Preparation method of Sn-Si alloy-type nano-composite powder

A nano-composite and alloy-type technology, which is applied in the field of nano-materials and new functional materials preparation, can solve the problems of low cost, high output and size controllable, and achieve strong controllability of technical parameters, simple process route, and process flow. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

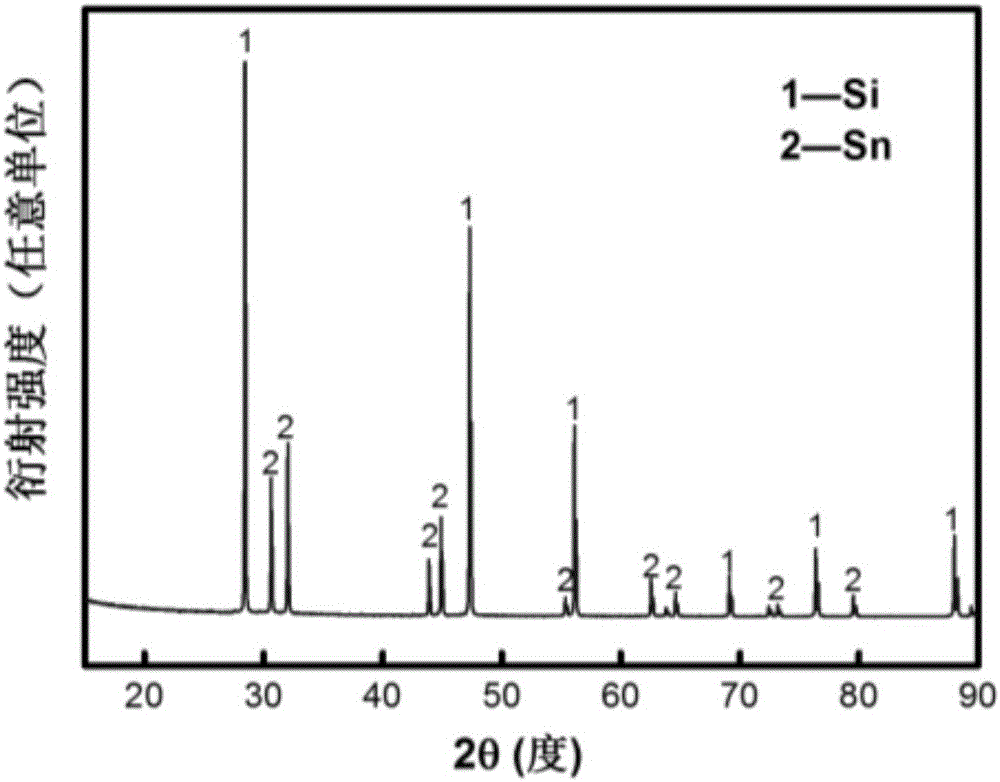

[0023] (1) First, make the ratio according to the stoichiometric ratio Sn:Si=0.34:0.66, and adjust the power in the high vacuum suspension smelting furnace to melt the Sn block (lower melting point and high gasification temperature) and gradually increase the power , The corresponding power range is 6-10kW, which melts the Si block. After the whole is liquefied, it is suspended for 2 minutes and then cooled.

[0024] (2) The prepared alloy ingot is used as the anode, and when the volume ratio of hydrogen to inert gas is 1:1, a high-intensity arc is formed by discharge, the arcing current is 250A, the arc voltage is 30V, evaporation and condensation Sn-Si particles are then formed. The whole process lasts for 40 minutes, the powder output is nearly 50%, and the Sn-Si material with a large amount of Si remains in the anode.

Embodiment 2

[0026] (1) First, make the ratio according to the stoichiometric ratio Sn:Si=0.3:0.7, and adjust the power in the high vacuum suspension melting furnace to melt the Sn block (lower melting point and high gasification temperature) and gradually increase the power , The corresponding power range is 6 ~ 11kW, so that the Si block melts. After the whole is liquefied, it is suspended for 2 minutes and then cooled.

[0027] (2) The prepared alloy ingot is used as the anode, and when the volume ratio of hydrogen to inert gas is 1:1, a high-intensity arc is formed through discharge, the arcing current is 100A, the arc voltage is 15V, evaporation and condensation Sn-Si particles are then formed. The entire process lasts for 40 minutes, the powder output is nearly 40%, and the Sn-Si material with a large amount of Si remains in the anode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com