Silicon/lithium silicate composite material, preparation method thereof and power battery

A composite material, lithium silicate technology, applied in silicates, secondary batteries, battery electrodes, etc., can solve the problem of lack of effective methods to suppress silicon electrode materials, improve the first charge and discharge efficiency, increase volume expansion Risk, bloat-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

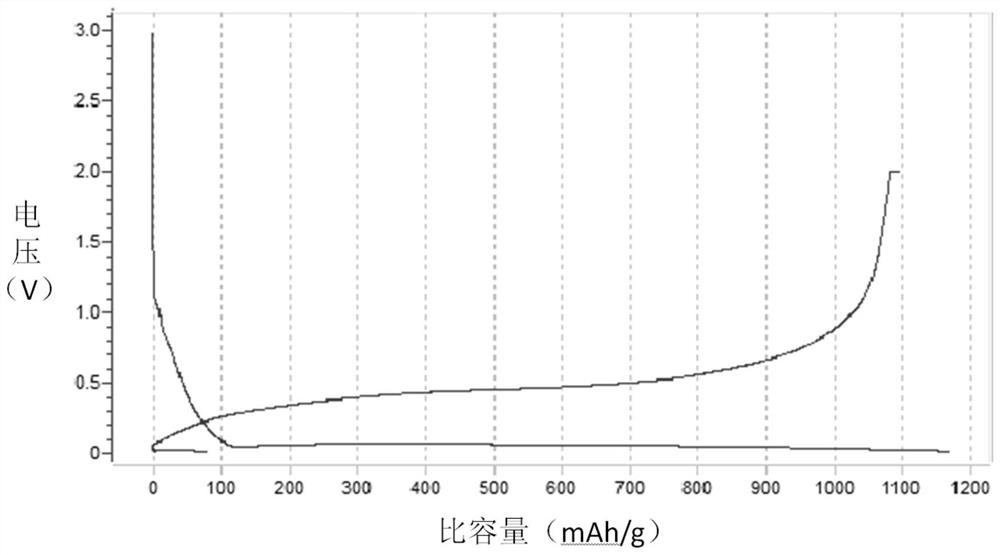

Image

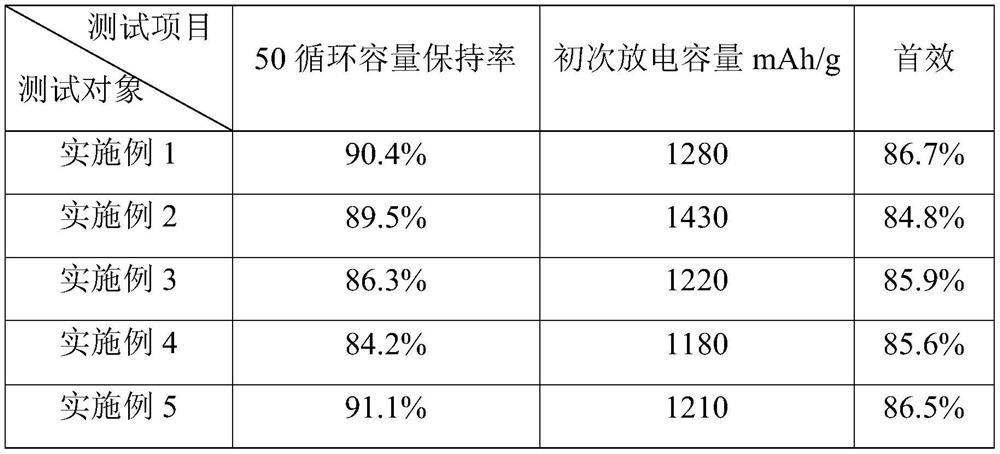

Examples

preparation example Construction

[0050] The first aspect of the embodiments of the present invention provides a method for preparing a silicon / lithium silicate composite material, comprising the following steps:

[0051] S10. Introducing gaseous Si and gaseous SiO into the reaction vessel 2 and gaseous Li 2 O, and react in the gas phase;

[0052] S20. Depositing the reaction product at a temperature of 500° C. to 700° C. to obtain a silicon / lithium silicate composite material.

[0053] In the preparation method of the silicon / lithium silicate composite material provided by the first aspect of the embodiment of the present invention, gaseous Si, gaseous SiO 2 and gaseous Li 2 O, and react in a gas phase state; then, at a temperature of 500°C to 700°C, deposit the reaction product to obtain a silicon / lithium silicate composite material. The preparation method of silicon / lithium silicate composite material of the embodiment of the present invention, with gaseous Si, SiO 2 and Li 2 O is the reaction raw mat...

Embodiment 1

[0093] A silicon / lithium silicate composite material, comprising the following preparation steps:

[0094] (1) Prepare silicon / lithium silicate composite materials in an alloying furnace with three evaporation sources. First, Si, SiO 2 and Li 2 O three raw materials are respectively placed in the three evaporation source reactors of the equipment, SiO 2 , Si and Li 2 The mass ratio of O is: SiO 2 :Si:Li 2 O=1:1:1;

[0095] (2) Adjust the atmosphere inside the alloying furnace to vacuum, and the vacuum degree is controlled at -0.1±0.01MPa; 2 , Si and Li 2 The temperature of the three evaporation sources of O increased to 1200 ° C, 1200 ° C, 1600 ° C, SiO 2 , Si and Li 2 O The three reactants are evaporated after heating up; the evaporator is heated in the equipment and undergoes a series of reactions to form silicon and lithium silicate, and then deposits in the collector. The temperature range of the collector is 500 ° C to obtain a silicon / lithium silicate composite m...

Embodiment 2

[0100] A silicon / lithium silicate composite material, comprising the following preparation steps:

[0101] (1) Prepare silicon / lithium silicate composite materials in an alloying furnace with three evaporation sources. First, Si, SiO 2 and Li 2 O three raw materials are respectively placed in the three evaporation source reactors of the equipment, SiO 2 , Si and Li 2 The mass ratio of O is: SiO 2 :Si:Li 2 O=1:3:1;

[0102] (2) Adjust the atmosphere inside the alloying furnace to vacuum, and the vacuum degree is controlled at -0.1±0.01MPa; 2 , Si and Li 2 The temperature of the three evaporation sources of O increased to 1200 °C, 1200 °C and 1600 °C, SiO 2 , Si and Li 2 O The three reactants are evaporated after heating up; the evaporator is heated in the equipment and undergoes a series of reactions to form silicon and lithium silicate, and then deposits in the collector, and the temperature range of the collector is 500°C;

[0103] (3) crushing the compound in the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com