Crystallized mesoporous zinc silicate/silicon oxide composite powder and preparation method thereof

A technology of mesoporous silicon oxide and composite powder, which is applied in the direction of silicon oxide, chemical instruments and methods, silicon compounds, etc., can solve the problems of inability to fill nanopores, difficult mesoscopic structure, low experimental efficiency, etc., and achieve solid-phase reaction Uniform and sufficient, high mesoscopic order, and the effect of inhibiting pore shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of Mesoporous Silica

[0021] Prepare a mixed solution consisting of 15mL deionized water and 60mL 2mol / L hydrochloric acid, add 2g of triblock copolymer P123 to the above mixed solution, and fully stir at 37°C for 4 hours until P123 is completely dissolved. Then 4.25 g of tetraethyl orthosilicate was added to the above solution, and after stirring at 37° C. for 24 hours, the reactant was transferred to a reaction kettle with a volume of 100 mL, and hydrothermally treated at 100° C. for 24 hours. After filtering, washing with deionized water for 4 times, and drying at room temperature, a white powder was obtained. The powder was calcined at 550° C. for 6 hours with a heating rate of 1° C. / min to obtain a mesoporous silicon oxide powder.

[0022] Weigh 0.189g of zinc nitrate hexahydrate in a 25mL beaker, then add 4mL of ethanol, fully stir and dissolve to obtain zinc nitrate ethanol solution. Add 1 g of the prepared mesoporous silica powder into the zinc ni...

Embodiment 2

[0024] The preparation of mesoporous silica is the same as in Example 1.

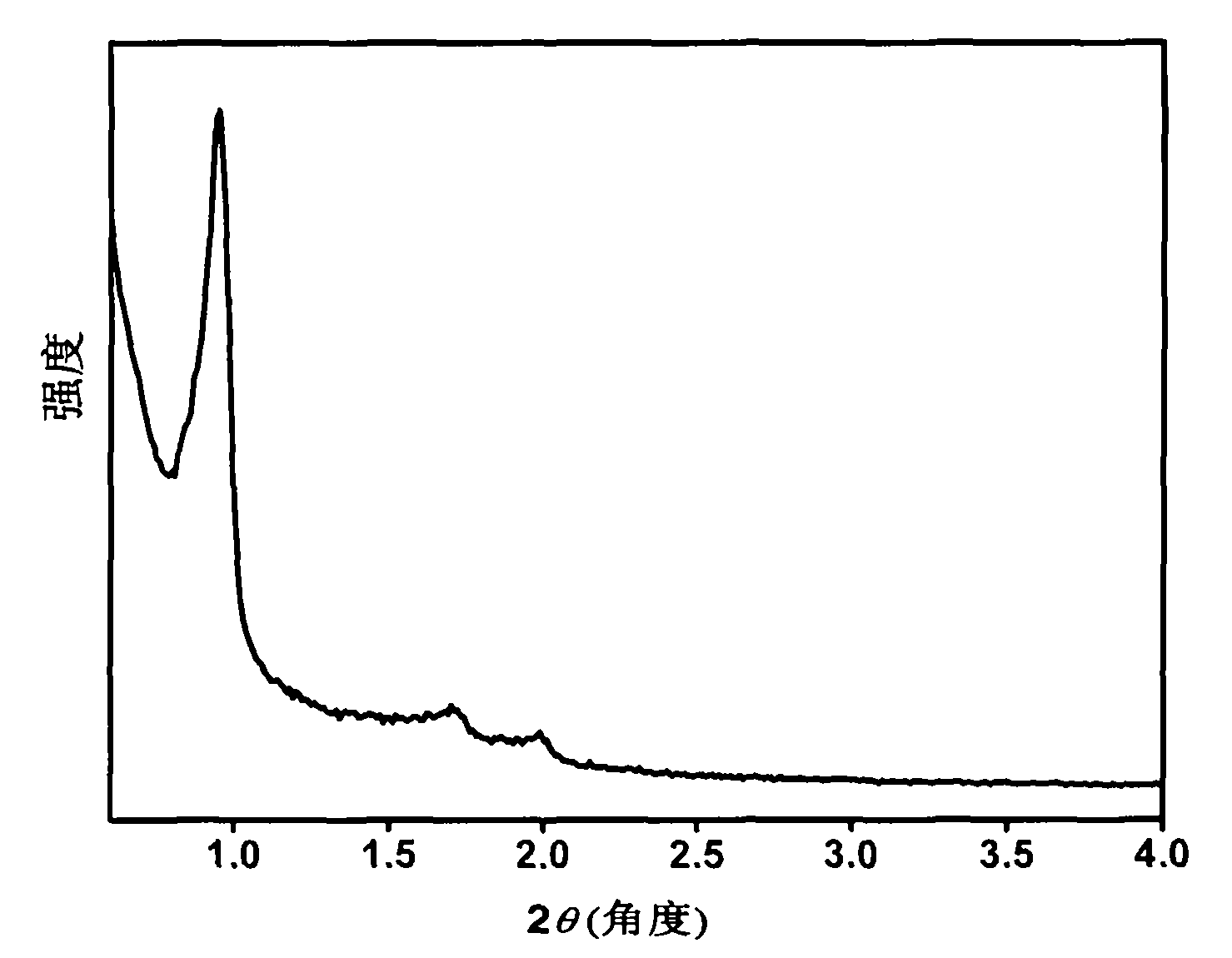

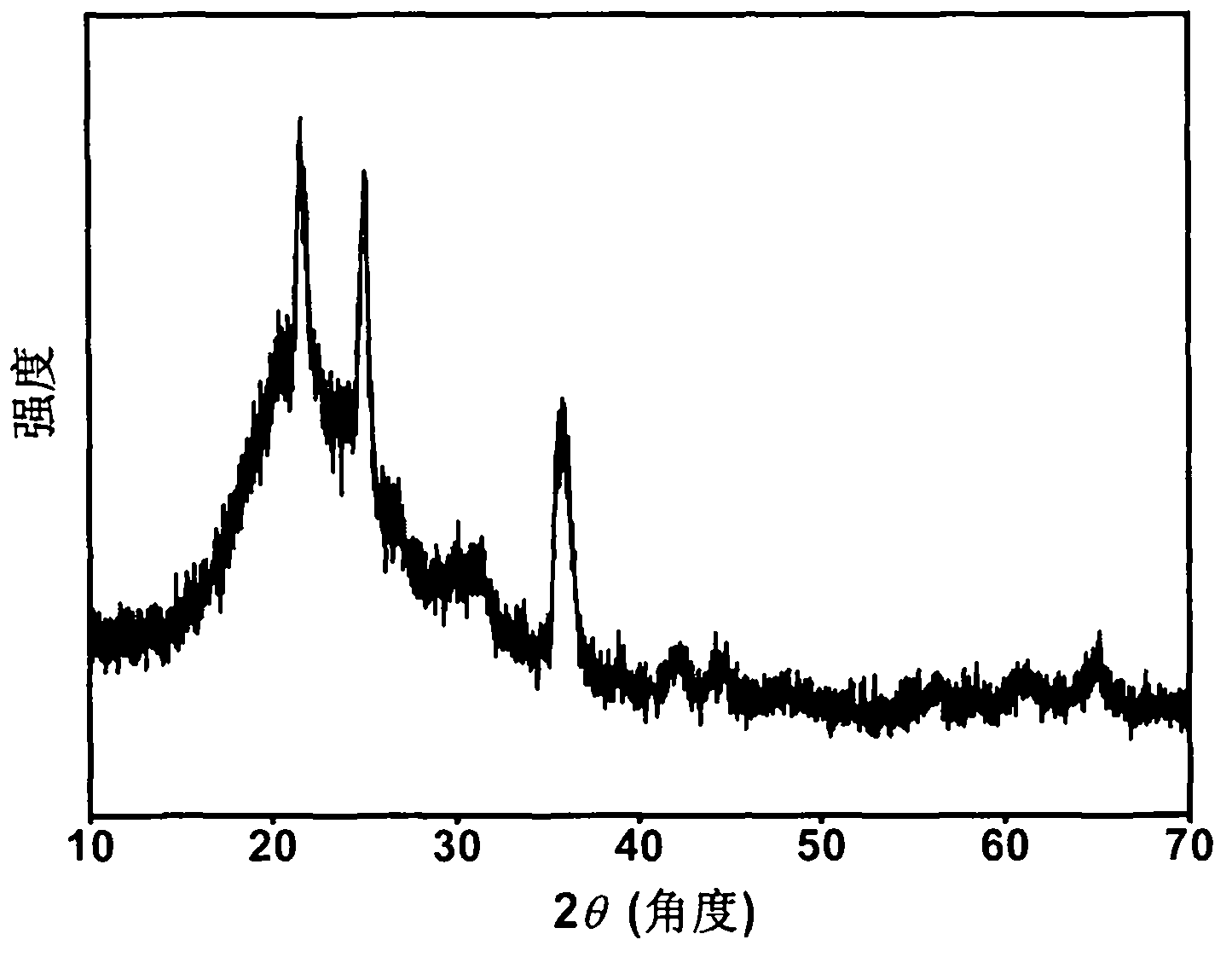

[0025] Weigh 0.833g of zinc nitrate hexahydrate in a 25mL beaker, then add 6mL of ethanol, fully stir and dissolve to obtain zinc nitrate ethanol solution. Add 1 g of the prepared mesoporous silica powder into the zinc nitrate solution under stirring, stir and volatilize the ethanol solvent at room temperature to obtain a white powder, then dry the powder in vacuum at 50°C for 8 hours, and then calcinate at 800°C for 4 hour, the heating rate is 1° C. / min, and the crystallized mesoporous zinc silicate / silicon oxide composite powder is obtained, and the molar ratio of silicon oxide to zinc silicate in the powder is 11. figure 2 It is the wide-angle X-ray diffraction pattern of the prepared crystalline mesoporous zinc silicate / silicon oxide composite powder.

Embodiment 3

[0027] The preparation of mesoporous silica is the same as in Example 1.

[0028] Weigh 1.963g of zinc nitrate hexahydrate in a 25mL beaker, then add 8mL of ethanol, fully stir and dissolve to obtain zinc nitrate ethanol solution. Add 1 g of the prepared mesoporous silica powder into the zinc nitrate solution under stirring, stir and volatilize the ethanol solvent at room temperature to obtain a white powder, then dry the powder in vacuum at 50°C for 8 hours, and then calcinate at 800°C for 4 hour, the heating rate is 1° C. / min, and the crystallized mesoporous zinc silicate / silicon oxide composite powder is obtained, and the molar ratio of silicon oxide and zinc silicate in the powder is 4. image 3 It is a transmission electron micrograph of the prepared crystalline mesoporous zinc silicate / silicon oxide composite powder. Figure 4 Nitrogen adsorption and desorption spectra of the prepared crystalline mesoporous zinc silicate / silicon oxide composite powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com