A method for making bricks without sintering by using dredged bottom mud

A technology for dredging sediment without sintering, applied in dewatering/drying/concentrating sludge treatment, etc., can solve the problems of high energy consumption of organic pollutants, secondary pollution, etc., to overcome high energy consumption, easy large-scale production, material easy-to-get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Collect the bottom mud generated by dredging in waterways, ditches, (along the river / sea) ports, docks, etc. After standing, aging, decontamination, sterilization and disinfection, add 15% effective concentration of 2,4 to the bottom mud. ,6-trimercapto-1,3,5-triazine trisodium salt (TMT-15) solution, the addition amount is 5% of the dry bottom mud mass. Mechanically stir for more than 5 minutes until the mixture is uniform. After weathering, exposure and other treatments, the moisture content of the sediment is controlled to be 1%-5%. If the moisture content exceeds 5%, it needs to be dried in time. After crushing, ball milling and sorting by pulverizer, ball mill and screen, select 100-150 mesh sediment particles for use.

[0030] Mix air-dried bottom mud, P.O42.5 cement, clinoptilolite powder and quicklime in a mass ratio of 100:45:10:1.5, and add water to adjust the water-cement mass ratio to 35-45%. Stir mechanically at room temperature, first at slow speed for 3...

Embodiment 2

[0045] The specific preparation steps are the same as those in Example 1.

[0046] Add heavy metal collector 2,4,6-trimercapto-1,3,5-triazine trisodium salt to dredged sediment, according to the ratio of dry sediment, 425# ordinary Portland cement, zeolite and quicklime to 100:45 : The mass ratio of 10:1.5 is mixed evenly, molded into molding, demoulded after curing for 1 day, and wet curing for 7-90 days. The size of the sinter-free brick is 240mm×115mm×53mm.

[0047] The mechanical properties test: 7-day average compressive strength: 4.3MPa, flexural strength: 1.0MPa; 28-day average compressive strength is 10.2MPa, flexural strength 2.1Mpa, in line with NYT671-2003 "Concrete Ordinary Bricks and Decorative Bricks" "Standard of load-bearing MU10 and non-load-bearing MU7.5 in the standard; 90-day average compressive strength is 15.6MPa, and flexural strength is 2.9MPa, reaching the load-bearing MU15 and non-load-bearing MU7 in NYT671-2003 "Concrete Ordinary Bricks and Decorati...

Embodiment 3

[0052] The specific preparation steps are the same as those in Example 1.

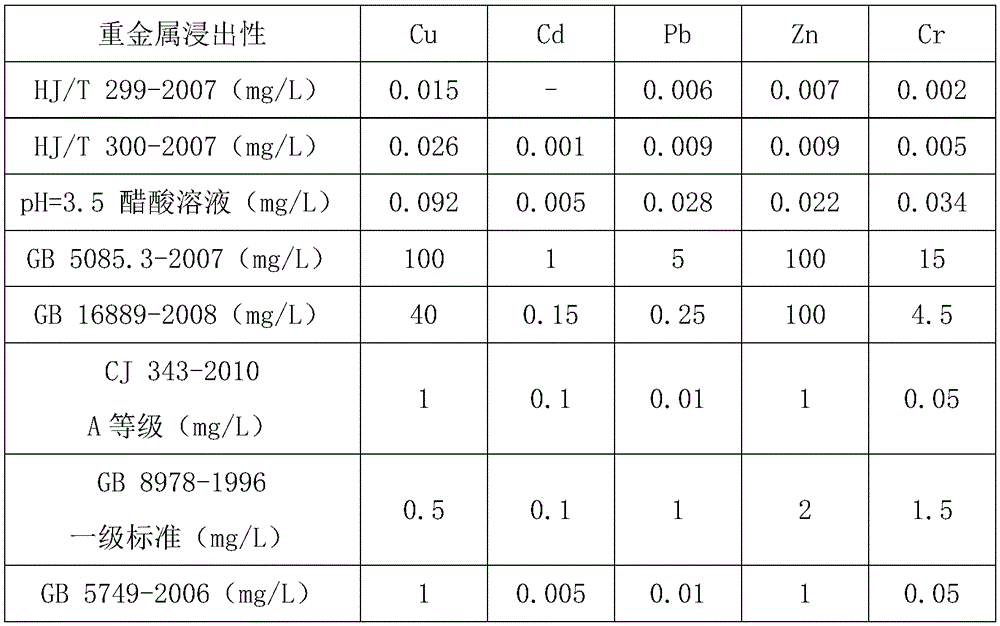

[0053] Add dredged sediment to TMT-15, dry sediment, 425-type cement, zeolite, and quicklime are mixed uniformly according to the mass ratio of 100:45:10:1.5, and mold is formed. After curing for 1 day, the mold is released, and wet curing is performed for 7-90 days. . The size of the sinter-free brick is 240mm×115mm×53mm. The 28-day average compressive strength after the mechanical property test meets the standard of load-bearing MU10 and non-load-bearing MU7.5 in NYT671-2003 "Concrete Ordinary Bricks and Decorative Bricks"; the 90-day average compressive strength reaches load-bearing MU15 and non-load-bearing MU7.5 It also meets the GB / T24493-2009 "Decorative Concrete Bricks" MU15 standard value. According to HJ / T299-2007 "Solid Waste Leaching Toxicity Leaching Method Sulfuric and Nitric Acid Method", the leaching concentration of Pb in the sediment is 0.006mg / L, Cd cannot be detected, the leaching...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com