Fullerene photocatalyst composite material composition and application thereof

A technology of composite materials and fullerene derivatives, applied in the field of photocatalysis, can solve the problems of solid powder dispersion, not easy to fix, and difficult to recycle, and achieve the effects of mild conditions, easy operation, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0187] Another aspect of the present disclosure relates to the preparation method of any fullerene photocatalyst composite material composition as described above, the preparation method of the fullerene photocatalyst composite material composition includes: first preparing the fullerene photocatalyst composite material , and then the fullerene photocatalyst composite material composition is prepared from the fullerene photocatalyst composite material and auxiliary materials.

[0188] In one embodiment, the preparation method of the fullerene photocatalyst composite material includes: mixing at least one of the semiconductor body and / or the semiconductor body precursor with fullerene or fullerene derivatives in a solvent , carry out solvothermal reaction; wherein, fullerene or fullerene derivative is as described above, and described semiconductor body comprises at least one in bismuth tungstate, titanium dioxide, manganese oxide, bismuth vanadate, zinc oxide, tin oxide , the ...

Embodiment 1

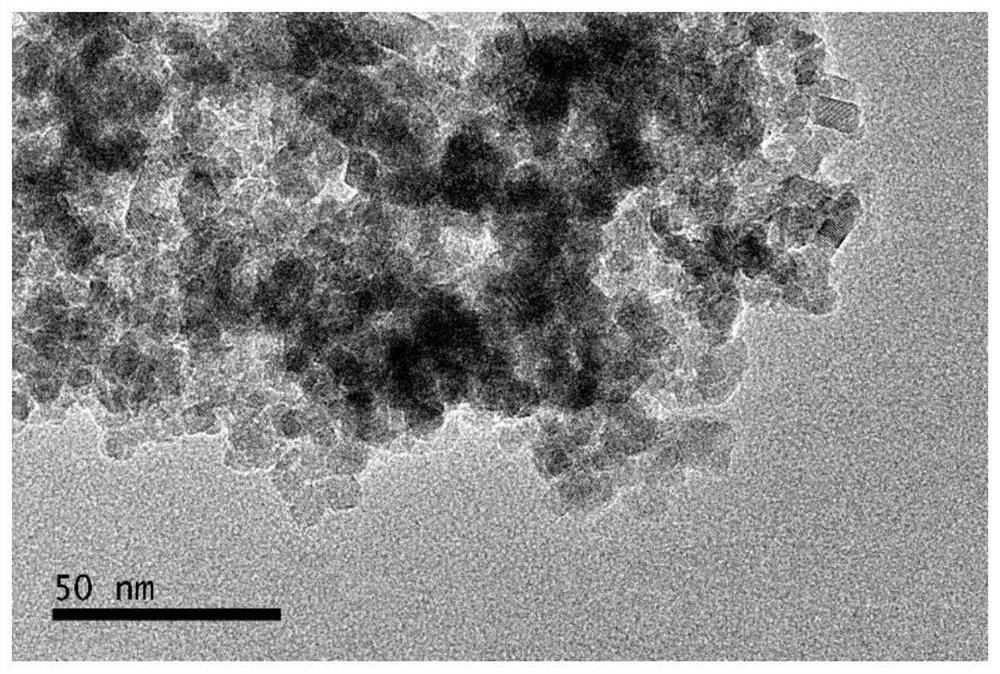

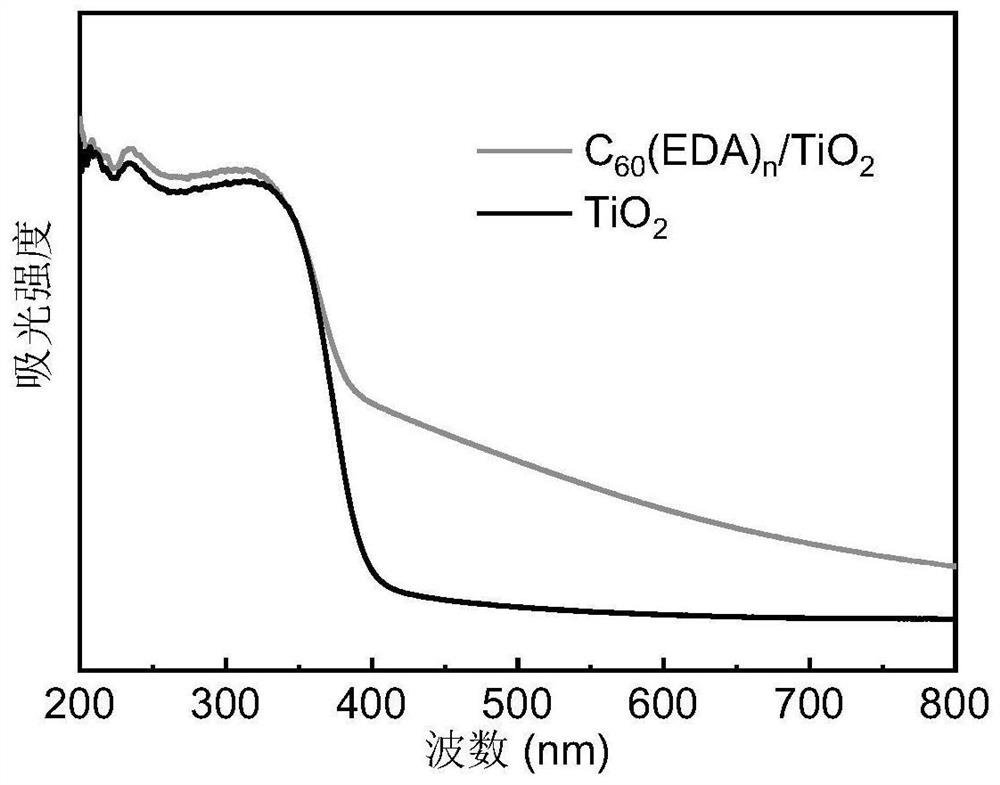

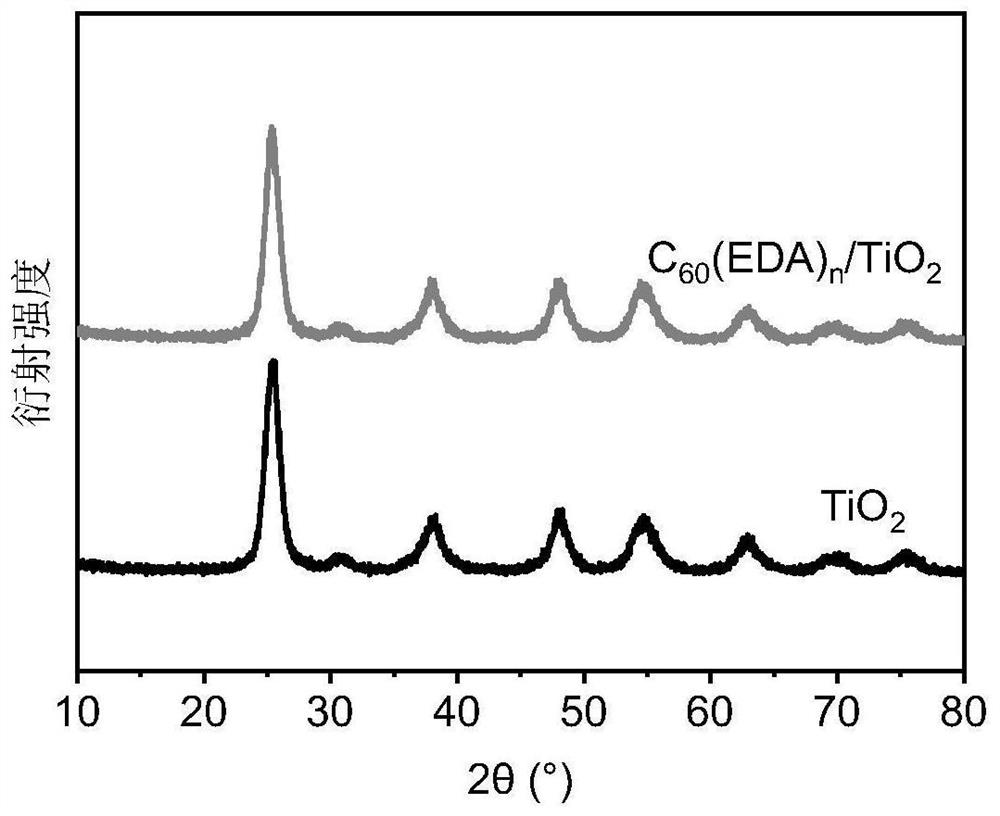

[0210] Example 1 TiO modified by aminofullerene derivatives 2 Preparation of composite materials

[0211] (1) Preparation of aminofullerene derivatives:

[0212] C 60 Aminated derivative C 60 (EDA) n Preparation of:

[0213] Weigh 50mg (0.069mmol) C 60 Dissolve the powder in 25ml of o-xylene solution, ultrasonically disperse for 30min, measure 50ml of ethylenediamine into a 100mL conical flask with a stopper, stir magnetically for 24h (room temperature, 1000r / min), use a solvent filter (volume: 1L, filter Membrane pore size: 200nm) After suction filtering the reactant, a brownish-red solution was obtained. The components of the solution are mainly unreacted ethylenediamine and C 60 (EDA) n and the solvent o-xylene. The obtained solution was added into a 250ml round-bottomed flask, and the filtrate was completely dried by rotary evaporation with a rotary evaporator (temperature: 60° C., rotational speed: 80 r / min). Add ultrapure water to dissolve, if there is a small ...

Embodiment 2

[0227] Example 2 TiO modified by carboxyfullerene derivatives 2 Preparation of composite materials

[0228] (1) Preparation of carboxyfullerene derivatives:

[0229] C 60 Carboxylated derivative C 60 (C(COOH) 2 ) m Preparation of:

[0230] Fullerene carboxyl derivative C 60 (C(COOH) 2 ) m According to the method of Zhu et al. (refer to Cheng, F.; Yang, X.; Zhu, H.; Sun, J.; Liu, Y., Synthesis of oligo adducts of malonic acid C 60 and their scavenging effects on hydroxyl radical. Journal of Physics and Chemistry of Solids, 2000, 61, (7), 1145-1148.), 7μl DBU (1,8-diazabicycloundec-7-ene) Dissolve in 2ml toluene to form solution A, dissolve 7.5μl diethyl bromomalonate in 2ml toluene to form solution B, dissolve 10mg C60 in 20ml toluene to form solution C, and mix solutions A and B under stirring Add dropwise to solution C to form a mixed solution, stir the mixed solution at room temperature under Ar for 5 h, and immediately spin evaporate and dry in a vacuum oven at 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com