Waterproof sealant at joints of prefabricated external wall panels of prefabricated buildings and production process thereof

A technology for waterproof sealing and exterior wall panels, which can be used in buildings, building components, building structures, etc., and can solve problems such as reducing the aesthetics and image value of buildings, surrounding pollution that is difficult to remove, and weak silicone adhesive bonding. , to achieve the effect of high-strength weather resistance, long service life and fast surface drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

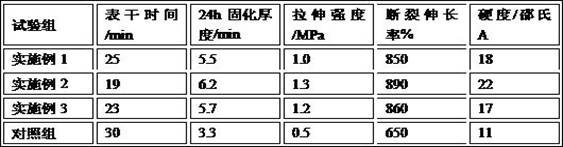

Examples

preparation example Construction

[0023] The preparation method of the waterproof sealant at the seams of prefabricated exterior wall panels of prefabricated buildings, the specific steps are as follows;

[0024] Step 1: Add MS polymer, polyether polyol, nano-calcium carbonate, polyamide wax, ultraviolet absorber and absolute ethanol into the reaction kettle, disperse at high speed for 30 minutes and then raise the temperature to 120 degrees Celsius to obtain mixture A;

[0025] Step 2: Add meteorological silica, dibutyltin dilaurate and nano-diatomaceous earth to mixture A in sequence, after stirring for 30 minutes, cool down to 80 degrees Celsius, and keep warm for 2 hours to obtain mixture B;

[0026] Step 3: Add antibacterial agent, crosslinking agent, flame retardant, curing agent and curing accelerator to mixture B in sequence, stir for 20 minutes and raise the temperature to 100 degrees Celsius, and keep it warm for 1 hour to obtain mixture C;

[0027] Step 4: Dehydrate the mixture C under vacuum for 1-...

Embodiment 1

[0030] Raw material formula: including 15 parts of MS polymer, 10 parts of polyether polyol, 10 parts of nano calcium carbonate, 2 parts of polyamide wax, 2 parts of coupling agent, 2 parts of catalyst, 6 parts of meteorological silica, dibutyl dibutyl 4 parts of tin laurate, 6 parts of nano diatomite, 2 parts of antibacterial agent, 2 parts of crosslinking agent, 2 parts of flame retardant, 2 parts of ultraviolet absorber, 2 parts of curing agent, 2 parts of curing accelerator and anhydrous 50 parts of ethanol.

[0031] Specific steps are as follows:

[0032] Step 1: Add MS polymer, polyether polyol, nano-calcium carbonate, polyamide wax, ultraviolet absorber and absolute ethanol into the reaction kettle, disperse at high speed for 30 minutes and then raise the temperature to 120 degrees Celsius to obtain mixture A;

[0033] Step 2: Add meteorological silica, dibutyltin dilaurate and nano-diatomaceous earth to mixture A in sequence, after stirring for 30 minutes, cool down t...

Embodiment 2

[0038] Raw material formula: including 20 parts of MS polymer, 20 parts of polyether polyol, 15 parts of nano calcium carbonate, 4 parts of polyamide wax, 3 parts of coupling agent, 4 parts of catalyst, 8 parts of meteorological silica, dibutyl dibutyl 6 parts of tin laurate, 7 parts of nano diatomite, 3 parts of antibacterial agent, 3 parts of crosslinking agent, 4 parts of flame retardant, 4 parts of ultraviolet absorber, 3 parts of curing agent, 2 parts of curing accelerator and anhydrous 60 parts of ethanol.

[0039] Specific steps are as follows:

[0040] Step 1: Add MS polymer, polyether polyol, nano-calcium carbonate, polyamide wax, ultraviolet absorber and absolute ethanol into the reaction kettle, disperse at high speed for 30 minutes and then raise the temperature to 120 degrees Celsius to obtain mixture A;

[0041] Step 2: Add meteorological silica, dibutyltin dilaurate and nano-diatomaceous earth to mixture A in sequence, after stirring for 30 minutes, cool down t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com