Fine-grain boron-rich boron carbide-based composite ceramic material and preparation method thereof

A technology of composite ceramics and ceramic materials, which is applied in the field of fine-grain boron-rich boron carbide-based composite ceramic materials and its preparation, can solve the problems of difficult to obtain nanostructured composite materials, coarse structure of composite materials, and poor material performance. To achieve the effect of optimizing the interface structure, uniform structure and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

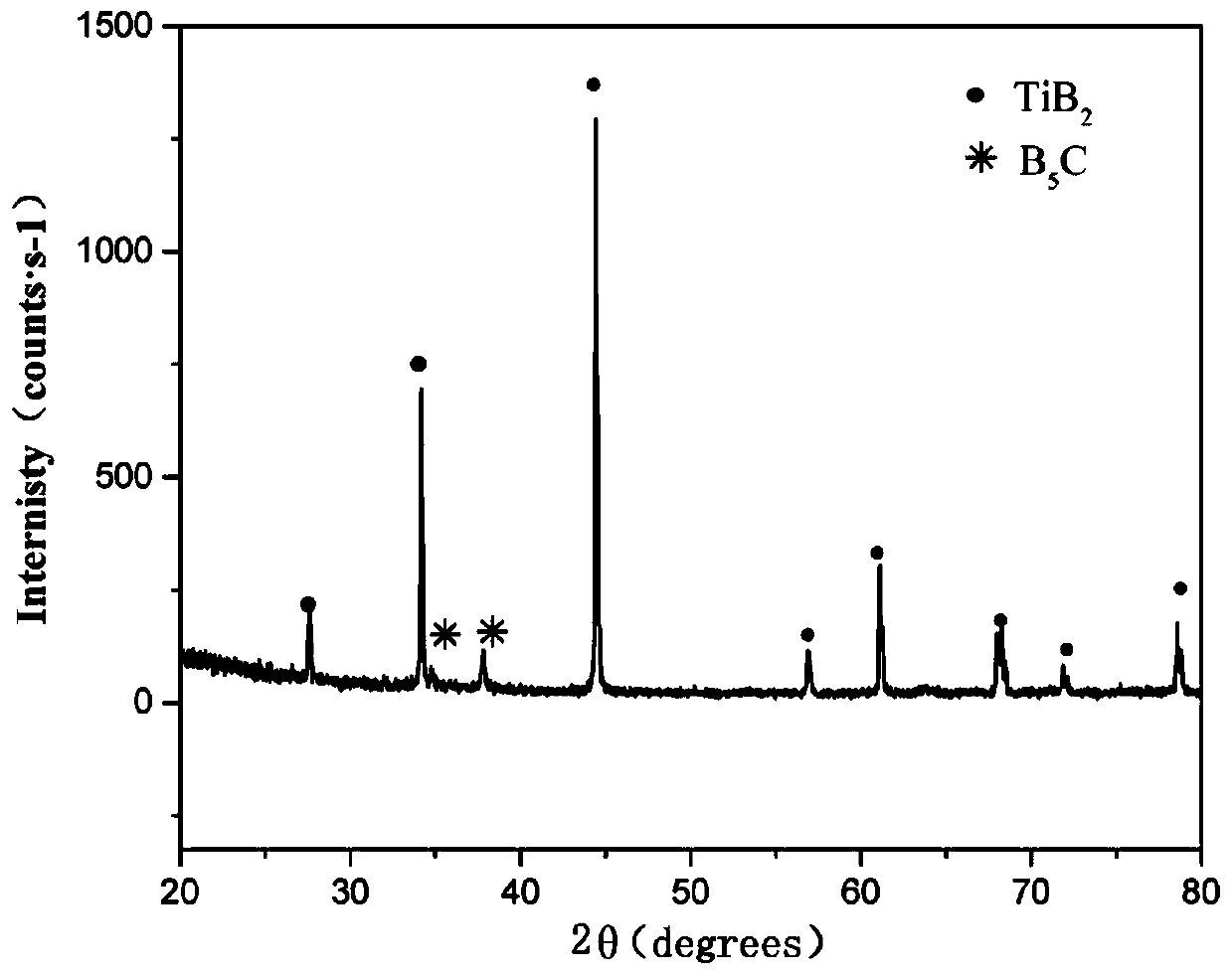

Embodiment 1

[0034] The preparation method of boron-rich boron carbide-titanium boride ceramic composite material described in this example, the specific steps include:

[0035] 1) weighing 44.25% of raw material titanium carbide powder and 55.75% of boron powder by weight percentage for subsequent use;

[0036] 2) Put the weighed powder into the zirconia ball mill tank of the planetary ball mill, add ethanol solution as the dispersion medium for mixing, the total volume of powder, balls and ethanol is two-thirds of the volume of the ball mill tank, planetary The rotating speed of the ball mill is 200r / min, and the ball milling time is 2h. After the mixing is completed, the balls are removed by sieving to obtain the slurry of the mixed powder;

[0037] 3) The slurry is dried in a vacuum oven at 60°C for 24 hours, ground after drying, and granulated through a 325-mesh sieve to obtain a mixed powder;

[0038] 4) Put the mixed powder obtained after drying and sieving into a cylindrical graph...

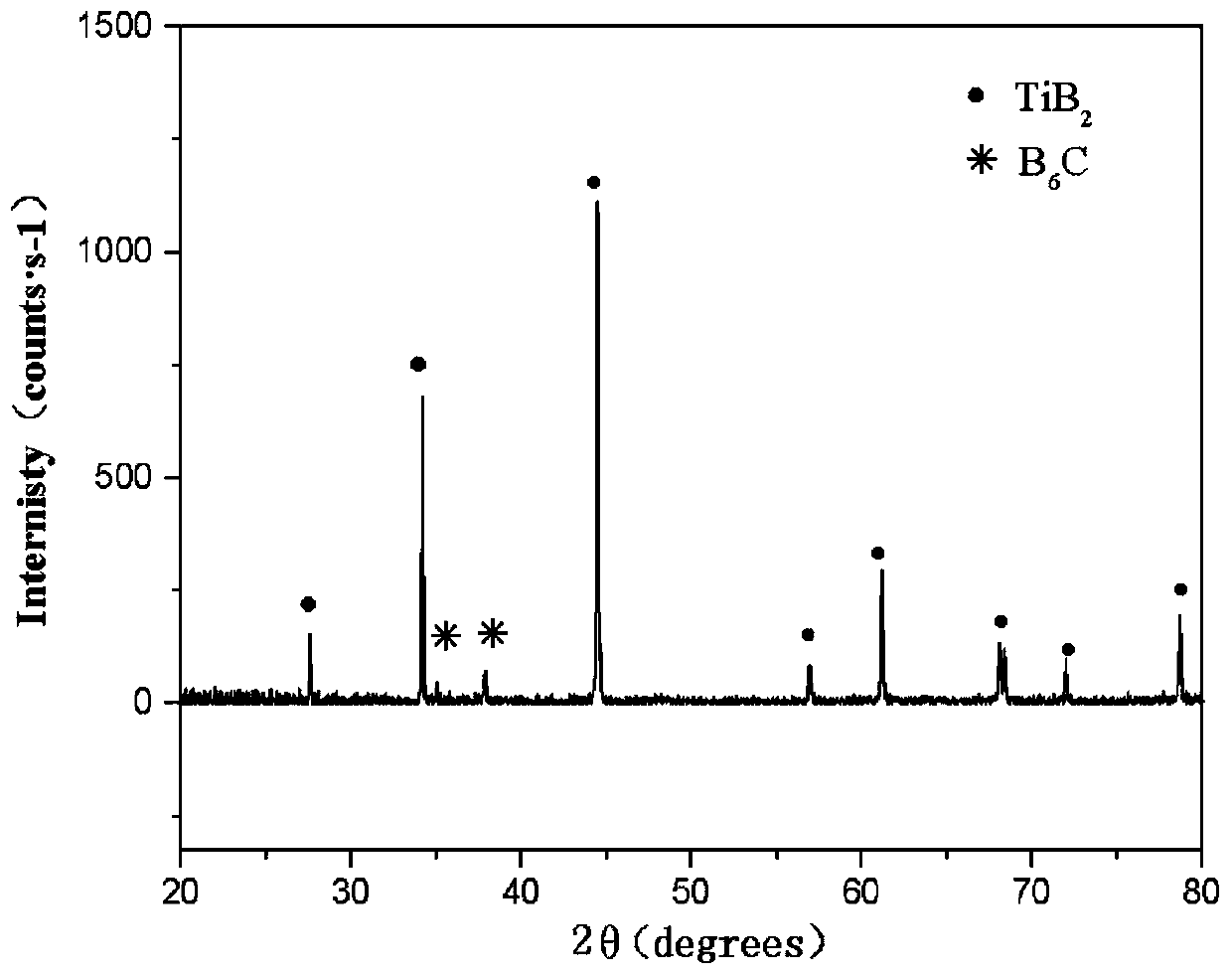

Embodiment 2

[0041] The preparation method of boron-rich boron carbide-titanium boride ceramic composite material described in this example, the specific steps include:

[0042] 1) weighing 40.98% of the raw material titanium carbide powder and 59.12% of the boron powder by weight percentage for subsequent use;

[0043]2) Put the weighed powder into the zirconia ball mill tank of the planetary ball mill, add ethanol solution as the dispersion medium for mixing, the total volume of powder, balls and ethanol is half of the volume of the ball mill tank, planetary The rotating speed of the ball mill is 250r / min, and the ball milling time is 2h. After the mixing is completed, the balls are removed by sieving to obtain the slurry of the mixed powder;

[0044] 3) The slurry is dried in a vacuum oven at 70°C for 36 hours, ground after drying, and granulated through a 200-mesh sieve to obtain a mixed powder;

[0045] 4) Put the mixed powder obtained after drying and sieving into a cylindrical grap...

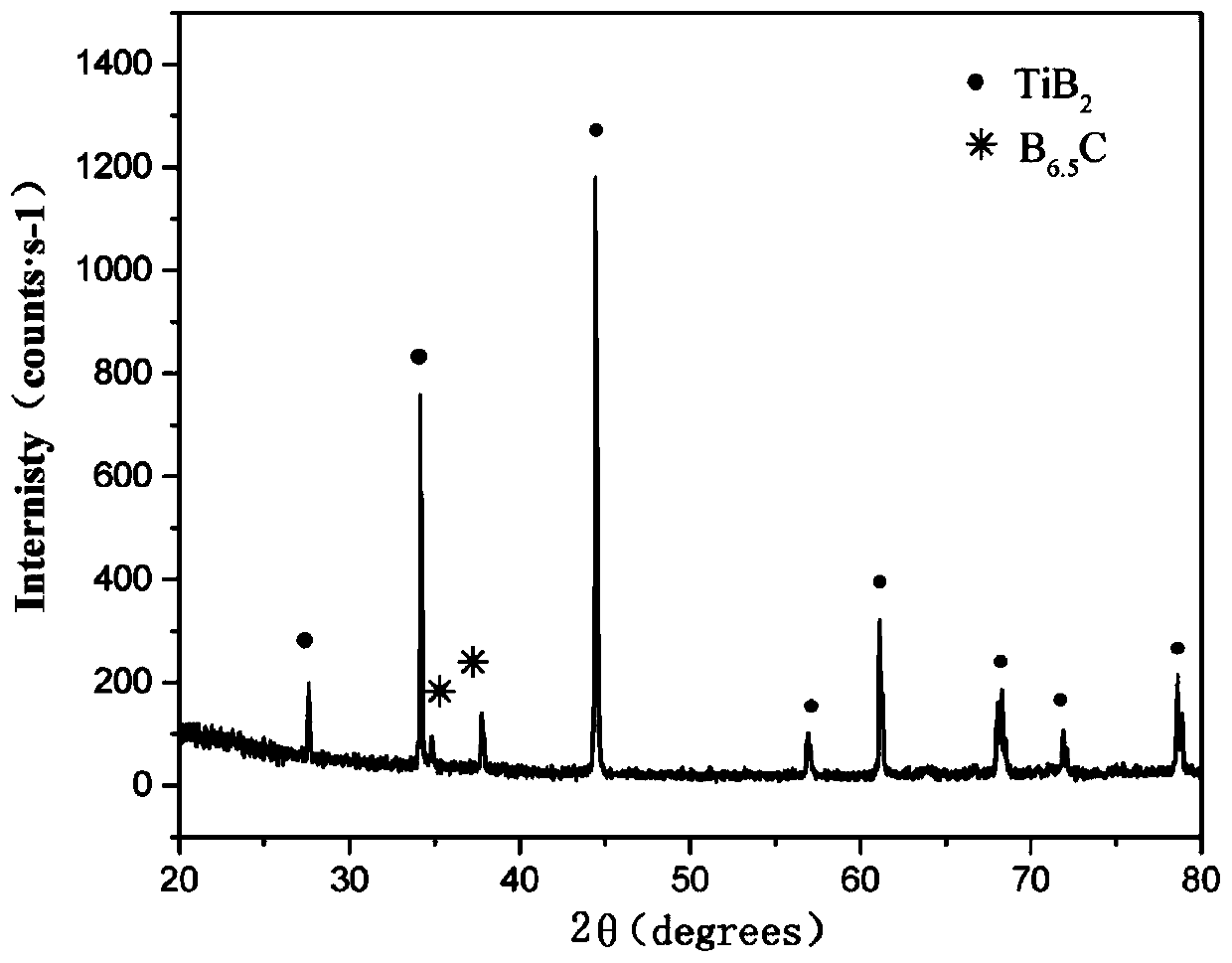

Embodiment 3

[0048] The preparation method of boron-rich boron carbide-titanium boride ceramic composite material described in this example, the specific steps include:

[0049] 1) weighing 39.52% of the raw material titanium carbide powder and 60.48% of the boron powder by weight percentage;

[0050] 2) Put the weighed powder into the zirconia ball mill tank of the planetary ball mill, add ethanol solution as the dispersion medium for mixing, the total volume of powder, balls and ethanol is two-thirds of the volume of the ball mill tank, planetary The rotating speed of the ball mill is 300r / min, and the ball milling time is 2h. After the mixing is completed, the balls are removed by sieving to obtain the slurry of the mixed powder;

[0051] 3) The slurry was dried in a vacuum drying oven at 80°C for 48 hours, ground after drying, and granulated through a 325 mesh sieve to obtain a mixed powder;

[0052] 4) Put the mixed powder obtained after drying and sieving into a cylindrical graphite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com