Polymer cement radiation refrigeration paint and coating

A radiation refrigeration and polymer technology, applied in reflection/signal coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of lack of radiation refrigeration and cooling performance, and achieve simple construction and construction, high-strength waterproof performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

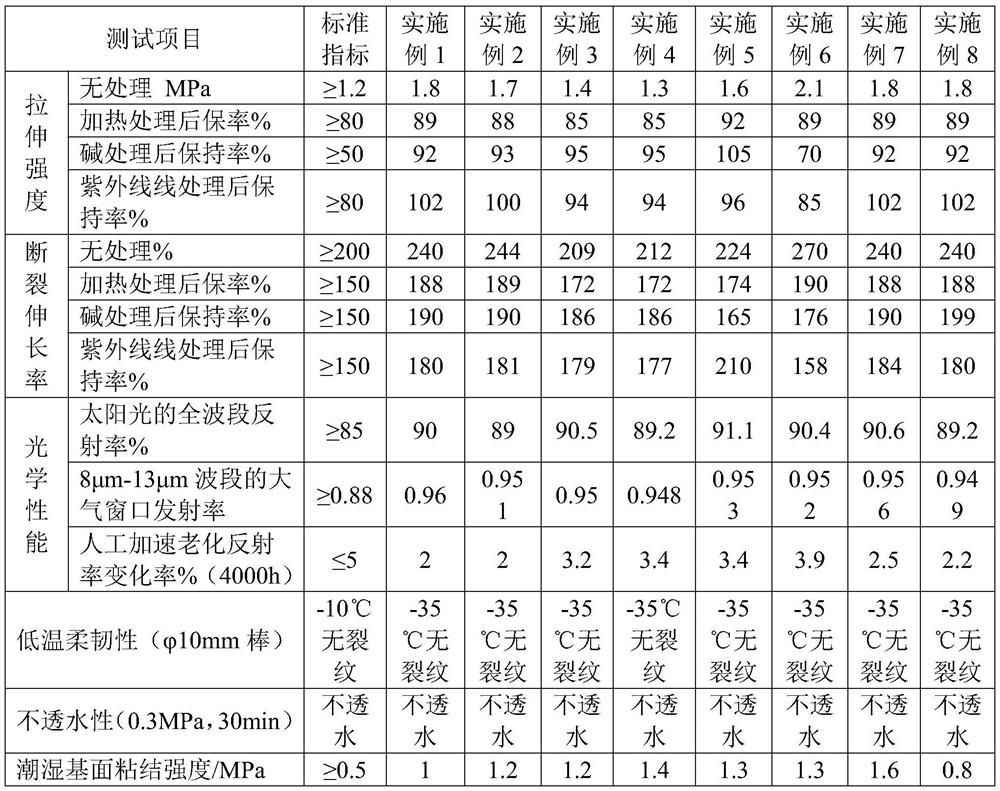

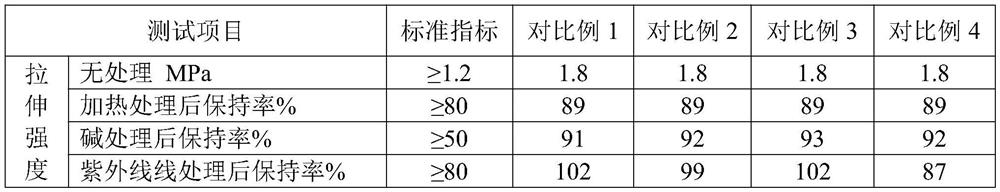

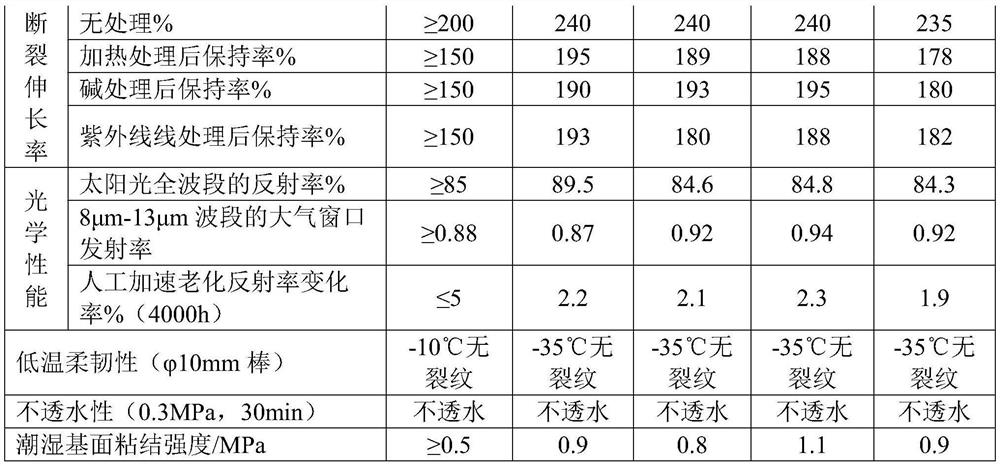

Examples

Embodiment 1

[0046] The polymer cement radiation refrigeration coating of this embodiment includes liquid material and powder material.

[0047] Among them, the liquid material includes 100 parts by weight of pure acrylic emulsion, 1 part by weight of CS12 film-forming agent, 1 part by weight of CA2500 dispersant, 0.3 parts by weight of 902W defoamer, 0.3 parts by weight of AS60 thickener and 0.3 parts by weight Parts of CMC fungicide.

[0048] The powder includes 100 parts by weight of white cement, 10 parts by weight of quartz powder, 0.1 parts by weight of metal cobalt accelerator, 60 parts by weight of rutile titanium dioxide (particle size is 0.4 μm, oil absorption is 18), 10 parts by weight ceramic powder (with a particle size of 5 μm and an oil absorption of 25) and 5 parts by weight of barium sulfate (with a particle size of 1 μm and an oil absorption of 12).

[0049] When in use, the liquid material and the powder material are stirred into a uniform and fine slurry according to t...

Embodiment 2

[0051] The polymer cement radiation refrigeration coating of this embodiment includes liquid material and powder material.

[0052] Among them, the liquid material includes 100 parts by weight of pure acrylic emulsion, 1 part by weight of CS12 film-forming agent, 1 part by weight of CA2500 dispersant, 0.3 parts by weight of 902W defoamer, 0.3 parts by weight of AS60 thickener and 0.3 parts by weight Parts of CMC fungicide.

[0053] The powder includes 100 parts by weight of white cement, 10 parts by weight of quartz powder, 0.2 parts by weight of metal cobalt accelerator, 60 parts by weight of rutile titanium dioxide (particle size is 0.4 μm, oil absorption is 18), 5 parts by weight ceramic powder (with a particle size of 5 μm and an oil absorption of 25) and 10 parts by weight of barium sulfate (with a particle size of 1 μm and an oil absorption of 12).

[0054] When in use, the liquid material and the powder material are stirred into a uniform and fine slurry according to t...

Embodiment 3

[0056] The polymer cement radiation refrigeration coating of this embodiment includes liquid material and powder material.

[0057] Among them, the liquid material includes 100 parts by weight of styrene-acrylic emulsion, 1 part by weight of CS12 film-forming agent, 1 part by weight of CA2500 dispersant, 0.3 parts by weight of 902W defoamer, 0.3 parts by weight of AS60 thickener and 0.3 parts by weight of Parts of CMC fungicide.

[0058] The powder includes 100 parts by weight of white cement, 10 parts by weight of quartz powder, 0.1 parts by weight of metal cobalt accelerator, 60 parts by weight of rutile titanium dioxide (particle size is 0.4 μm, oil absorption is 18), 10 parts by weight ceramic powder (with a particle size of 5 μm and an oil absorption of 25) and 10 parts by weight of barium sulfate (with a particle size of 1 μm and an oil absorption of 12).

[0059] When in use, the liquid material and the powder material are stirred into a uniform and fine slurry accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com