Method for synthesizing high-density SiC ceramic at low temperature

A ceramic and dense technology, applied in the field of high-temperature ceramics, can solve problems such as the difficulty in effectively preparing high-density SiC ceramics, and achieve the effects of tight combination, short production cycle, and improved exhaust efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, liquid polycarbosilane VHPCS purchased from the Institute of Chemistry, Chinese Academy of Sciences was used as the SiC polymer precursor.

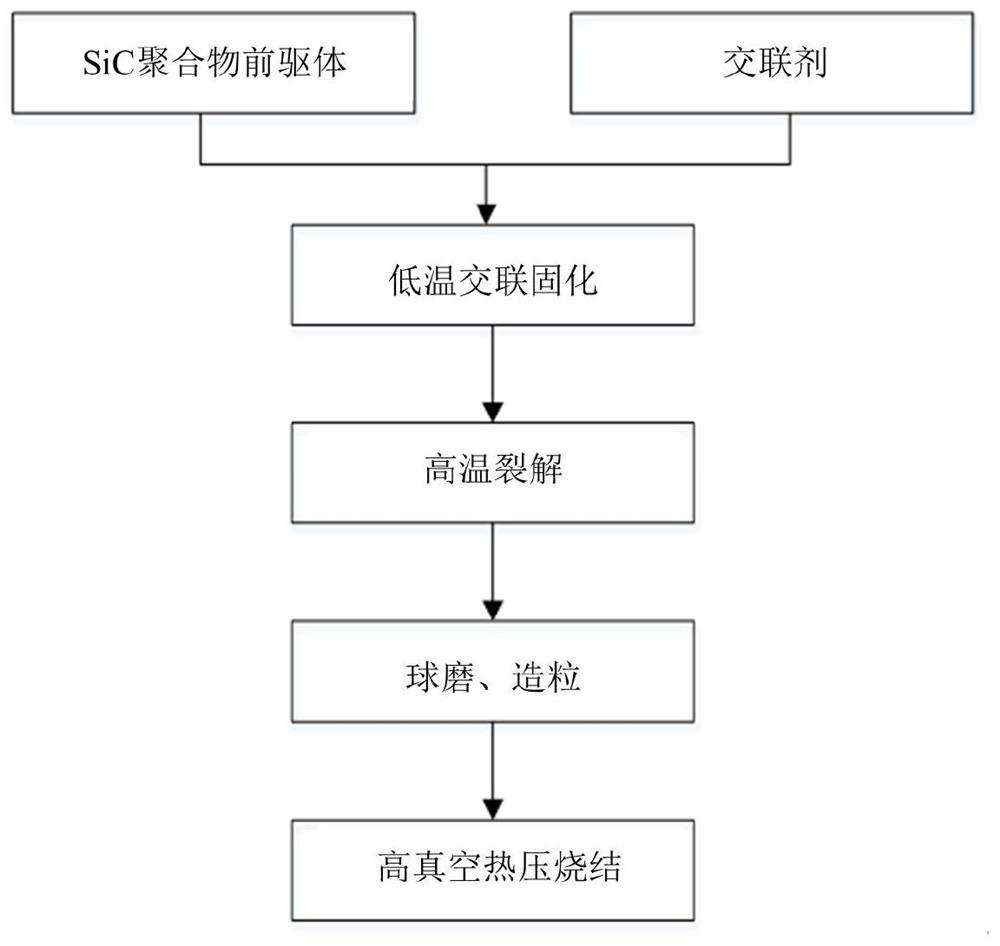

[0034] The steps of low-temperature synthesis of high-density SiC ceramics provided in this example are as follows:

[0035] (1) Add DCP cross-linking agent to the SiC polymer precursor (the amount of DCP cross-linking agent added is 1.5wt.% of the weight of the SiC polymer precursor), cross-link at 70°C for 3 hours and put it into a vacuum drying oven (vacuum degree <0.09MPa) and cured at 150°C for 4h; after curing, the sample C / Si=1.184.

[0036] (2) The solidified product in step (1) is heated up to 1000° C. at a heating rate of 2° C. / min under an argon atmosphere, and kept at this temperature for 3 hours for pyrolysis treatment.

[0037] (3) Add sintering aids (which include 2.85wt.% Y 2 o 3 and 2.15wt.% Al 2 o 3 ), then according to the ball-to-material ratio of 5:1, the rotation speed of 250rpm, the p...

Embodiment 2

[0041] In this embodiment, liquid polycarbosilane VHPCS and divinylbenzene DVB purchased from the Institute of Chemistry, Chinese Academy of Sciences were used as SiC polymer precursors, and the mass ratio of VHPCS to DVB was 9:1.

[0042] The steps of low-temperature synthesis of high-density SiC ceramics provided in this example are as follows:

[0043] (1) Add DCP cross-linking agent to the SiC polymer precursor (the amount of DCP cross-linking agent added is 1.5wt.% of the weight of the SiC polymer precursor), cross-link at 70°C for 3 hours and put it into a vacuum drying oven (vacuum degree <0.09MPa) and cured at 150°C for 4h; the sample C / Si=1.552 after curing.

[0044] (2) The product cured in step (1) was heated up to 1400° C. at a heating rate of 2° C. / min under an argon atmosphere, and kept at this temperature for 3 hours for pyrolysis treatment.

[0045] (3) Add sintering aids (which include 2.85wt.% Y 2 o 3 and 2.15wt.% Al 2 o 3 ), then according to the ball-t...

Embodiment 3

[0049] In this embodiment, liquid polycarbosilane VHPCS and divinylbenzene DVB purchased from the Institute of Chemistry, Chinese Academy of Sciences were used as SiC polymer precursors, and the mass ratio of VHPCS to DVB was 8:2.

[0050] The steps of low-temperature synthesis of high-density SiC ceramics provided in this example are as follows:

[0051] (1) Add DCP cross-linking agent to the SiC polymer precursor (the amount of DCP cross-linking agent added is 1.5wt.% of the weight of the SiC polymer precursor), cross-link at 70°C for 3 hours and put it into a vacuum drying oven (vacuum degree <0.09MPa) and cured at 150°C for 4h; the sample C / Si=2.068 after curing.

[0052] (2) The product cured in step (1) was heated up to 1400° C. at a heating rate of 2° C. / min under an argon atmosphere, and kept at this temperature for 3 hours for pyrolysis treatment.

[0053] (3) Add sintering aids (which include 2.85wt.% Y 2 o 3 and 2.15wt.% Al 2 o 3 ), then according to the ball-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com