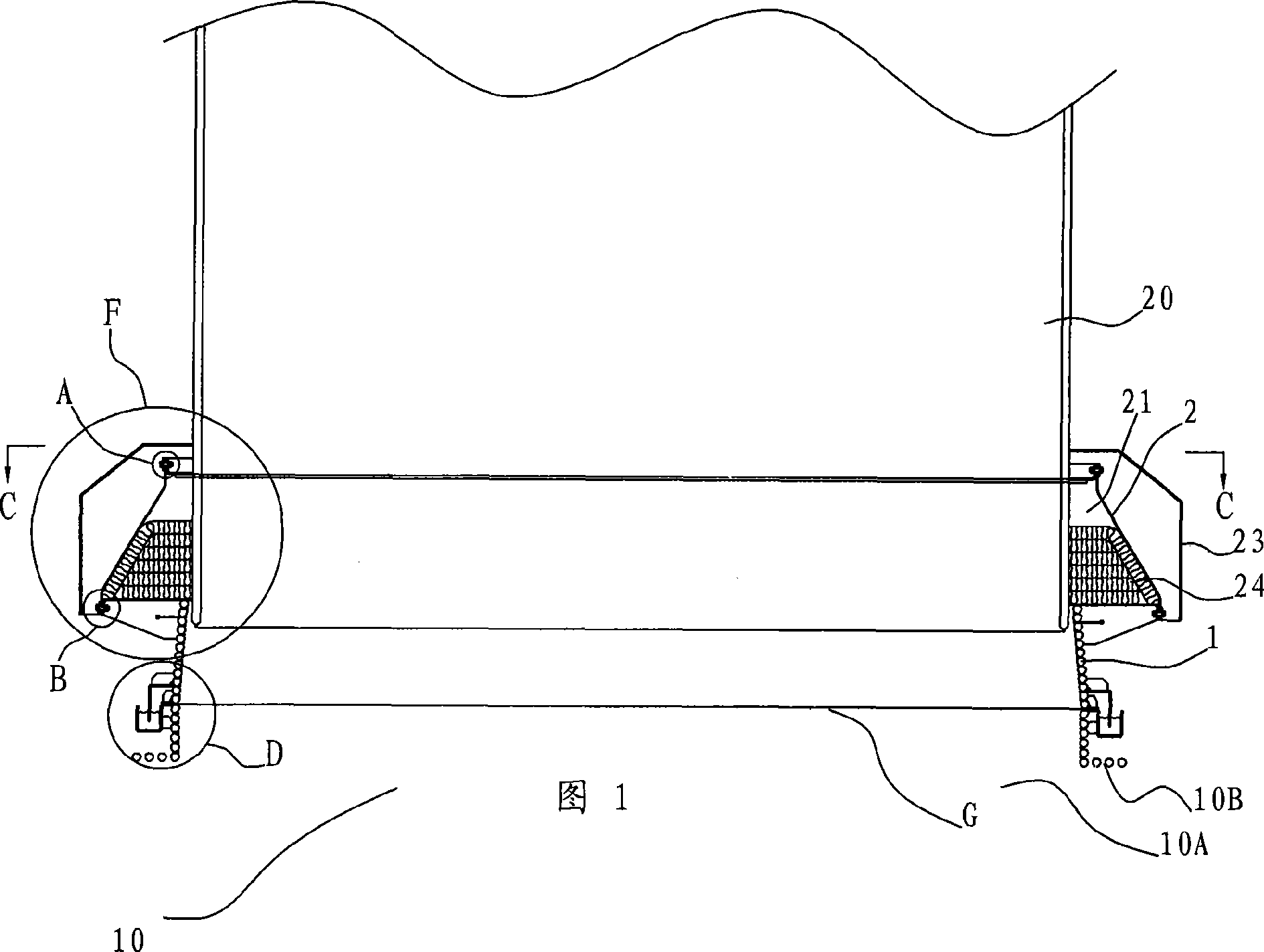

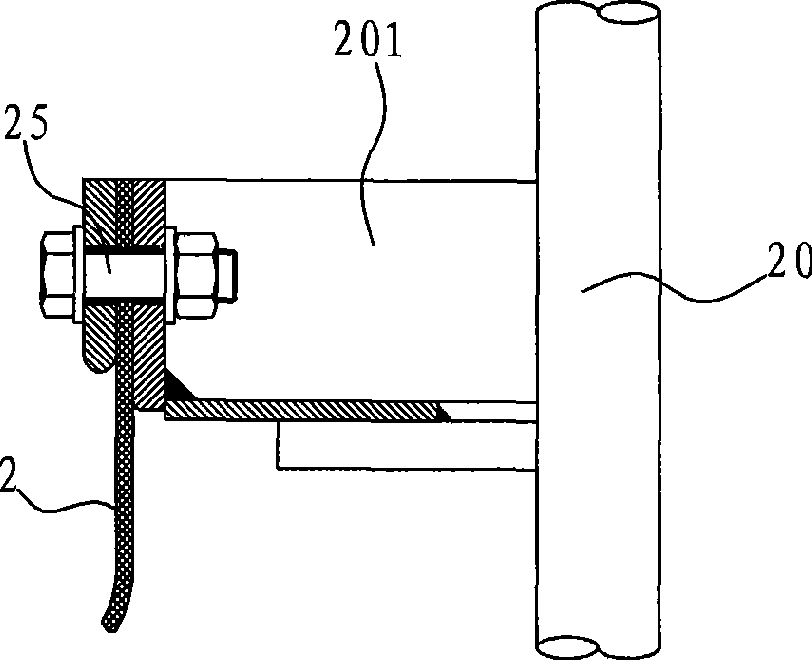

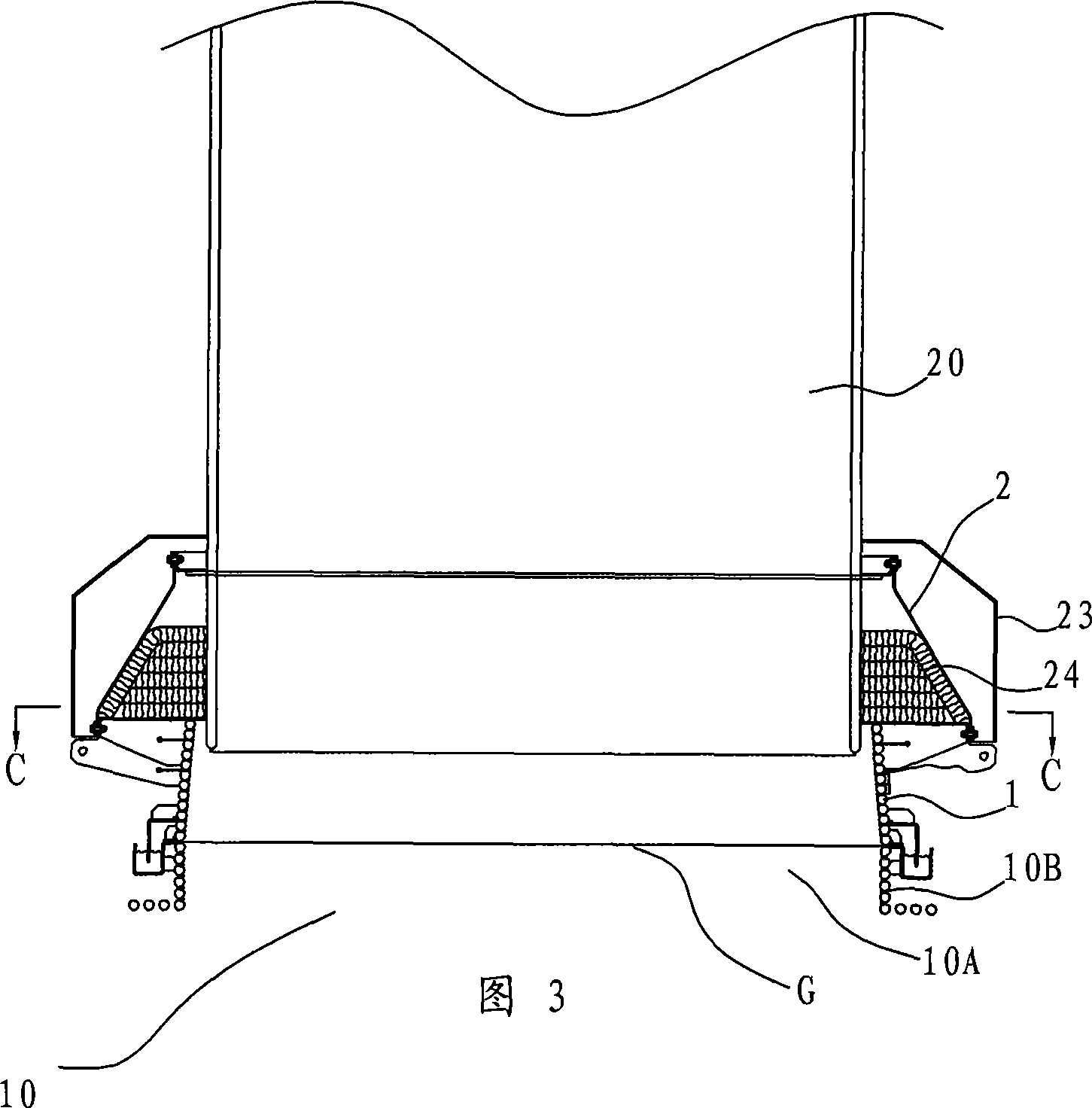

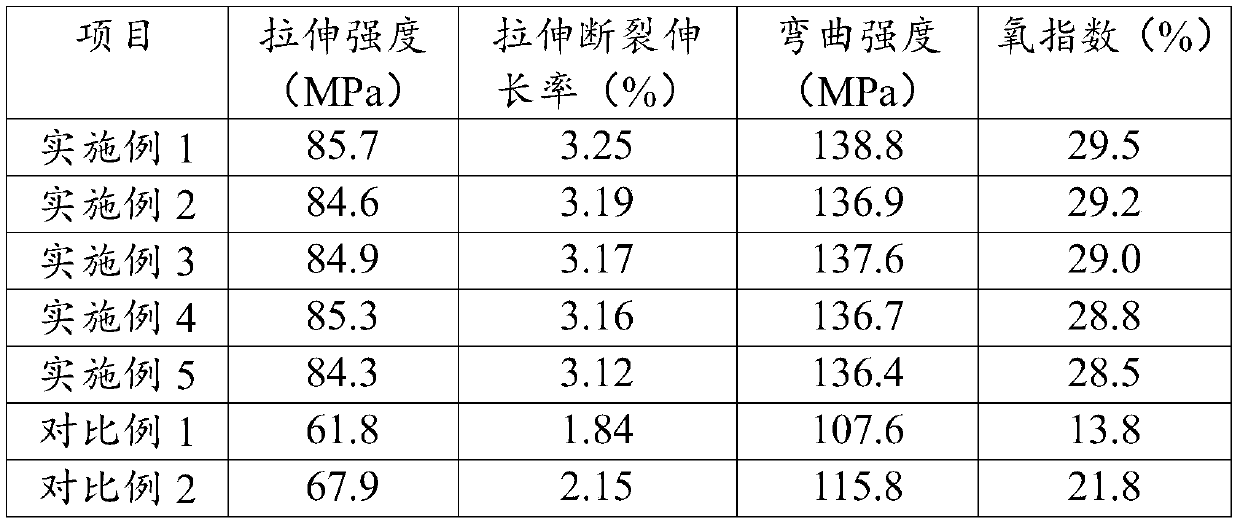

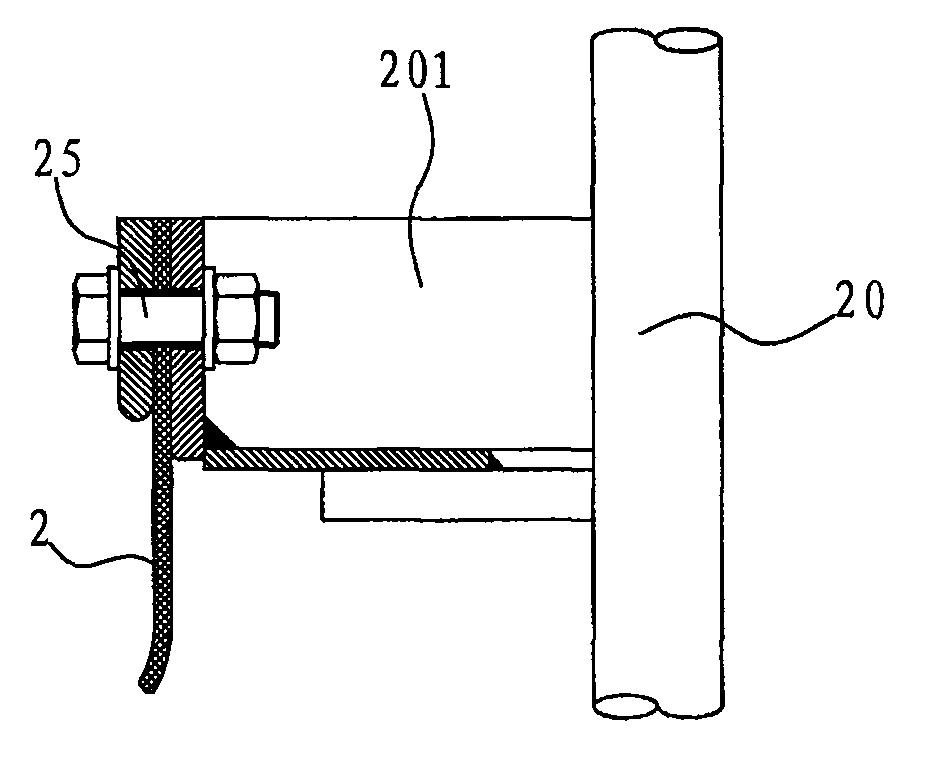

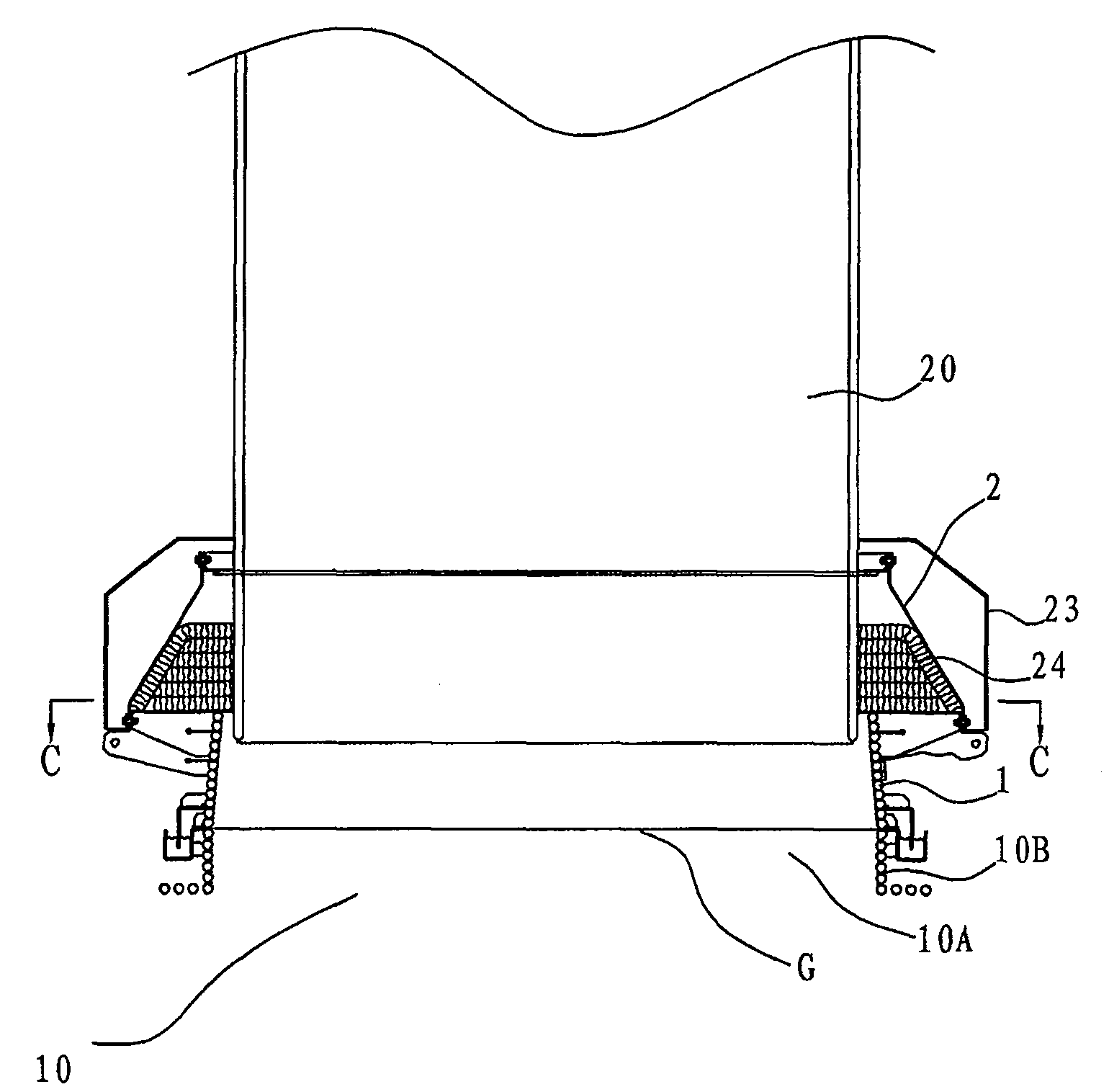

Inlet sealing and connecting device for exhaust-heating boiler

ActiveCN101451704AEasy to operateGood sealing performanceSteam generation using hot heat carriersEngineeringFlue gas

The invention discloses a connection device used for sealing entrance of waste heat boiler, comprising a lower part sealing connection piece which is buttoned up at the flue gas exit of melting furnace, and a flexible sealing connection piece one end of which is suitable to be in sealed connection with the waste heat boiler and the other end of which is in sealed connection with the lower part sealing connection piece, thus the flexible sealing connection piece and the lower part sealing connection piece can move relative to the waste heat boiler. The sealing connection device of the invention is composed of the lower part connection part and the flexible connection part, wherein, the flexible connection part is provided with expansion margin, thus satisfying thermal expansion when in performance and avoiding the occurrence of gap due to the thermal expansion of the waste heat boiler and the melting furnace. Therefore, the connection device used for sealing entrance of waste heat boiler has the advantages of fine sealing performance, simple operation and low cost.

Owner:CHINA ENFI ENGINEERING CORPORATION

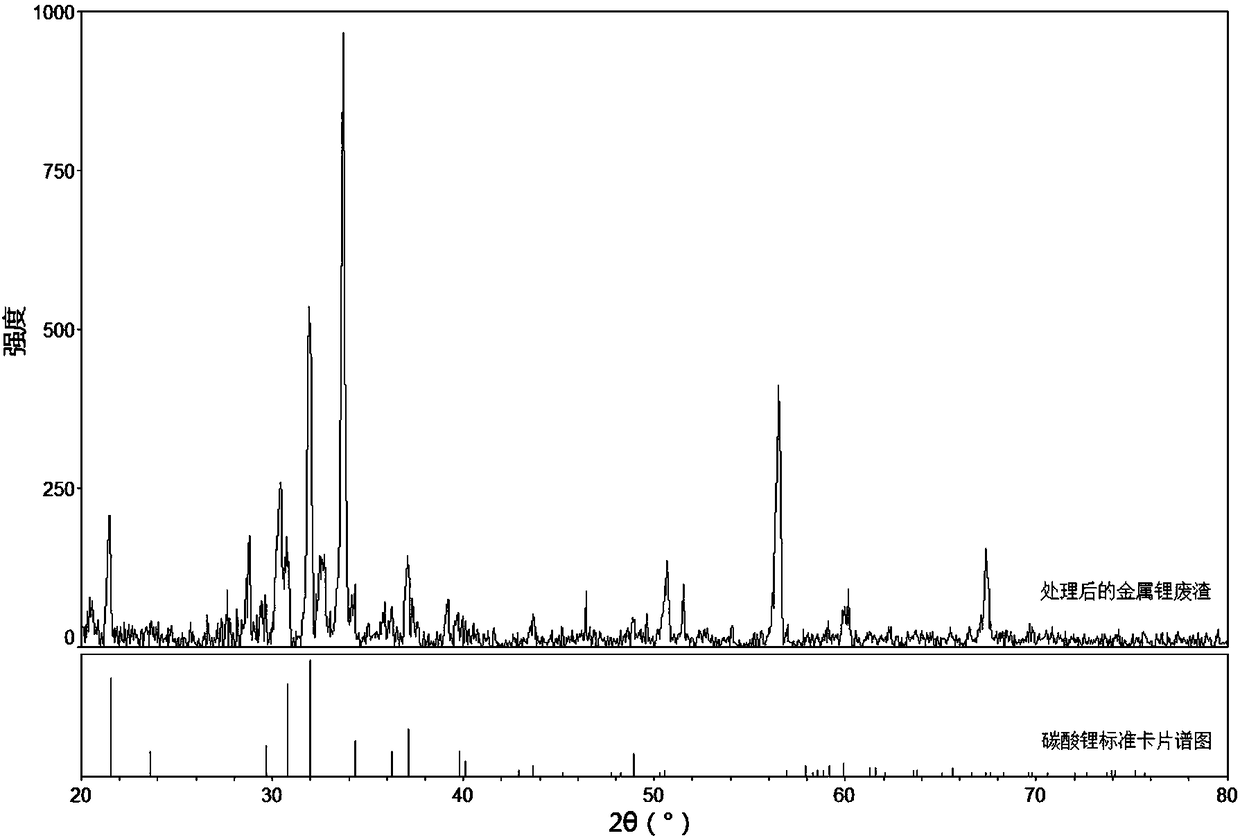

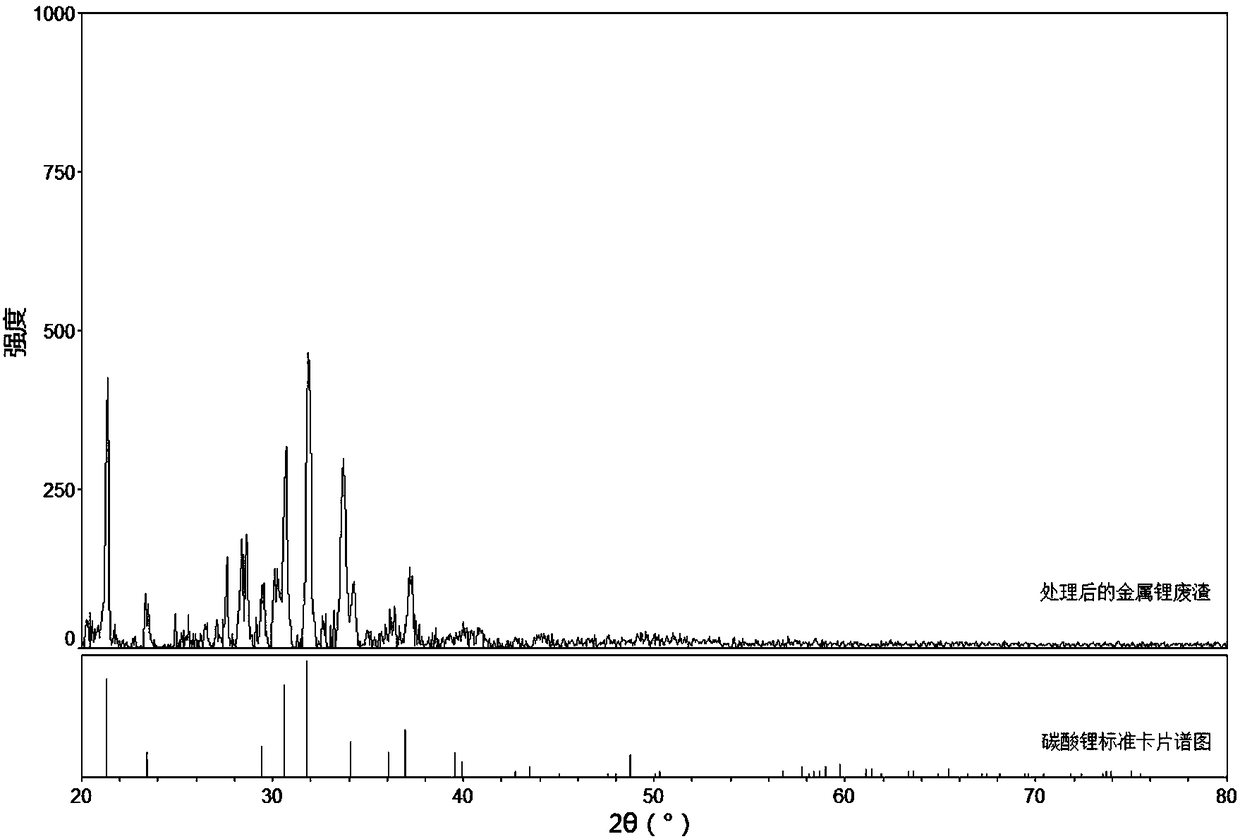

Method for treating lithium-containing waste residues

ActiveCN108101076AWill not produceAvoid safety hazardsLithium carbonates/bicarbonatesToxic gasLithium carbonate

The invention relates to a method for treating lithium-containing waste residues, and belongs to the technical field of recovery of lithium. The technical problem to be solved by the invention is to provide the method for treating lithium-containing waste residues. The method comprises the following steps: heating the lithium-containing waste residues to reach a temperature higher than 200 DEG C under the air-isolating environment, introducing treating gas, performing reaction, and transforming lithium in the lithium-containing waste residues into lithium carbonate, wherein the treating gas contains carbon dioxide. By the treatment method provided by the invention, potential safety hazard is avoided, combustible and toxic gas is not generated, and safety and environmental friendliness areachieved. Reaction is rapid and the treatment time consumption is low; and the method is simple, special equipment is not needed and the process flow is simple and convenient. The lithium-containing waste residues treated by the method have high safety performance and avoid obvious reaction with air and water; and the obtained lithium carbonate is safe and easy to recover.

Owner:TIANQI LITHIUM CORP

Preparation method of high-piece-weight and high-performance titanium and titanium alloy bright coiled wire

The invention belongs to the field of metal machining, relates to titanium alloy wire machining, and in particular to a preparation method of a high-piece-weight and high-performance titanium and titanium alloy bright coiled wire. The preparation method comprises the steps of raw material preparation, hot continuous rolling, polishing, multi-gate rolling mold continuous cold drawing, online heat treatment, and inspection warehousing. Compared with the prior art, the preparation method has the following technical effects: the production of high-piece-weight disc round blanks is realized; the all-flow bright surface finishing of wire rods is realized; no environmental hazard is generated to satisfy the national environment protecting requirements; multiple processes are saved; the cost is prominently reduced; and the performance uniformity is stable.

Owner:BAOJI HEXIN METAL

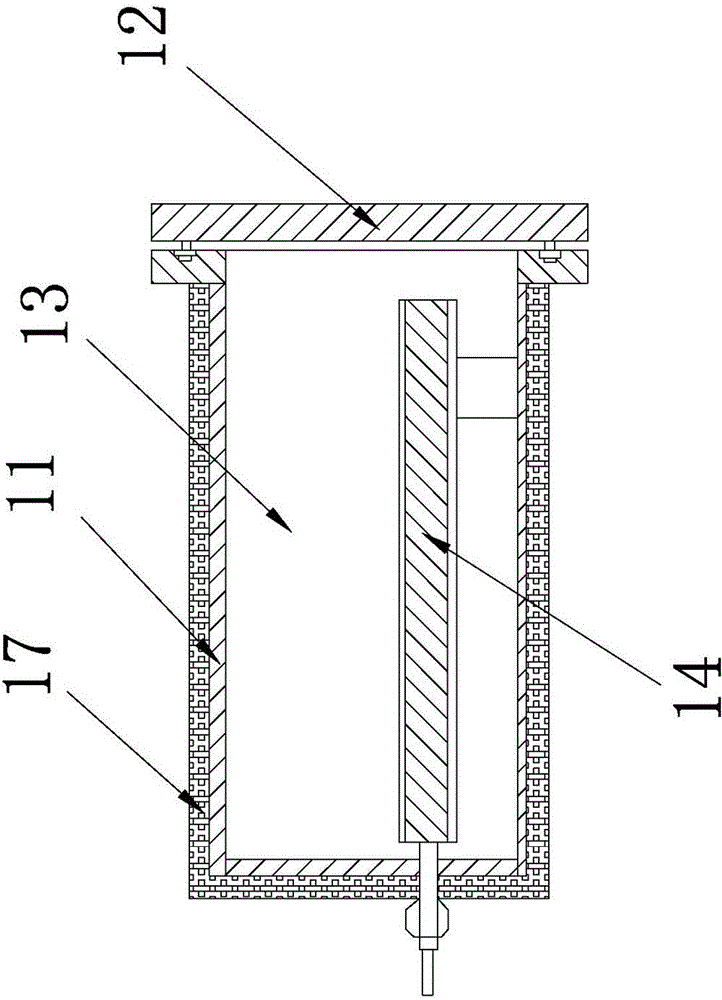

Nano-material vacuum coating machine

InactiveCN104878345AShould not fall offWill not produceVacuum evaporation coatingSputtering coatingEvaporationPneumatic valve

The invention relates to the technical field of nano-material coating equipment, in particular to a nano-material vacuum coating machine which comprises an evaporation furnace for evaporating a coating material into gas, a cracking furnace for cracking the gas, and a coating device for coating a product, wherein the coating device comprises a vacuum furnace, a vacuum pump for evacuating the vacuum furnace and a pressure pump for pressurizing the vacuum furnace, wherein the vacuum furnace is connected with the vacuum pump and the pressure pump through pipelines respectively; the evaporation furnace, the cracking furnace and the vacuum furnace are communicated through a pipeline; a pneumatic valve is further arranged between the cracking furnace and the vacuum furnace. The nano-material vacuum coating machine is simple and compact in structure, strong in sealing property and good in coating effect; a film is unlikely to fall off; and the coating material is nano-material so as to avoid producing harmful gases.

Owner:GUANGDONG YINENG NANO SCI & TECH

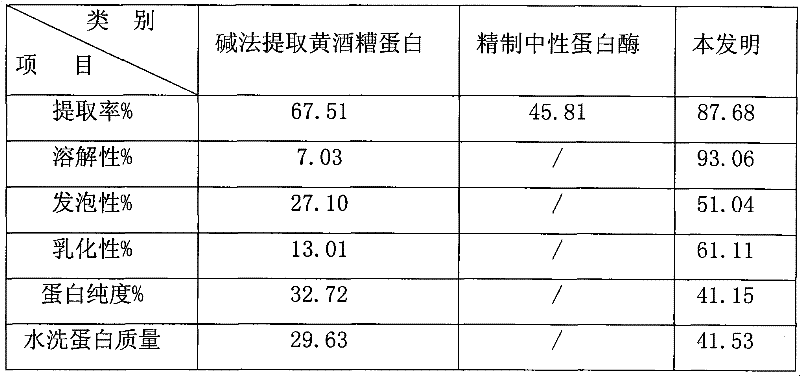

Enzymatic extraction of rice distiller's grain protein production process

The invention discloses a production technology of yellow wine lees proteins by the enzymatic extraction. By the production technology, nutritional components are not destroyed and the extraction efficiency is high. The production technology comprises the following steps of: 1) washing the yellow wine lees and removing impurities, carrying out hydrolysis by the use of cellulose, drying the yellow wine lees after the hydrolysis by the use of cellulose until the water content reaches about 50%; 2) using alkaline enzyme and a-amylase as enzyme preparations with the ratio of alkaline enzyme to a-amylase being 5: 1 and the enzymatic amount being 1832AU, carrying out hydrolysis on the yellow wine lees proteins for 4 hours while the temperature is 48-50 DEG C and the PH value is 9.5; 3) separating a yellow wine lees protein hydrolysate by the membrane separation technology while the pressure is 30psi, the pH value is 9, the concentration ratio is 5:1, the temperature is room temperature and the permeation flux is 33.2L / m<2>h. The invention is suitable for the extraction of the yellow wine lees proteins.

Owner:绍兴市古煌酿酒有限公司

Method for connecting prefabricated floor and prefabricated vertical component

A method for connecting a prefabricated floor and a prefabricated vertical component is characterized in the steps that (1) the prefabricated floor of a concrete cast-in-place plate strip is connected with the prefabricated vertical component, wherein the concrete cast-in-place plate strip is disposed at the joint between the prefabricated floor and the prefabricated vertical component, and a rough face or a teeth-shaped face is disposed on a connecting end face of the prefabricated floor, and upper and lower reinforcing steel bars of the prefabricated floor form a closed circle and are stretched into a rear casting strip, the prefabricated vertical component is stretched from one corner of an annular reinforcing steel bar, the two kinds of reinforcing steel bars form a new closed circle, and longitudinal reinforcing steel bars are inserted into the closed circle; and (2) the concrete cast-in-place plate strip is poured by fine aggregate concrete. The method for connecting the prefabricated floor and the prefabricated vertical component provided by the invention is beneficial in that the method can reduce a lot of floor wet construction and can realize overall prefabrication of a wall body and the floor. The method for connecting the prefabricated floor and the prefabricated vertical component provided by the invention increases an assembly rate of a building, reduces a floor thickness, avoids cracks at a floor support and can also satisfy overall performance of the floor.

Owner:YUNNAN INST OF BUILDING RES

Aluminum silica sol composite combined aluminum silicon carbide castable and preparation method thereof

The invention discloses an aluminum silica sol composite combined aluminum silicon carbide castable and a preparation method thereof. The castable is prepared from the following raw materials in percentage by weight: 25-35% of 12-8mm bauxite aggregate, 10-15% of 8-3mm bauxite aggregate, 15-20% of 3-0mm bauxite aggregate, 15-25% of <88 mu m corundum fine powder or alumina fine powder, 5-12% of <88 mu m SiC fine powder, 1-5% of <5 mu m silicon micropowder and 5-10% of <5 mu m alpha-Al2O3 micropowder. An aluminum silica sol composite binder accounting for 10-15 wt% of all the raw materials is also added. The castable has the characteristics of high moderate-temperature strength, favorable thermal shock resistance and high corrosion resistance, can implement flash baking, and enhances the turnaround efficiency of the iron ladle; and since the service life is doubled, the castable can effectively save the consumption of the refractory material.

Owner:河南竹林耐材有限公司

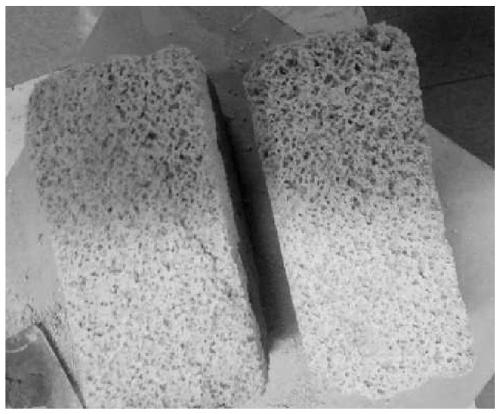

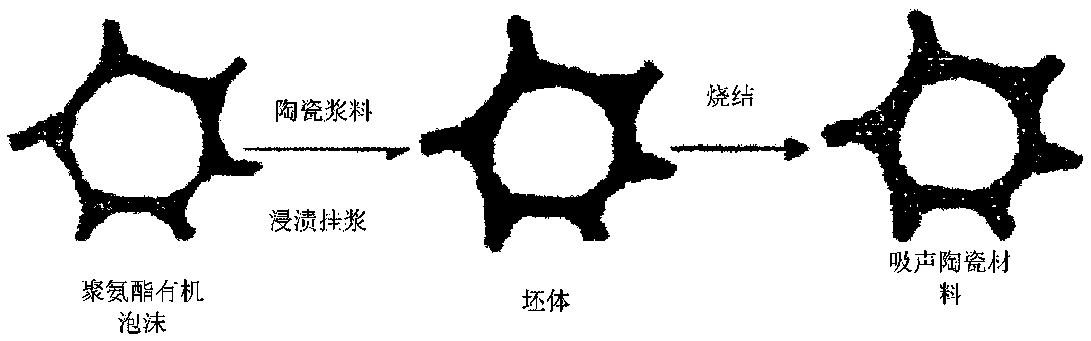

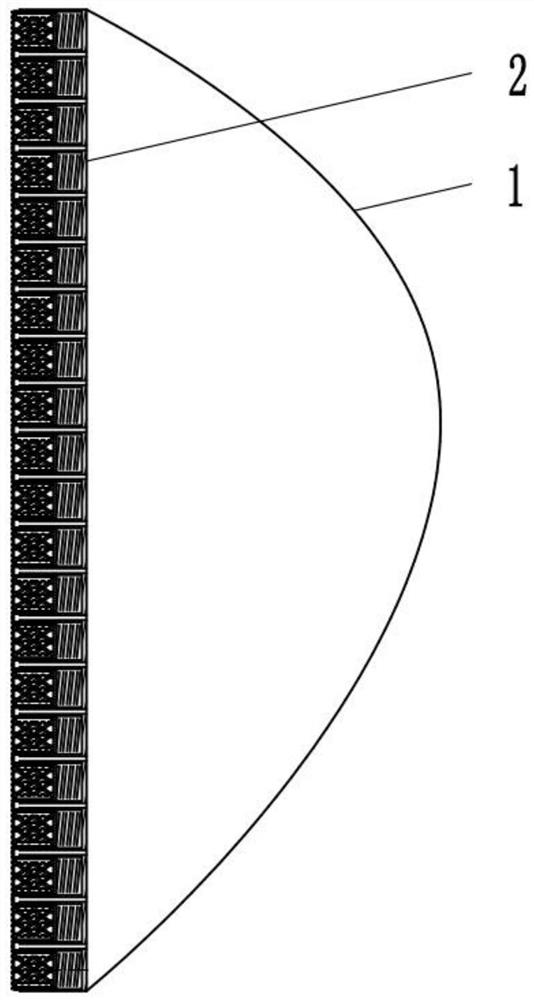

Sound-absorbing ceramic material and preparation method thereof

InactiveCN109678456AEvenly distributedDepends on attachment thicknessCeramicwareClaywaresCarboxymethyl celluloseSlurry coating

The invention discloses a sound-absorbing ceramic material which is prepared from the following raw materials in parts by weight: 25-35 parts of aluminum oxide ceramics, 25-35 parts of silicon carbide, 25-35 parts of talcum, 10-15 parts of silicate, 1-2 parts of polyurethane organic foams and 30-40 parts of a solvent. The invention also provides a preparation method of the sound-absorbing ceramicmaterial. The preparation method comprises the following steps: uniformly mixing the aluminum oxide ceramics, the silicon carbide, the talcum and the silicate and adding the solvent into the mixture,so as to obtain ceramic slurry; pretreating the polyurethane organic foams with sodium hydroxide solution and carboxymethyl cellulose solution in sequence, soaking the pretreated polyurethane organicfoams into the ceramic slurry for slurry coating, and drying, so as to obtain a green body; sintering the green body, so as to obtain the sound-absorbing ceramic material after sintering is completed.The sound-absorbing ceramic material has the advantage of being good in sound absorption.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

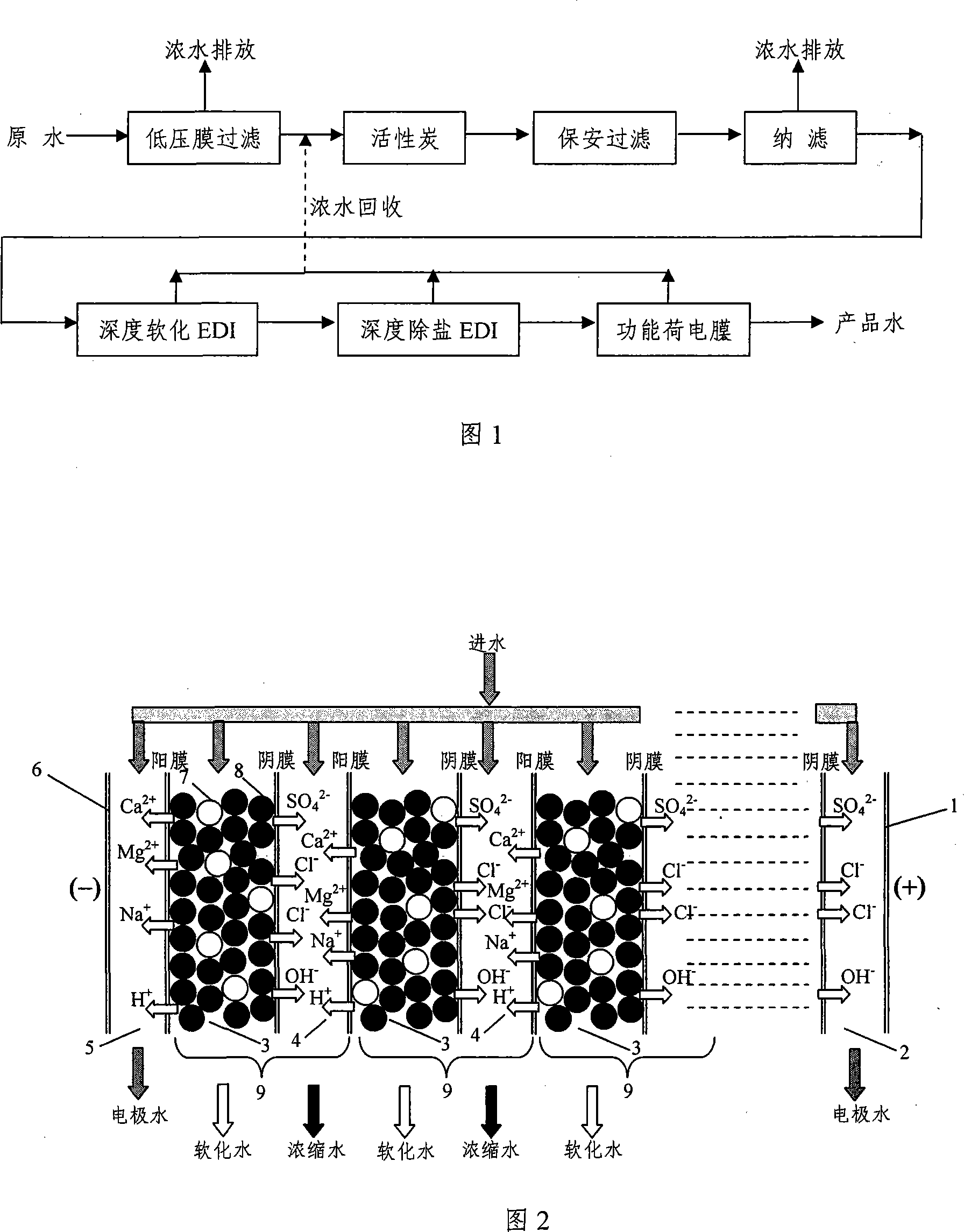

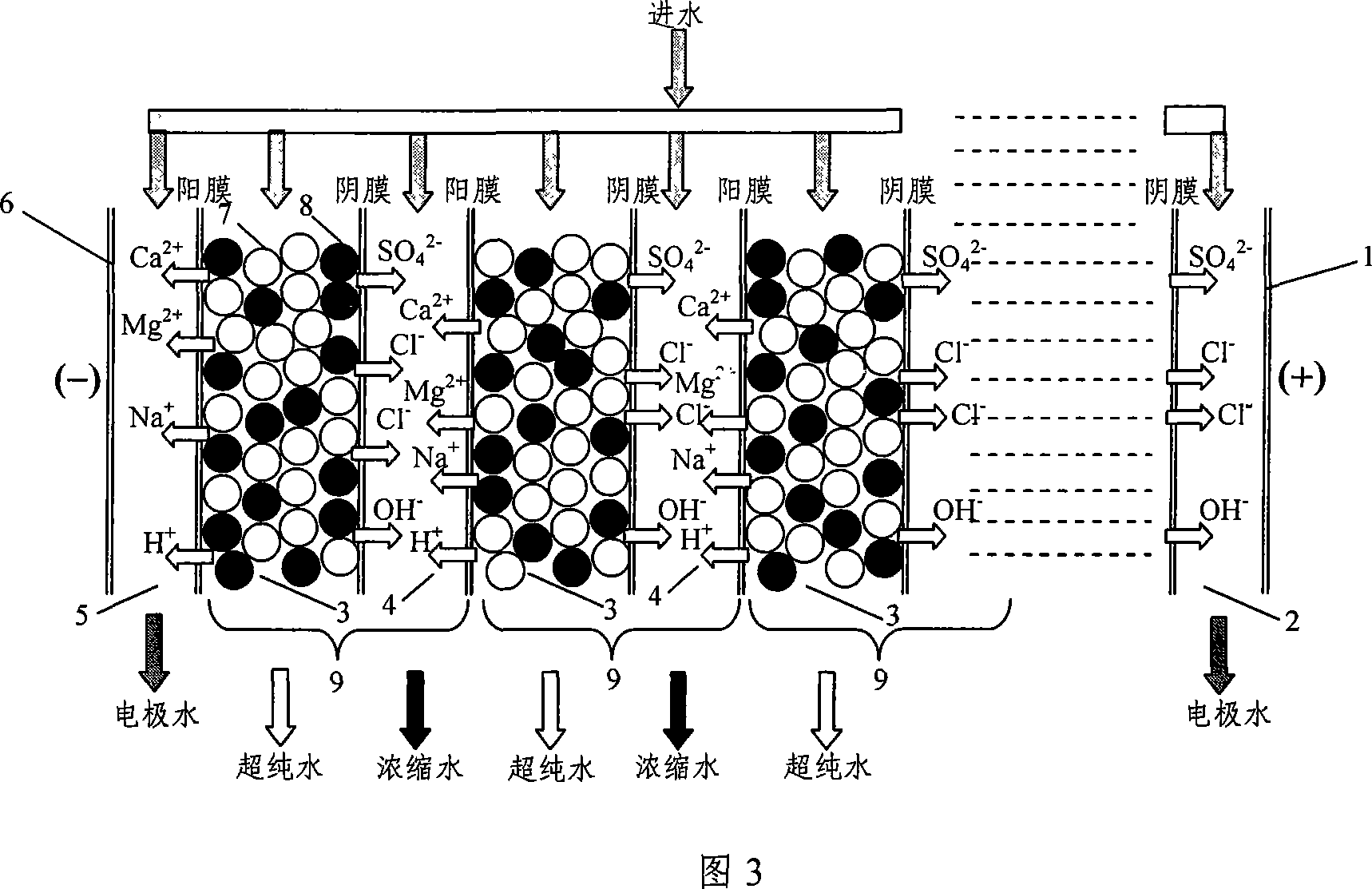

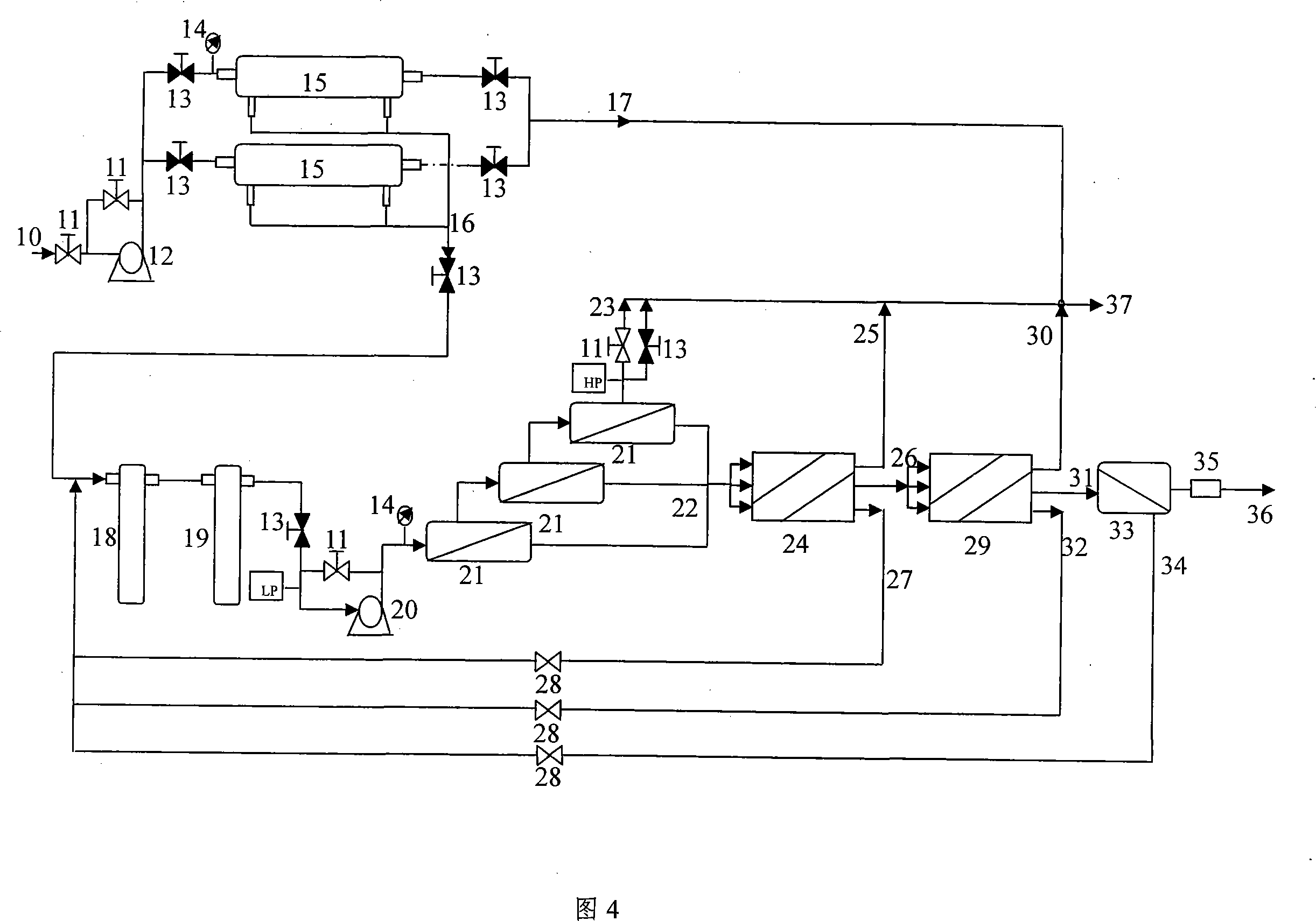

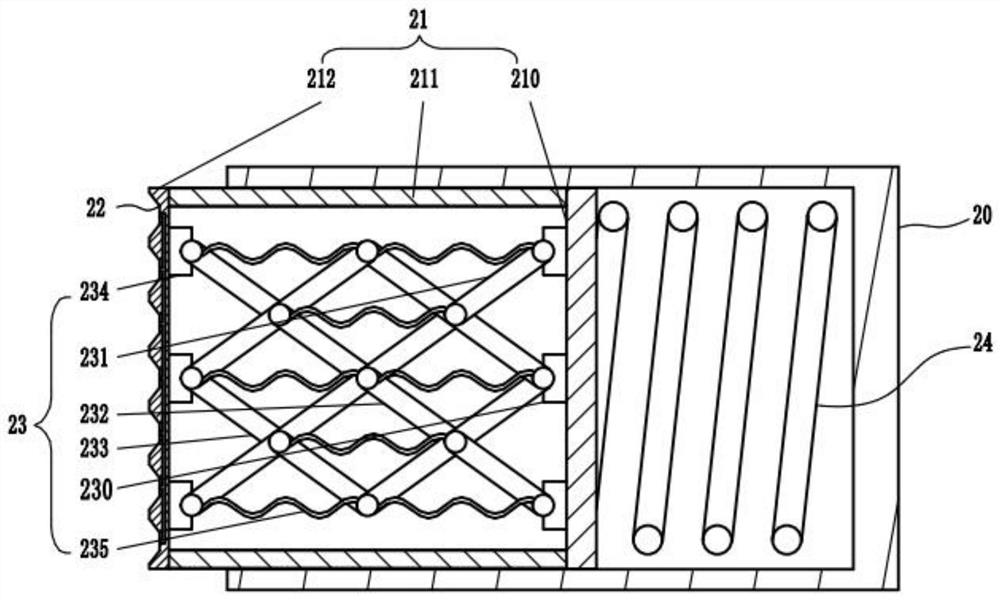

Method and device for producing water used for medicine preparation by collective film separation and electric deionizing

InactiveCN101100340AMitigate Flux FadeAvoid softeningGeneral water supply conservationWater/sewage treatment by electrochemical methodsWater useFiltration

This invention discloses a method and equipment for producing pure water used in pharmaceutical plant, by using membrane separation and electro-deionization, by using urban running water as raw water. The procedures are: low pressure membrane filtration, absorption by activated-carbon, precision filtration, nanometer filtration and softening and desalination, electro-deionization and deep softening, electro-deionization and deep desalination, functional charged membrane filtration. This invention method can remove, from water, inorganic ions, organic pollutants, bacteria, virus and other microorganisms. Compared with prior art process, this inventive process has advantages of: low cost, high utilization rate of raw water, no need of regeneration process, no consumption of alkali and acid, no environmental pollution, wide available of raw water, high reliability and continuous production of high pureness water.

Owner:天津中领水系统技术有限公司

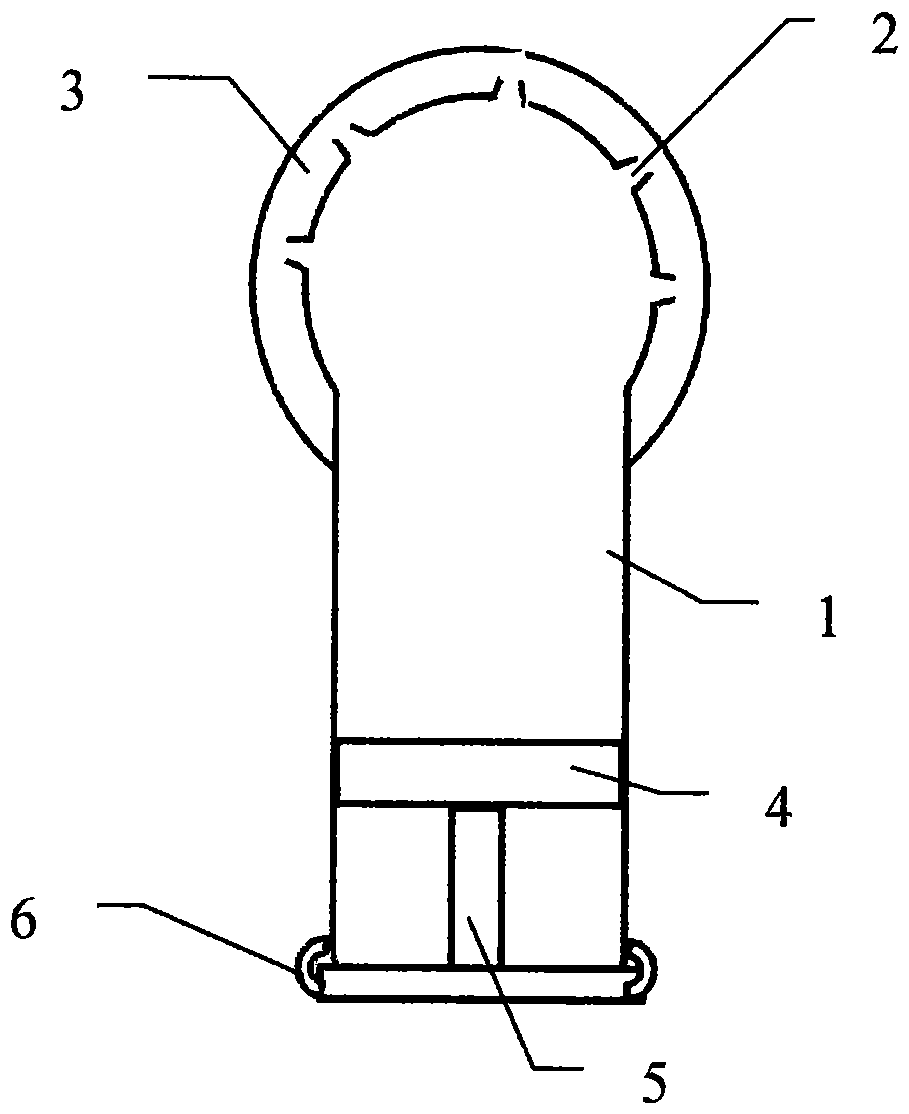

Automatic medicine feeder for infants

The invention discloses an automatic medicine feeder for infants. The automatic medicine feeder comprises a hollow tube, a plunger and a soluble shell. A first end of the hollow tube is closed while a second end of the hollow tube is open, and liquid outlet holes are formed in the first end of the hollow tube. The plunger enables the second end of the hollow tube to be closed and moves along the hollow tube under the action of external force. The soluble shell wraps the outer portion of the first end of the hollow tube and enables the liquid outlet holes of the first end of the hollow tube to be closed. The automatic medicine feeder for the infants has the advantages that liquid medicine cannot contact with the taste bud of one infant directly immediately, so that resistance of the infant to the automatic medicine feeder is avoided; since the soluble shell is tasty, the infant can suck the soluble shell into the mouth voluntarily, and the liquid medicine is fed into the mouth of the infant automatically under the action of pressure after the soluble shell is molten partly; since the taste of the medicine can be masked by the taste of the soluble shell, the infant accepts the medicine easily and takes the medicine happily and voluntarily without any resistance, and medicine waste can be avoided.

Owner:徐州科悦电子科技有限公司

Coal mine hard roof grouting fracturing method and system

InactiveCN108756883AWill not igniteWon't happenUnderground miningSurface miningSlurryUltimate tensile strength

The invention discloses a coal mine hard roof grouting fracturing method and system. Chemical expansion slurry is injected into roof holes through stirring-grouting equipment and a grouting hole-sealing device, sealing film bags are mounted in the holes, and the effect that during grouting, the slurry does not leak towards peripheral fractures of the holes is achieved. Through the volume expansionreaction principle of the slurry, a designed roadway roof is subjected to blastproof drilling fracturing, and the effect of destroying the integrity of the hard roof is achieved. The problems of coalmine hard roof suspension, the tail mining section roof pressure and hard coal body caving can be solved. The coal mine hard roof grouting fracturing method and system have the characteristics of small downhole operation engineering amount, low labor intensity, good fracturing effect and the like.

Owner:SHAANXI COAL & CHEM TECH INST

Silane modified polyurethane adhesive for bottom layer material of plastic runway and preparation method and application of silane modified polyurethane adhesive

InactiveCN111534264AGood storage stabilityLow viscosityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesive cementPolymer science

The invention relates to the field of adhesives, in particular to a silane modified polyurethane adhesive for a bottom layer material of a plastic runway and a preparation method and application of the silane modified polyurethane adhesive. The silane modified polyurethane adhesive is prepared from the following raw materials in parts by weight: 90 to 110 parts of polyether polyol, 20 to 30 partsof isocyanate silane, 0.1 to 1 part of an antioxidant, 0.01 to 0.05 part of a catalyst and 0.1 to 0.5 part of a stabilizer. The silane modified polyurethane adhesive has the advantages of being environmentally friendly, good in storage stability, low in viscosity, easy to construct and free of foaming after construction forming.

Owner:上海抚佳精细化工有限公司

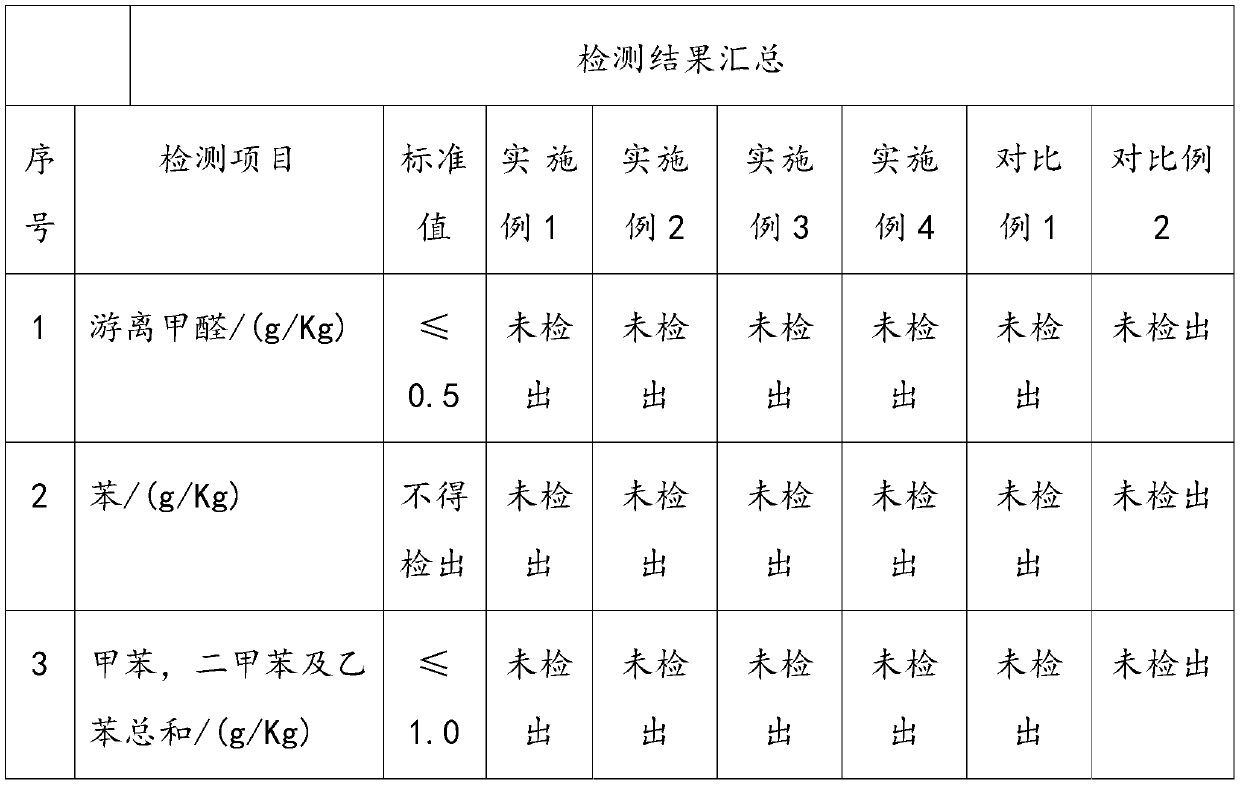

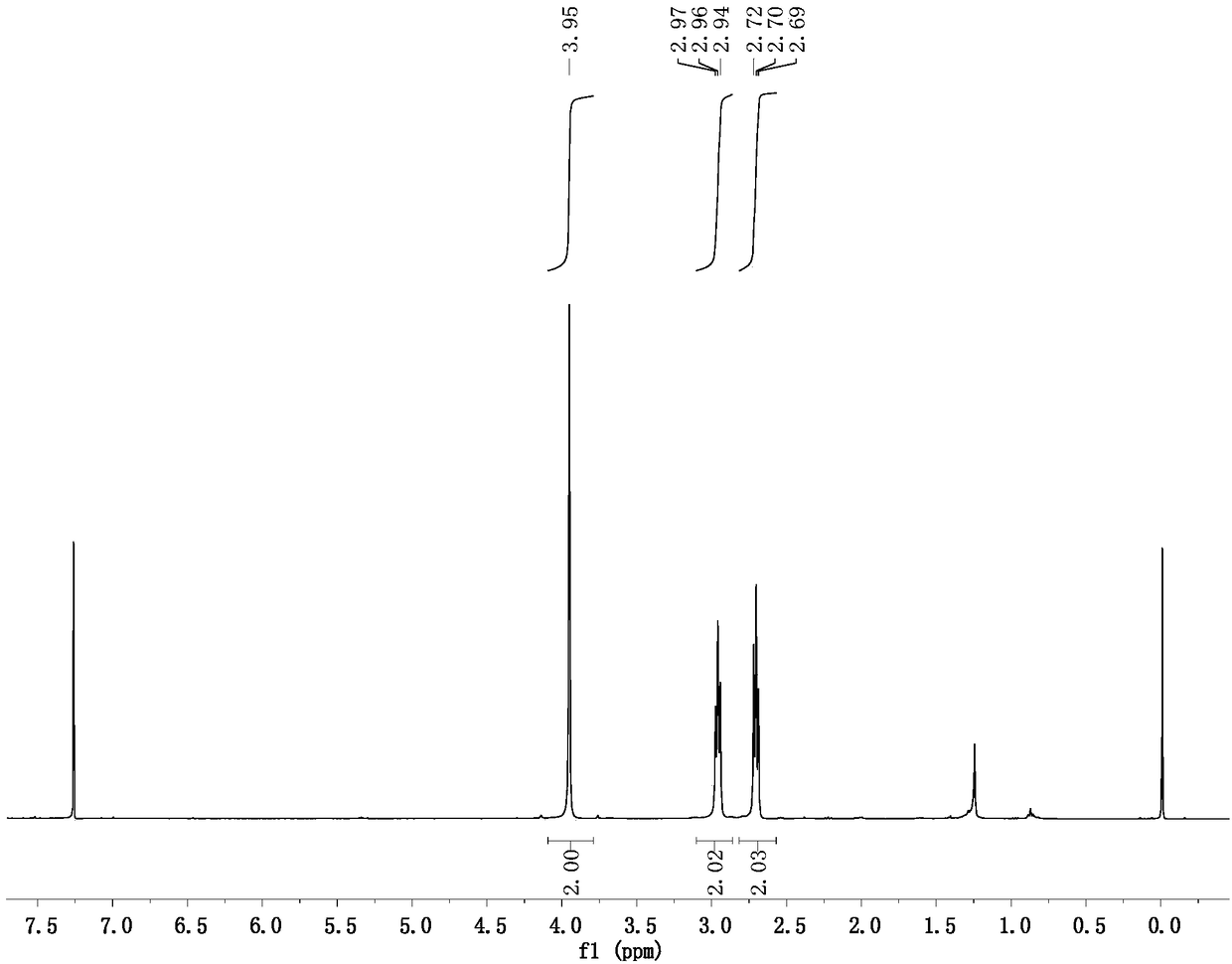

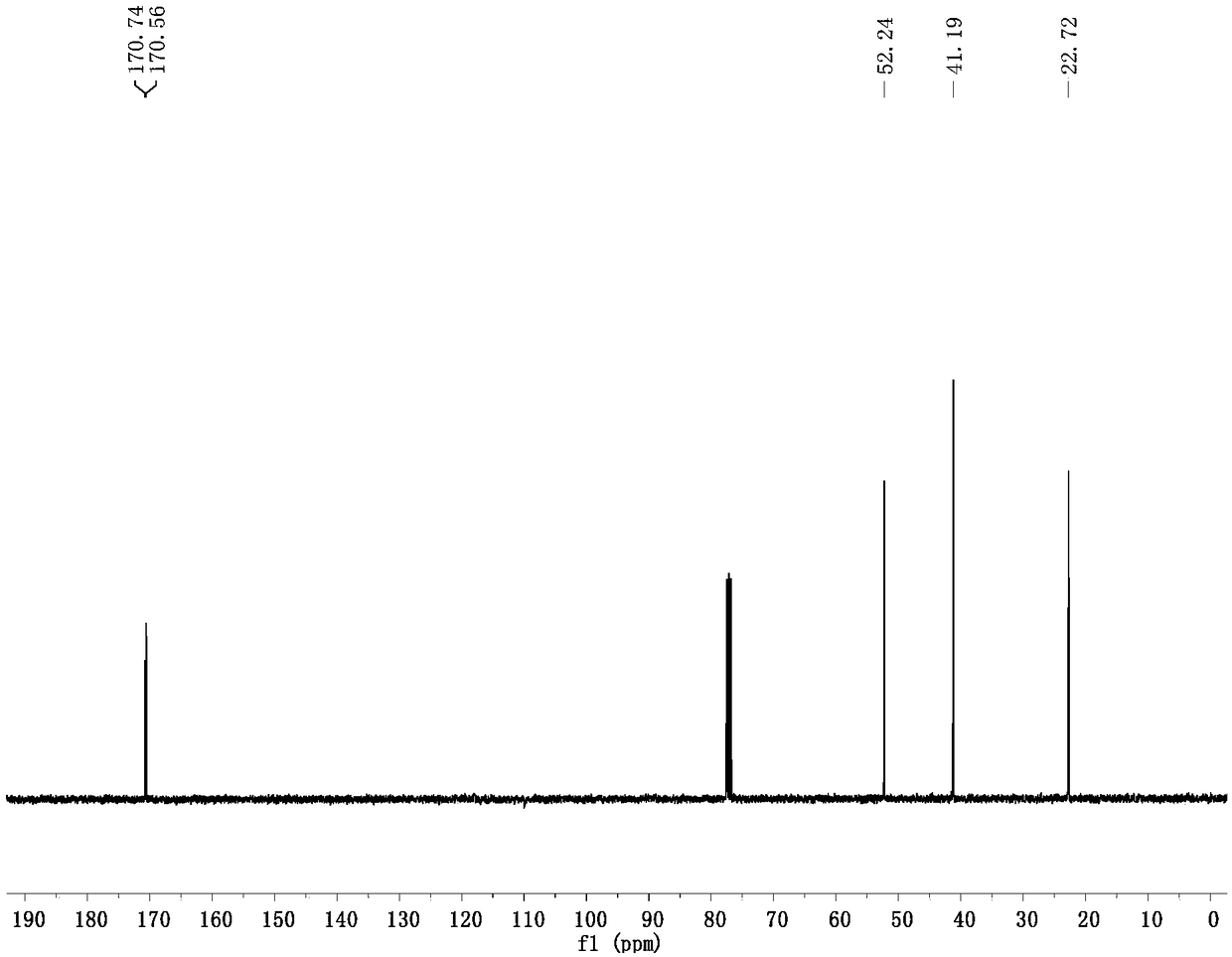

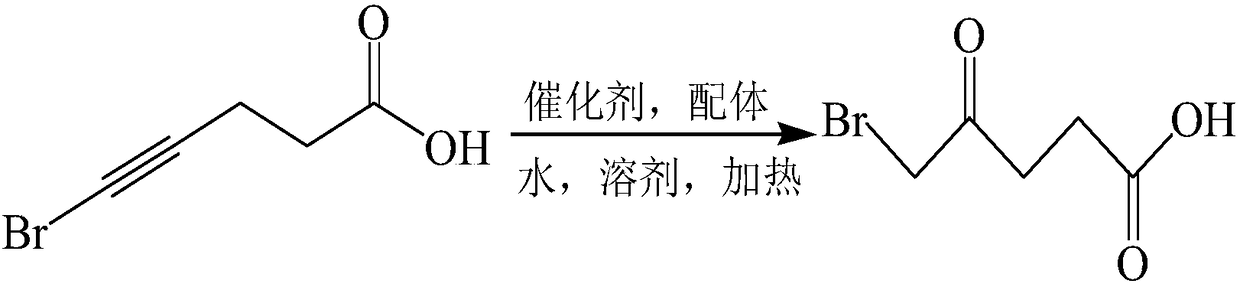

Preparation method of 5-bromolevulinic acid

InactiveCN109400464AWill not produceIncrease profitOrganic compound preparationCarboxylic compound preparationPhenanthrolineChemical preparation

The invention discloses apreparation method of 5-bromolevulinic acid, and belongs to the field of chemical preparation. The preparation method of the 5-bromolevulinic acid comprises the following steps: dissolving 5-bromo-4-pentinoic acid in a solvent; then adding water, copper salt (II) and a ligand for reacting at a temperature of 25 to 90 DEG C for 4 to 6 hours; performing separation to obtain5-bromolevulinic acid, wherein the ligand is selected from at least one of 1,10-phenanthroline or a derivative thereof. By adopting the preparation method of the 5-bromolevulinic acid provided by theinvention, the side product of 3-bromolevulinic acid is avoided, and high raw material utilization rate, easiness in product separation and high yield are achieved.

Owner:HUBEI UNIV

Low-toxicity and harm-free vehicle door-window sealing tape

The present invention discloses a low-toxicity and harm-free vehicle door-window sealing tape, which comprises, by weight, an ethylene-propylene-diene monomer, carbon black, paraffin oil, calcium carbonate, talc powder, a dispersant, an anti-ultraviolet agent, an antioxidant, an anti-scorching agent CTP, a foaming agent, a nitrogen-free vulcanizing agent, an auxiliary vulcanizing agent, polyethylene glycol, zinc borate, phosphate, and alpha-tocopherol. The low-toxicity and harm-free vehicle door-window sealing tape has characteristics of environmental pollution reducing and reasonable cost maintaining.

Owner:成都昱阳鑫达实业有限公司

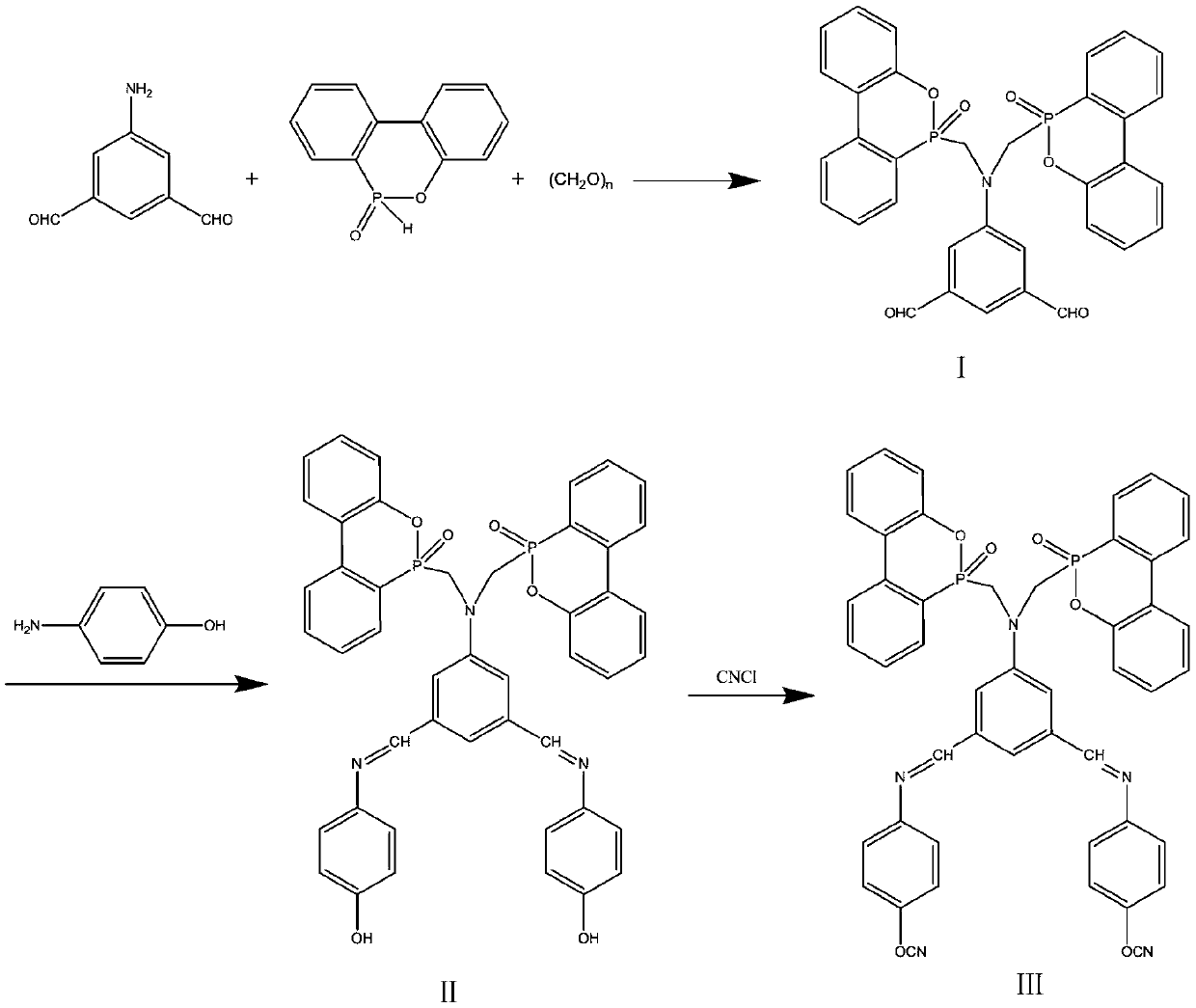

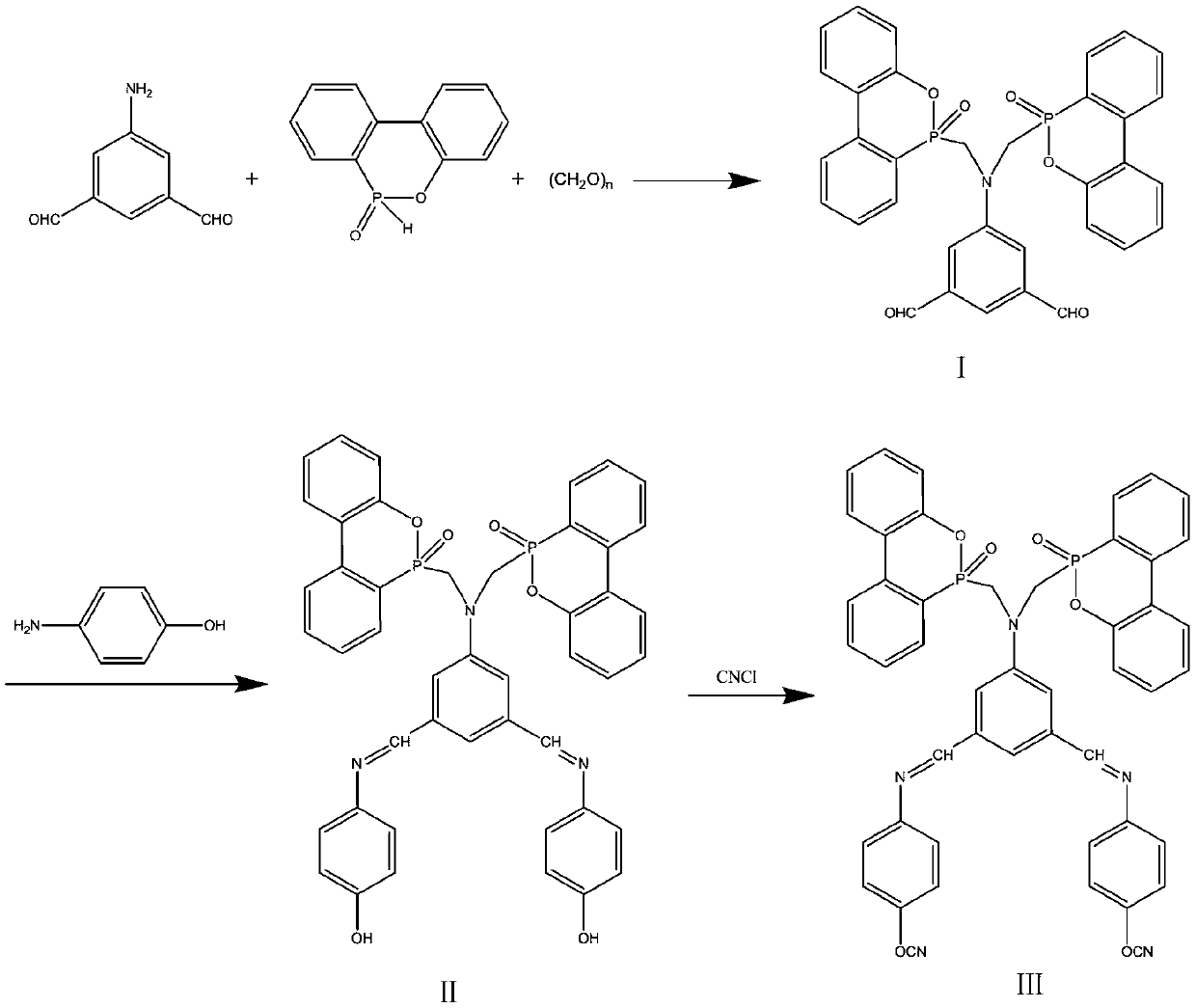

High-toughness halogen-free cyanate ester resin composite material and preparation method thereof

The invention discloses a high-toughness halogen-free cyanate ester resin composite material and a preparation method thereof. According to the composite material, after modified cyanate ester resin is mixed with carbon nanotubes, surfactants and deionized water, high-speed uniform stirring and ultrasonic dispersion are performed, during which a layer of the surfactants is combined on the surfacesof the single-walled carbon nanotubes and the multi-walled carbon nanotubes, so that the dispersion state of the carbon nanotubes is favorably maintained; the surfactants are all non-ionic type surfactants so that the composite material maintains good solubility in water or an organic solvent, has good stability, is not easily influenced by strong electrolyte inorganic salts, acids and alkalis, is not easy to foam in the curing process, improves the compatibility of the carbon nanotubes and the modified cyanate ester resin, and improves the mechanical properties and processability of the composite material; at high temperature, side phosphorus groups in the DOPO structure are dehydrated and carbonized, oxygen is isolated, and smoke and halogen hydride toxic and harmful substances cannot be generated.

Owner:YANGZHOU TECHIA MATERIAL CO LTD

Inlet sealing and connecting device used for waste-heat boiler

ActiveCN100595483CNo leakageReduce power consumptionSteam generation using hot heat carriersFlue gasThermal expansion

The invention discloses a connection device used for sealing entrance of waste heat boiler, comprising a lower part sealing connection piece which is buttoned up at the flue gas exit of melting furnace, and a flexible sealing connection piece one end of which is suitable to be in sealed connection with the waste heat boiler and the other end of which is in sealed connection with the lower part sealing connection piece, thus the flexible sealing connection piece and the lower part sealing connection piece can move relative to the waste heat boiler. The sealing connection device of the inventionis composed of the lower part connection part and the flexible connection part, wherein, the flexible connection part is provided with expansion margin, thus satisfying thermal expansion when in performance and avoiding the occurrence of gap due to the thermal expansion of the waste heat boiler and the melting furnace. Therefore, the connection device used for sealing entrance of waste heat boiler has the advantages of fine sealing performance, simple operation and low cost.

Owner:CHINA ENFI ENGINEERING CORPORATION

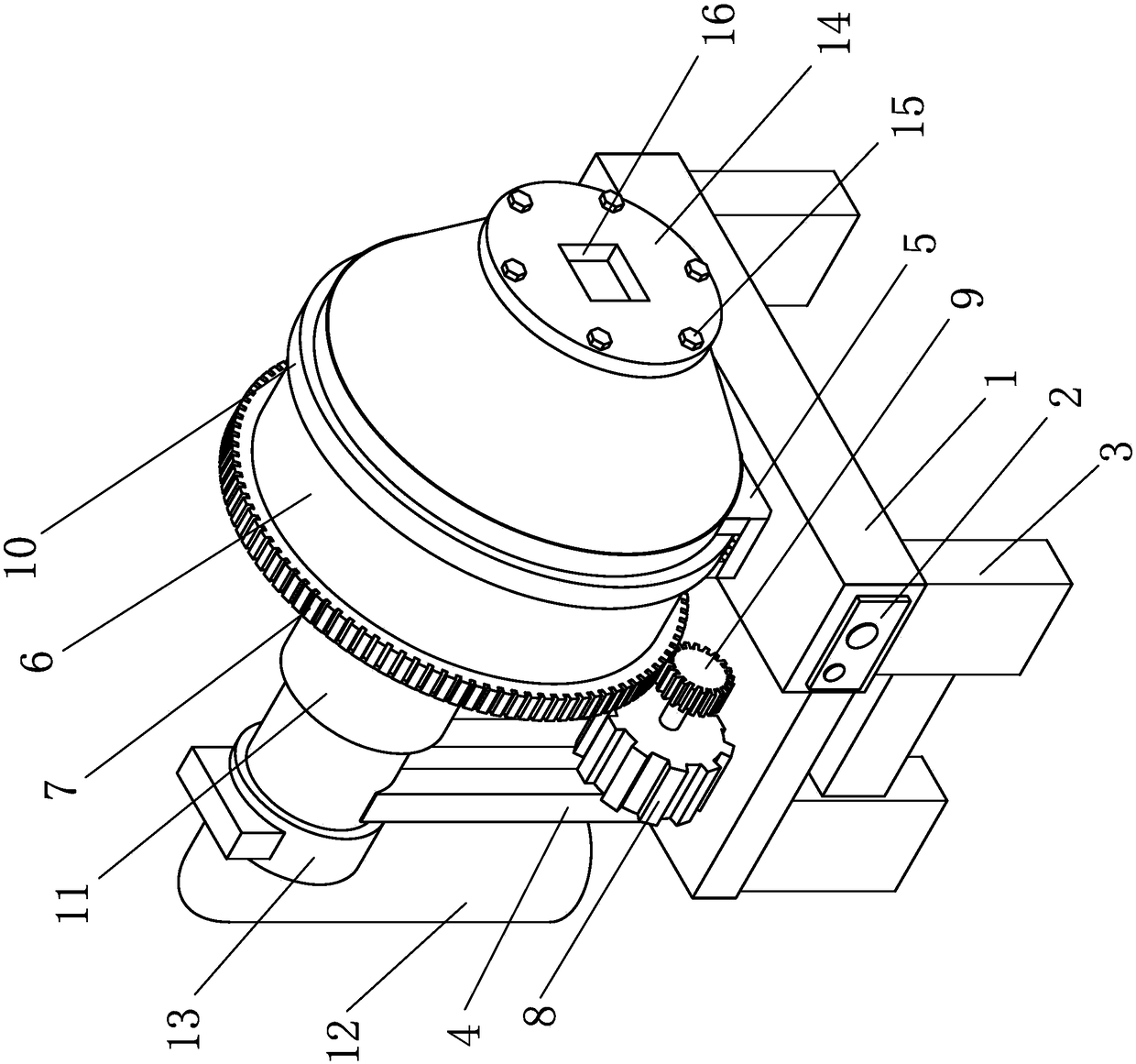

Roller mixer for resin sand production

InactiveCN108465775AWon't spillWill not produceMould handling/dressing devicesPulp and paper industryControl switch

The invention discloses a roller mixer for resin sand production, the roller mixer for resin sand production comprises a mounting plate, wherein the side surface of the mounting plate is provided witha control switch, the input end of the control switch is electrically connected with the output end of an external power source, the lower surface of the mounting plate is provided with a standing column, the upper surface of the mounting plate is respectively provided with a curved plate and a motor, the input end of the motor is electrically connected with the output end of the control switch,the output shaft of the motor is fixedly connected with a driving gear, the upper surface of the curved plate is provided with a roller, the outer surface of the roller is provided with a driven gear,and the driven gear and the driving gear mesh with each other. The roller mixer used for the resin sand production is simple in operation and convenient to use during material conveying, no raw material spilling or dust is generated during a stirring process, raw materials are saved, environment is not polluted, the roller is rotated by a sliding bar in a sliding groove arranged in the curved plate, the inner surface of the sliding groove is evenly distributed with roller balls, friction is reduced, wear is reduced, and service life is prolonged.

Owner:GUANGDONG KNOWLEDGE CITY OPERATION SERVICES CO LTD

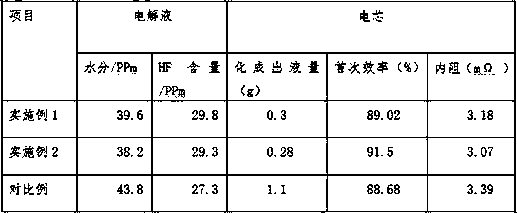

Standing and forming process of liquid-injected aluminum shell lithium ion battery

InactiveCN109742314ALow environmental requirementsSimple processFinal product manufactureSecondary cells charging/dischargingElectrical batteryNitrogen

The invention discloses a standing and forming process of a liquid-injected aluminum shell lithium ion battery. The process is carried out according to the following steps of injecting liquid into battery cores in a normal amount; after liquid is injected into the same batch of battery cores, connecting the battery cores in series; placing the battery cores connected in series in a closed box; performing standing on the battery cores for 1-2 hours under normal temperature and normal pressure conditions; then vacuumizing the closed box; performing standing on the closed box for 20-24 hours in avacuum state; injecting nitrogen into the closed box to break the vacuum, performing standing on the closed box at normal pressure for at least 10 min; transferring the battery cores which are stillin parallel after the standing treatment to a forming box; vacuumizing the forming box after the battery cores are connected; performing a forming process according to conventional indexes in the vacuum state; after forming is completed, sealing an aluminum shell battery core opening by using a steel ball. According to the standing and forming process of the liquid-injected aluminum shell lithiumion battery disclosed by the invention, standing is performed under the vacuum condition, on the one hand, the electrolyte in the battery cores is not directly in contact with air in the workshop, andthe HF acid is not generated; on the other hand, internally installed polar plates of the battery cores are sufficiently soaked by the electrolyte so that the quality of the produced battery is goodand stable.

Owner:JIANGSU FRONT NEW ENERGY +1

Rubbish regeneration environment-friendly brick and production method thereof

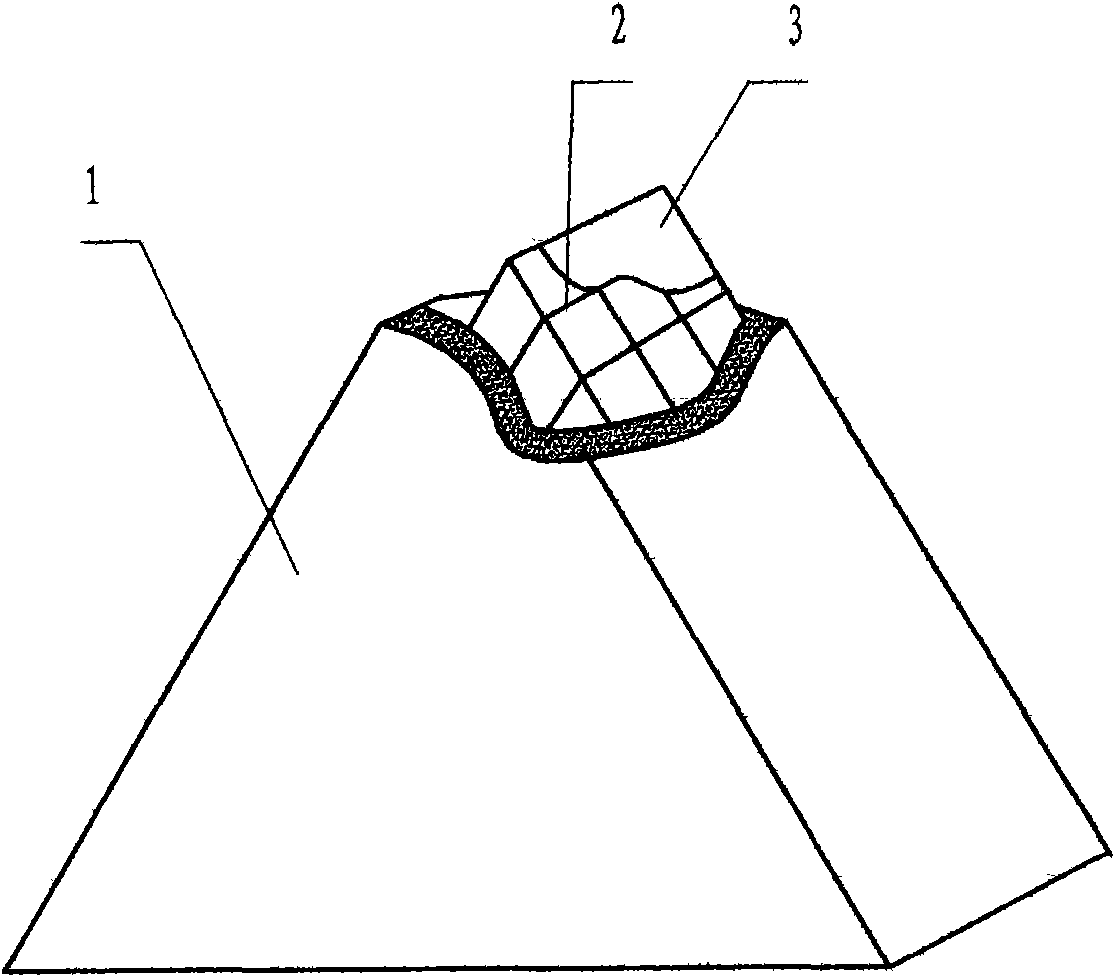

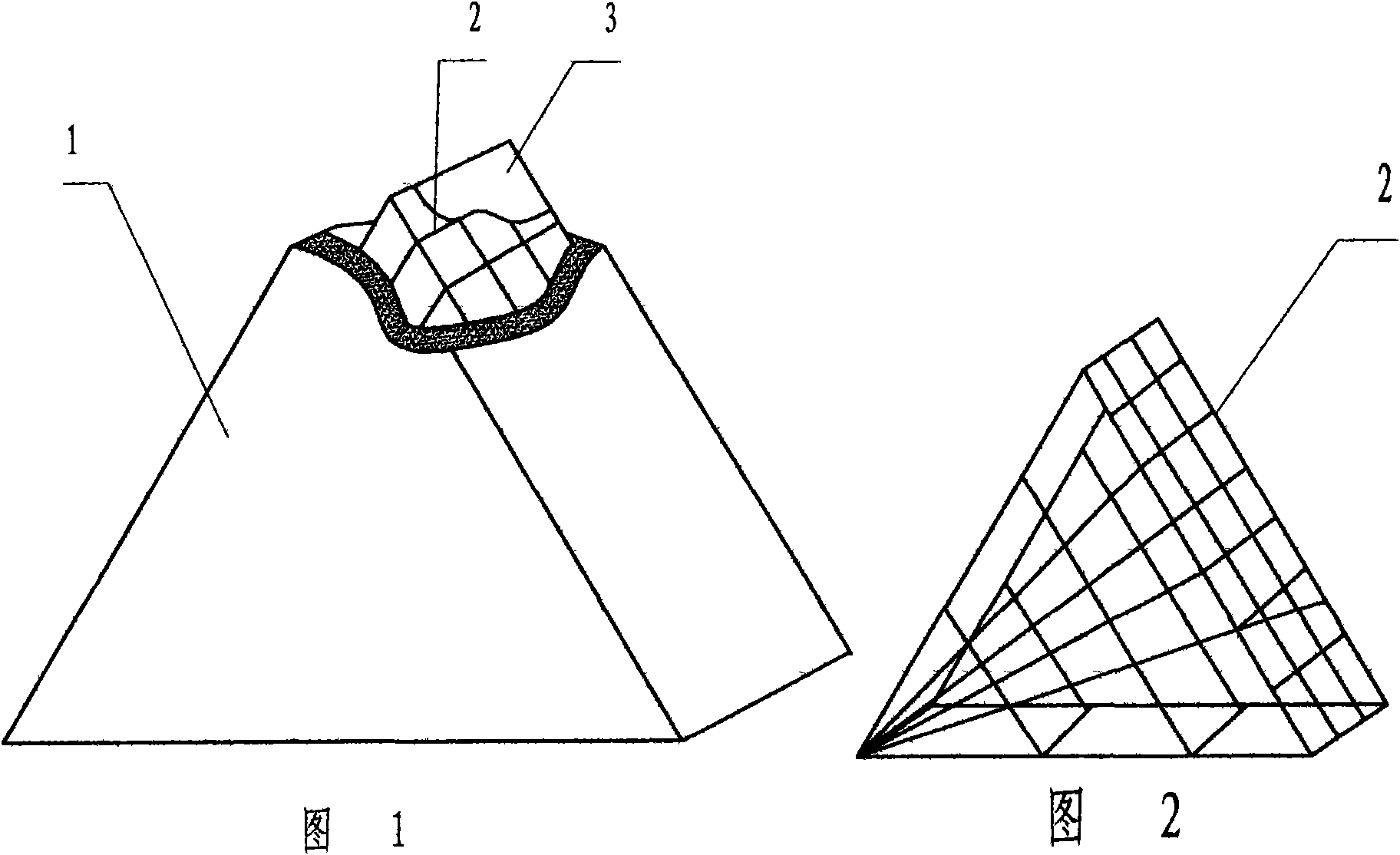

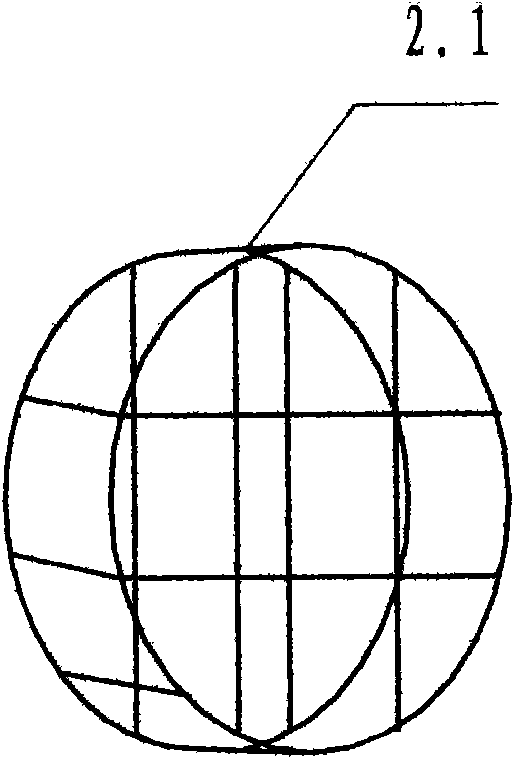

The invention discloses a rubbish regeneration environment-friendly brick and a production method thereof, and the brick consists of a rubbish compression block, a reinforcement cage and a cement casting shell, wherein the rubbish compression block is a block body formed by compression of house refuse; a layer of plastic cloth coats outside the rubbish compression block in a vacuum sealed manner; the rubbish compression block is placed in the reinforcement cage; the cement casting shell is casted outside the reinforcement cage; and the rubbish compression block, the reinforcement cage and the cement casting shell are of triangles or squares, rectangles, circles and polygons. The production method of the environment-friendly brick comprises the following steps: 1. collecting and treating the rubbishes; 2. carrying out compression forming on the rubbish powder; 3. vacuum sealing and coating; 4. producing steel skeletons; 5. embedding the rubbish compression blocks into the steel skeletons; and 6. casting the shell. The invention is suitable for producing bricks with the rubbishes, which can enable the rubbishes to be regenerated and reused and has energy conservation and environmental protection functions.

Owner:雷新国

Automatic medicine feeder for infants and young children

ActiveCN105168001BEliminate resistanceResistance will not ariseOral administration devicePediatricsPharmaceutical Substances

Owner:徐州科悦电子科技有限公司

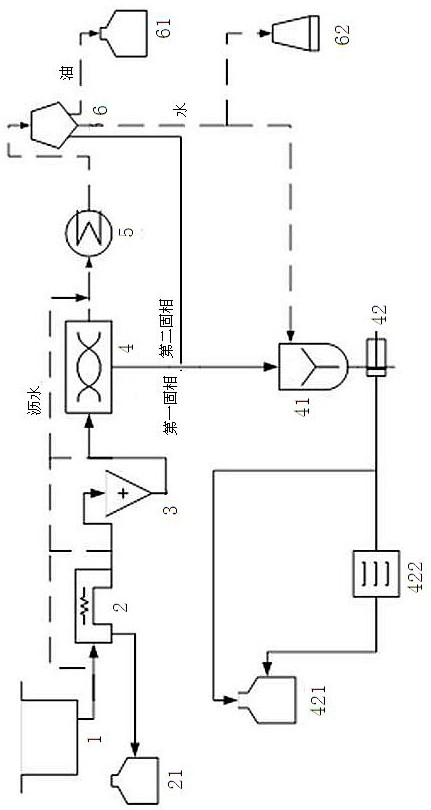

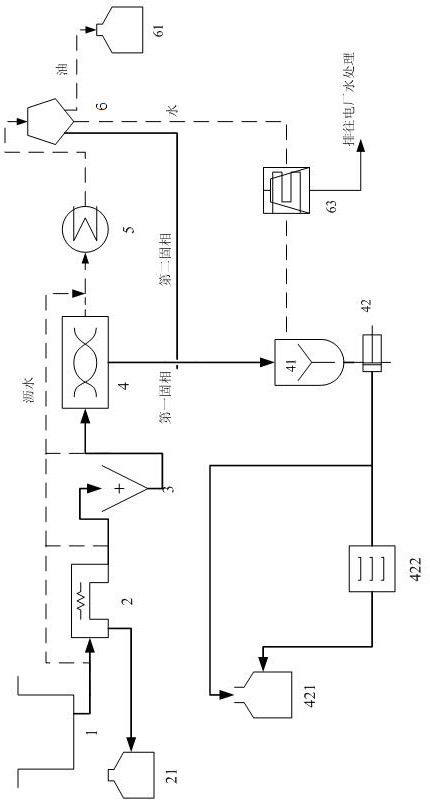

Food waste pretreatment coupling power generation system applied to thermal power plant

PendingCN113976596AWill not produceReduce initial investmentSolid waste disposalTransportation and packagingBoiler (power generation)Anaerobic treatment

The invention discloses a food waste pretreatment coupling power generation system applied to a thermal power plant. Produced wastewater needs to enter an anaerobic digestion system and a water treatment system, the system is complex, and the treatment cost is high; biogas generated by anaerobic treatment is difficult to continuously and stably supply, and resource waste is caused by torch incineration. The system comprises a material receiving bin (1), a sorting machine (2), a crusher (3), a dry-wet separation device (4), a heater (5), a three-phase separator (6), an oil storage tank (61), a mixer (41), a conveying device, a boiler (421) and a drying device (422). The system is used for food waste pretreatment coupling power generation of the thermal power plant.

Owner:北京华能长江环保科技研究院有限公司 +1

Anesthesia respirator for anesthesiology department

InactiveCN113425969AIncrease contact areaFit tightlyRespiratory masksPhysical medicine and rehabilitationAnesthetic department

The invention relates to the technical field of breathing machines, and discloses an anesthetic respirator for anesthesiology department. The anesthetic respirator comprises a breathing mask body and a plurality of deformation pieces, the plurality of deformation pieces are arranged at equal intervals along a side edge of the breathing mask body in contact with the face of a human, and the plurality of deformation pieces are sequentially hinged into a whole; wherein the deformation piece comprises a fixing sleeve and an extending body, a closed end of the fixing sleeve is fixedly connected with a side edge, making contact with the face of a human, of the breathing mask body, and one end of the extending body penetrates through a free end of the fixing sleeve, enters the fixing sleeve and is elastically connected with an inner bottom wall of the fixing sleeve, so that the extending body can move in an axial direction of the fixing sleeve; and a horn-shaped groove is arranged on an end surface of the extending body away from the breathing mask body. According to the anesthetic respirator, a breathing mask can be tightly attached to the face of a patient with a high cheekbone or the face of a patient with serious face collapse due to defects for a long time.

Owner:LIUZHOU WORKERS HOSPITAL

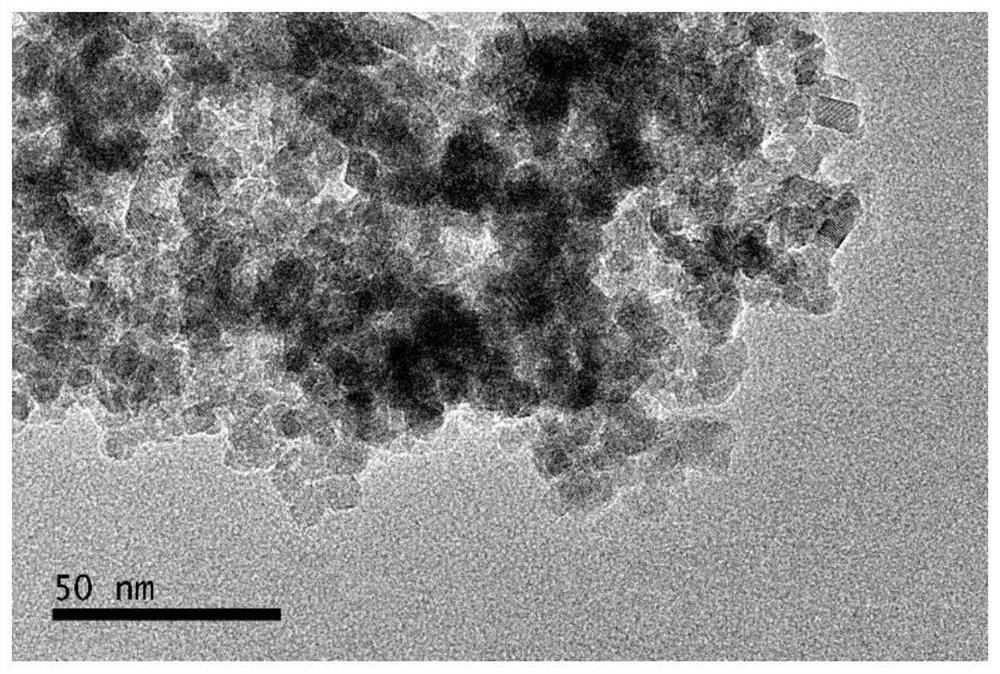

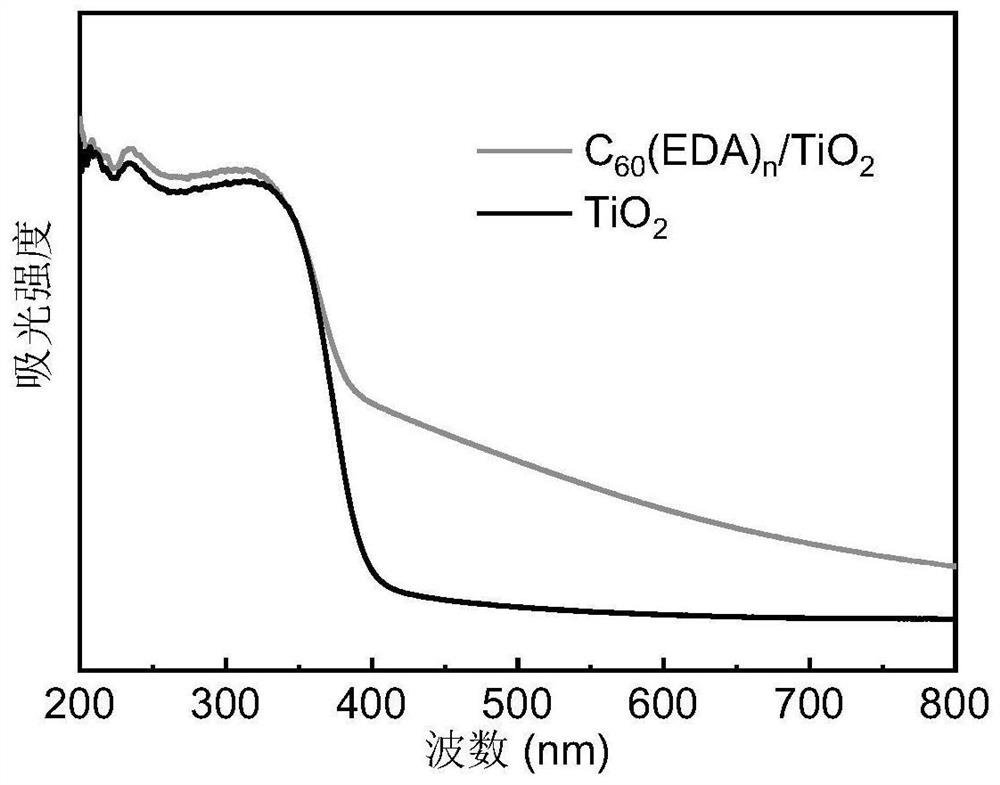

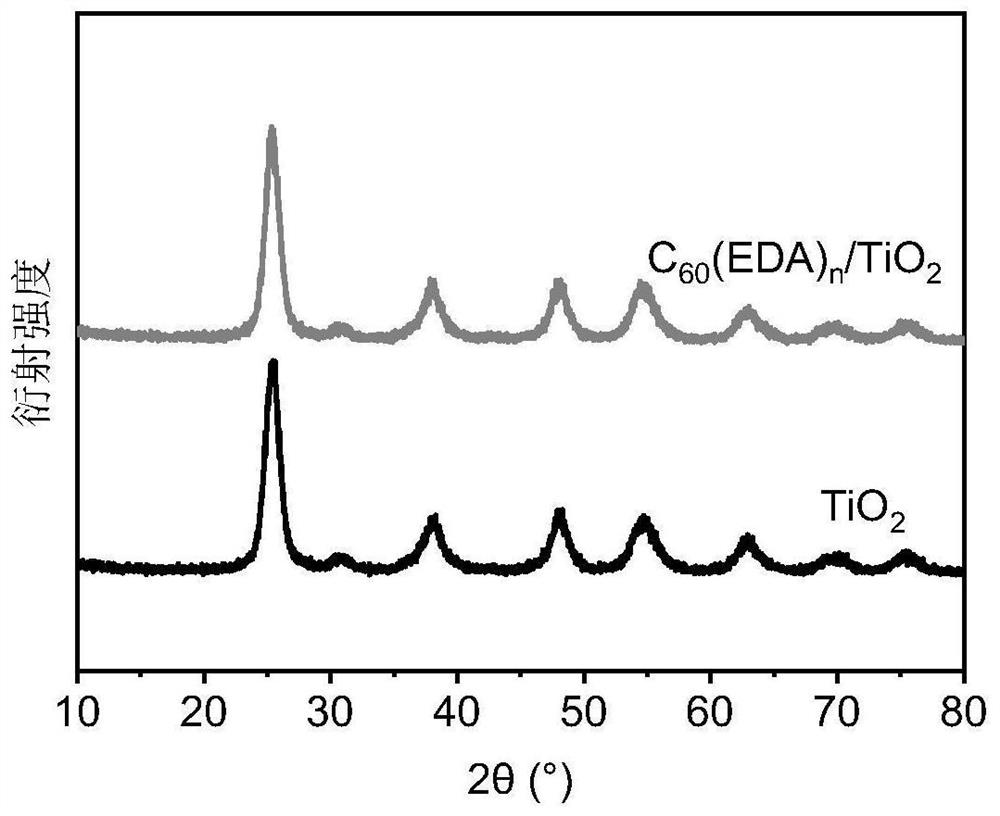

Fullerene photocatalyst composite material composition and application thereof

PendingCN113797906AEasy to sprayEasy to useGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsAir pollutantsFullerene

The invention mainly relates to a fullerene photocatalyst composite material composition. The composite material composition can degrade formaldehyde, TVOC and other air pollutants under visible light, and is low in cost, simple in process route, excellent in air pollutant degradation performance and free of secondary pollution. The fullerene photocatalyst composite material composition disclosed by the invention has good photochemical stability, and the catalytic performance of the material is not obviously changed after the fullerene photocatalyst composite material composition is recycled.

Owner:INST OF CHEM CHINESE ACAD OF SCI +2

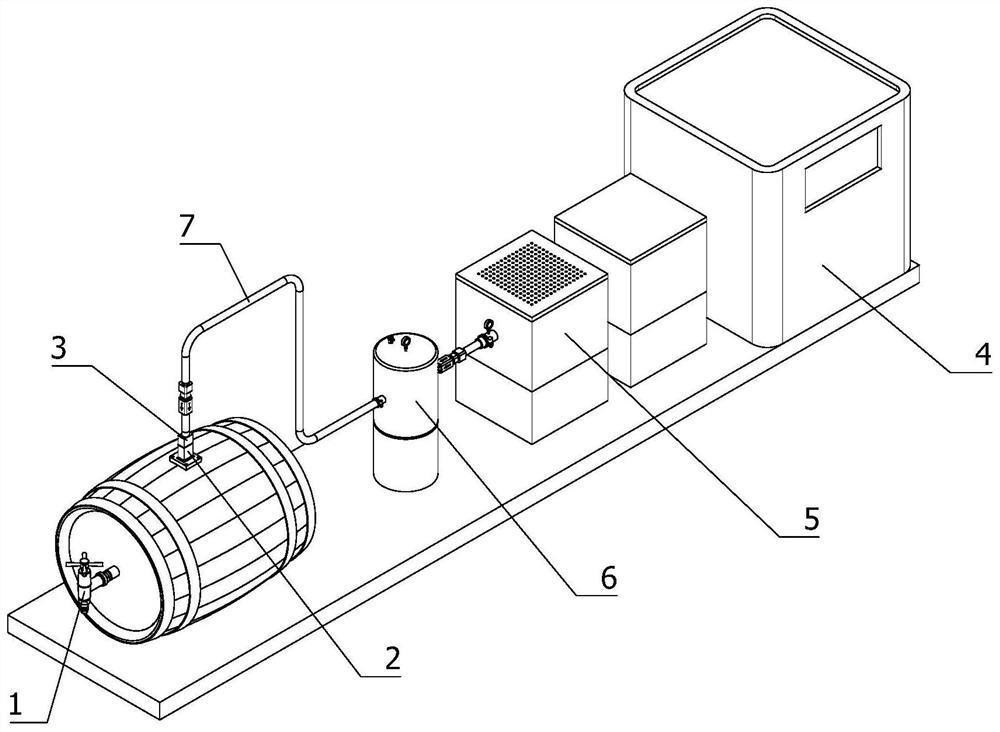

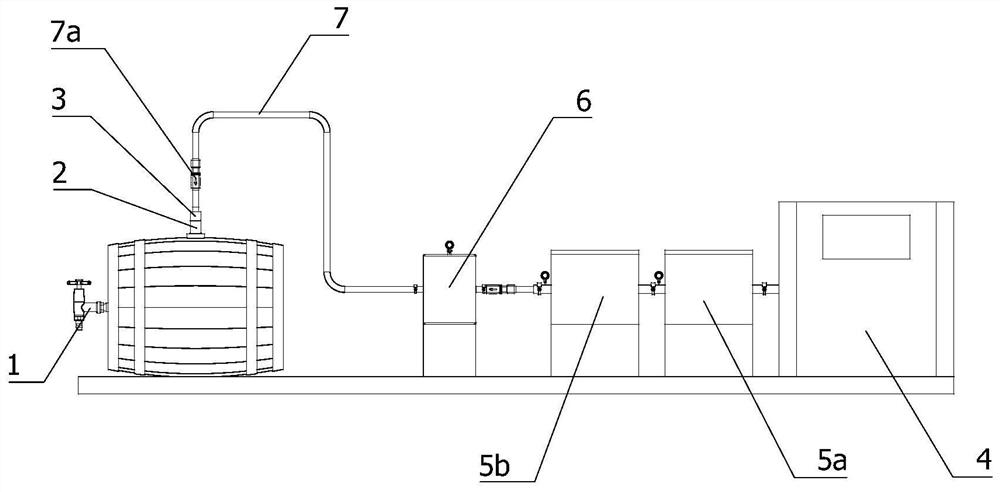

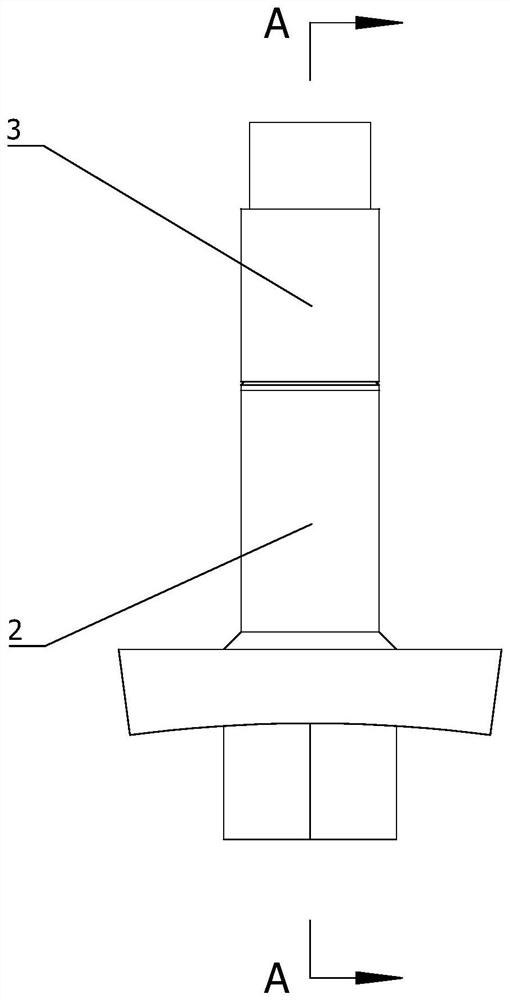

Unsealing-free sampling equipment in beer aging process

PendingCN113029668AGuaranteed internal tightnessAvoid internal contaminationWithdrawing sample devicesHeatProcess engineeringBarrel

The invention relates to the technical field of beer brewing, in particular to unsealing-free sampling equipment in a beer aging process. The unsealing-free sampling equipment comprises a sampling faucet, a first butt-joint mechanism, a second butt-joint mechanism, a nitrogen generator, a sterilization mechanism, a storage mechanism, a pressurization pipeline and a controller, wherein the sampling faucet is installed at the end of an oak barrel and communicated with the interior of the oak barrel, the first butt-joint mechanism is installed at the waist opening of the oak barrel, the first butt-joint mechanism is closed in a non-working state, the nitrogen generator, the sterilization mechanism, the storage mechanism and the pressurization pipeline are sequentially arranged on one side of the oak barrel in an end-to-end mode, the second butt-joint mechanism is installed at the output end of the pressurization pipeline, the second butt-joint mechanism is closed in the non-working state, and the first butt-joint mechanism and the second butt-joint mechanism are in bell and spigot joint with each other and are switched to be in the open state in the working state. According to the scheme, the internal sealing performance of the oak barrel during sampling is effectively guaranteed, and wine is prevented from being changed during sampling.

Owner:管应杰

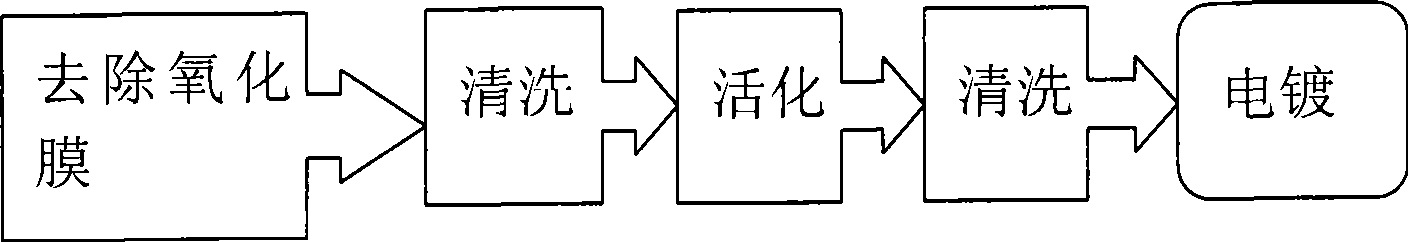

Tinning method for SMD stamp-mounting-paper diode

InactiveCN101388350BShort processing timeStrong bondSemiconductor/solid-state device manufacturingSurface mountingTin plating

The invention relates to a plating method, in particular to a tin plating method of an SMD surface mounting diode, which comprises removing oxide films on the surface of the pins of the SMD surface mounting diode with sulfuric acid solution, cleaning the pins of the SMD surface mounting diode through adopting a multi-stage back rinsing device, placing the cleaned SMD surface mounting diode into methanesulfonic acid solution with 3-5% concentration, removing the oxide films generated on the surface of the pins to expose metal crystalline structures on the surface of the pins, placing the SMD surface mounting diode into an electroplating bath which holds electroplating solution to electroplate for 1.5-2 hours, and adopting 25-35 DEG C temperature when in the electroplating, wherein the electroplating solution is mixing solution which comprises methanesulfonic acid, tin methanesulfonic acid and methanesulfonic acid additive. The invention provides a tin plating method of the SMD surface mounting diode, which can increase the product quality and electroplating efficiency, and can prevent the tin plate layer from growing tin beards.

Owner:CHANGZHOUSR SEA ELECTRONICS

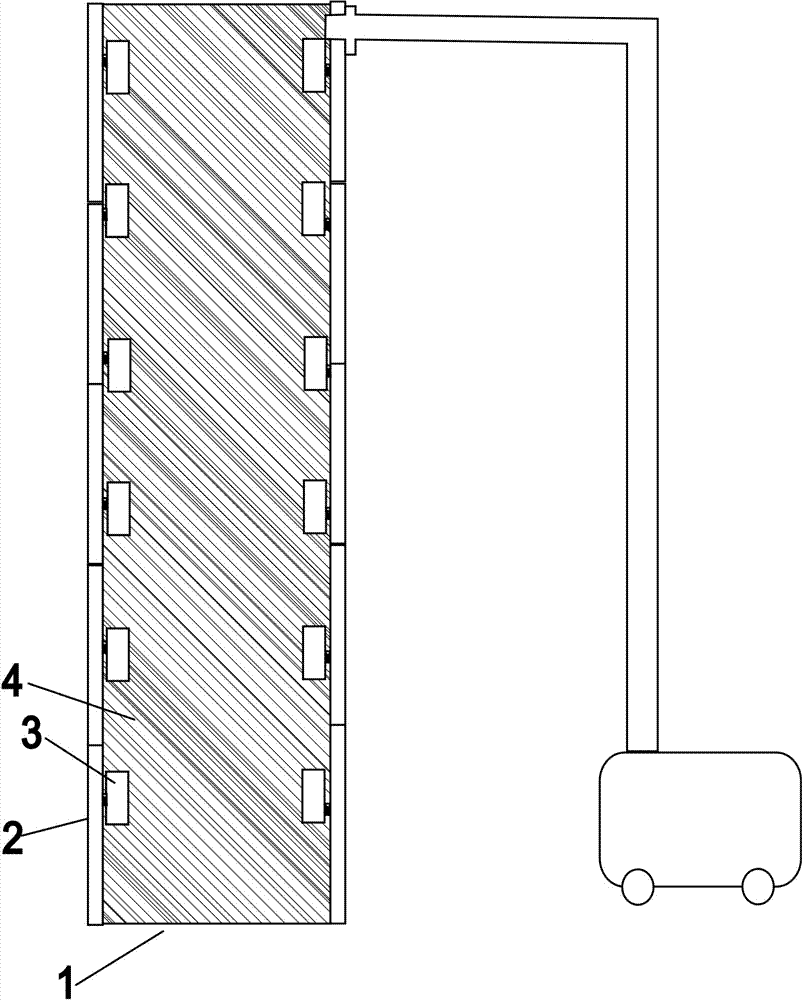

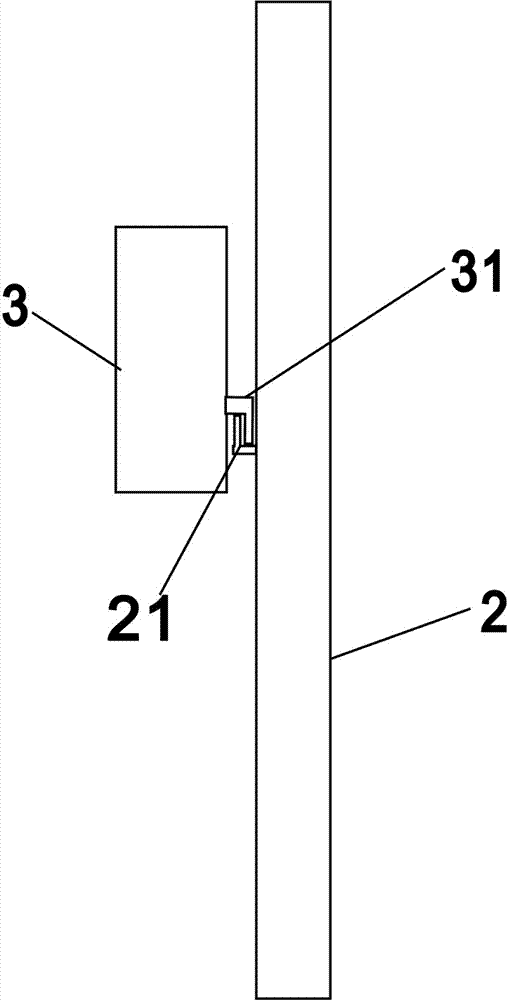

Environmental protection and energy saving pouring-type wall body and construction method thereof

InactiveCN107119830AImprove adhesionNo collapseWallsBuilding material handlingInterior spaceFireproofing

The invention provides an environmental protection and energy saving pouring-type wall body and a construction method thereof and relates to a building method, in particular to the building method of the wall body. The environmental protection and energy saving pouring-type wall body is characterized by being composed of face plates, metal supports and pouring material layers; hooks are arranged on the back faces of the face plates; the metal supports are composed of telescopic grilles; buckles are arranged on the side faces of the metal supports; a wall body framework is composed of more than two sets of mutually-parallel metal supports; the multiple face plates cover the exteriors of the whole metal supports; the hooks and the buckles are mutually and closely buckled to prevent the face plates from falling off and deforming at the time of pouring; pouring openings or socket switch reserved openings are formed in one or multiple of the face plates; and interior space between the face plates hung on every two sets of metal supports is filled with the corresponding pouring material layer, and the pouring material layers cover the metal supports. Compared with a traditional light wall, the environmental protection and energy saving pouring-type wall body is smaller in mass, higher in strength and toughness, the heat preservation, fireproofing, heat insulation and sound insulation properties of the environmental protection and energy saving pouring-type wall body are all superior to those of the traditional light wall, and the construction time only needs one fifth of the construction time of the traditional light wall.

Owner:广东构想营销科技有限公司

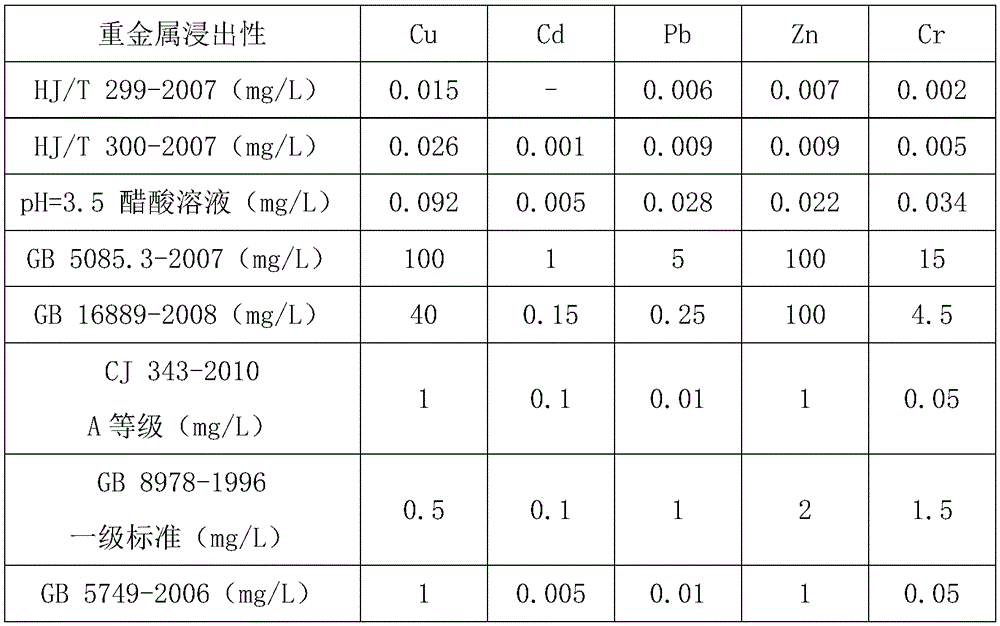

A method for making bricks without sintering by using dredged bottom mud

InactiveCN104108915BReduce LeachabilityHigh compressive strengthSludge treatment by de-watering/drying/thickeningPorosityBrick

The invention relates to a sintering-free method for preparing bricks from dredged sediment, which comprises the following steps: collecting the dredged sediment and abandoning the overlaying water; uniformly spraying 2,4,6-trithione-1,3,5-triazine trisodium salt to the dredged sediment, stirring quickly, crushing and grinding the dredged sediment with a pulverizer after naturally airing; screening the sediment with a sieve of 100-150 meshes and then mixing with P.O42.5 cement, natural zeolite and quicklime with the mass ratio of (90-110): (40-60): (5-20): (0.5-5); controlling the water cement mass ratio to be 35-45% at room temperature; pouring into a standard mold and conducting wet curing for 24-48 hours; and then demolding and continuing the curing for 7-90 days to obtain the non-sintered brick. The method provided by the invention has advantages such as simple process, energy conservation, environmental protection, low leachability of heavy metals, high compression strength, high porosity and good adsorption. The non-sintered brick can be used as building materials, and also can adsorb and stabilize heavy metals and organic substances in water.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Aluminum-silica sol composite bonded aluminum-silicon carbide castable and preparation method thereof

The invention discloses an aluminum silica sol composite combined aluminum silicon carbide castable and a preparation method thereof. The castable is prepared from the following raw materials in percentage by weight: 25-35% of 12-8mm bauxite aggregate, 10-15% of 8-3mm bauxite aggregate, 15-20% of 3-0mm bauxite aggregate, 15-25% of <88 mu m corundum fine powder or alumina fine powder, 5-12% of <88 mu m SiC fine powder, 1-5% of <5 mu m silicon micropowder and 5-10% of <5 mu m alpha-Al2O3 micropowder. An aluminum silica sol composite binder accounting for 10-15 wt% of all the raw materials is also added. The castable has the characteristics of high moderate-temperature strength, favorable thermal shock resistance and high corrosion resistance, can implement flash baking, and enhances the turnaround efficiency of the iron ladle; and since the service life is doubled, the castable can effectively save the consumption of the refractory material.

Owner:河南竹林耐材有限公司

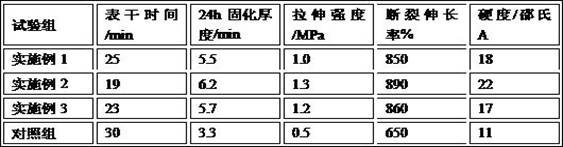

Waterproof sealant at joints of prefabricated external wall panels of prefabricated buildings and production process thereof

PendingCN112094613AHigh-strength waterproof performanceGood weather resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesWaxDibutyl tin dilaurate

The invention discloses a waterproof sealant at joints of prefabricated external wall panels of prefabricated buildings and a production process of the waterproof sealant. The waterproof sealant comprises an MS polymer, polyether polyol, nano calcium carbonate, polyamide wax, a coupling agent, a catalyst, fumed silica, dibutyltin dilaurate, nano diatomite, an antibacterial agent, a cross-linking agent, a flame retardant, an ultraviolet absorbent, a curing agent, a curing accelerator and absolute ethyl alcohol. The waterproof sealant at the joints of the prefabricated external wall panels of the prefabricated buildings has the advantages of high waterproof performance, good weather resistance, high cohesiveness, short surface drying time, high tensile strength, high elongation at break, high hardness, high corrosion resistance, high falling resistance, long service life, no toxicity, low cost and the like, and is suitable for large-scale popularization and application. The sealant is ahigh-performance waterproof sealant; the sealant has the advantages that the stress is mild, the sealant has stress and elasticity at the same time, and even if the sealant is in a stretched state fora long time, the influence caused by shrinkage of building base materials can be eliminated to the maximum extent under the action of stress relaxation.

Owner:NANNING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com