Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Uniform phase distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

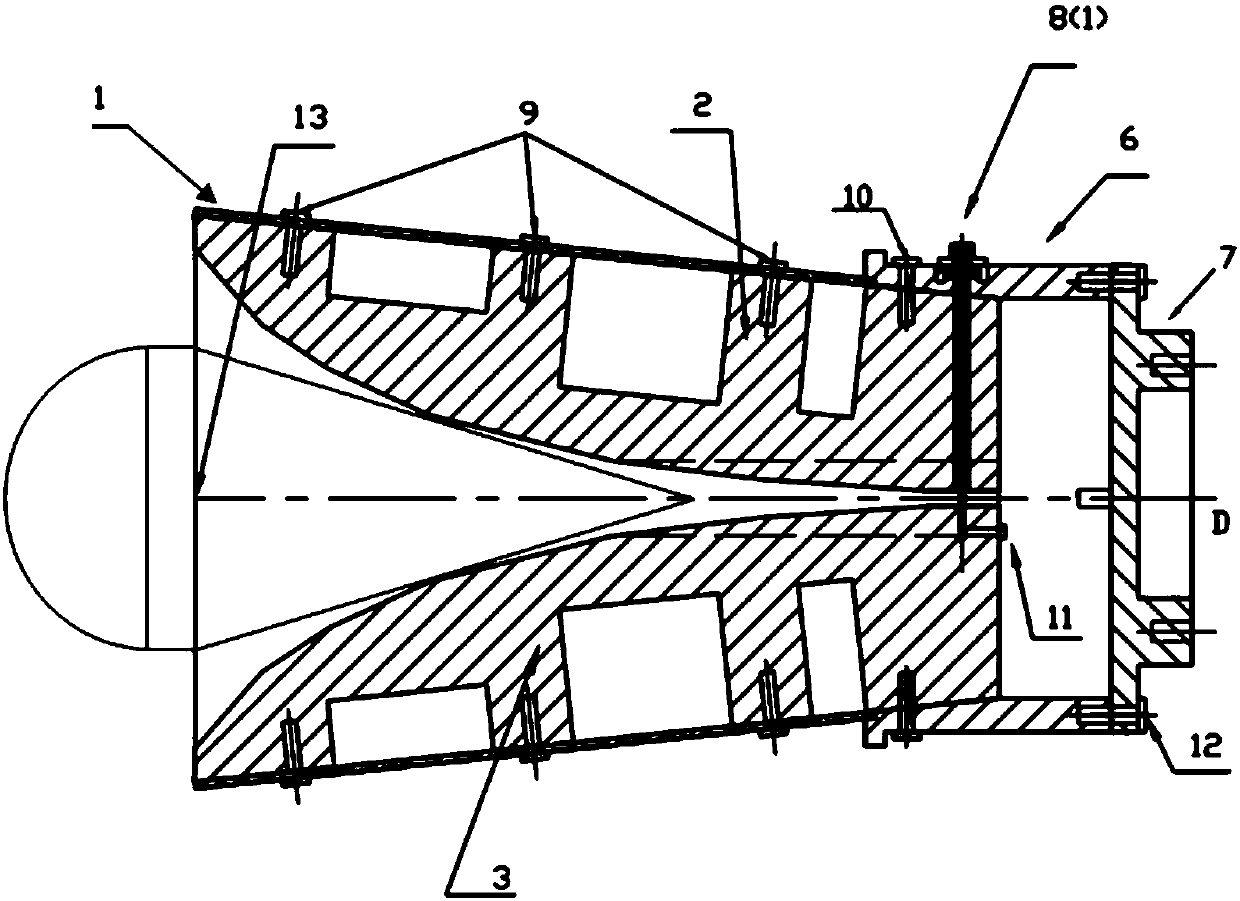

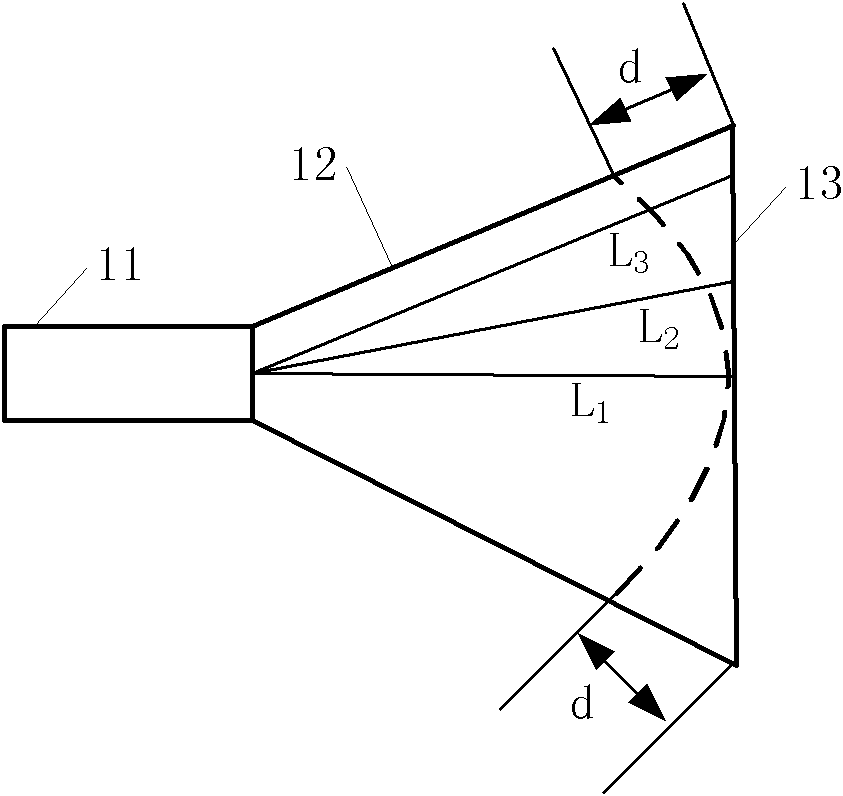

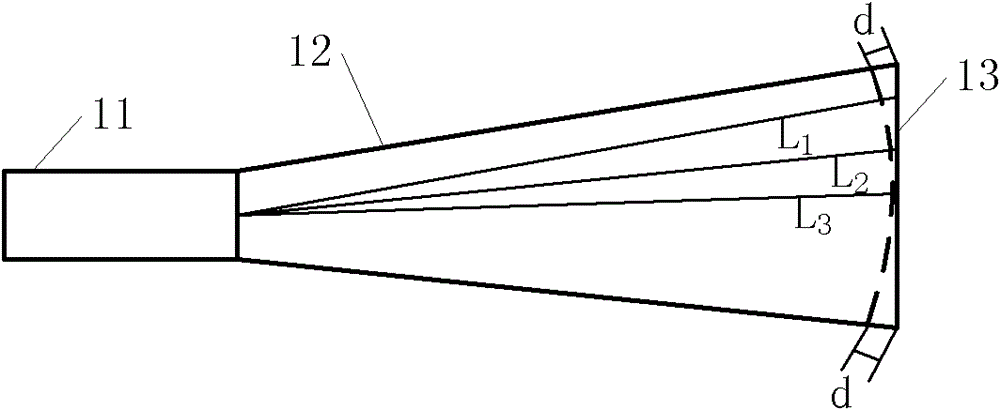

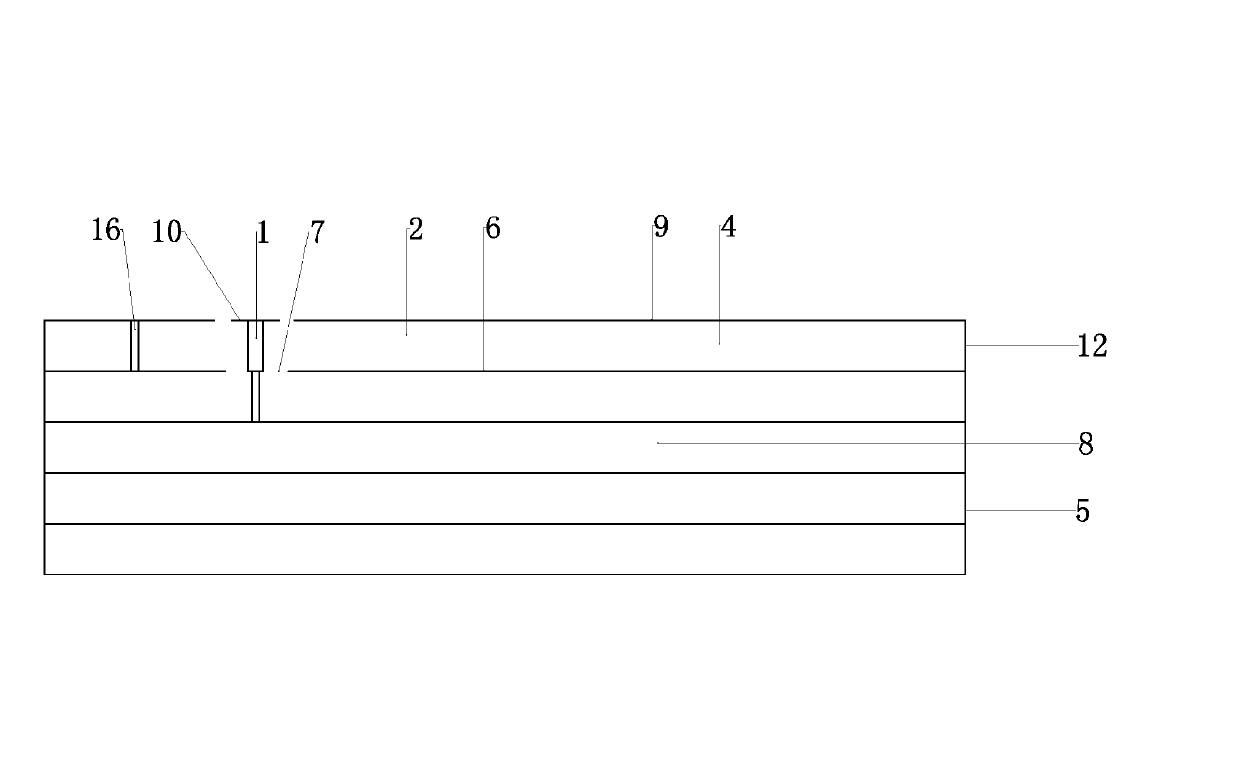

Planar horn antenna for phase calibration

InactiveCN103022715AUniform phase distributionCorrect Phase InconsistencyWaveguide hornsHorn antennaPhysics

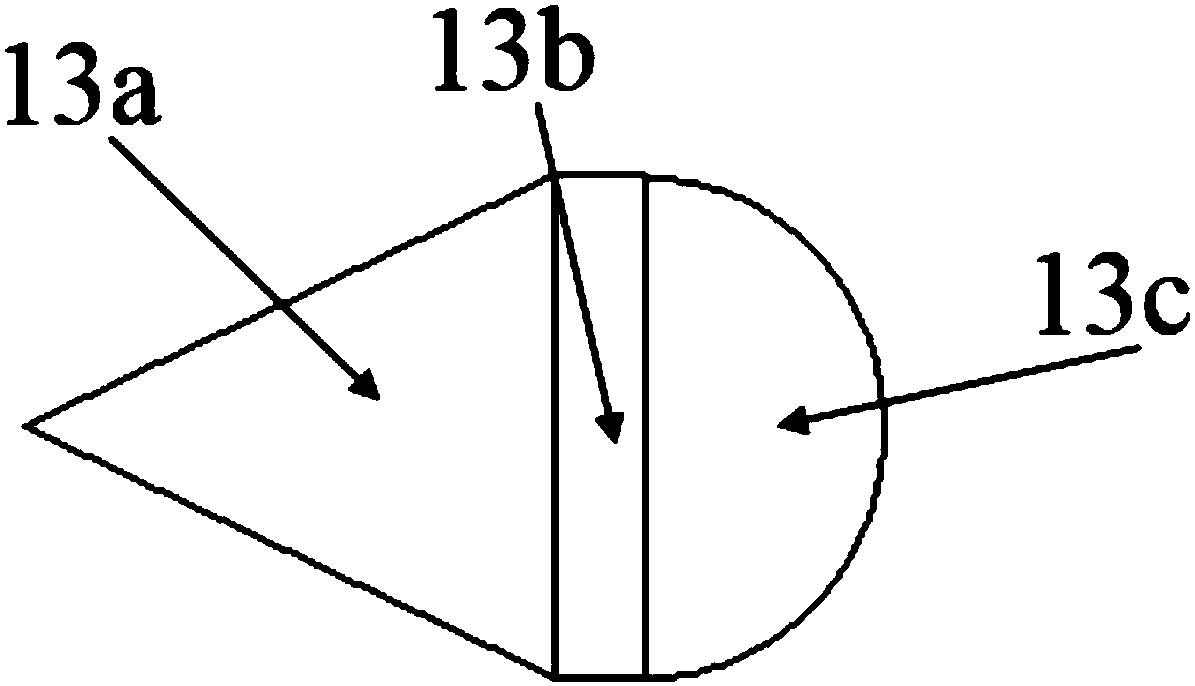

The invention relates to a planar horn antenna, in particular to a planar horn antenna for phase calibration. The antenna comprises a micro-strip feeder (1), a substrate integrated waveguide horn antenna (2) and a plurality of embedded plated-through holes (3) which are integrated on a dielectric substrate (4), the horn antenna (2) is composed of a first metal plane (8), a second metal plane (10) and two rows of plated-through hole horn side walls (11), the plated-through holes (3) are disposed in the horn antenna (2) and form a column or multiple columns of through hole linear arrays (12), each two adjacent columns of linear arrays (12) or one column of linear arrays (12), one row of horn side walls (11), the first metal plane (8) and the second metal plane (10) form a dielectric-filled waveguide (13), and one end of each dielectric-filled waveguide (13) is disposed in the horn antenna (2) while the other end thereof is disposed on an antenna aperture surface (14). In addition, the antenna is capable of increasing antenna gain.

Owner:SOUTHEAST UNIV

Low frequency octave wide wave beam compact range feed source based on medium loading

ActiveCN107732435ADecrease in orofacial sizeWorking frequency bandwidthRadiating elements structural formsAntennas earthing switches associationPhase differenceOctave

The invention relates to a low frequency octave wide wave beam compact range feed source based on medium loading. A ridge waveguide part cooperates with the ridge curve of a horn, which can widen thethickness of the ridge to the most extent. A feed probe is a semi-rigid coaxial cable feed joint (8) which is connected by SMA joints, and the two feed probes are vertically arranged, and are respectively corresponding to two polarizations of the feed source. The terminal position at the oral surface of the ridge curve is disposed in a horn oral surface but not at the edge of a horn wall (1), which effectively reduces the distribution area of a high frequency antenna oral surface without affecting the low frequency antenna oral surface. The invention is advantageous in that a rather small hornopening angle is adopted, and the phase difference of the high frequency oral surface field can be further reduced; through optimizing the shape of medium loading materials and the relative positionof a quadruple-ridged horn, the radiation electric field of feed source antenna can be concentrated in the medium area, and the wave beam can be widened and the phase center can be stabilized; the medium loading quadruple-ridged horn antenna is small in volume, light in weight, and low in cost.

Owner:BEIHANG UNIV

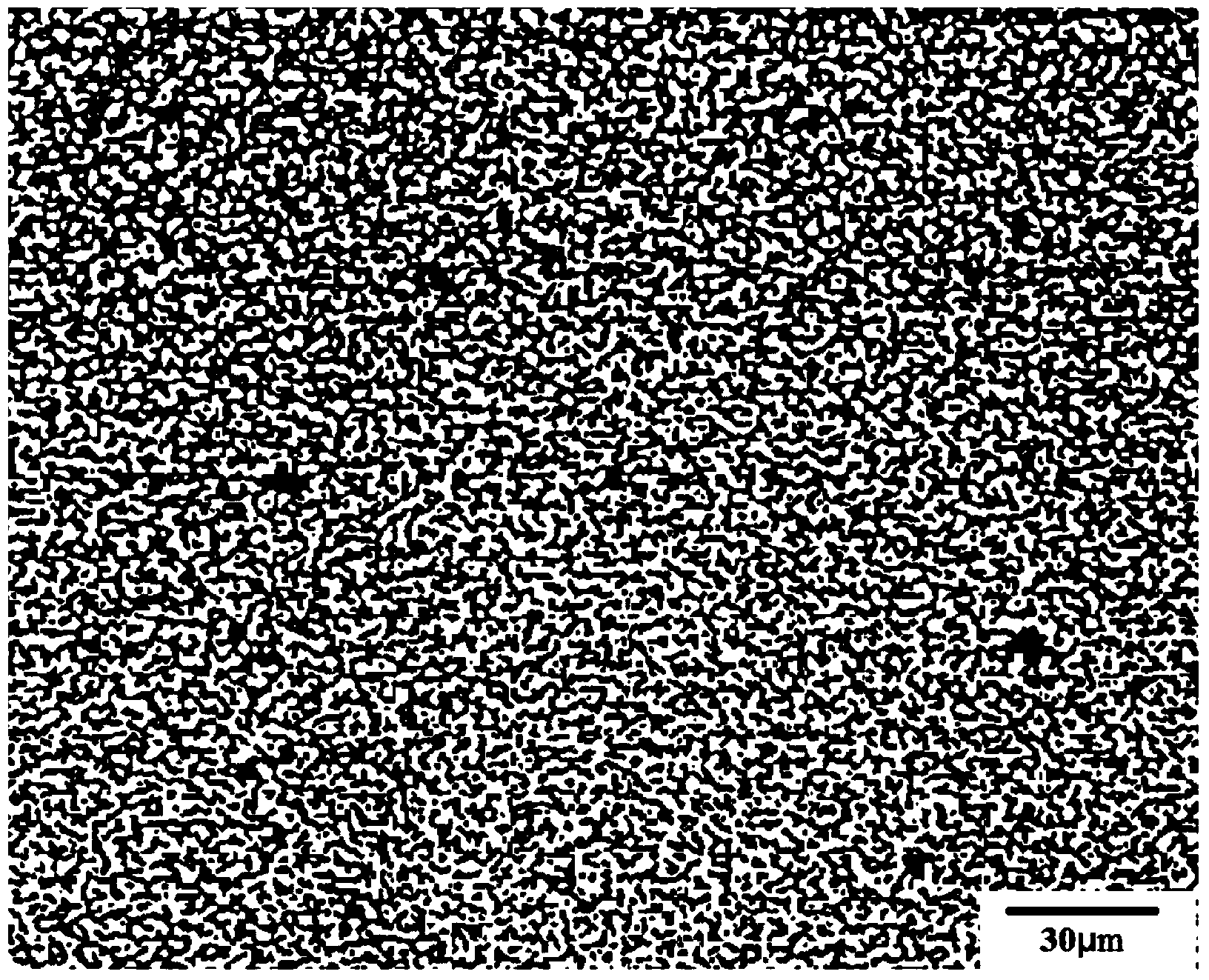

Large-sized ruthenium-based alloy sputtering target and preparation method thereof

ActiveCN104032270AUniform phase distributionSmall grain sizeVacuum evaporation coatingSputtering coatingAlloy elementCoating

The invention discloses a large-sized ruthenium-based alloy sputtering target and a preparation method thereof. The ruthenium-based alloy target comprises one or more of Al, Co, Cr and the like and the balance of Ru and is in a cake shape, wherein the diameter of the target is not less than 100mm, the density is not less than 99.5%, the density difference between the central zone and the marginal zone of the target does not exceed 0.3%, and a second phase formed by the Ru and other alloy elements is uniformly distributed in an Ru matrix phase. The preparation method for the ruthenium-based alloy sputtering target comprises the steps of preparing brittle phase ruthenium-based alloy powder with relatively low melting point through a gas atomization method, treating the brittle phase through an air-current mill to obtain fine and uniform alloy powder, and sintering the powder to obtain the ruthenium-based alloy target of which the diameter is more than 100mm. The alloy target is low in impurity content, high and uniform in density, uniform in component distribution and fine and uniform in grains, a coating sputtered by using the target is uniform in thickness and stable in performance, and the phenomena of abnormal discharge and the like in the sputtering process are reduced.

Owner:SINO PLATINUM METALS CO LTD

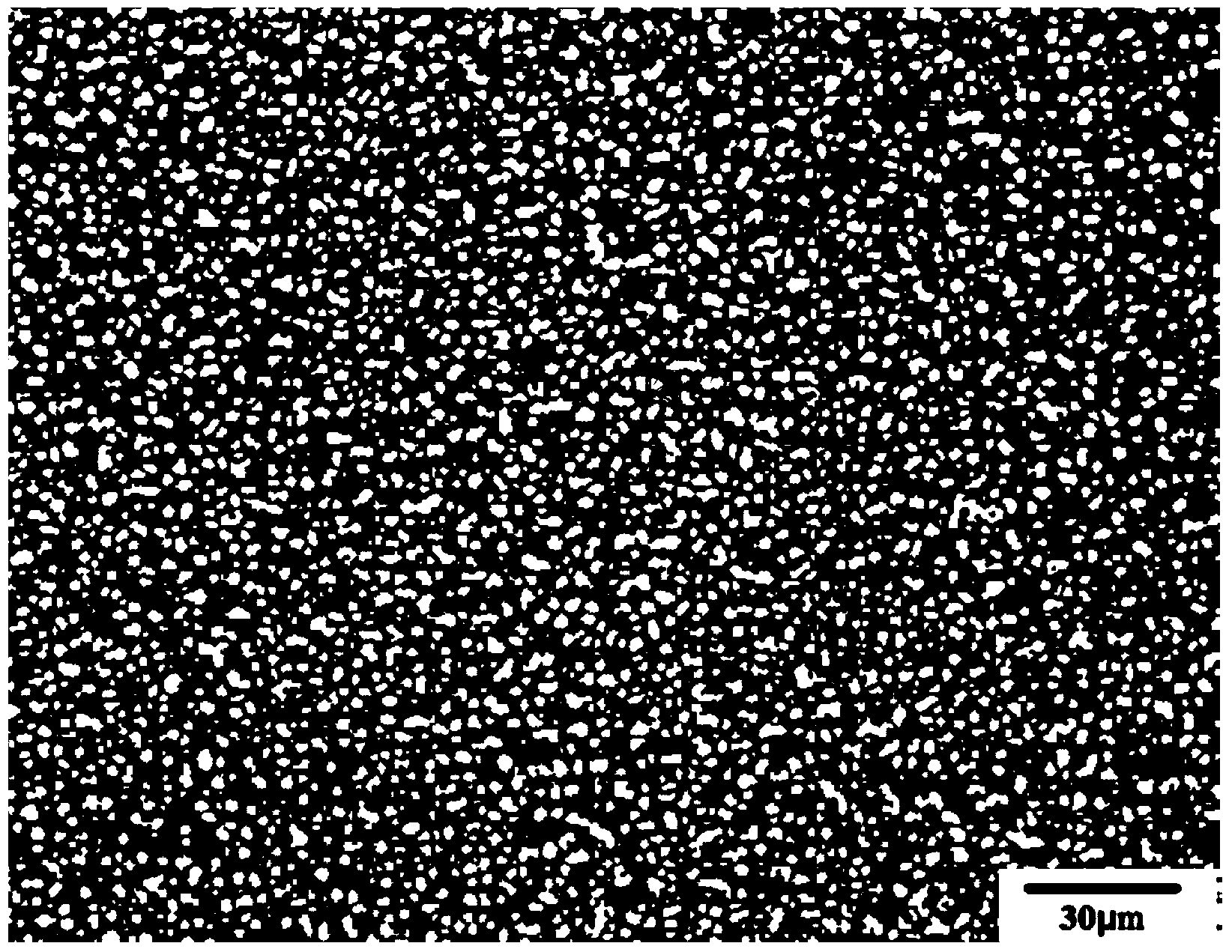

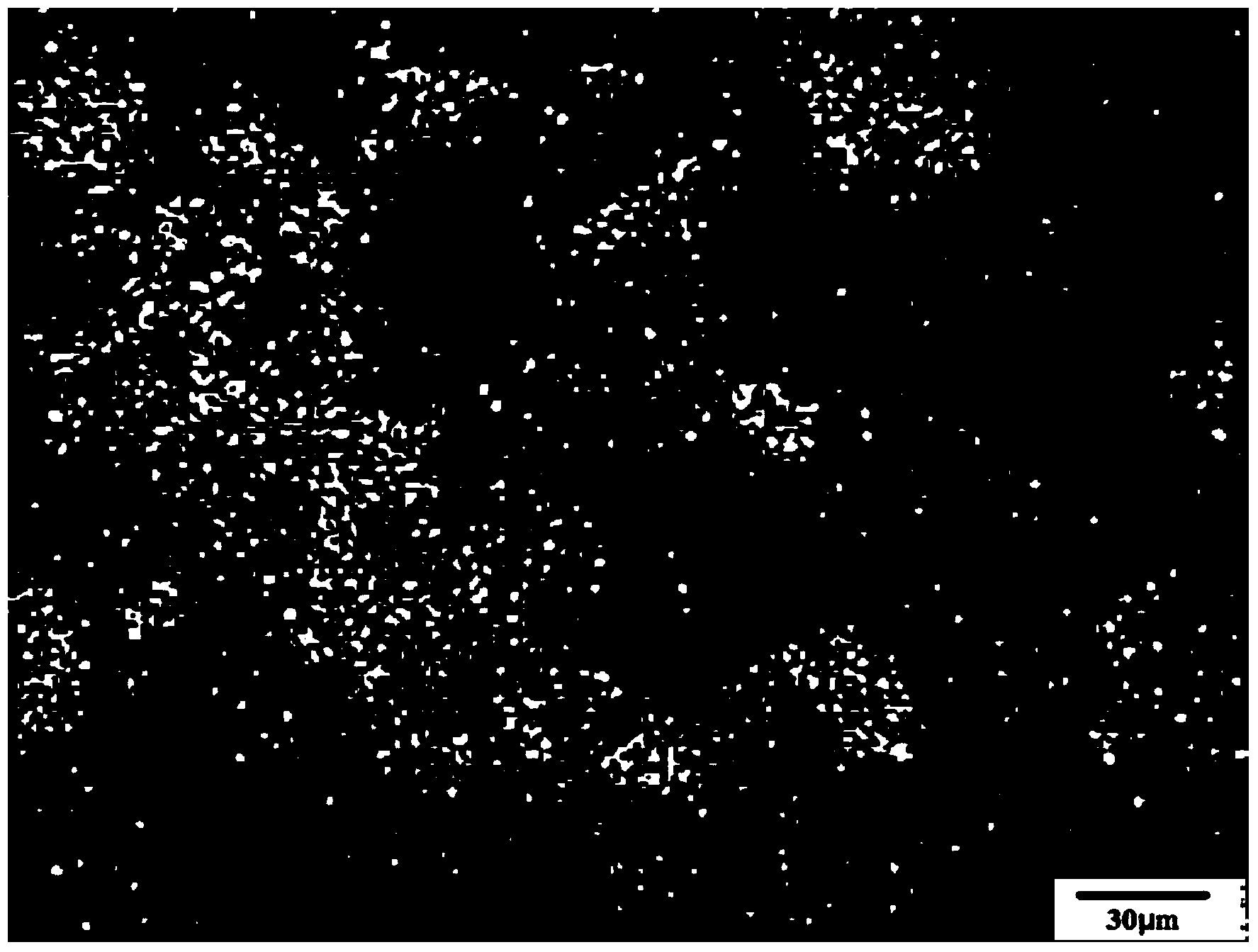

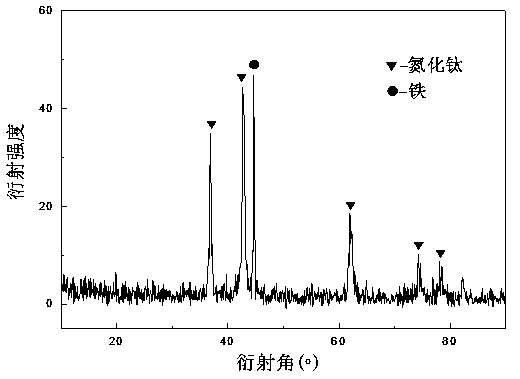

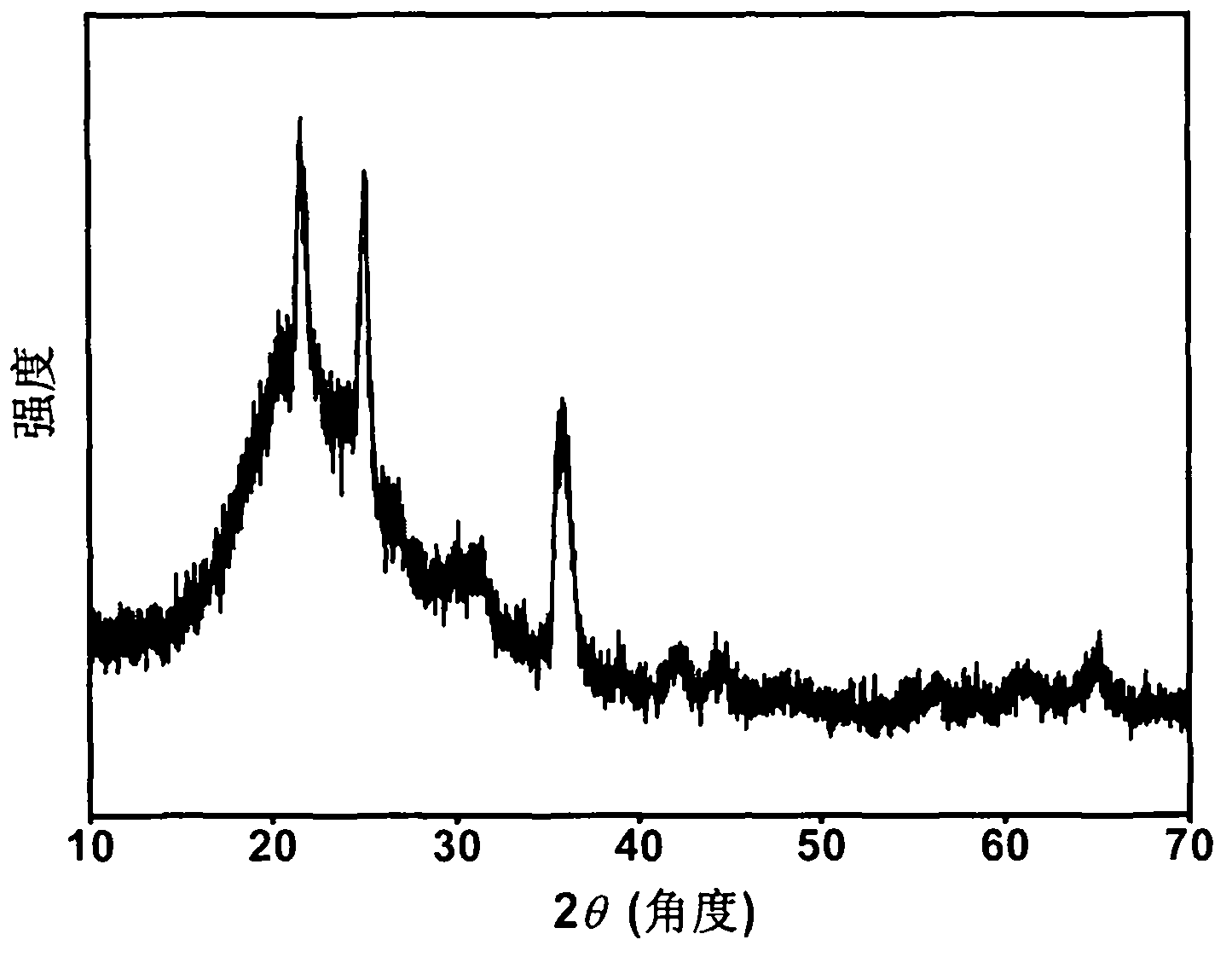

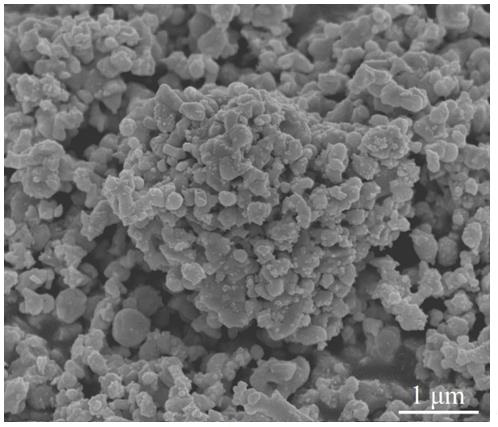

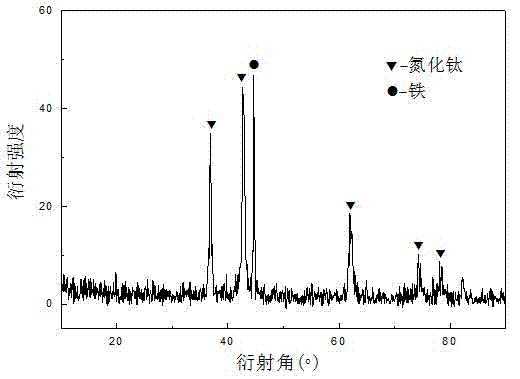

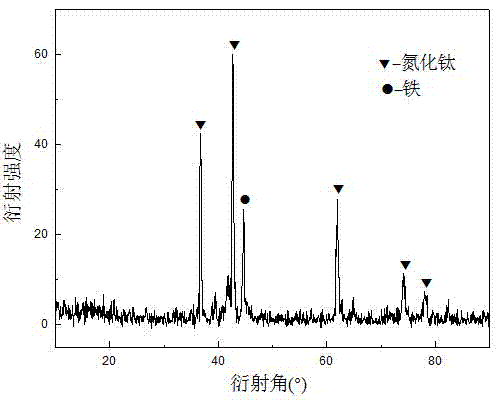

Preparation method of titanium nitride-ferrous metal ceramics

The invention relates to a preparation method of titanium nitride-ferrous metal ceramics. The preparation method comprises the steps of preparing a titanium-ferrous (Ti-Fe) alloy cast ingot with a vacuum melting method to enable Fe to exist in Ti in a form of solid solution and TiFe intermediate phase; carrying out hydrogenation embrittlement, ball-milling crushing and dehydrogenation and nitrogen treatment on the Ti-Fe alloy cast ingot to obtain titanium nitride-ferrous (TiN-Fe) metal-ceramic composite powder; sintering the composite powder subjected to green compacting to obtain a TiN-Fe metal-ceramic material. The TiN-Fe metal-ceramic composite powder prepared by the method provided by the invention consists of two phases, i.e. TiN and Fe, and is uniform in powder size and good in fluidity, the TiN-Fe block metal-ceramic material obtained by sintering the TiN-Fe metal-ceramic composite powder subjected to green compacting is uniform in phase distribution and relatively high in density, and the average microscopy Vickers hardness of the materials reaches 1023 HV.

Owner:NANCHANG UNIV

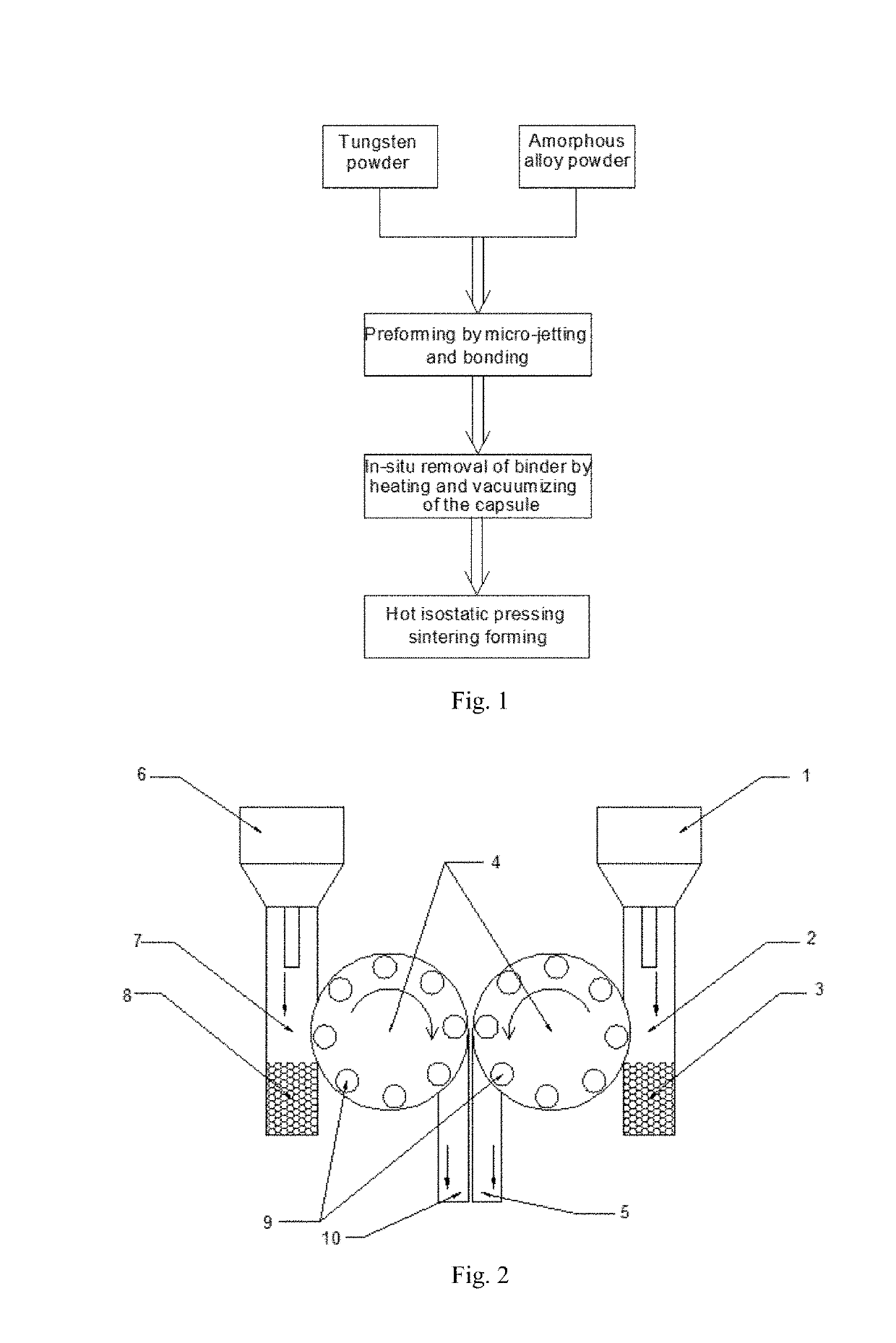

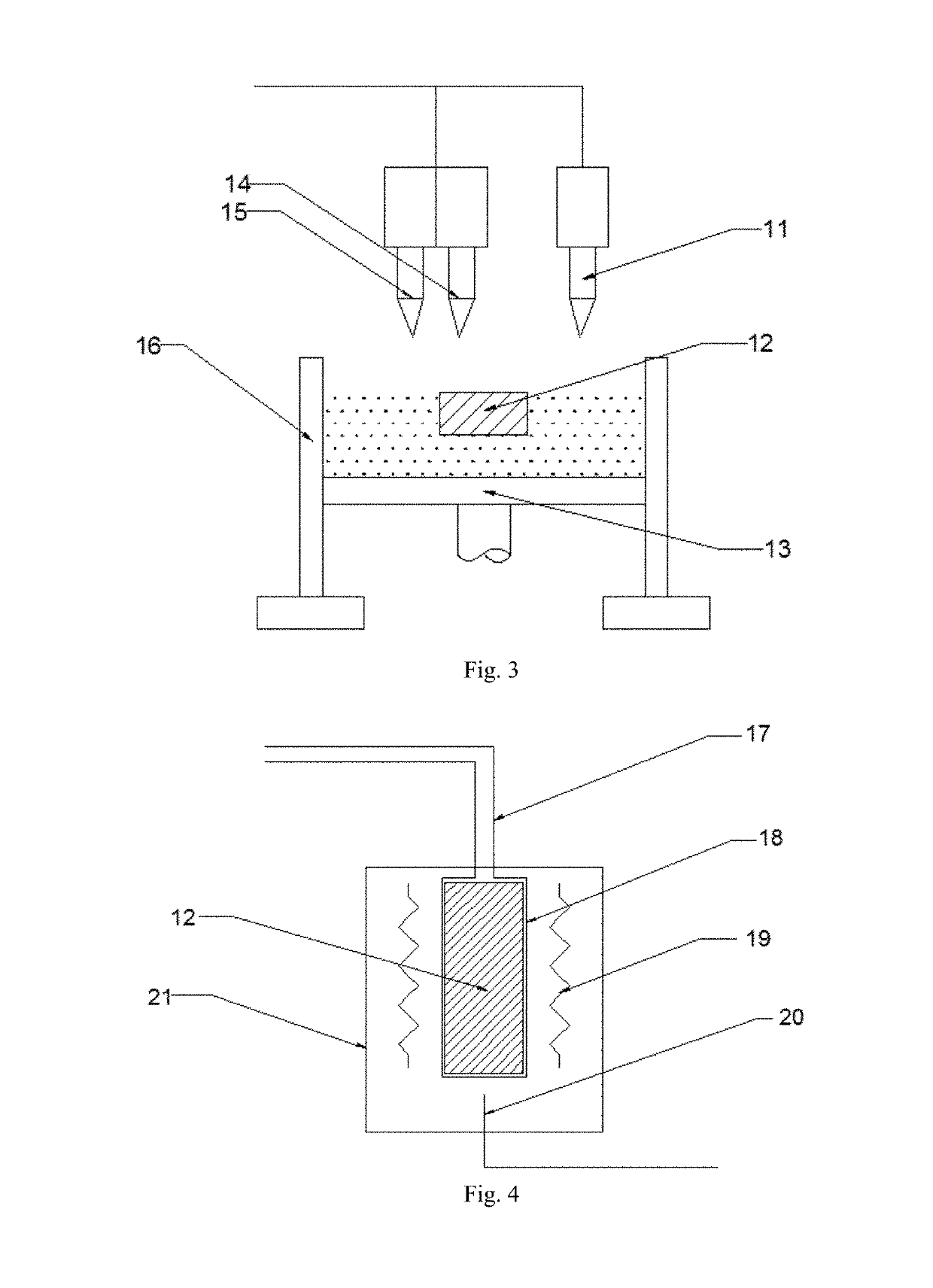

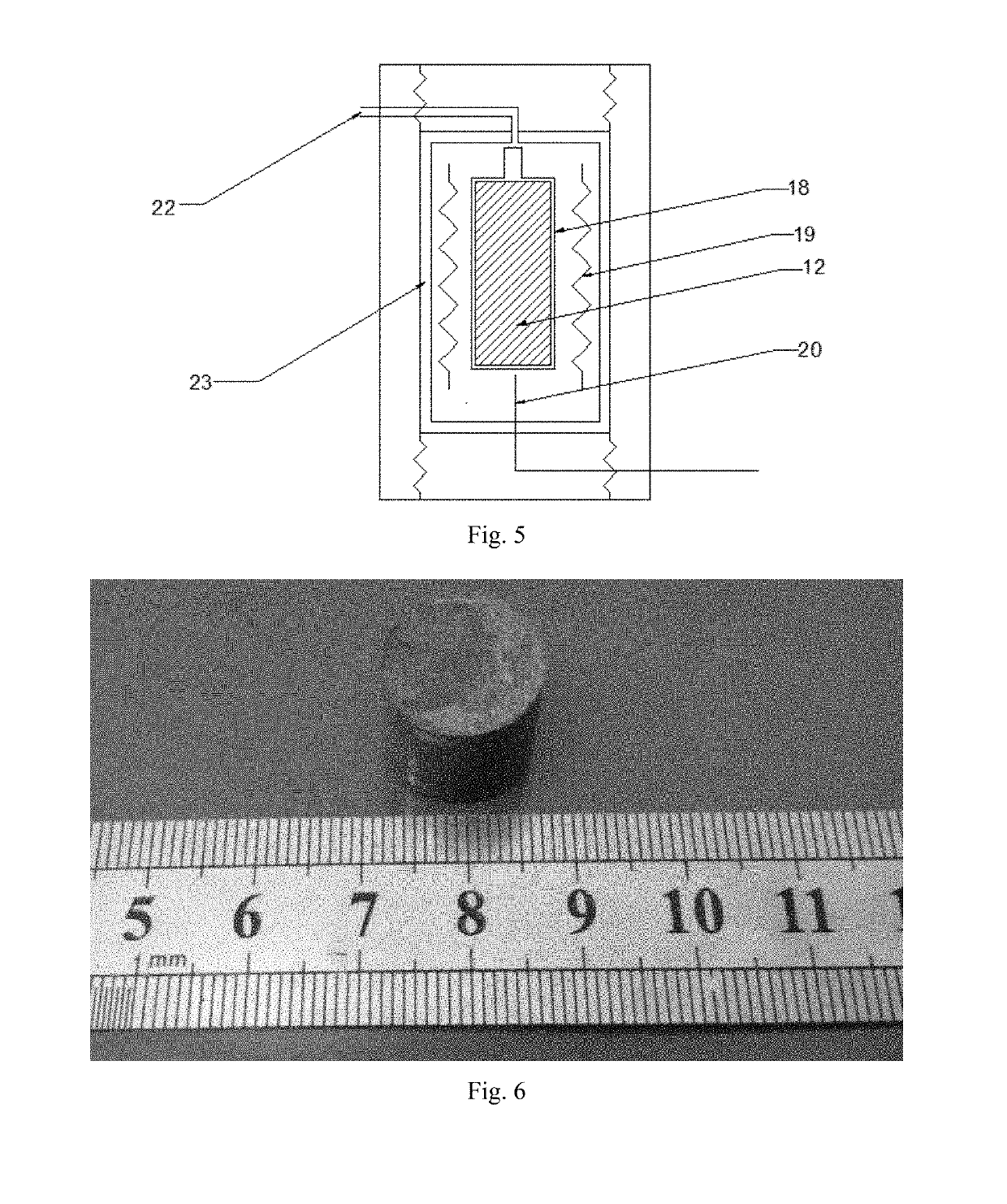

Preparation method of tungsten particle reinforced amorphous matrix composites

ActiveUS20190232366A1Evenly distributedSmall sizeAdditive manufacturing apparatusTransportation and packagingManufacturing technologyAlloy composite

The invention belongs to the fields of amorphous alloy composites, additive manufacturing technology and hot isostatic pressing sintering forming, and in particular relates to a preparation method of tungsten particle reinforced amorphous matrix composites, comprising the following steps: (1) making tungsten powder and amorphous alloy powder into a preform by the micro-jetting and bonding 3D printing technology, specifically comprising: in the preforming process by micro-jetting and bonding, through a double-drum type powder feeding device, spraying tungsten powder and amorphous alloy powder into a layer of uniformly mixed powder layer by double nozzles, then bonding the powder layer into a bonding layer by the binder, and repeating the operations of spraying the powders and binder, so that a preform with uniform particle phase distribution is finally prepared; (2) placing the preform in a capsule, and performing heating and vacuumizing on the capsule in a heating furnace; and (3) placing the capsule in the hot isostatic pressing sintering furnace and performing hot press forming to obtain an amorphous matrix composite. In the present invention, through combining the cold additive micro-jetting and bonding technology with hot isostatic pressing sintering forming, a tungsten particle reinforced amorphous matrix composite with large size and uniform particle phase distribution can be prepared.

Owner:HUAZHONG UNIV OF SCI & TECH

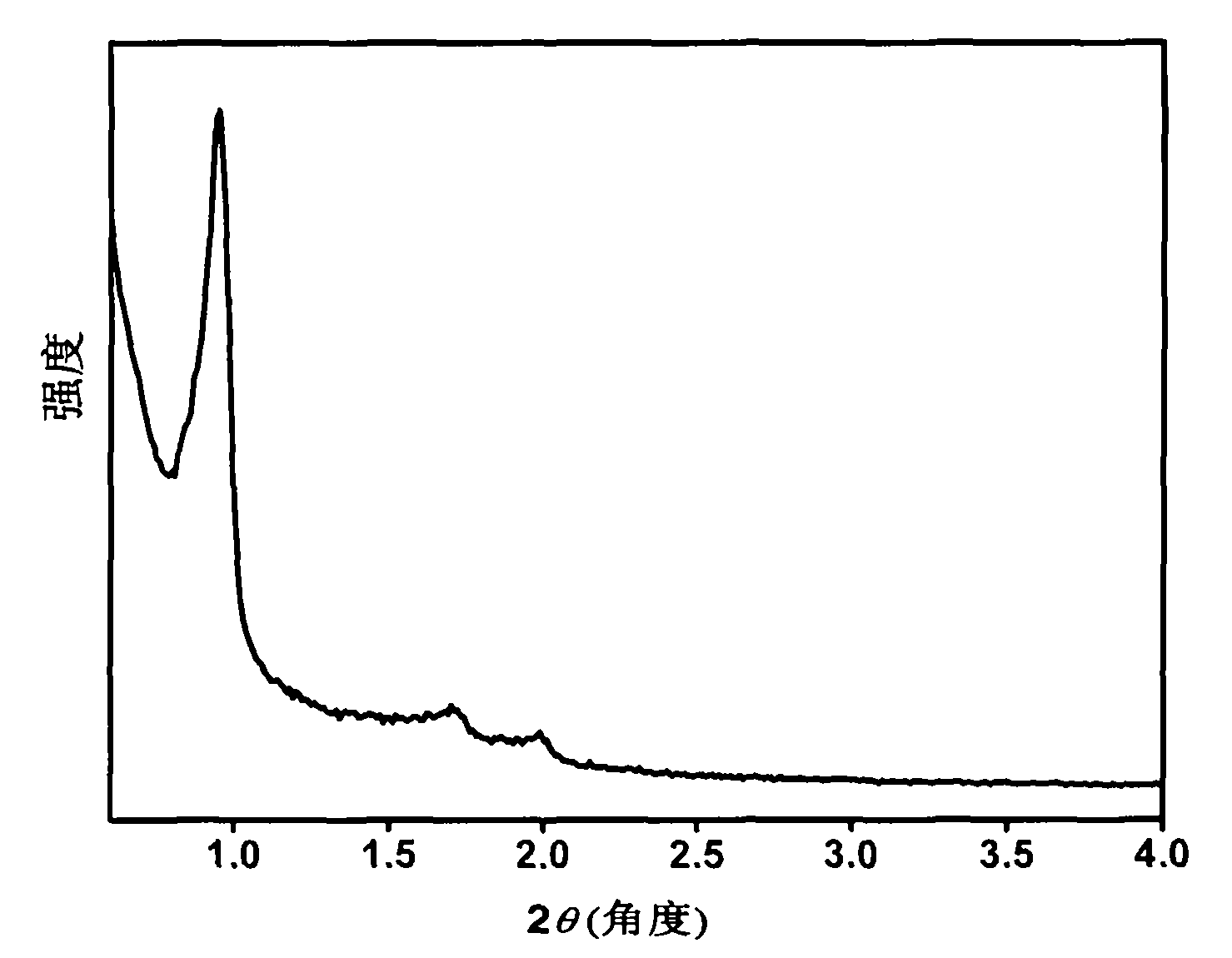

Crystallized mesoporous zinc silicate/silicon oxide composite powder and preparation method thereof

InactiveCN103232043AThe reaction raw materials are simpleLow costSilicon oxidesInorganic saltsRoom temperature

The invention discloses crystallized mesoporous zinc silicate / silicon oxide composite powder and a preparation method thereof. The composite powder is of a two-dimensional hexagonal mesoporous structure and the mesoporous wall is composed of crystalline zinc silicate and amorphous silicon oxide. The preparation method comprises the following steps of firstly preparing mesoporous silicon oxide and dissolving the inorganic salt of zinc in ethanol to prepare a zinc salt solution; adding the mesoporous silicon oxide in the zinc salt solution according to compositions of the prepared powder, wherein the molar ratio of the mesoporous silicon oxide to the zinc salt is 2-25; uniformly dispersing the mesoporous silicon oxide into the zinc salt solution through fully stirring; and in the meantime, continuing stirring at room temperature, volatilizing the ethanol to obtain powder and obtaining the crystallized mesoporous zinc silicate / silicon oxide composite powder via vacuum drying and calcination. The preparation method is simple and convenient in operation; and the prepared mesoporous zinc silicate / silicon oxide composite powder is high in order degree, large in pore size and specific surface area, high in crystallinity and good in stability.

Owner:INNER MONGOLIA UNIVERSITY

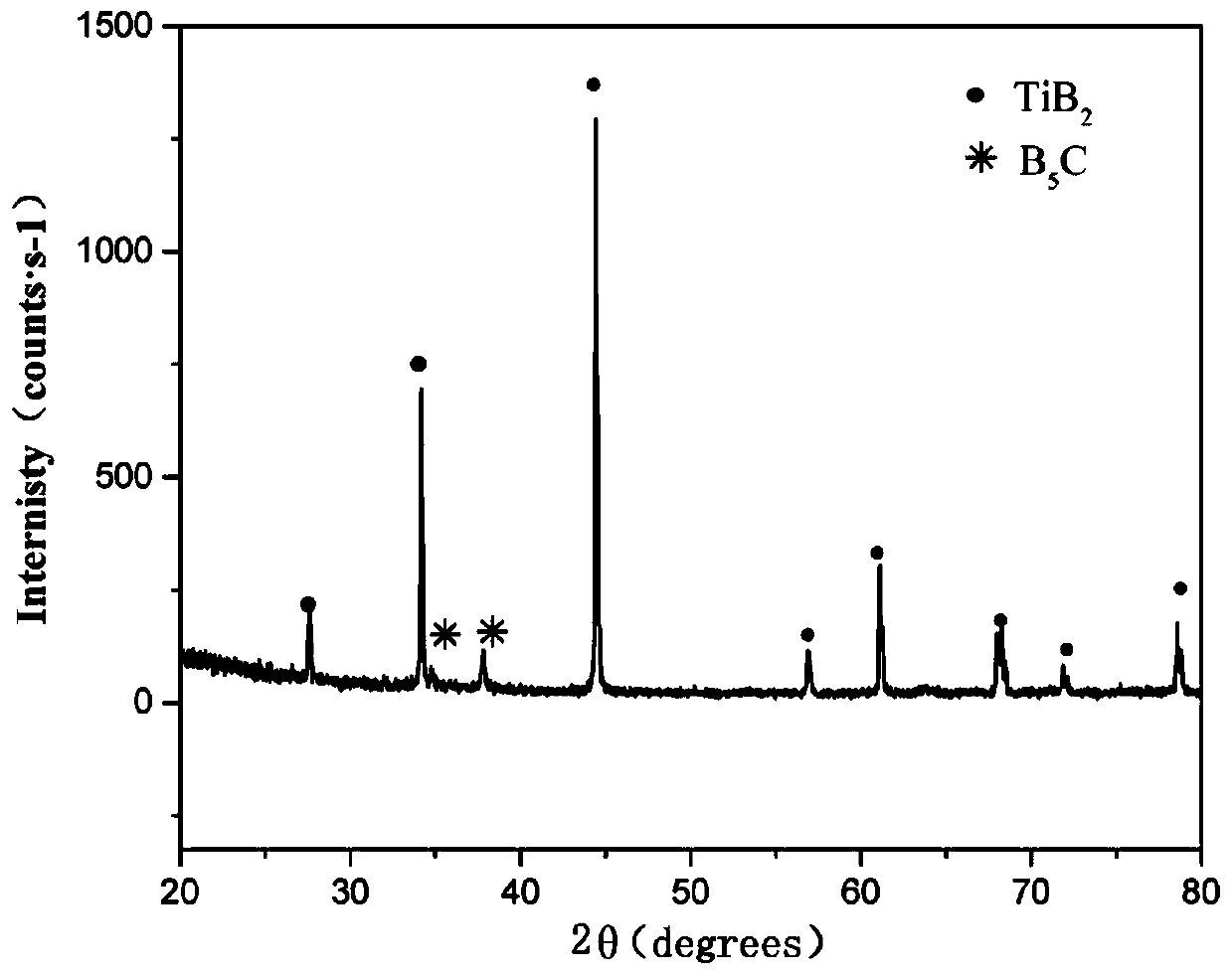

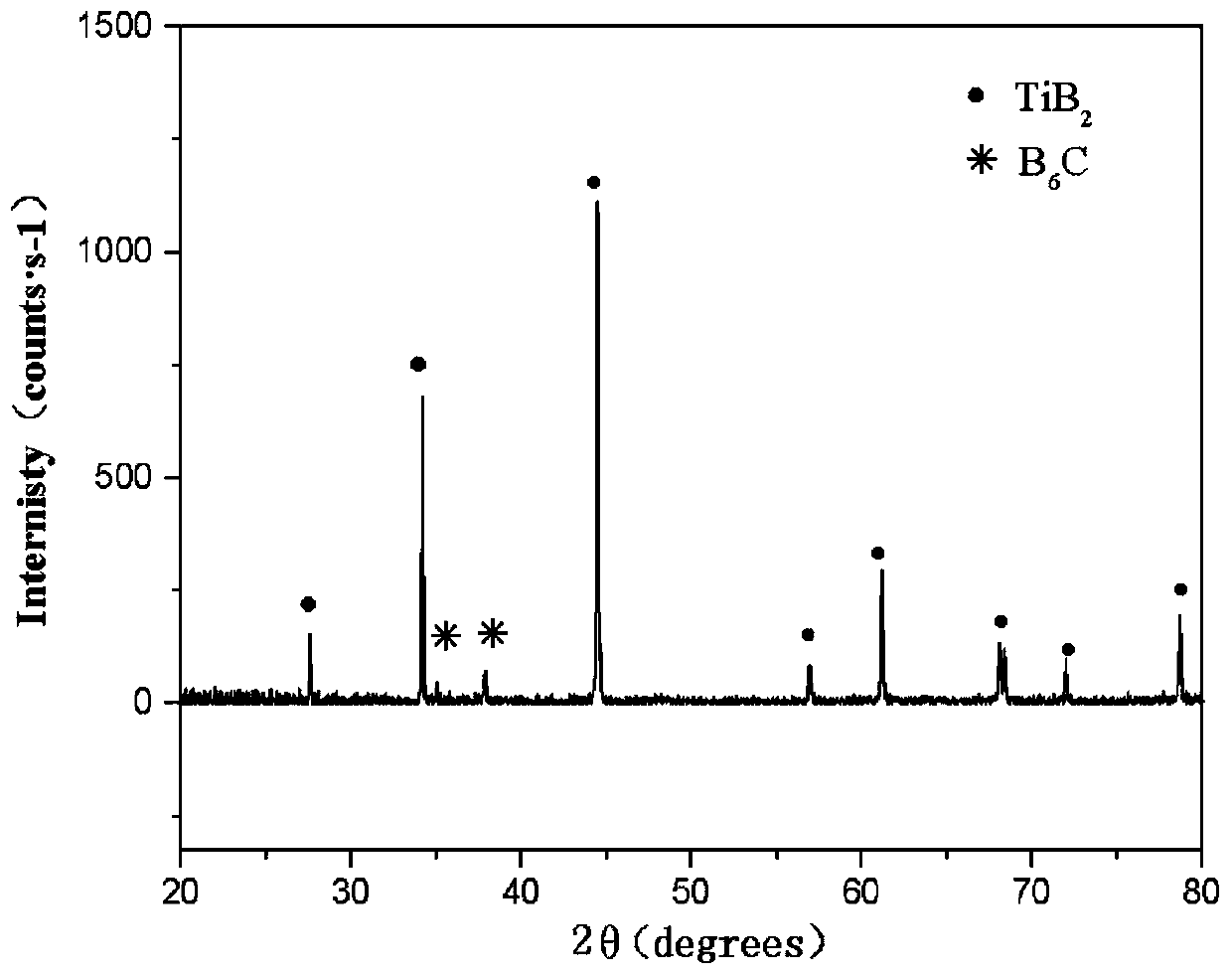

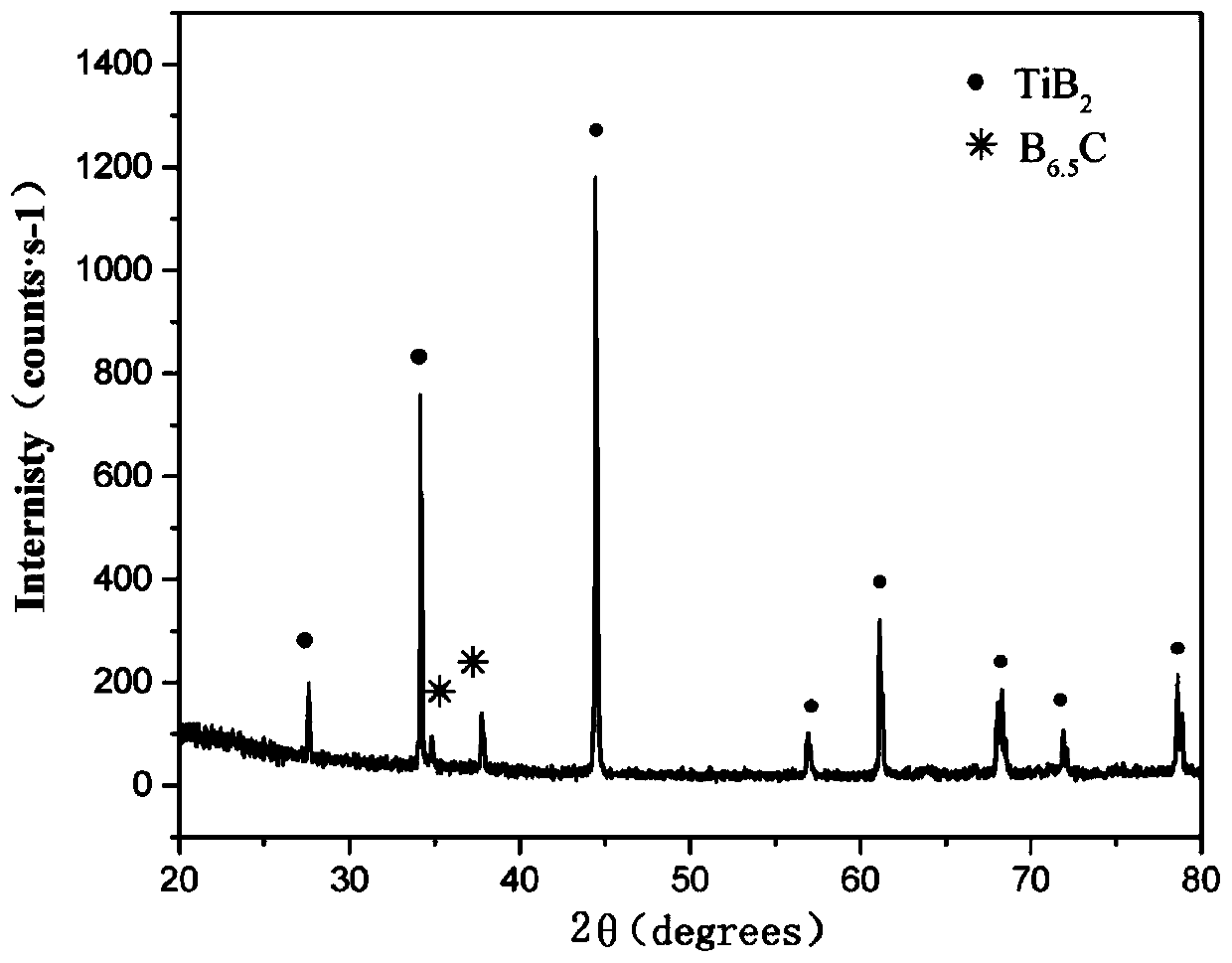

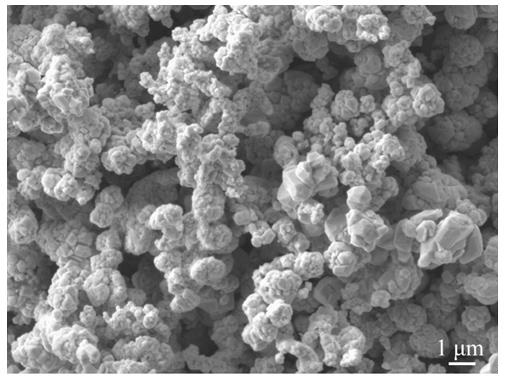

Fine-grain boron-rich boron carbide-based composite ceramic material and preparation method thereof

The invention relates to a fine-grain boron-rich boron carbide-based ceramic composite material and a preparation method thereof, the main phases are boron-rich boron carbide and titanium boride, thetitanium boride is dispersed in the boron-rich boron carbide, the boron-rich boron carbide and titanium boride phases are uniformly distributed, and no crack exists between crystal grains. The fine-grain boron-rich boron carbide-based composite ceramic material is prepared from 39.5%-44.3% of titanium carbide powder and 55.7%-60.5% of boron powder in percentage by mass through spark plasma sintering of mixed powder of the titanium carbide powder and the boron powder. The boron-rich boron carbide-titanium boride ceramic composite material provided by the invention has uniform grain size and phase distribution, and the boron carbide-carbon ratio is large and convenient to regulate and control, the material has high density and excellent performance.

Owner:WUHAN UNIV OF TECH

Method for preparing silicon carbide bonded silicon nitride composite material by using microwave sintering process

InactiveCN104177087AFast heatingFacilitated solid phase diffusionCarbide siliconCarboxymethyl cellulose

The invention relates to a method for preparing a silicon carbide bonded silicon nitride composite material by using a microwave sintering process. The method is characterized by comprising the following steps: mixing the following components in percentage by weight: 50-80 percent of silicon carbide particles, 5-25 percent of silicon carbide powder, 5-30 percent of silicon powder, 1-4 percent of carboxymethyl cellulose and 1-5 percent of water, and molding; putting a molded blank body into a vacuum microwave sintering furnace, vacuumizing until the pressure intensity in the microwave sintering furnace is less than or equal to 20Pa, filling nitrogen, and sintering for 0.5-5 hours in a nitrogen atmosphere at 1300-1600 DEG C so as to obtain the silicon carbide bonded silicon nitride composite material. The method is short in production cycle and high in production efficiency; and the prepared silicon carbide bonded silicon nitride composite material is uniform in phase distribution and relatively high in strength, and has excellent thermal shock resistance, oxidation resistance, high-temperature creep resistance and erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

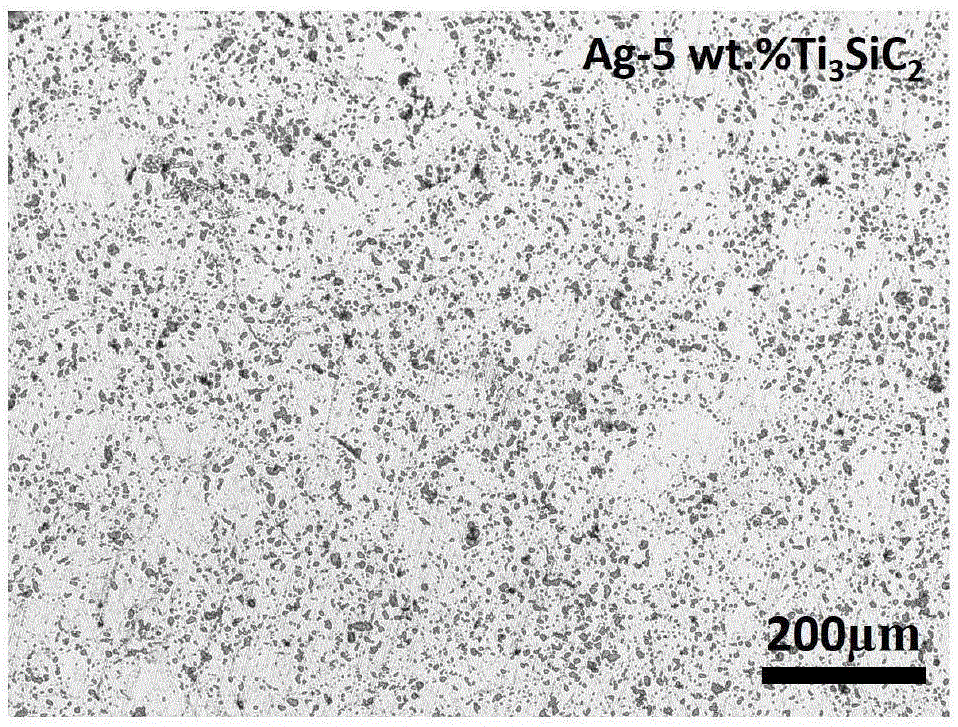

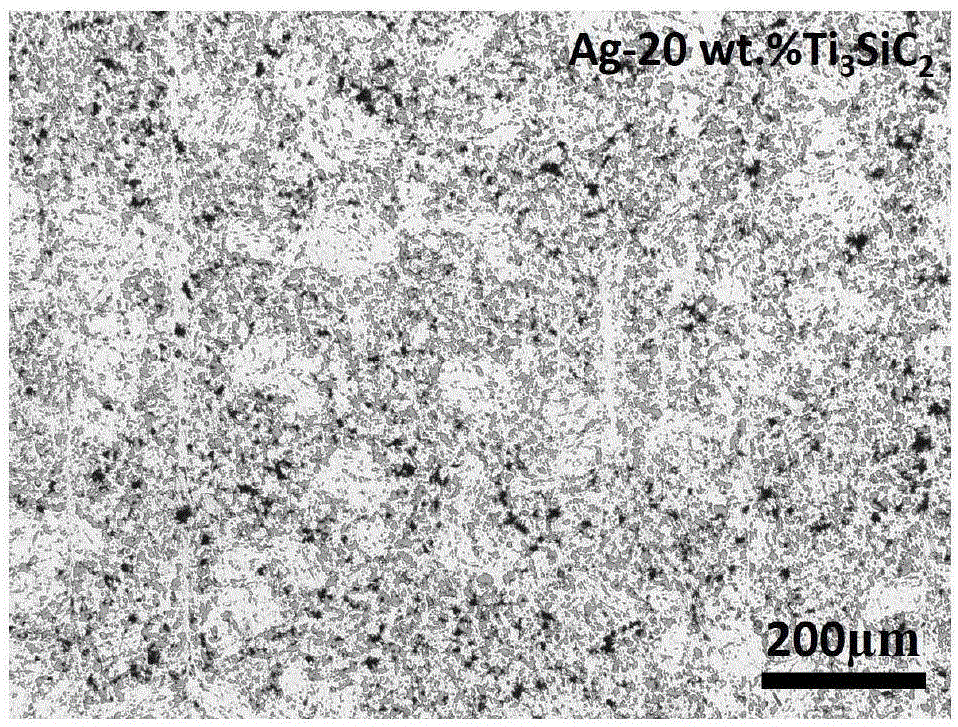

Preparation method of Ti3SiC2 reinforced Ag-based electric contact material

The invention discloses a preparation method of a Ti3SiC2 reinforced Ag-based electric contact material. The preparation method is characterized in that the composite material consists of a Ti3SiC2 reinforced phase and an Ag matrix, wherein the mass percentage of Ti3SiC2 is 1-40%. The preparation method comprises the following specific preparation steps: weighing Ti3SiC2 powder and Ag powder in proportion; then ball-milling and mixing for 5-120 minutes by a wet process; after drying the powder, molding the powder under the pressure of 100-800 MPa in a cold pressing manner to obtain a green body; and then sintering the green body for 1-12 hours at the temperature of 700-1,100 DEG C in an inert atmosphere or a vacuum environment, and cooling in a furnace to obtain the Ti3SiC2 reinforced Ag-based electric contact composite material. The Ag-based composite material prepared by the preparation method is uniform in structure, high in compactness and excellent in conductivity. Moreover, the method is simple in process, low in cost and environmentally friendly, and has great significance on preparation of high-performance electric contact materials.

Owner:SOUTHEAST UNIV

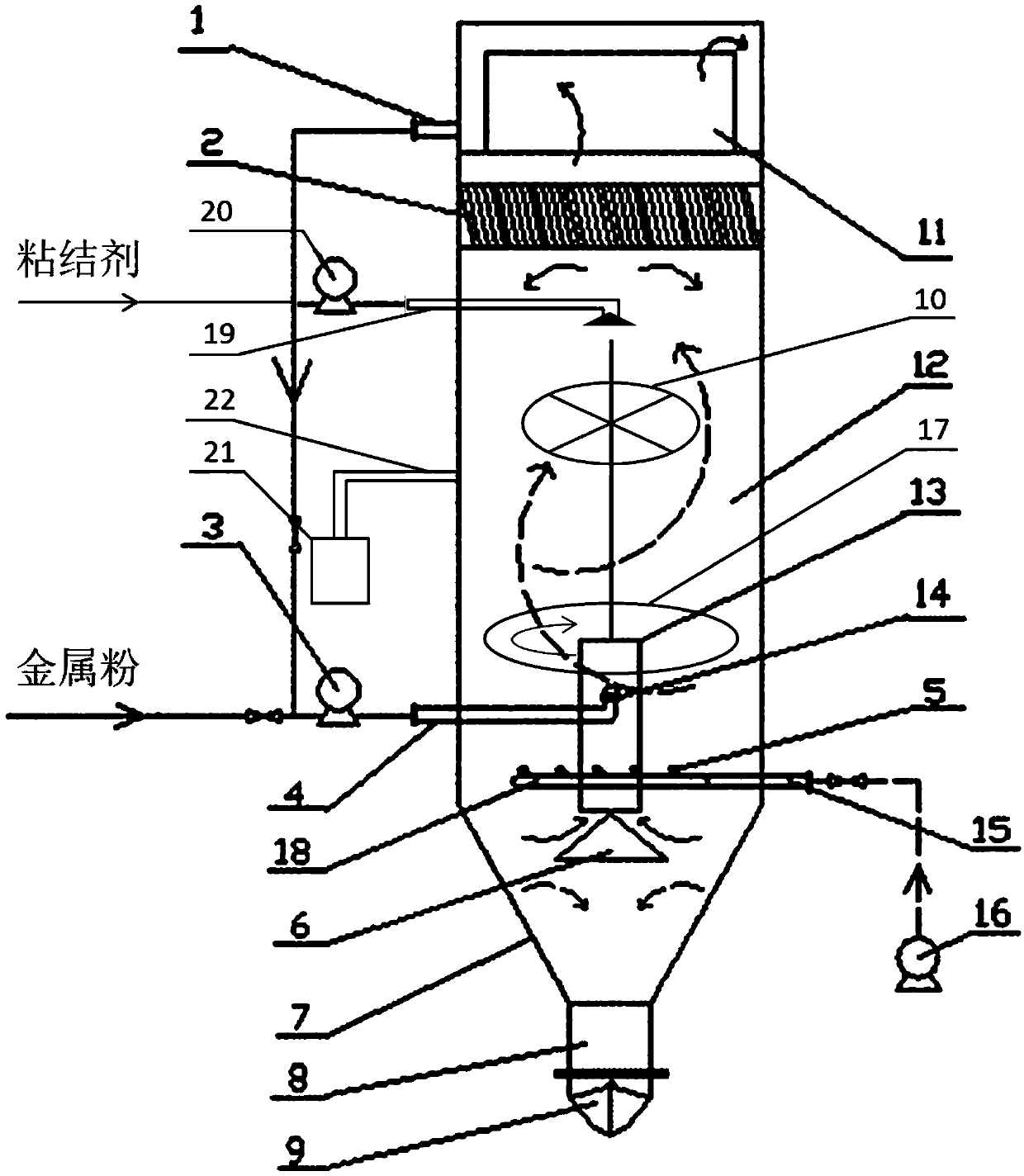

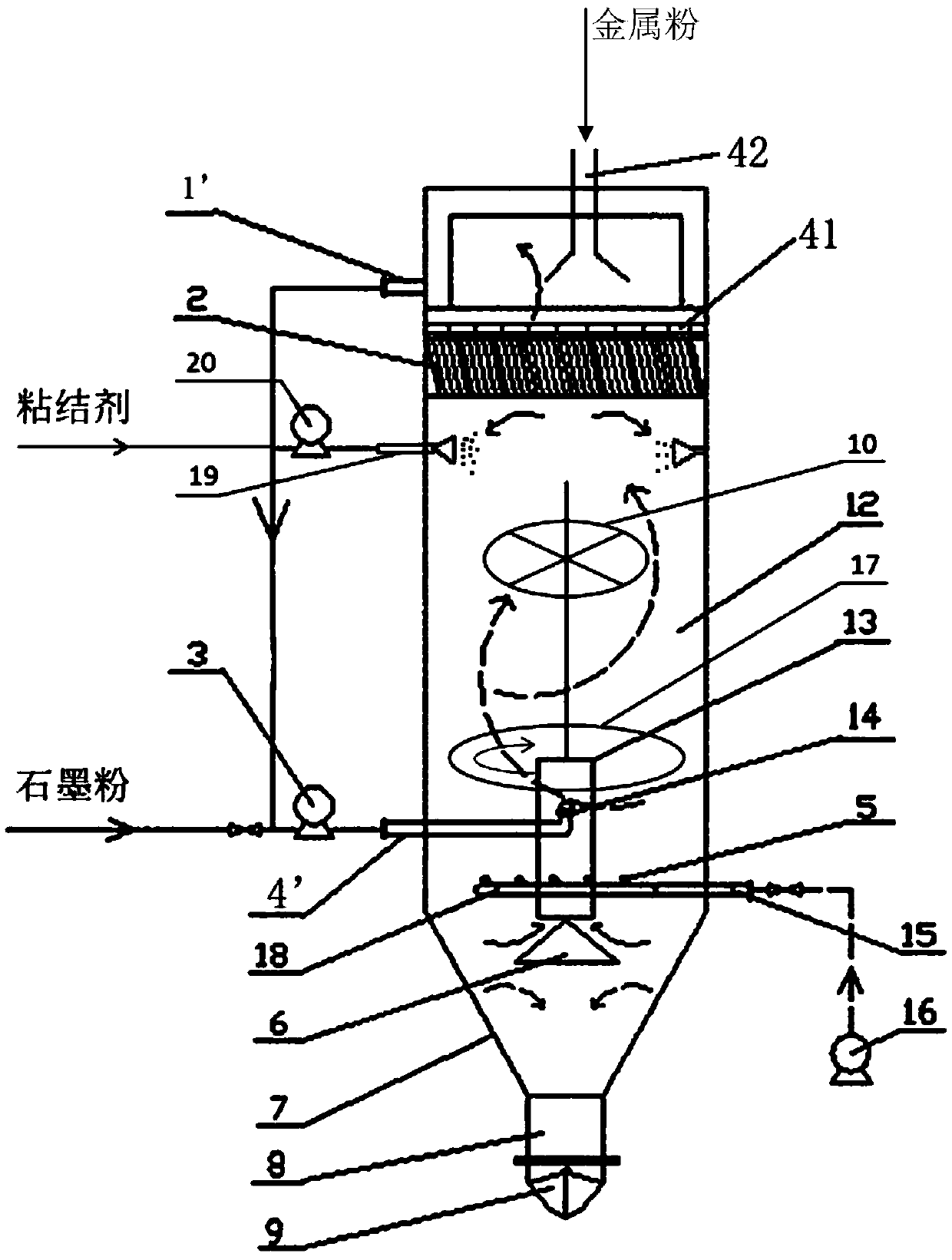

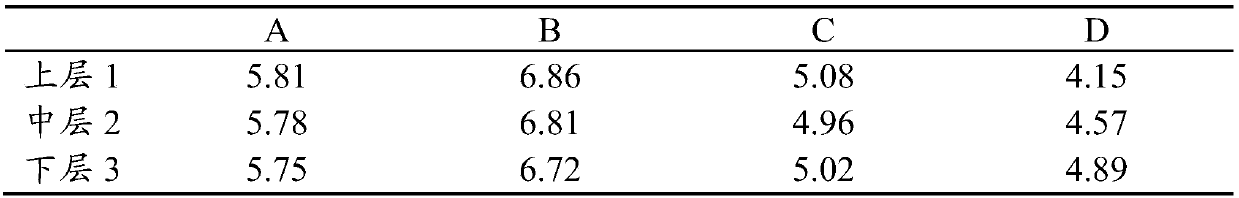

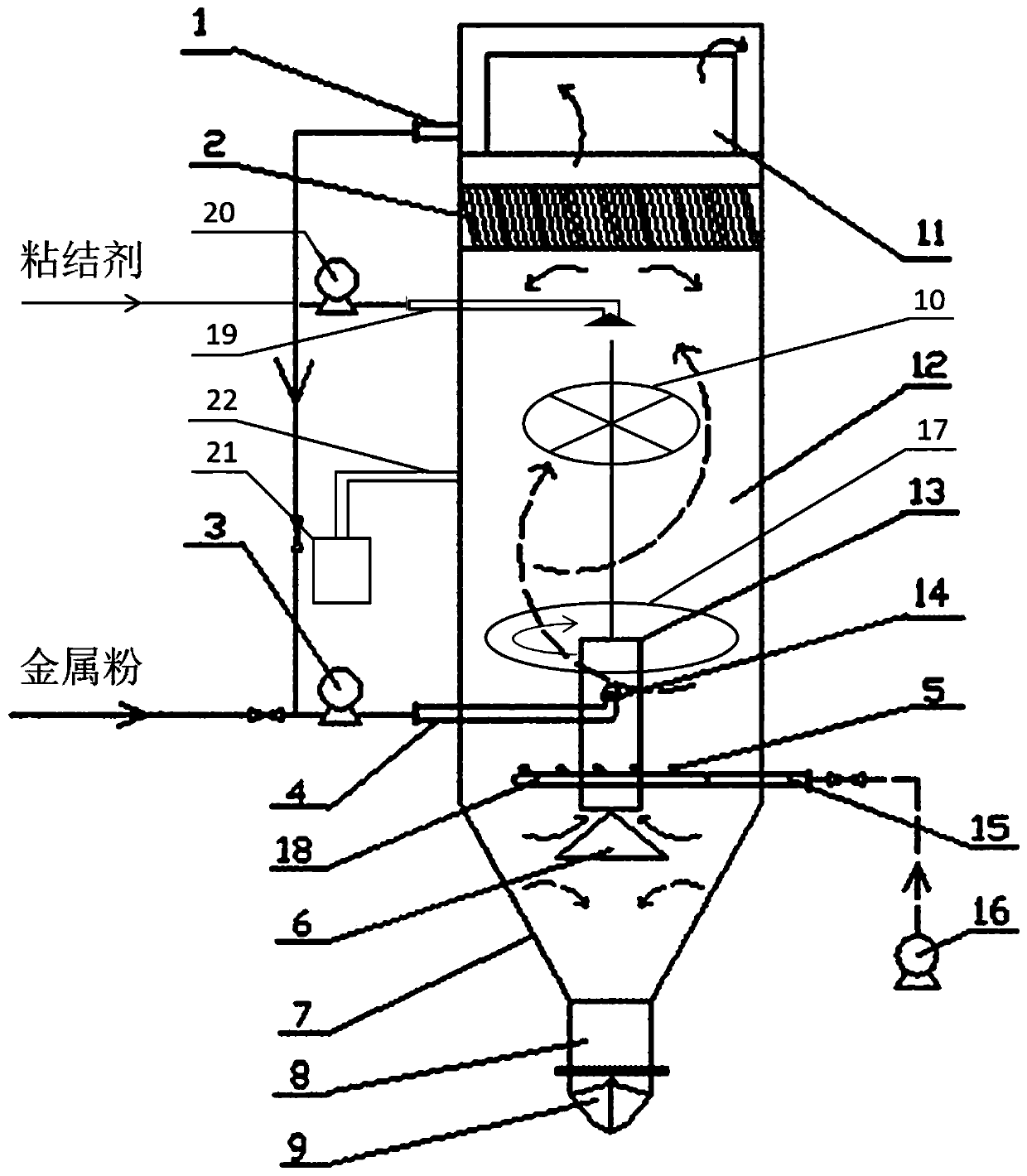

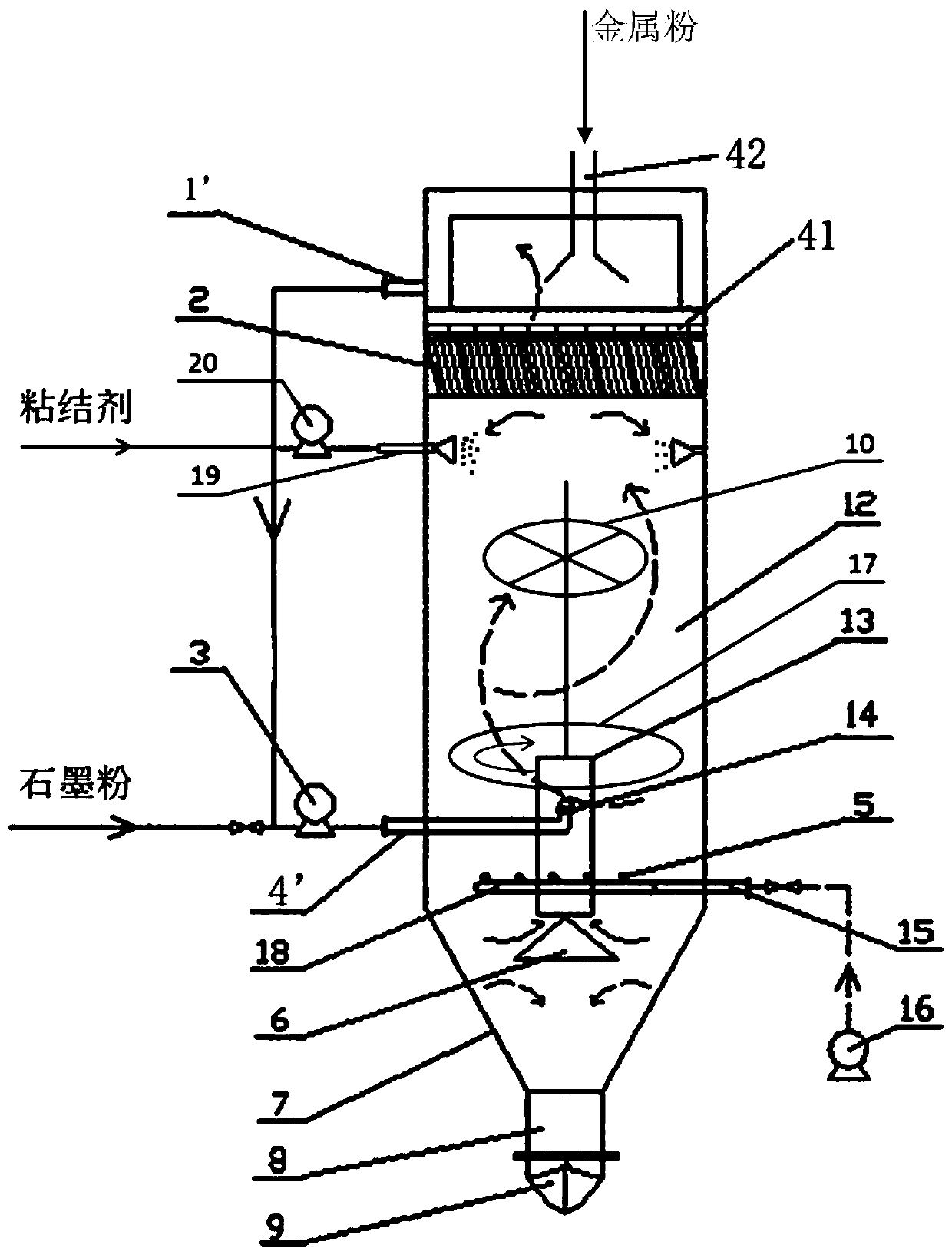

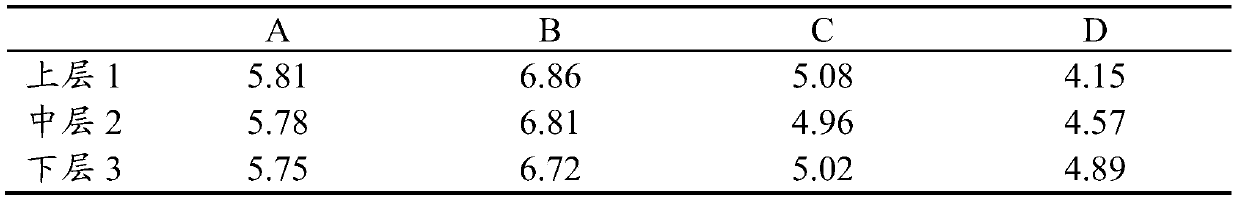

General suspension granulation method for preparing sintered metal-graphite composite

ActiveCN109622946AFix unstable performanceExtended service lifeTransportation and packagingMetal-working apparatusPrillCritical dimension

The invention relates to a general suspension granulation method for preparing a sintered metal-graphite composite. The general suspension granulation method includes the steps that graphite particlesare suspended in an air flow with a fluidized chamber; binder solutions are introduced into the fluidized chamber; metal powder is introduced into the fluidized chamber; and after preset fluidizationtime, the graphite particles adhere to the metal powder through binders to form core particles. By adjusting the fluidization air pressure and the fluidization time, each graphite particle can adhereto a metal layer with a certain thickness to obtain the core particles with a predetermined critical dimension. At the moment, above the critical dimension, because the fluidized air flow cannot support the gravity of the core particles, the core particles fall and are collected in a material bin at the bottom of a bed body. The method is high in universality and can be applied to raw material granulation processes of a variety of metal-graphite composite products, the phases of subsequent objects manufactured by the obtained composite powder core are uniformly distributed, density is uniform, and mechanical properties are good.

Owner:UNIV OF SCI & TECH BEIJING

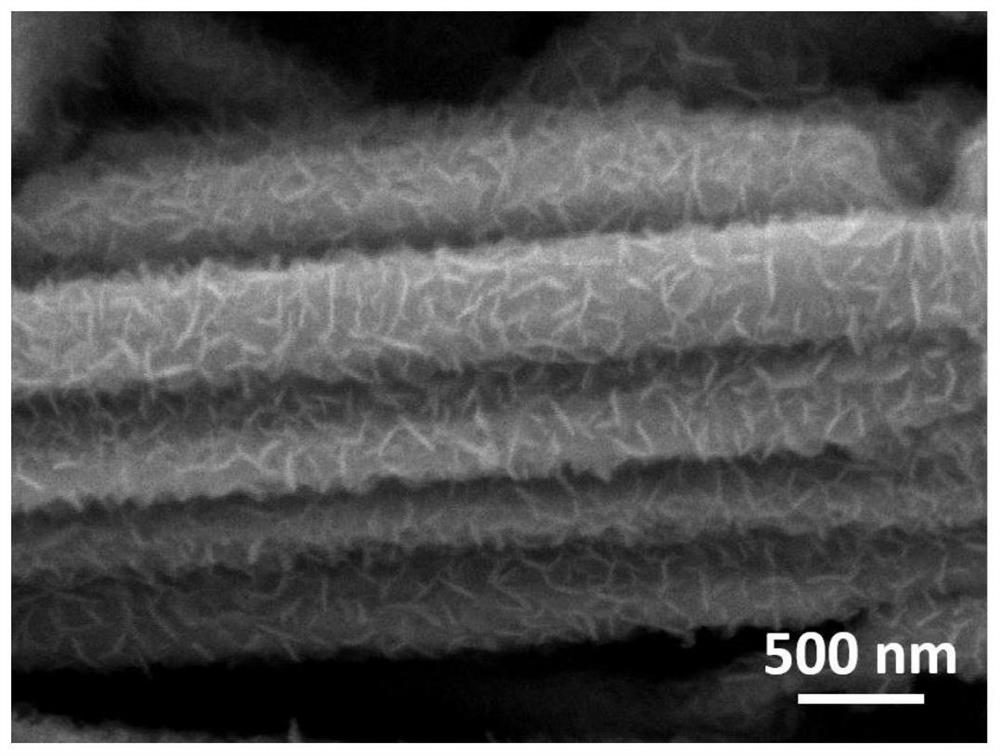

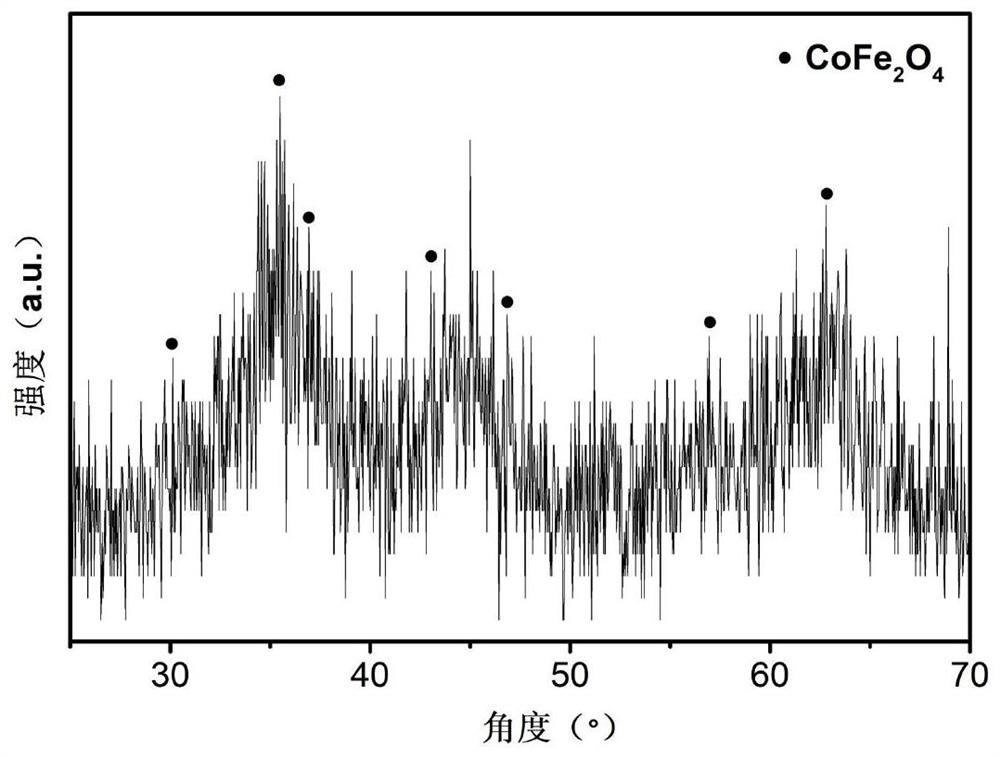

Preparation method and application of spinel type oxide catalyst

PendingCN111841543AReduce manufacturing costRapid coolingMetal/metal-oxides/metal-hydroxide catalystsElectrodesAir atmospherePtru catalyst

The invention discloses a preparation method of a spinel type oxide catalyst. One or two transition metals of cobalt, iron, nickel, manganese, copper, chromium and zinc and aluminum are jointly heatedto a molten state by adopting a vacuum induction melting furnace, cooling is performed to obtain a rod-shaped alloy ingot, a vacuum melt-spinning device is employed for melting for blow casting intoa corresponding alloy strip, carrying out dealloying treatment on the alloy strip in an alkaline solution to obtain a dealloyed product, and in order to improve the crystallinity and stability of thematerial, the dealloyed product is placed in a tubular furnace for high-temperature annealing treatment in an air atmosphere, thus obtaining the spinel type oxide catalyst. The invention also relatesto application of the electrode material. The obtained catalyst has a multi-metal mixed valence state, can significantly enhance the conductivity of the material, shows good electrocatalytic activityto oxygen evolution reaction (OER) and oxygen reduction reaction (ORR) in an alkaline environment, has good stability, and can be used as a cathode catalyst of a chargeable and dischargeable metal-airbattery.

Owner:ZHONGBEI UNIV

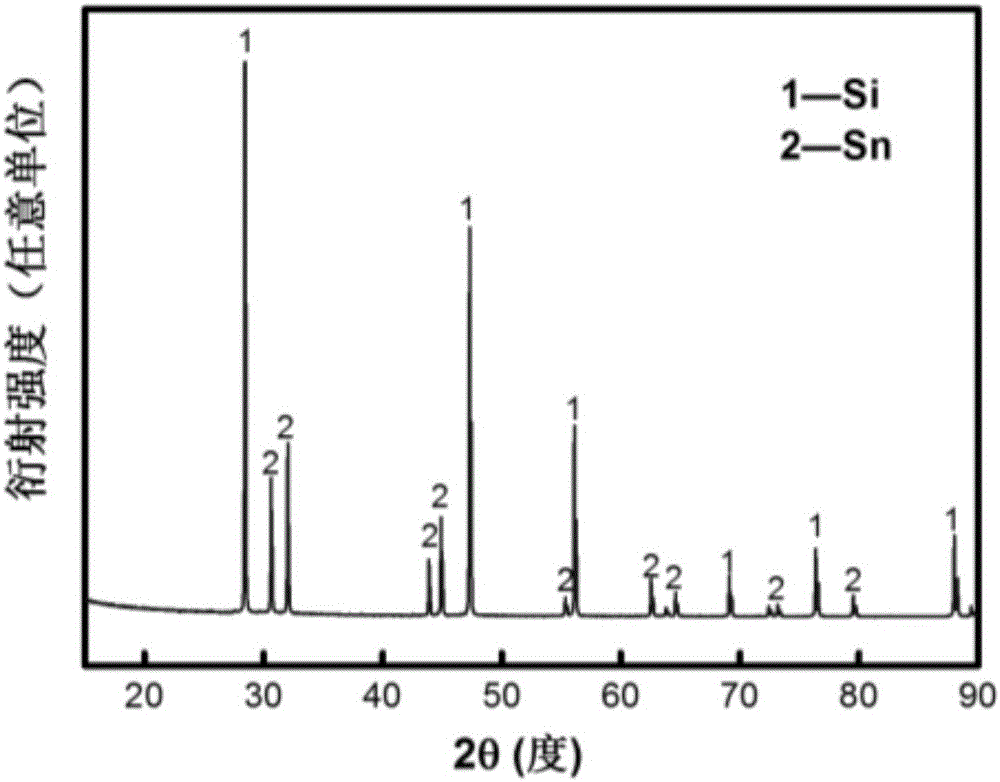

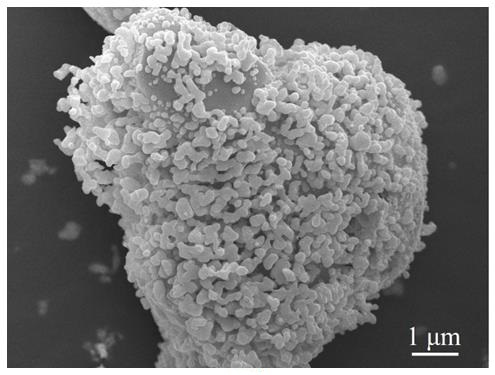

Preparation method of Sn-Si alloy-type nano-composite powder

ActiveCN105720249ASimple process routeShort processCell electrodesSecondary cellsEvaporationControllability

The invention provides a preparation method of Sn-Si alloy-type nano-composite powder, and belongs to the field of novel functional materials. The method comprises the following steps: firstly, carrying out mass proportioning on high-purity Sn and high-purity Si blocks at a certain stoichiometric ratio; carrying out smelting in a vacuum induction melting furnace to obtain an Sn-Si alloy block material; and carrying out electric arc evaporation on the obtained block material in an inert gas environment to prepare the Sn-Si alloy-type nano-composite powder. The average particle sizes of the Sn-Si alloy-type nano-composite powder particles obtained by the method are in nanoscale; and the method is simple and feasible in process route, short in synthesis period and high in controllability of technical parameters.

Owner:BEIJING UNIV OF TECH

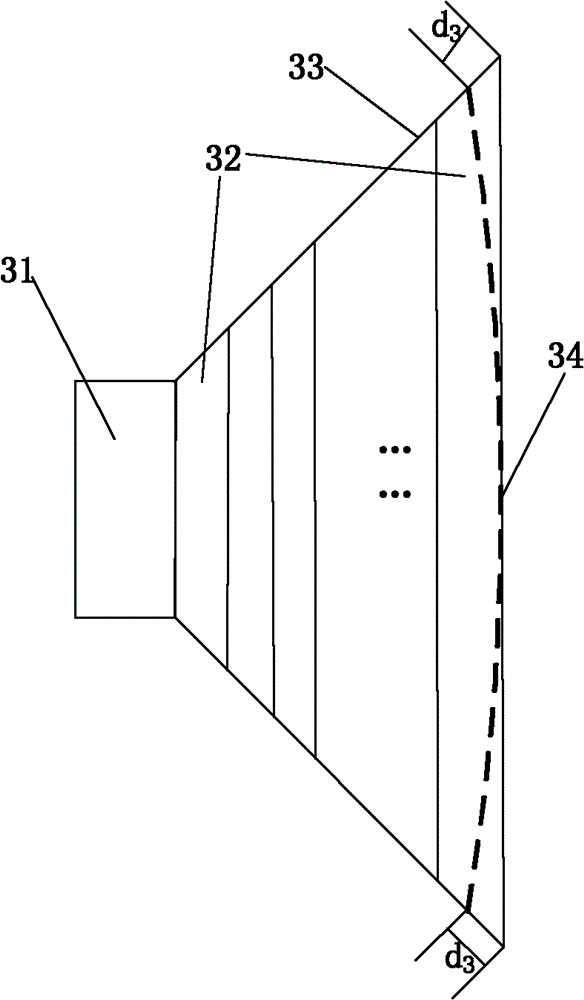

Horn antenna device

InactiveCN102751576AUniform phase distributionReduce reflectionWaveguide hornsMiniaturizationImpedance matching

The invention provides a horn antenna device which comprises an electromagnetic wave waveguide and a horn and further comprises an uneven metamaterial filled in a horn. The uneven metamaterial is formed by laminating a plurality of sheets of even metamaterial sheet layers, and each sheet layer comprises a sheet-shaped substrate and a plurality of porous microstructures arranged on the substrate. The porous microstructures on each substrate are arranged to be different to enable the impedance values of the uneven metamaterial to be gradually increased from the electromagnetic wave waveguide position to a horn mouth, accordingly the impedance of the waveguide is changed, the gradual increasing or gradual descending of waveguide impedance is achieved, further impedance matching is achieved, reflection is reduced, and the aim of minimizing the horn antenna is achieved. Moreover, compared with extremely long small field angle horn antennas in the prior art, the horn antenna device has the advantage that phase distribution of horn diameter of the minimized horn antenna is more even.

Owner:KUANG CHI INST OF ADVANCED TECH +1

Corundum-calcium hexaluminate based on aluminum chromium slag and preparation method thereof

The invention relates to corundum-calcium hexaluminate based on aluminum chromium slag and a preparation method thereof. The corundum-calcium hexaluminate is characterized in that aluminum chromium slag and carbon powder are put into a ball mill according to the mass ratio of 100:(0.7 to 1.2); the ball milling is performed to reach the granularity being smaller than or equal to 100 mu m to obtainball milling powder materials; the ball milling powder materials and limestone are mixed for 0.5 to 1 hours according to the mass ratio of 100:(8 to 13) to obtain mixed powder; the mixed powder is added into a vacuum electric arc furnace; the temperature is raised to 1950 to 2050 DEG C; heat insulation is performed for 1 to 2 hours; then, the temperature is lowered to 1800 to 1850 DEG C; heat insulation is performed for 3 to 5 hours; the cooling is performed along with the furnace; the corundum-calcium hexaluminate based on aluminum chromium slag is obtained; the corundum-calcium hexaluminatebased on aluminum chromium slag is a greyish-white product at the upper part of the vacuum electric arc furnace. The corundum-calcium hexaluminate has the characteristics that the process is simple; the production cost is low; the high-quality raw material resources are saved; the environment pollution is reduced; the prepared products have high purity and uniform material phase distribution.

Owner:WUHAN UNIV OF SCI & TECH +1

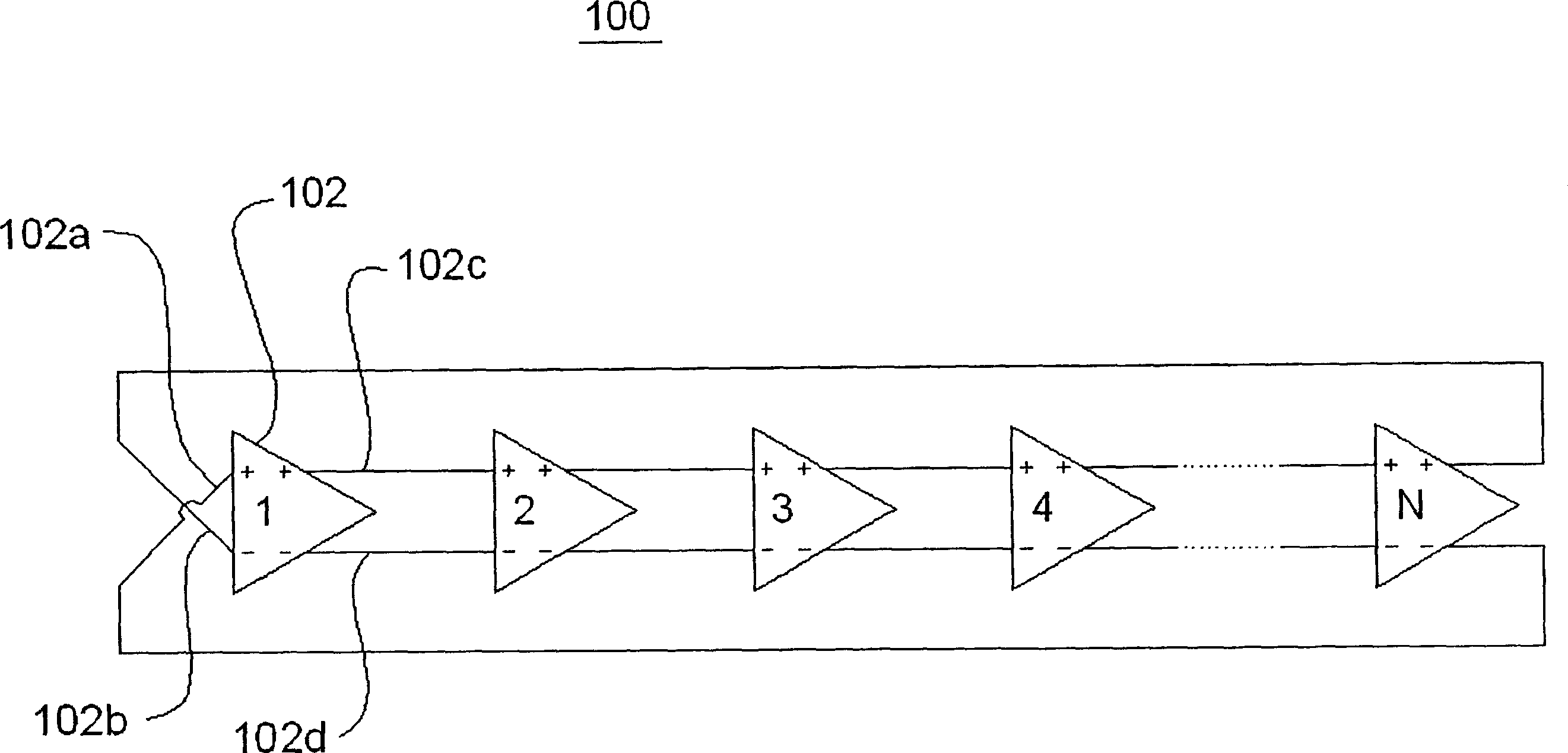

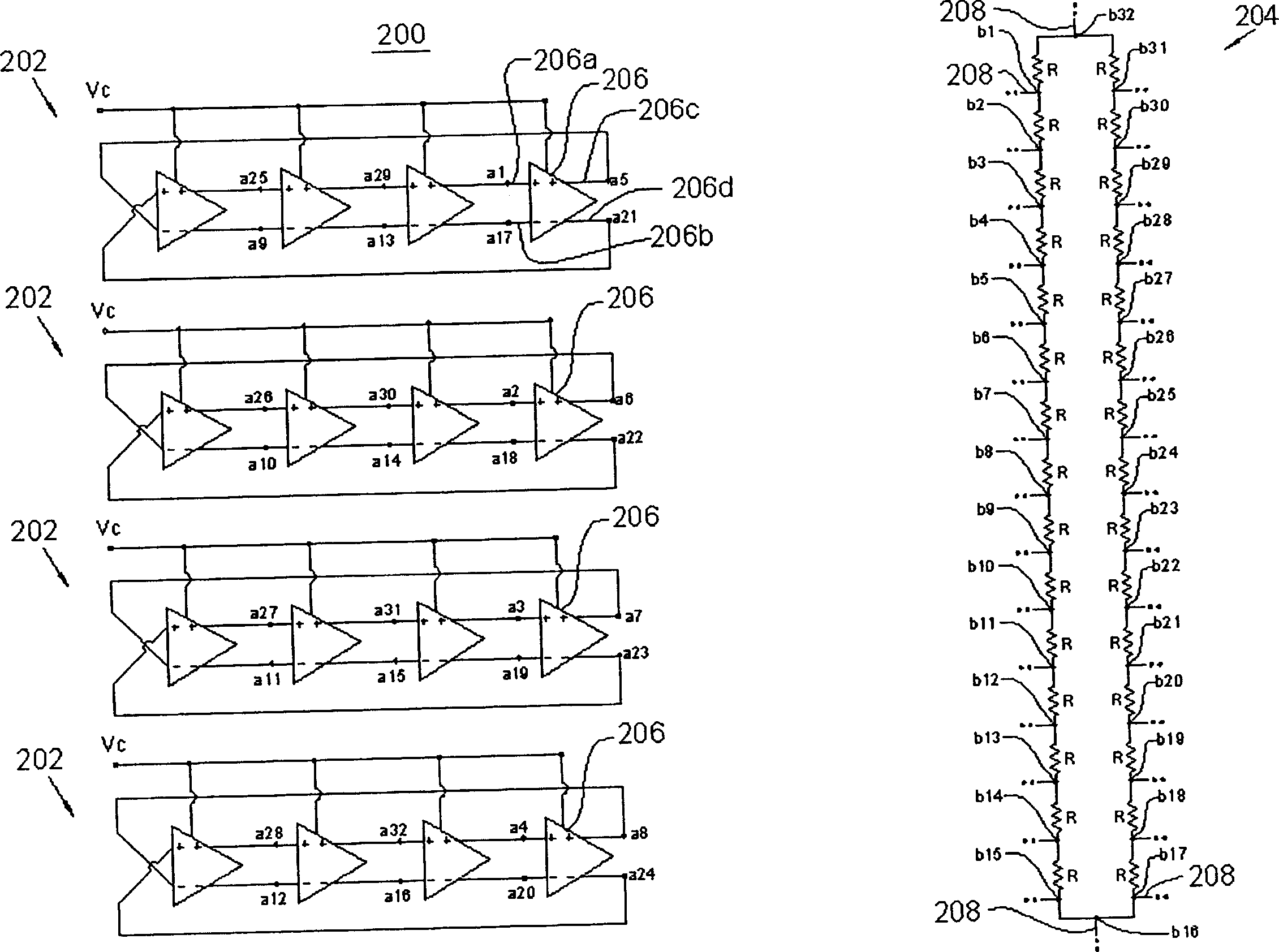

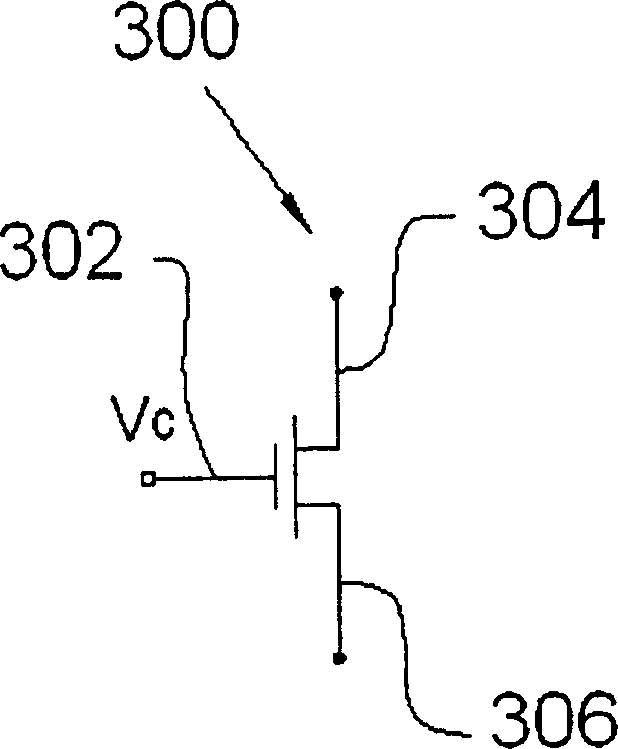

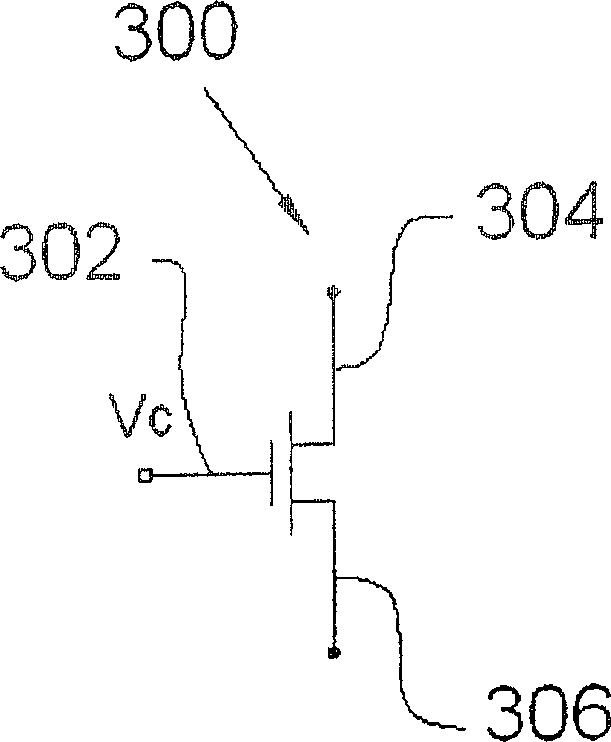

Multi-phase voltage control oscillator

ActiveCN1773841AIncrease the number ofUniform phase distributionOscillations generatorsPhase differenceVoltage control

A oscillator of multiphase voltage control consists of a ring oscillation unit formed by series- connecting a numbers of phase delay components and a resistance ring formed by series ¿C connecting a numbers of resistance components. Its features that series ¿C connected node in each ring oscillation unit is electric ¿C connected to series ¿C connected node in resistance ring to let ring oscillation unit generate a numbers of oscillating signals with uniform phase difference.

Owner:REALTEK SEMICON CORP

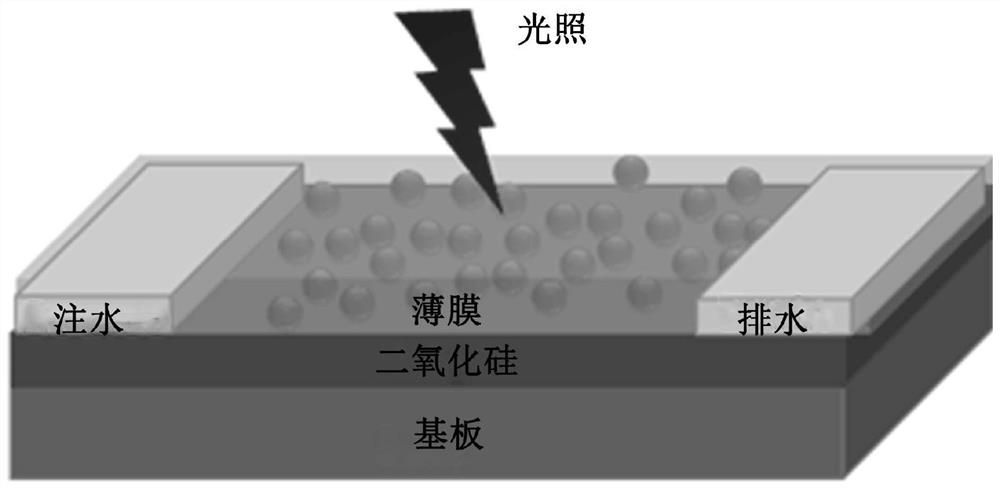

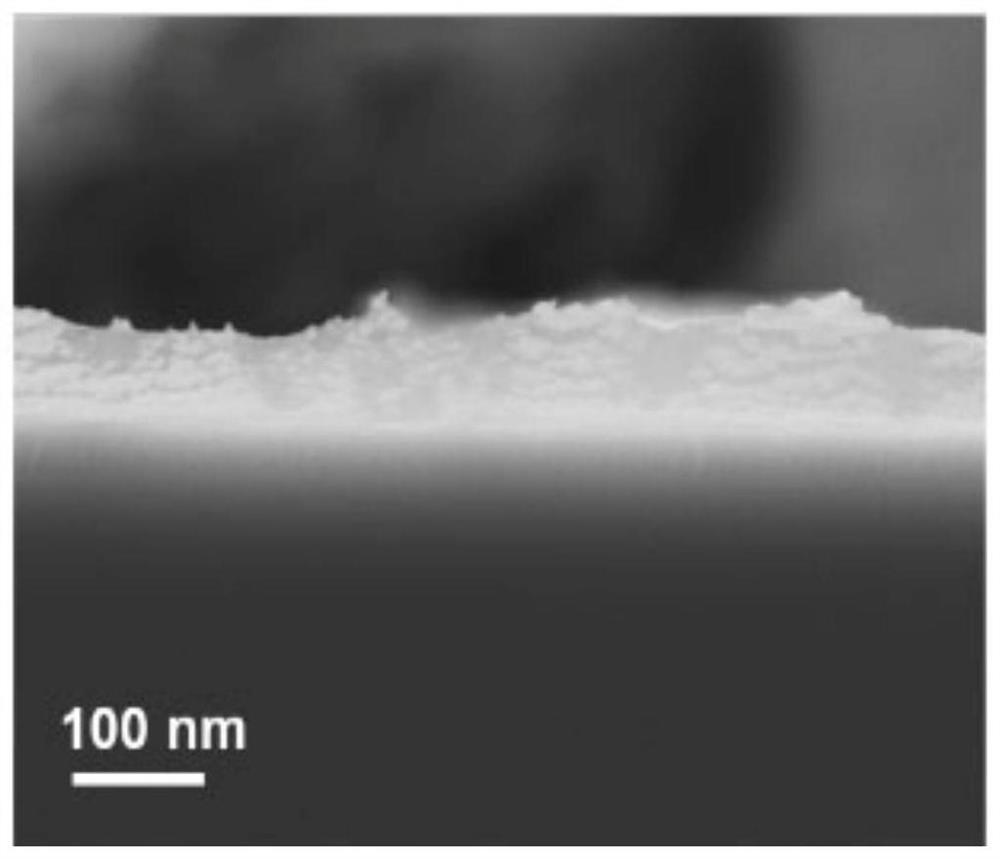

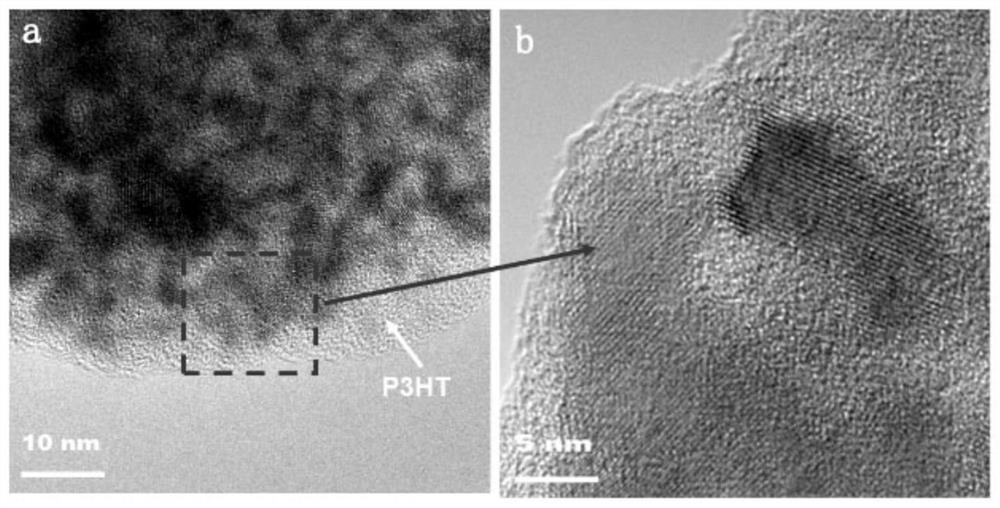

Hybrid phototransistor constructed by poly (3-hexylthiophene) and mercury telluride quantum dots and preparation method and application thereof

InactiveCN111640875AImprove response speedQuick responseFinal product manufactureSolid-state devicesLow noiseChemical physics

The invention discloses a hybrid phototransistor constructed by poly (3-hexylthiophene) and mercury telluride quantum dots as well as a preparation method and application thereof. According to the invention, DMF is used as a reaction solvent, so that aggregation of QDs is reduced to the greatest extent, and the QDs are kept in a good dispersion state in a solution; ligands such as DPE, TEA and FMTare used for controlling nucleation, growth, morphology, fluorescence property and stability of QDs; the low-temperature stage is a nucleation stage of QDs, small QDs are generated, then growth is started in the process of raising the temperature to the room temperature, and finally the emission band is reached in the high-temperature stage; then, the HgTe QDs are purified; ligand exchange is performed; the HgTe QDs are purified; HgTe QDs are dissolved in methylbenzene to form a solution, so that quantum dot polymerization before film deposition is inhibited; p3HT is directly added into the prepared HgTe QDs solution to prepare a P3HT: HgTe QDs solution, and a P3HT: HgTe QDs phototransistor is obtained after deposition and washing in S11 and S12. The phototransistor provided by the invention has excellent response speed, high sensitivity and low noise level at the same time.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

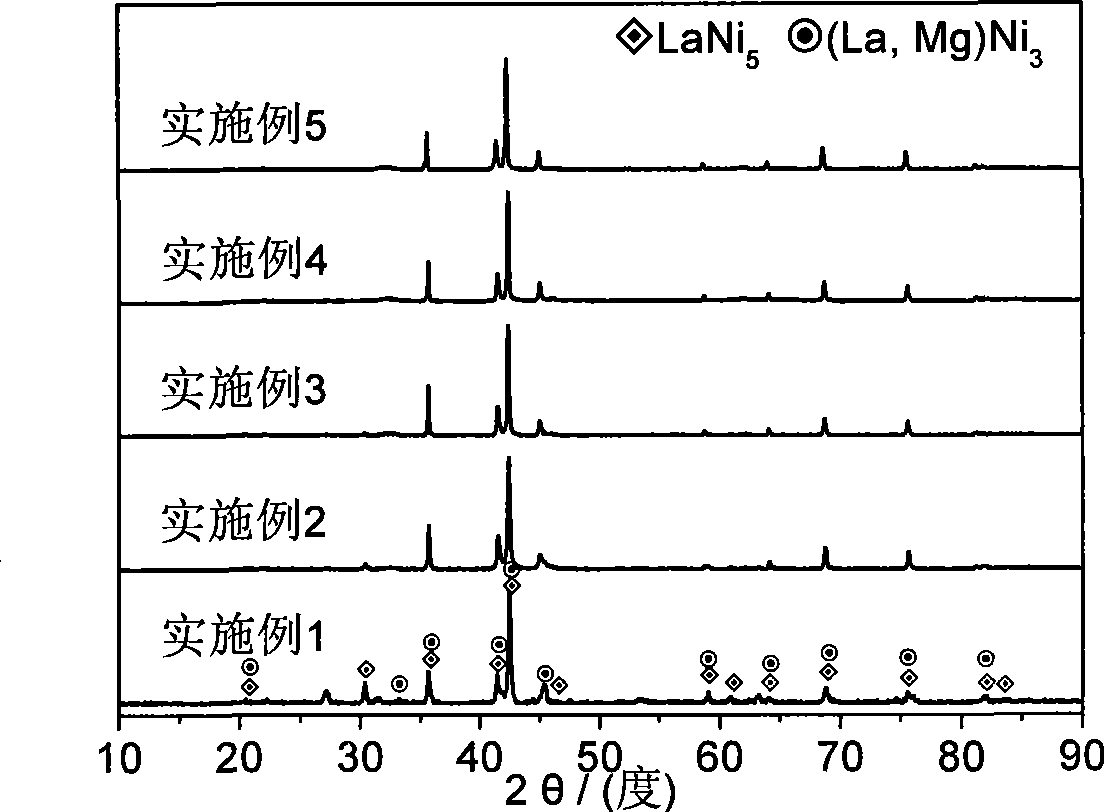

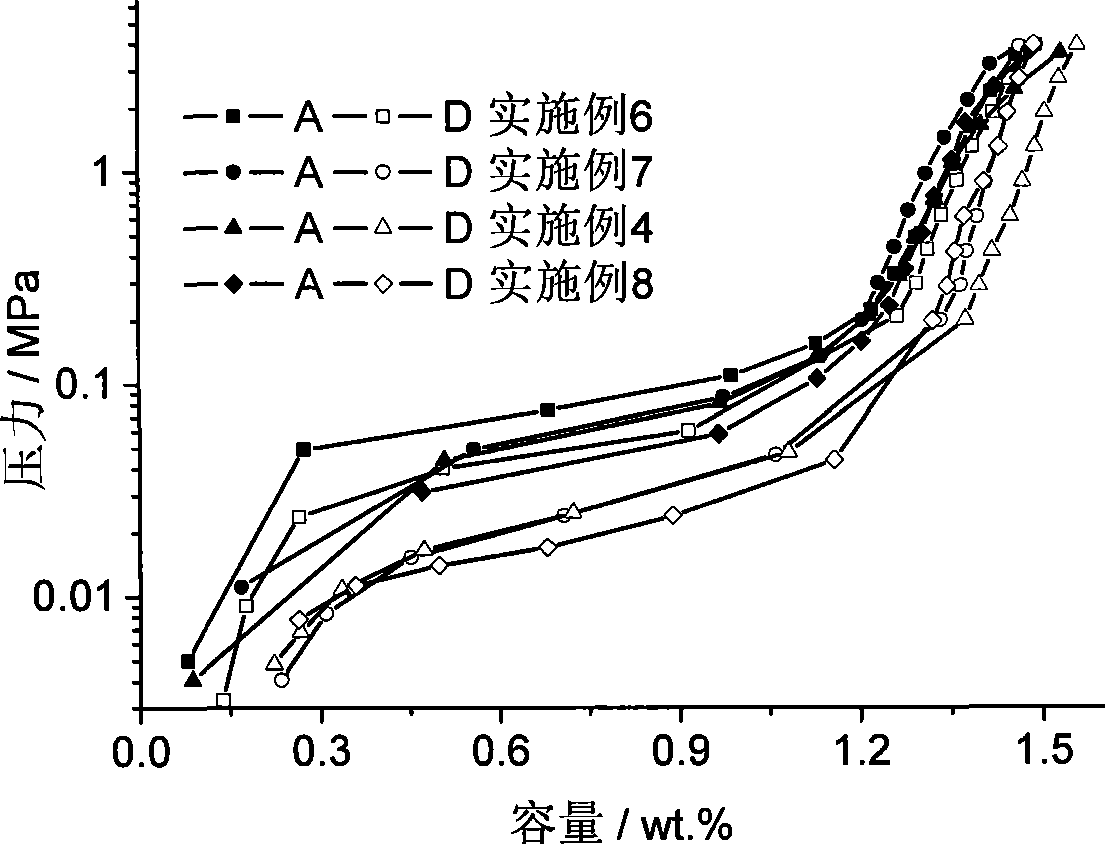

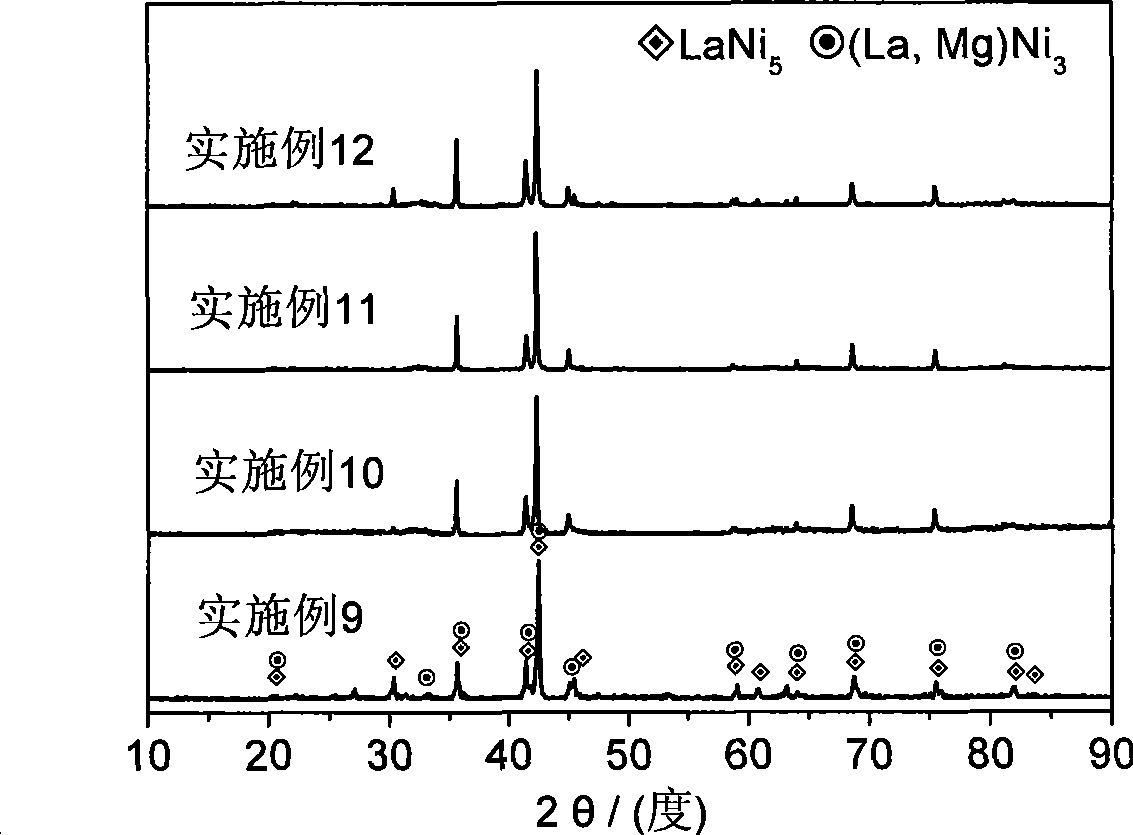

Method for sintering La-Mg-Ni based type AB3 hydrogen storage alloy in magnetic field

The invention relates to a method for preparing La-Mg-Ni based AB3 type hydrogen storage alloy by magnetic field sintering, which belongs to the technical field of metallic functional material and powder metallurgy. The method mainly comprises the following steps: firstly, mixing La and Mg metal powder or master alloy La2Mg prepared by a molten salt method with one or two of Ni powder, Co powder or Cu powder according to the atom molar mass proportion of AB3, and pre-ball milling the mixture by adopting proper technology; secondly, pressing the milled and mixed raw material powder under a pressure of between 200 and 500MPa into a cake of Phi 15mmx(3-5)mm, putting the cake into a self-made high-pressure reaction kettle and filling 0.5MPa argon after repeated vacuum pumping; and finally putting the high-pressure kettle into a steady high magnetic field of between 1 and 8T and heating to between 610 and 850 DEG C, sintering the cake and slowly reducing the temperature to obtain the La-Mg-Ni based AB3 type hydrogen storage alloy. The material prepared by the method has the advantages of high activity, even compositions, low impurity content and the like. Electrochemistry and PCT tests find that the hydrogen storage material has high capacity and better comprehensive performance.

Owner:SHANGHAI UNIV

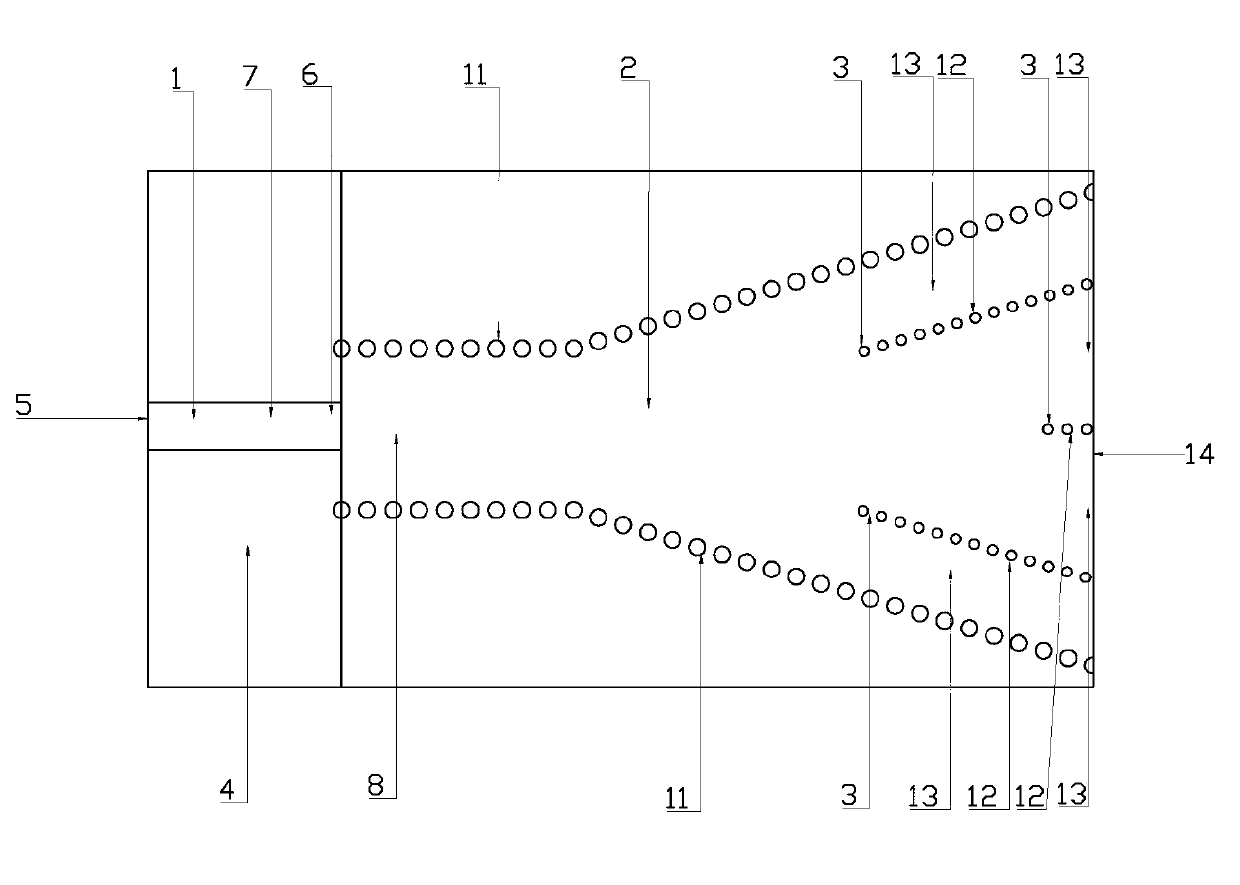

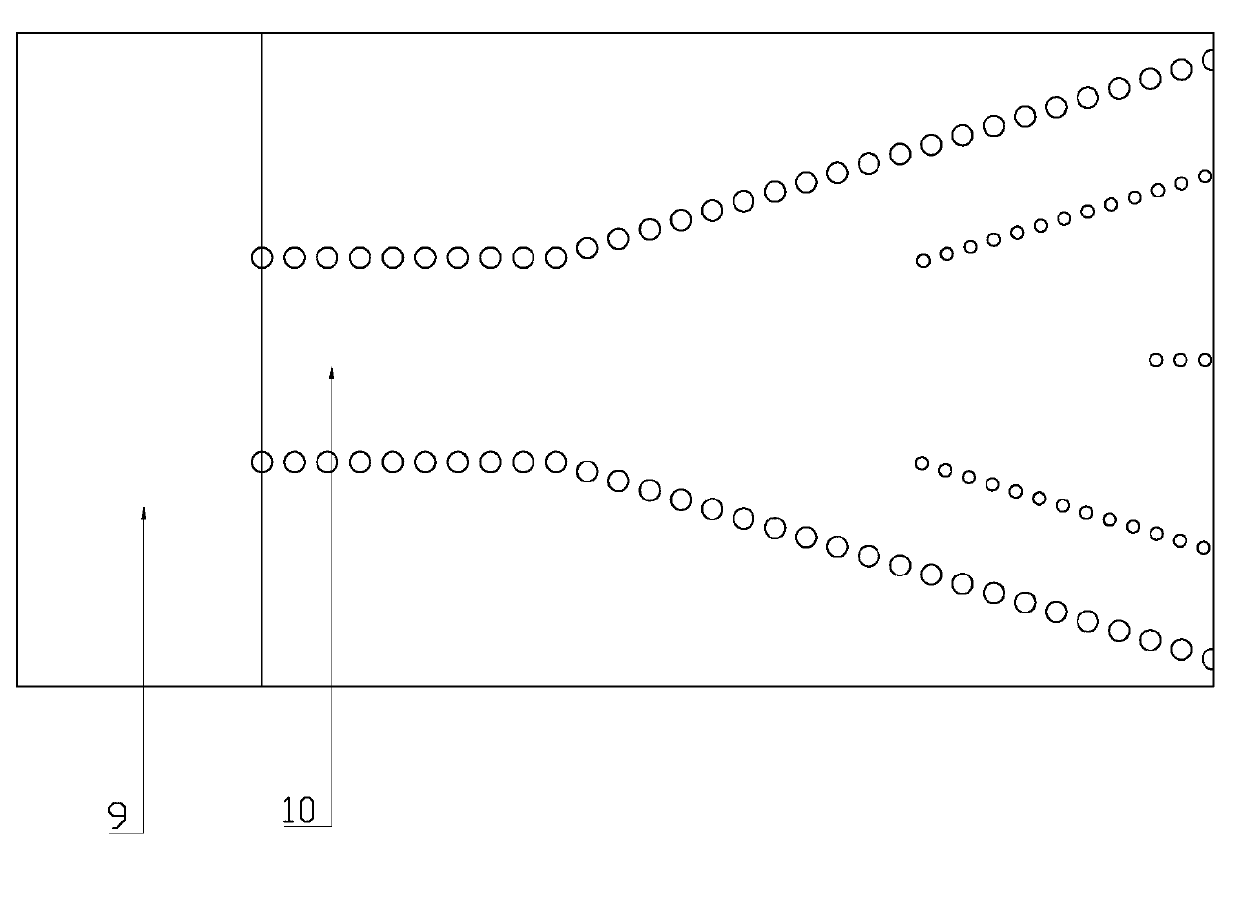

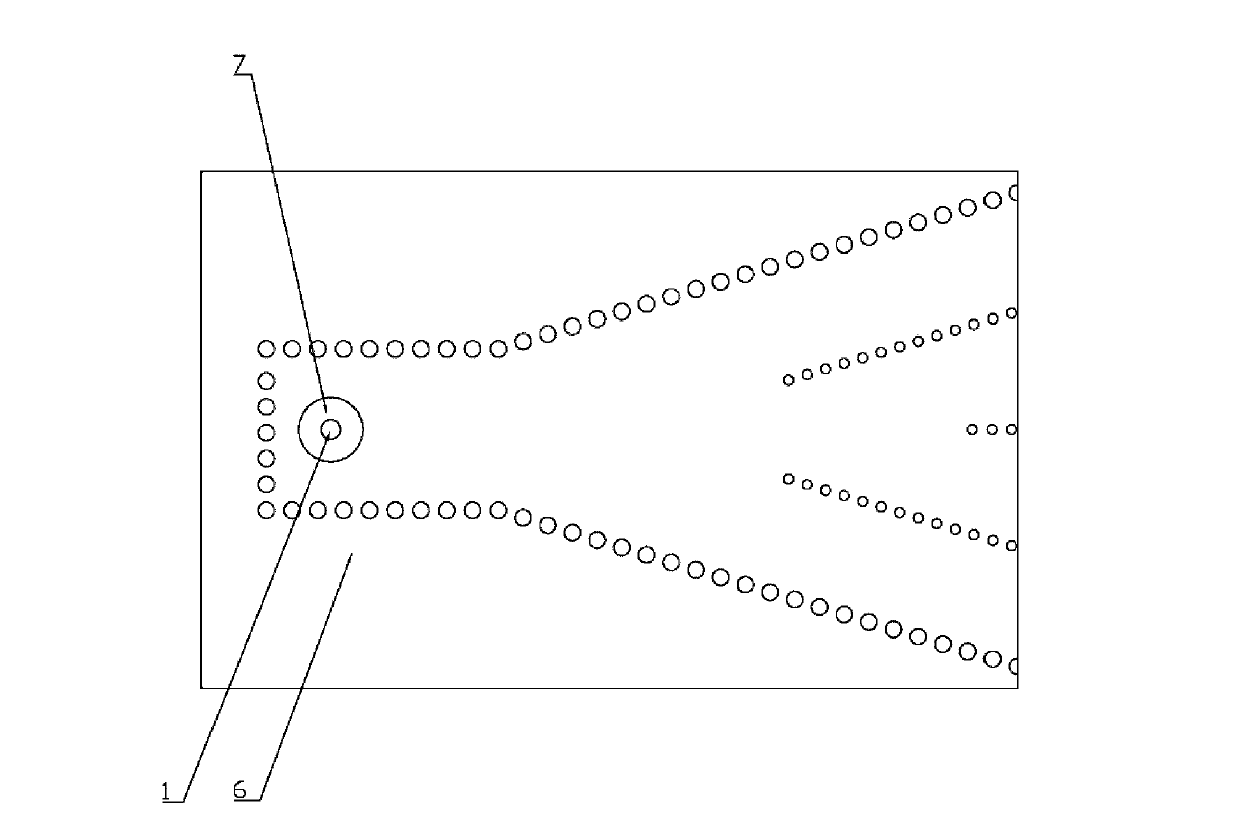

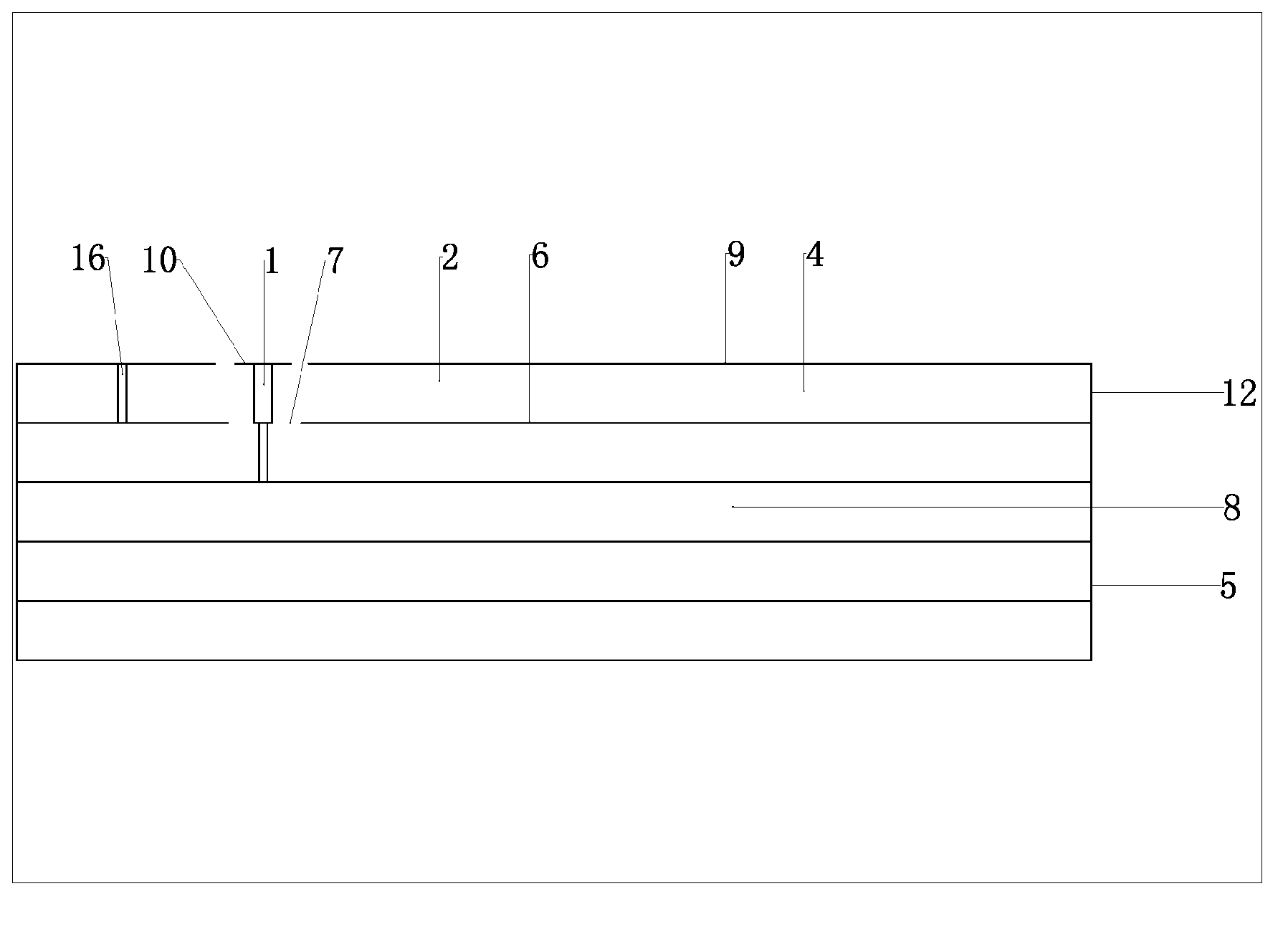

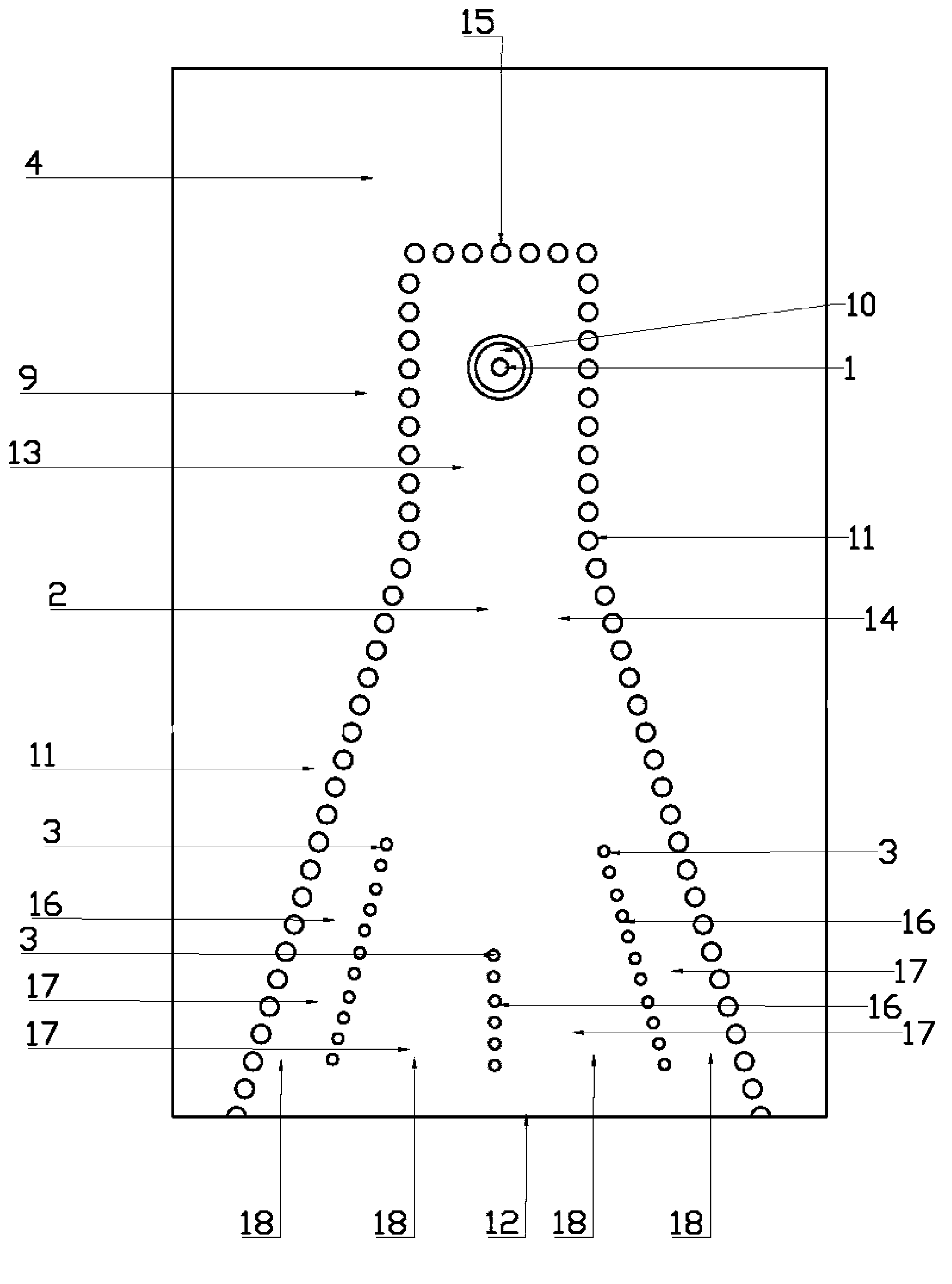

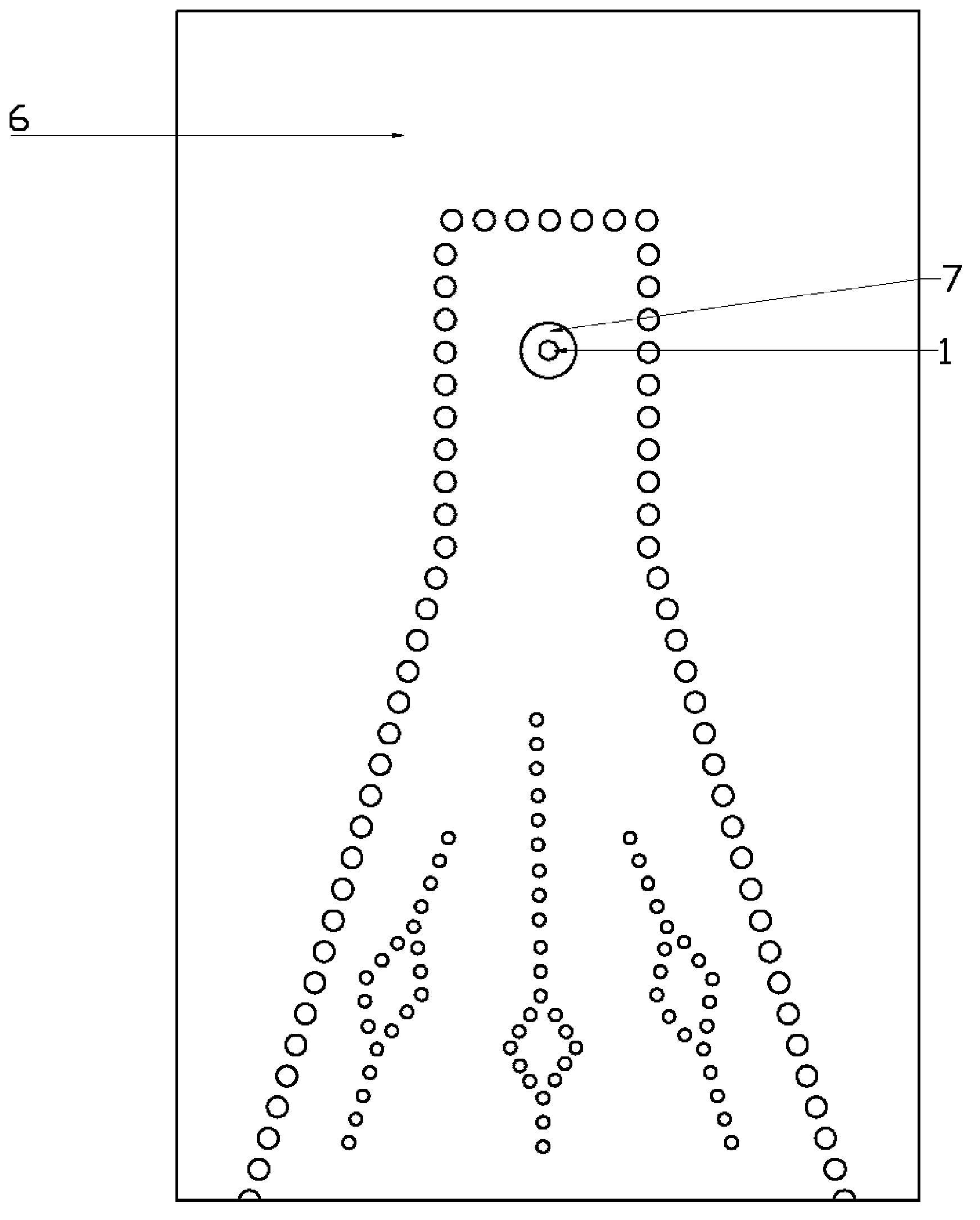

Three-dimensional surface antenna for phase calibration

InactiveCN103022675AChange widthUniform phase distributionWaveguide hornsRadiating elements structural formsDielectric substrateHorn antenna

The invention relates to a horn antenna, in particular to a three-dimensional surface antenna for phase calibration. The antenna comprises a vertical plated-through hole feeder (1), a horn antenna (2) and plated-through holes (3) which are integrated on a dielectric substrate (4), the dielectric substrate (4) is disposed on the top side of a three-dimensional package (5), one end of the vertical plated-through hole feeder (1) is connected with an internal circuit (8), the horn antenna (2) is composed of a bottom metal plane (6), a top metal plane (9) and plated-through hole side walls (11), through hole arrays (16) composed of the plated-through holes (3) form a plurality of dielectric-filled waveguides (17) in the horn antenna (2), and one port of each dielectric-filled waveguide (17) faces the direction of a short-path surface (15) of a narrow-section waveguide (13) while the other port of each dielectric-filled waveguide (17) is positioned on a horn antenna aperture surface (12). Besides, electromagnetic waves in the antenna can reach to the antenna aperture surface (12) by the same phase. The antenna is capable of improving antenna aperture efficiency as well as increasing antenna aperture gain.

Owner:SOUTHEAST UNIV

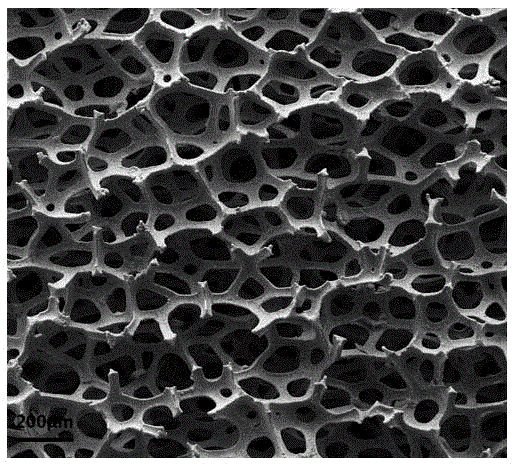

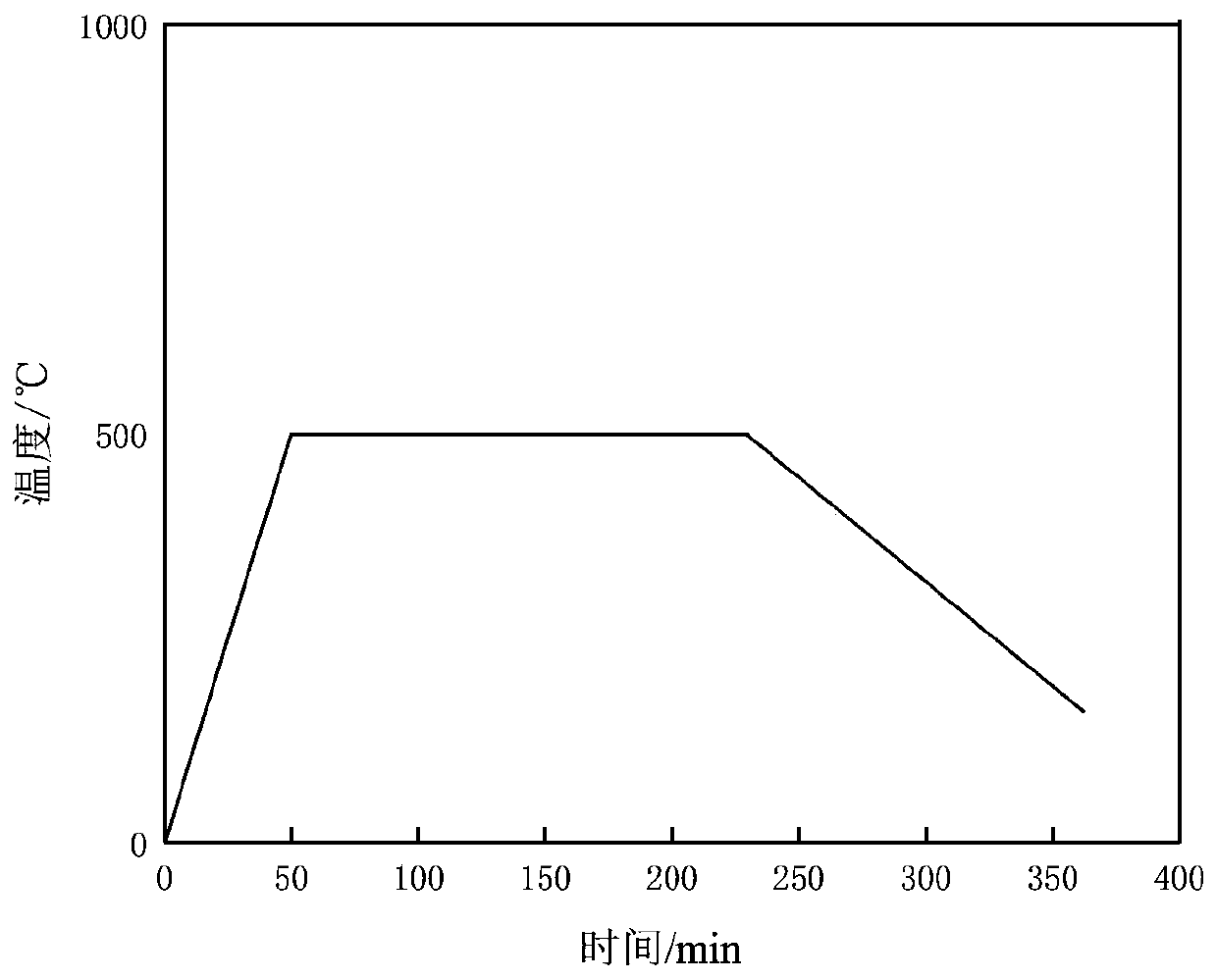

Preparation method for NiCrAl foam metal

The invention relates to a preparation method for NiCrAl foam metal. The preparation method comprises the steps that a foam NiCr alloy is prepared through a sintering process, Al seeps through a powder embedding method based on the foam NiCr alloy, a permeating agent is composed of aluminum and nickel alloy powder, AI2O3 powder and NH 4CI, and the NiCrAl foam metal is formed. The preparation method overcomes the defects of a traditional electrothermal alloy, and the produced NiCrAl foam metal has excellent oxidation resistance and specific resistance.

Owner:CHANGDE LYRUN MATERIAL

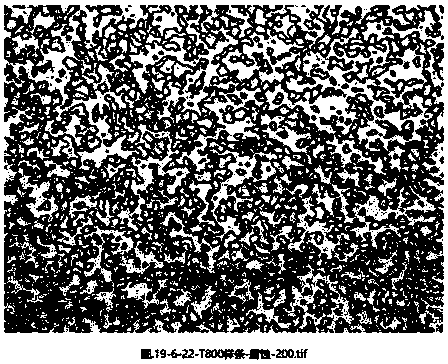

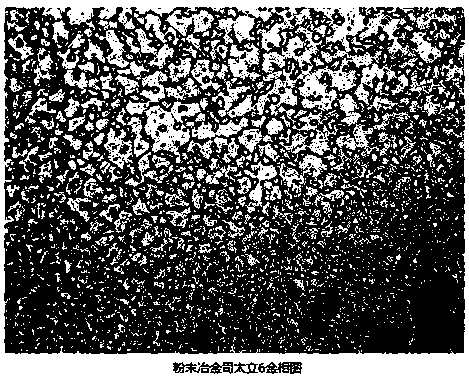

Manufacturing process for producing cobalt-based alloy powder metallurgy by using simple substance ball milling method

The invention discloses a manufacturing process for producing cobalt-based alloy powder metallurgy by using a simple substance ball milling method. The manufacturing process overcomes the casting defects such as coarse crystal grains, pores, inclusions, and component segregation in the prior art by adopting a casting process and the problems of high energy consumption, low material utilization rate and incapability of component fine adjustment on materials of the same grade by adopting the alloy powder metallurgy method. The manufacturing process is characterized by adopting simple substance materials for proportioning, and directly carrying out granulation, shaping, sintering and inspection after grinding. The manufacturing process has the beneficial effects that the casting defects for producing a cobalt-based alloy by adopting the casting method are overcome, the obtained metallographic structure is finer, the phases are more uniformly distributed, the comprehensive performance is better, and the two procedures of smelting and powder spraying for producing the cobalt-based alloy by the alloy powder metallurgy method are omitted, so that the production efficiency is high, and theenergy consumption is low; all the powder can be pressed and sintered after the grinding materials are granulated, and the material utilization rate is more than 99%; and the components of the materials of the same grade can be finely adjusted, quick and small batch production can be achieved, and the special needs of customers can be met.

Owner:沈阳拓普新材料有限公司

Preparation method of alumina-YAG eutectic melt growth composite material

ActiveCN111235629ASmooth and dense surfaceUniform phase distributionPolycrystalline material growthEutectic material solidificationOxide ceramicDirectional solidification

The invention relates to the field of oxide ceramics, and provides a preparation method of an Al2O3-YAG eutectic melt growth composite material. By controlling the seeding temperature, the pulling rate and the rotating speed, convection in the preform melt tends to be stable, a certain degree of super-cooling is formed at the contact position between a seed crystal and the preform melt, and orderly arrangement of crystal atoms at a solid-liquid interface is achieved. As the crystallization process is continuously carried out, new crystals continuously grow out of the melt, atoms in the preformmelt are orderly arranged at the lower end of the seed crystal by pulling the seed crystal, Al2O3 and YAG phases can form stable single-orientation crystals (single crystals), and directional solidification is realized. The provided preparation method can obtain the Al2O3-YAG eutectic melt growth composite material which is free of pores, smooth and compact in surface, uniform in phase distribution and high in relative density and texturing degree; and moreover, the eutectic material grown by the method is relatively large in size.

Owner:RES & DEV INST OF NORTHWESTERN POLYTECHNICAL UNIV IN SHENZHEN +1

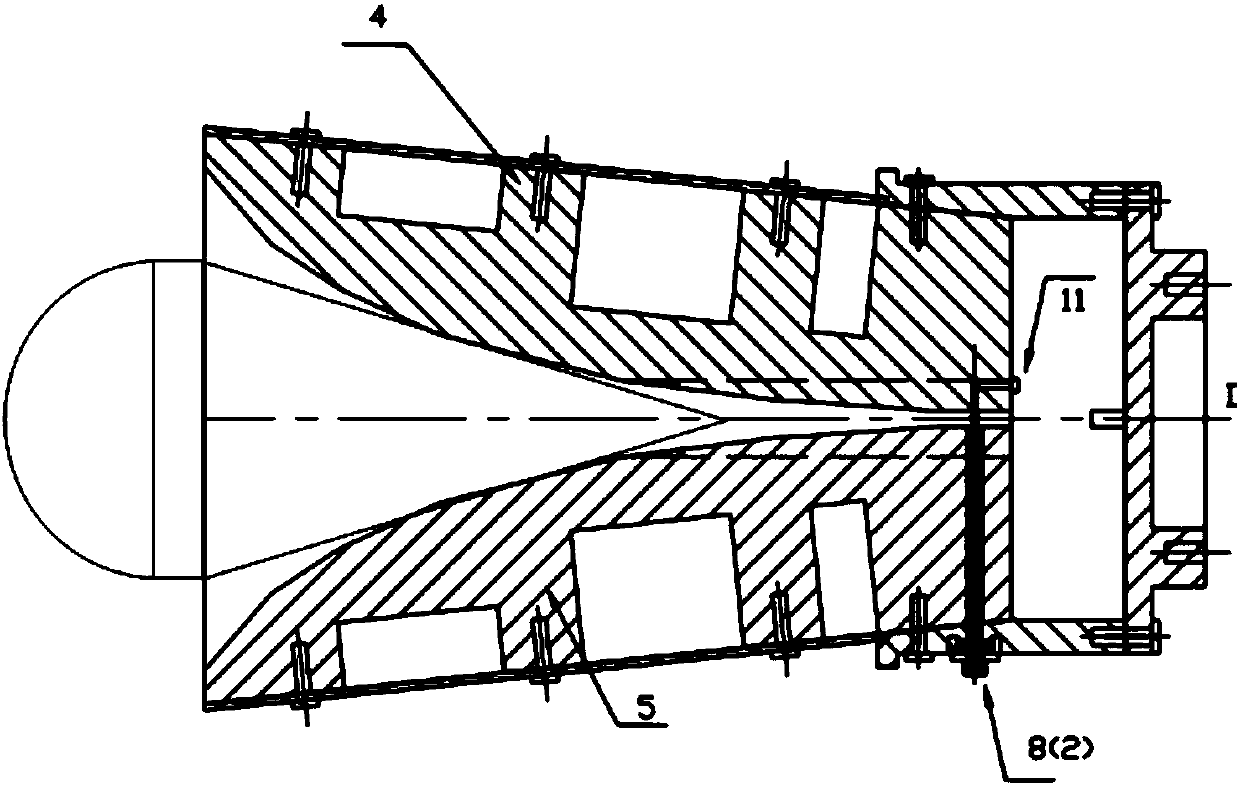

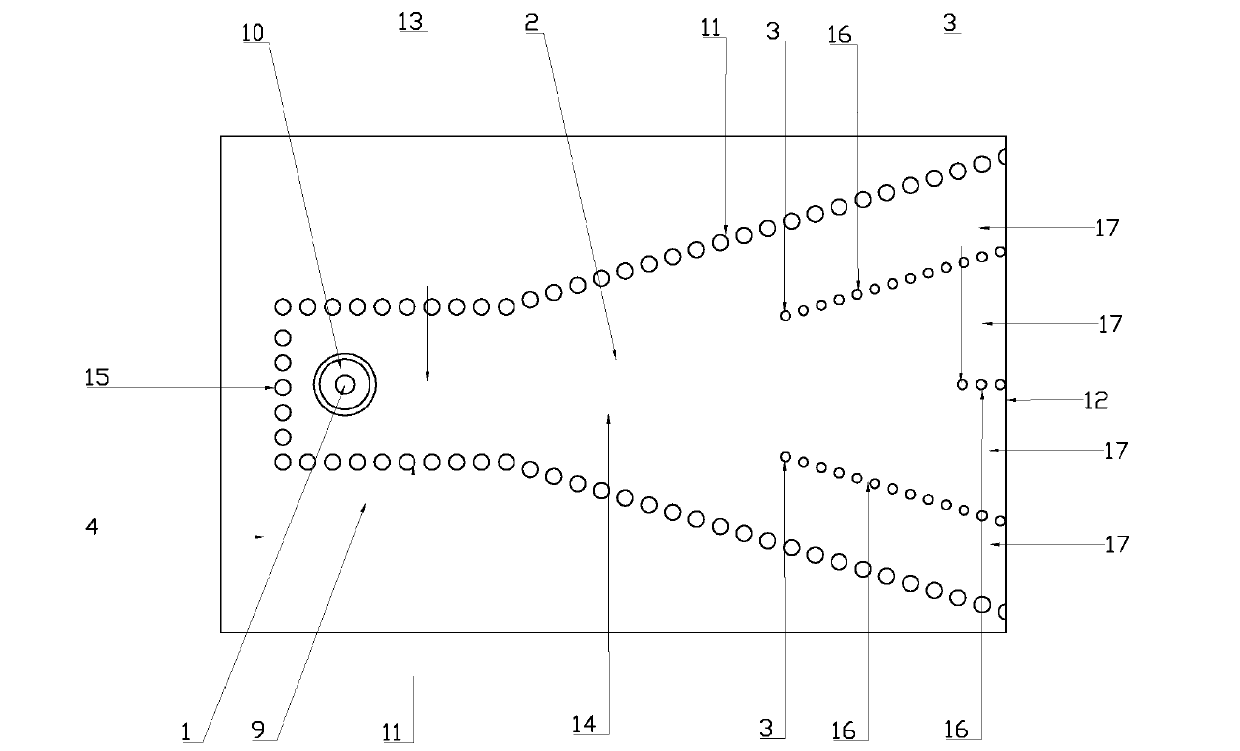

Phase-calibrated 3D-package surface antenna with embedded plated through holes

InactiveCN103022680AChange widthUniform phase distributionWaveguide hornsRadiating elements structural formsDielectric substrateRoad surface

The invention relates to a horn antenna, in particular to a phase-calibrated 3D-package surface antenna with embedded plated through holes. The antenna comprises a plated vertical through hole feeder (1), a horn antenna (2) and plated through holes (3), wherein the plated vertical through hole feeder (1), the horn antenna (2) and the plated through holes (3) are integrated on a dielectric substrate (4). The dielectric substrate (4) is arranged at the topmost of 3D package (5). One end of the plated vertical through hole feeder (1) is connected with an internal circuit (8). The horn antenna (2) comprises a bottom metal plane (6), a top metal plane (9) and plated through hole sidewalls (11). Through hole arrays (16) of the plated through holes (3) form a plurality of dielectric loaded waveguides (17) in the horn antenna (2). One port of each dielectric loaded waveguide (17) faces to a short surface (15) of a narrow-section waveguide (13), and the other port (18) of each dielectric loaded waveguide (17) extends towards an antenna aperture surface (12) without reaching the same. Gain of the phase-calibrated 3D-package surface antenna with embedded plated through holes can be increased.

Owner:SOUTHEAST UNIV

Stannum-stibium intermediate alloy and preparation process thereof

The invention discloses a stannum-stibium intermediate alloy and a preparation process thereof. The stannum-stibium intermediate alloy takes stannum (Sn) as the base material and also comprises the following components by weight percent: 0.1-30 percent of stibium (Sb) and 0.01-5 percent of gallium Ga. Preferably, the content of the base material Sn is 75-95 percent, the content of Sb is 5-25 percent, and the content of Ga is 0.1-5 percent. The stannum-stibium intermediate alloy can be used for synthesizing various multicomponent alloys or multicomponent alloy tin solders, and ensures that various alloy components have uniform phasestate distribution and good compatibility. The preparation process comprises the following steps of: fusing and casting quantitive component Sb into a die; immersing the die loaded with a stibium ingot into a stannum pot filled with quantitive base material Sn according to the weight proportion, and adding quantitive component Ga; stirring and casting to prepare the stannum-stibium intermediate alloy with defined content of each component. The preparation process has simplified working procedures, can obviously shorten the production time of stannum-stibium alloys and reduce the cost.

Owner:高新锡业(惠州)有限公司

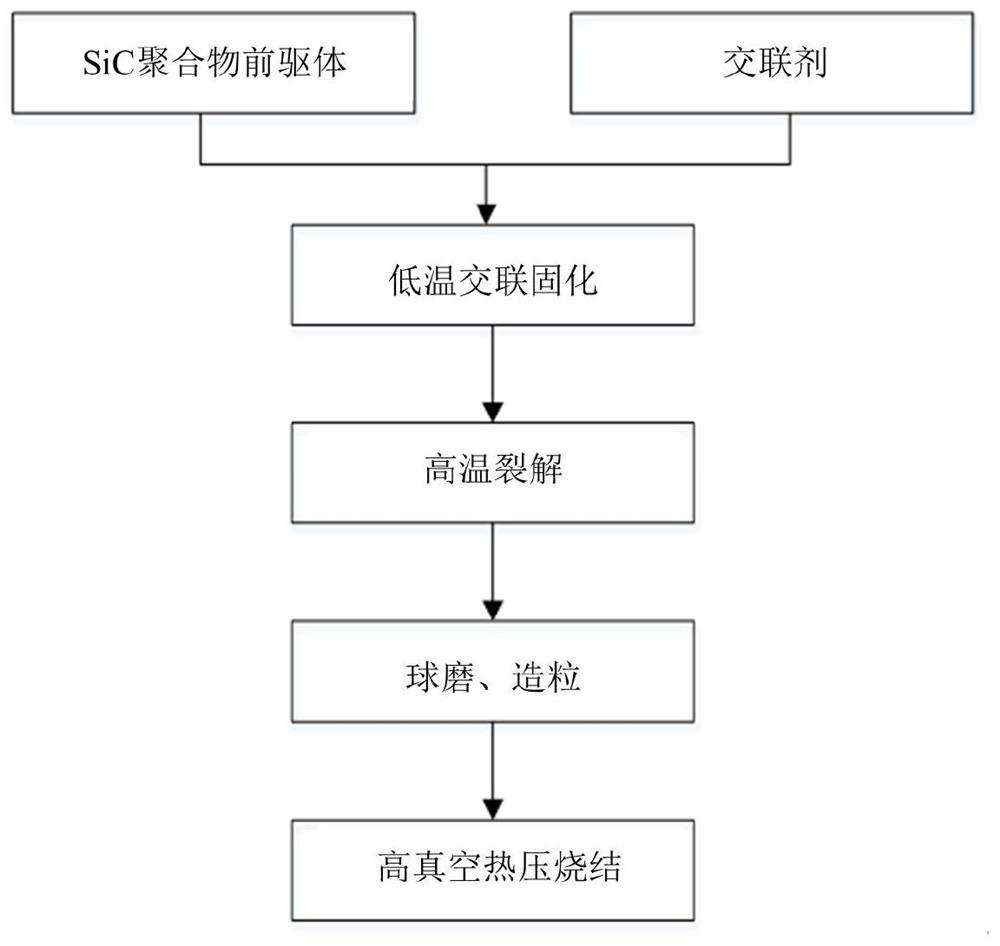

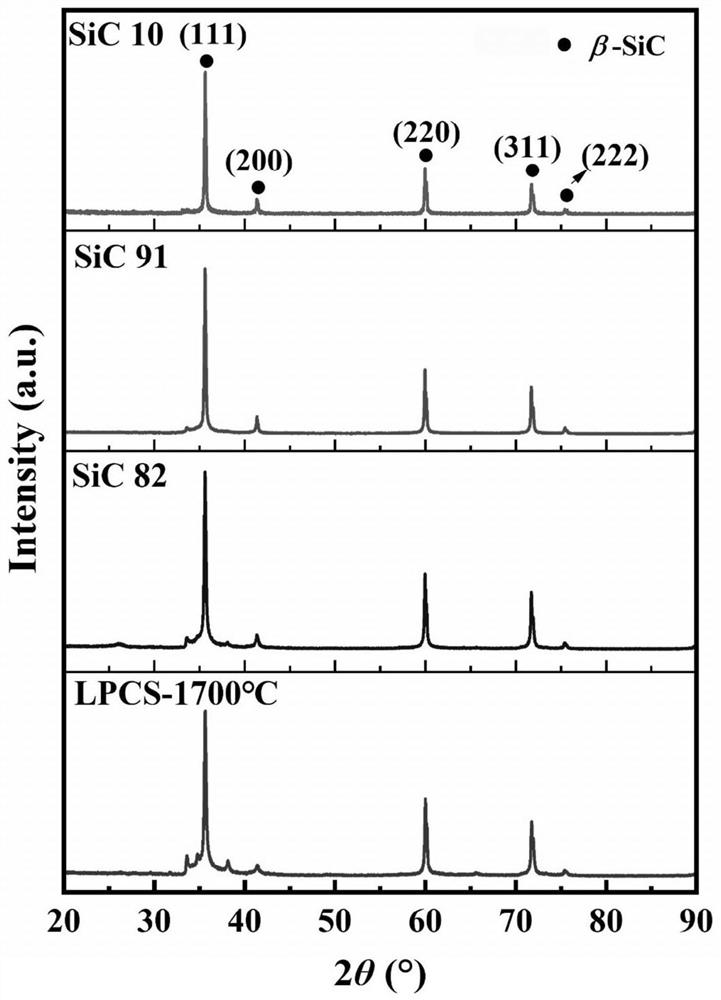

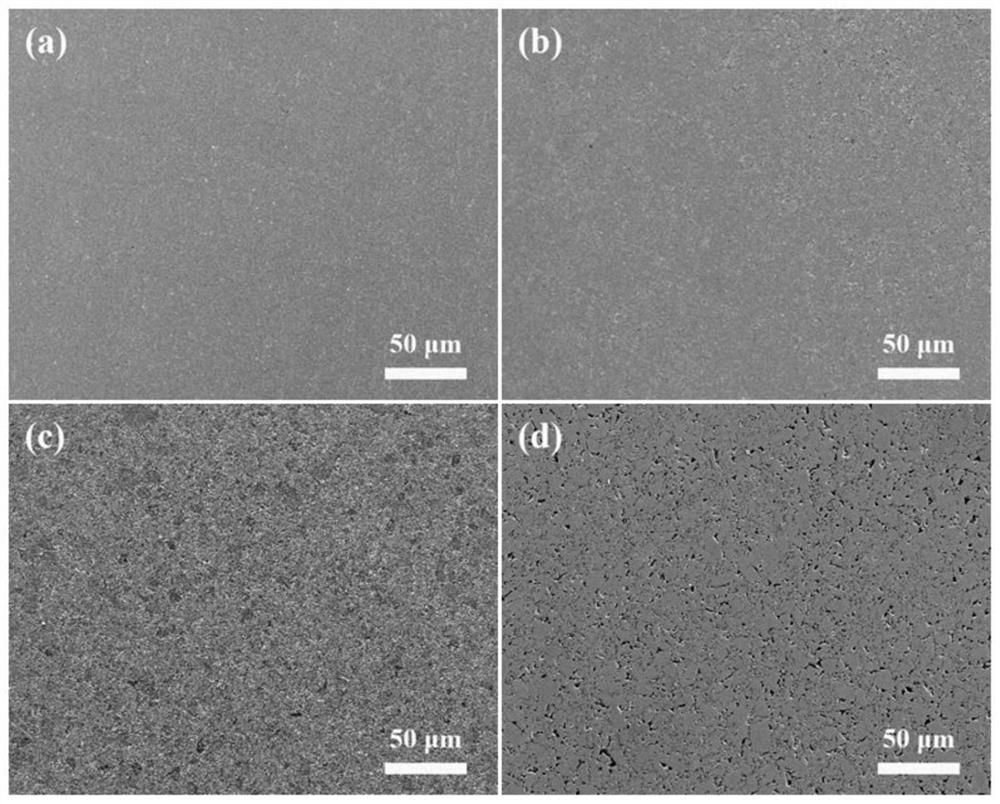

Method for synthesizing high-density SiC ceramic at low temperature

The invention discloses a method for synthesizing high-density SiC ceramic at low temperature, which mainly utilizes polycarbosilane as a precursor, and realizes close packing among silicon carbide grains by adopting a high-vacuum hot pressed sintering technology through cross-linking curing, high-temperature cracking and granulation to obtain high-density polycrystalline bulk ceramic. The volume density of the silicon carbide ceramic prepared by the method is close to theoretical density, and the porosity is close to zero.

Owner:ZHENGZHOU UNIV

A general suspension granulation method for the preparation of sintered metal-graphite composites

ActiveCN109622946BGood size controlImprove liquidityTransportation and packagingMetal-working apparatusGraphite particleMetal powder

The present invention relates to a general suspension granulation process for the preparation of sintered metal-graphite composites, comprising the steps of: suspending graphite particles in an air stream in a fluidization chamber; introducing bonded particles into the fluidization chamber agent solution; introduce metal powder into the fluidization chamber; after a preset fluidization time, the graphite particles are bonded with the metal powder through the binder to form core particles; time to make each graphite particle adhere to a metal layer of a certain thickness to obtain a core particle of a predetermined critical size. At this time, the core particle falls and Collected in the material bin at the bottom of the bed. The method of the present invention has strong versatility, and can be applied to the raw material granulation process of various metal-graphite composite material products. The obtained composite powder core has uniform distribution of phases, uniform density, and good mechanical properties of the object made later. .

Owner:UNIV OF SCI & TECH BEIJING

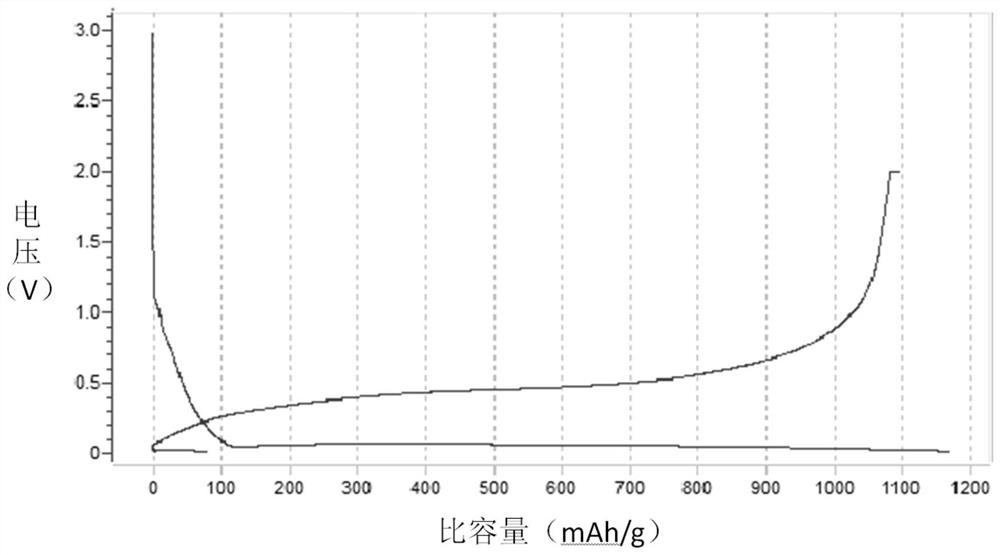

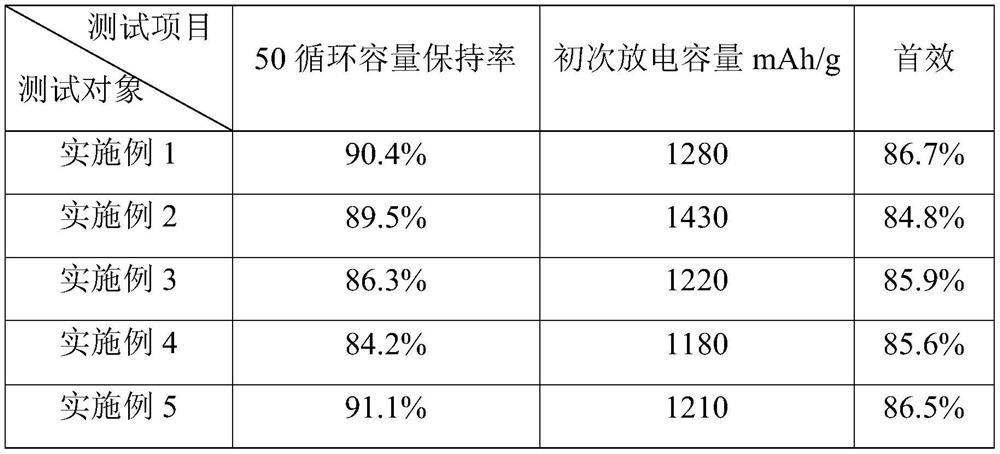

Silicon/lithium silicate composite material, preparation method thereof and power battery

PendingCN113782740AThe contact reaction is fully and evenlyUniform phase distributionSiliconCell electrodesComposite materialCharge and discharge

The invention belongs to the technical field of new energy, and particularly relates to a preparation method of a silicon / lithium silicate composite material. The preparation method comprises the steps of introducing gaseous Si, gaseous SiO2 and gaseous Li2O into a reaction container, and reacting in a gaseous phase state; and depositing a reaction product at the temperature of 500-700 DEG C to obtain the silicon / lithium silicate composite material. According to the preparation method of the silicon / lithium silicate composite material, all the raw material components react in a gas phase state, the reaction is more sufficient and uniform, phase state distribution in a product is more uniform, internal defect materials of the composite material are reduced, material volume expansion caused by stress between different phases in the composite material is avoided, and the stability and the first charge-discharge efficiency of the material are improved.

Owner:EVERGRANDE NEW ENERGY TECH SHENZHEN CO LTD

Multi-phase voltage control oscillator

ActiveCN100539397CIncrease the number ofUniform phase distributionOscillations generatorsPhase differenceMulti phase

A multi-phase voltage-controlled oscillator, which includes at least one ring oscillator unit and a resistance ring, the ring oscillator unit is formed by a plurality of phase delay components connected in series, and the resistance ring is formed by a plurality of resistance components connected in series The series connection node in each ring oscillation unit is electrically connected to the series connection node in the resistance ring, so that the ring oscillation unit can generate multiple oscillation signals with uniform phase difference.

Owner:REALTEK SEMICON CORP

Core-shell structure composite powder and preparation method thereof

PendingCN114769583AUniform phase distributionSimple processMaterial nanotechnologyTransportation and packagingNanoparticlePhysical chemistry

The invention discloses core-shell structure composite powder and a preparation method thereof. The preparation method specifically comprises the steps that deionized water is used for wetting insoluble metal salt, an ice coating layer is formed on the surface of the metal salt, low-temperature ball milling is conducted, nano metal salt-ice mixed powder is obtained, and wet nano metal salt is obtained after ice melts; adding wet nano metal salt, powder particles and a gelling agent into deionized water, and fully stirring and dispersing to obtain a gel suspension; carrying out solid-liquid separation on the gel suspension, and drying to obtain the nano metal salt coated on the surfaces of the powder particles; and under the reducing atmosphere, the obtained nano metal salt wrapping the surfaces of the powder particles is subjected to heating reduction treatment, the gelling agent is removed, and the composite powder of the core-shell structure is obtained. Metal salt is subjected to low-temperature brittle ball milling to form nano-particles, gel suspension is prepared with the assistance of a gelatinizing agent, powder particles coated with nano-metal salt are obtained through drying, and composite powder with highly uniform phase distribution and good dispersity is obtained through heating reduction.

Owner:GANNAN NORMAL UNIV +2

A kind of synthetic method of ammonium dihydrogen phosphate compound

ActiveCN103811755BStable carbon contentUniform phase distributionPhosphatesCell electrodesLithium iron phosphateOrganic solvent

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Preparation method of titanium nitride-ferrous metal ceramics

The invention relates to a preparation method of titanium nitride-ferrous metal ceramics. The preparation method comprises the steps of preparing a titanium-ferrous (Ti-Fe) alloy cast ingot with a vacuum melting method to enable Fe to exist in Ti in a form of solid solution and TiFe intermediate phase; carrying out hydrogenation embrittlement, ball-milling crushing and dehydrogenation and nitrogen treatment on the Ti-Fe alloy cast ingot to obtain titanium nitride-ferrous (TiN-Fe) metal-ceramic composite powder; sintering the composite powder subjected to green compacting to obtain a TiN-Fe metal-ceramic material. The TiN-Fe metal-ceramic composite powder prepared by the method provided by the invention consists of two phases, i.e. TiN and Fe, and is uniform in powder size and good in fluidity, the TiN-Fe block metal-ceramic material obtained by sintering the TiN-Fe metal-ceramic composite powder subjected to green compacting is uniform in phase distribution and relatively high in density, and the average microscopy Vickers hardness of the materials reaches 1023 HV.

Owner:NANCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com