Manufacturing process for producing cobalt-based alloy powder metallurgy by using simple substance ball milling method

A powder metallurgy, cobalt-based alloy technology, applied in the field of powder metallurgy manufacturing, can solve problems such as can only be used for other purposes or re-melting, high energy consumption, low yield and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

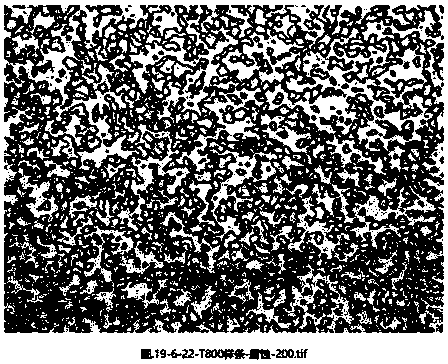

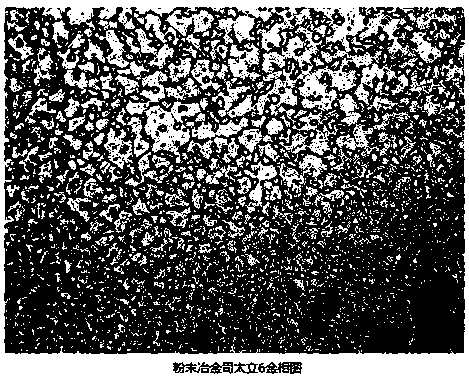

Image

Examples

specific Embodiment approach 1

[0081] Such as figure 1 As shown, the preparation process of cobalt-based alloy powder metallurgy produced by the simple substance ball milling method of the present invention adopts the following steps:

[0082] Step 1, Ingredients:

[0083] The cobalt-based alloy of the present invention is formed by the ratio of simple components, and the weight percentage content of each component is as follows:

[0084] Metal cobalt powder 40-65%; metal chromium powder 5-30%; metal tungsten powder 0-20%; silicon powder 0.1-4%; metal manganese powder 0.1-2%; metal molybdenum powder 0.1-30%; metal niobium powder 0-6%; metal nickel powder 0.1-8%; metal iron powder 0.1-10%; tungsten carbide powder 0-15%; chromium carbide powder 0.1-20%; niobium carbide powder 0-10%;

[0085] Step 2, Abrasives:

[0086] There are two methods of wet grinding or dry grinding for the abrasive material. The wet grinding means that grinding balls are installed in the barrel of the vertical stirring ball mill. a...

specific Embodiment approach 2

[0100] Same as Embodiment 1, the difference is:

[0101] The weight percentage content of each ingredient of the batching described in step 1 is as follows: 41.3% of metal cobalt powder, 16% of metal chromium powder, 14% of metal tungsten powder, 0.1% of silicon powder, 1.5% of metal manganese powder, 0.1% of metal molybdenum powder, metal niobium powder 1%, 3% metallic nickel powder, 2% metallic iron powder, 3% tungsten carbide powder, 15% chromium carbide powder, 3% niobium carbide powder; that is, it contains all 12 ingredients;

[0102] The ball-to-material weight ratio in the wet milling described in step 2 is 10:1, the rotating speed of the vertical agitating ball mill is 80 revolutions per minute, and the ball milling time is 5 hours, so that the particle size of the mixture reaches D50 and is 4 μm;

[0103] Glue blending and drying described in step 3, that is, put the mixed material after wet grinding in step 2 into the barrel of a vertical vacuum mixer, add 0.5% powd...

specific Embodiment approach 3

[0109] Same as Embodiment 1, the difference is:

[0110] The weight percentage content of each ingredient of the batching described in step 1 is as follows: 42.% of metal cobalt powder, 13% of metal chromium powder, 17% of metal tungsten powder, 0.5% of silicon powder, 0.5% of metal manganese powder, 1% of metal molybdenum powder, metal nickel 2% powder, 2% metal iron powder, 1% tungsten carbide powder, 20% chromium carbide powder, 1% niobium carbide powder; that is, it contains 11 kinds of ingredients except metal niobium;

[0111] The weight ratio of balls in the wet milling described in step 2 is 6:1, the rotating speed of the vertical stirring ball mill is 90 revolutions per minute, and the ball milling time is 8 hours, so that the particle size of the mixture reaches D50 of 3 μm;

[0112] The direct drying described in step 3 is to put the mixed material after the wet grinding in step 2 into the barrel of the vertical vacuum mixer, heat and distill after vacuumizing, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com