Preparation method of Ti3SiC2 reinforced Ag-based electric contact material

A technology of electrical contact materials and reinforcement phases, applied in the field of metal matrix composite materials, can solve the problems of complex process, high cost, and large energy consumption, and achieve the effects of low cost, short production cycle, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] First, weigh Ti 3 SiC 2 powder 0.1g, Ag powder 9.9g as the preparation of Ag-Ti 3 SiC 2 The raw material of the electric contact material is dried by wet ball milling for 5 minutes to obtain a mixed powder, which is cold-pressed at 100 MPa to obtain a green body, and finally sintered in a sintering furnace under the protection of an Ar atmosphere. The sintering temperature is 700 ° C, and the heating rate is 5°C / min, sintering time 12h, to get Ag-1wt.%Ti 3 SiC 2 electrical contact material. The relative density reaches 90.3%, the hardness reaches HV55, and the resistivity is 1.87×10 -3 mΩ·cm.

Embodiment 2

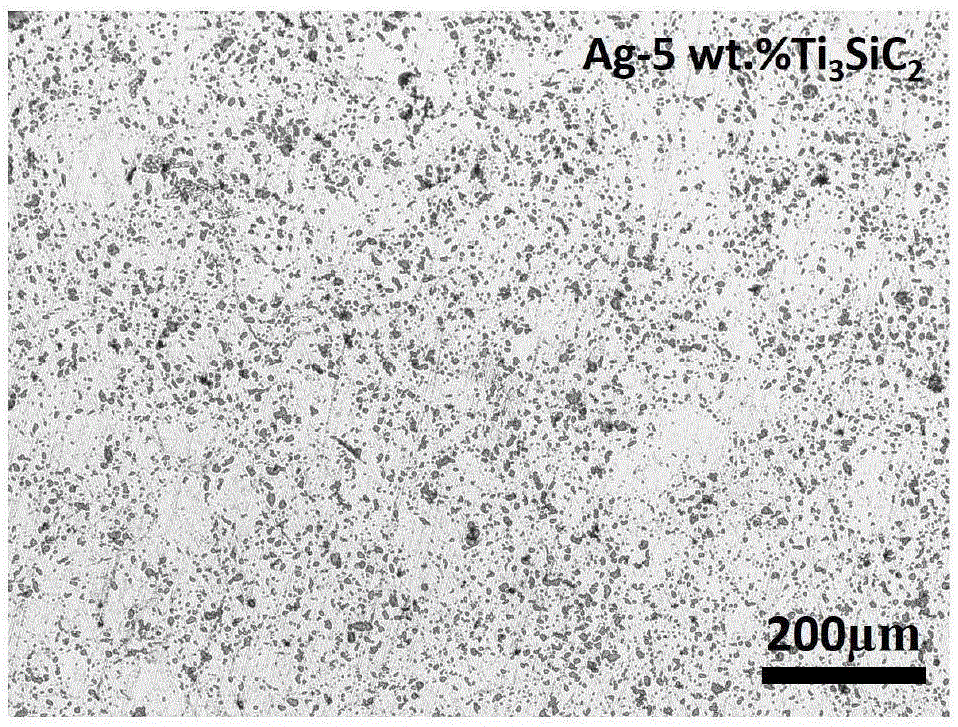

[0021] First, weigh Ti 3 SiC 2 powder 0.5g, Ag powder 9.5g as the preparation of Ag-Ti 3 SiC 2 The raw material of the electric contact material is dried by wet ball milling for 90 minutes to obtain a mixed powder, which is cold-pressed at 600MPa to form a green body, and finally sintered in a sintering furnace under the protection of an Ar atmosphere. The sintering temperature is 800°C and the heating rate is 5°C / min, sintering time 6h, to get Ag-5wt.%Ti 3 SiC 2 electrical contact material. The relative density reaches 95.77%, the hardness reaches HV53, and the resistivity is 2.35×10 -3 mΩ·cm.

Embodiment 3

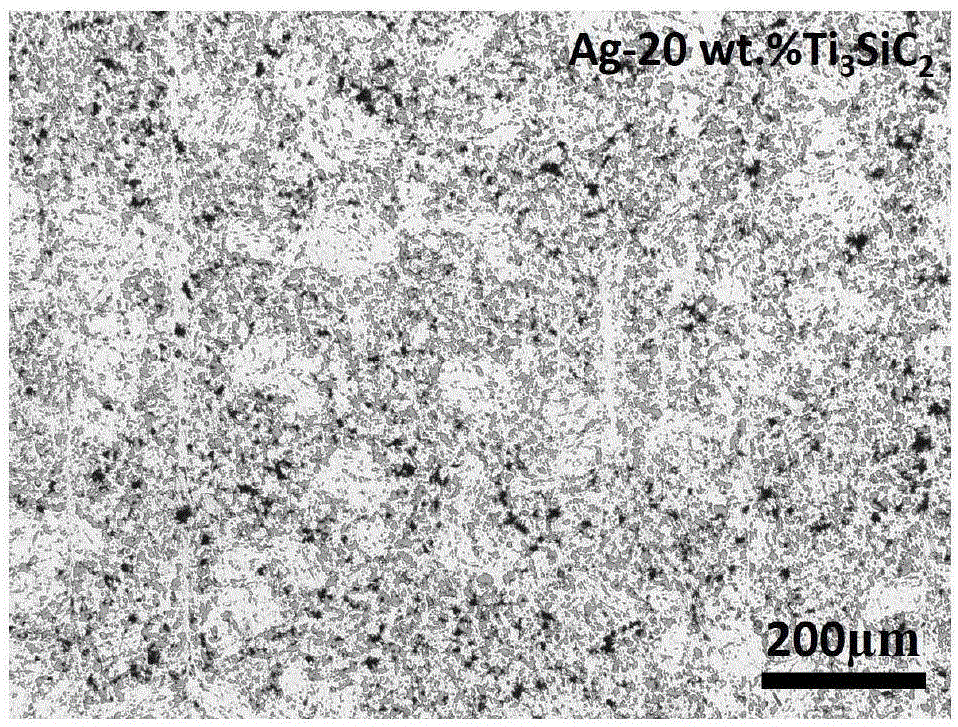

[0023] First, weigh Ti 3 SiC 2 powder 2.0g, Ag powder 8.0g as the preparation of Ag-Ti 3 SiC 2 The raw material of the electric contact material is dried by wet ball milling for 60 minutes to obtain a mixed powder, which is cold-pressed at 550MPa to obtain a green body, and finally sintered in a sintering furnace under the protection of an Ar atmosphere. The sintering temperature is 900°C and the heating rate is 10℃ / min, sintering time 4h, get Ag-20wt.%Ti 3 SiC 2 electrical contact material. The relative density reaches 93.5%, the hardness reaches HV71, and the resistivity is 5.98×10 -3 mΩ·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com