Alxga1-xn ternary alloy microcrystalline ball with high al composition and preparation method thereof

A technology of ternary alloys and microcrystalline balls, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of spontaneous phase separation, high cost, unsuitable for commercial development, etc., and achieve the suppression of phase separation , Simple preparation process, good repeatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

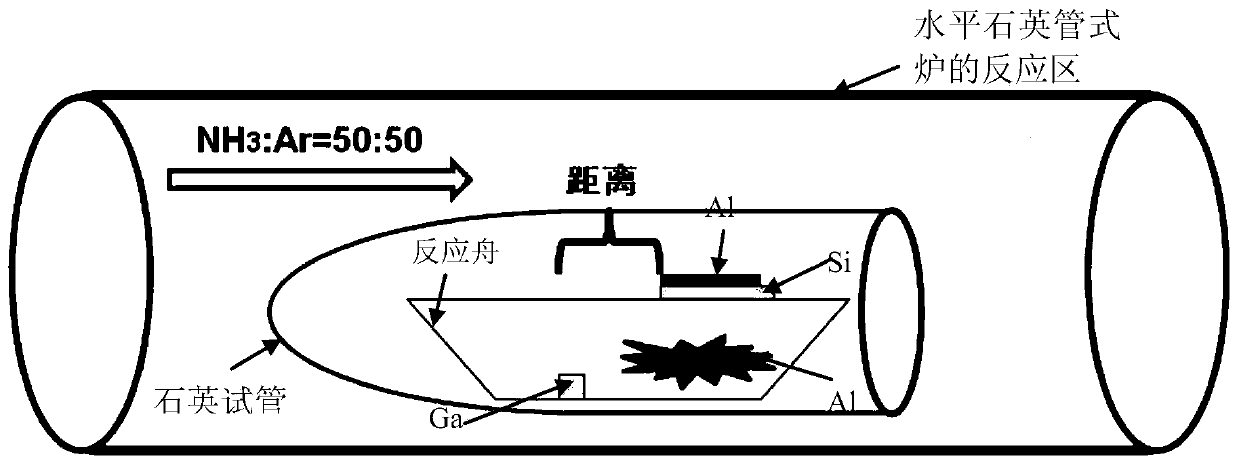

Method used

Image

Examples

Embodiment 1

[0047] A high Al composition Al x Ga 1-x N ternary alloy crystal balls, Al with x=0.77 x Ga 1-x N semiconductor alloy, the diffraction angles of its XRD pattern characteristic peaks (100), (002) and (101) are between the diffraction angles of wurtzite structure AlN and GaN, indicating that the product is AlGaN crystal with wurtzite structure, see figure 2 .

[0048] For high Al composition Al x Ga 1-x N(x=0.77) microcrystal balls were scanned and analyzed, and the scanning electron micrograph is shown in image 3 , it can be concluded from the figure that Al 0.77 Ga 0.23 Morphology of N ternary alloy crystallite balls, the crystallite balls have a regular and uniform spherical structure with an average diameter of 5.0 μm.

[0049] A high Al composition Al x Ga 1-x The preparation method of N ternary alloy crystal balls comprises the following steps:

[0050] Step 1, pre-deposition thin layer of aluminum powder

[0051] (1) Ultrasonic treatment is carried out to th...

Embodiment 2

[0065] A high Al composition Al x Ga 1-x N ternary alloy crystallite ball, Al x Ga 1-x N semiconductor alloy with wurtzite structure AlGaN crystals. The microcrystalline sphere has a regular and uniform spherical structure with an average diameter of 5.0 μm.

[0066] A high Al composition Al x Ga 1-x The preparation method of N ternary alloy crystal balls comprises the following steps:

[0067] Step 1, pre-deposition thin layer of aluminum powder

[0068] (1) Ultrasonic treatment is carried out to the silicon substrate with ethanol, and after cleaning, the silicon substrate after ultrasonic is obtained;

[0069] Add aluminum powder with a purity of 99.999 and an average particle size of 10 μm into methanol, and perform ultrasonic vibration for 60 minutes. When the aluminum powder is uniformly dispersed, the ultrasonically mixed aluminum powder is obtained;

[0070] (2) Put the ultrasonicated silicon substrate into the ultrasonicated aluminum powder mixture, and air-dry...

Embodiment 3

[0082] A high Al composition Al x Ga 1-x N ternary alloy crystallite ball, Al x Ga 1-x N semiconductor alloy with wurtzite structure AlGaN crystals. The microcrystalline sphere has a regular and uniform spherical structure with an average diameter of 5.0 μm.

[0083] A high Al composition Al x Ga 1-x The preparation method of N ternary alloy crystal balls comprises the following steps:

[0084] Step 1, pre-deposition thin layer of aluminum powder

[0085] (1) Ultrasonic treatment is carried out to the silicon substrate with deionized water, and after cleaning, the silicon substrate after ultrasonic is obtained;

[0086] Add aluminum powder with a purity of 99.999 and an average particle size of 8 μm into methanol, and perform ultrasonic vibration for 40 minutes. When the aluminum powder is uniformly dispersed, the ultrasonically mixed aluminum powder is obtained;

[0087] (2) Put the ultrasonic silicon substrate into the ultrasonic aluminum powder mixture, and let it a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com