Nanometer titanium dioxide film and preparation method thereof, and preparation method of photoelectric device

A technology of nano-titanium dioxide and thin film, which is applied in the fields of electrical solid-state devices, semiconductor/solid-state device manufacturing, nanotechnology, etc., can solve the problems of poor uniformity and poor compactness of the nano-titanium dioxide electron transport layer film, and achieve improved photoelectric efficiency, surface compactness, The effect of increasing the migration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

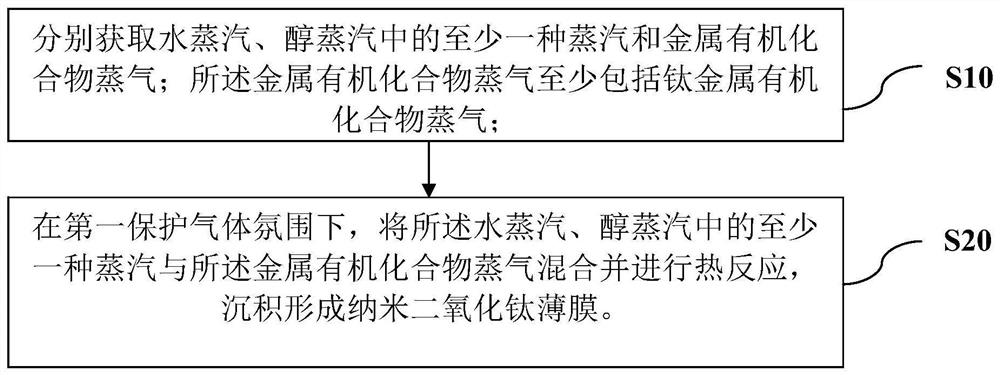

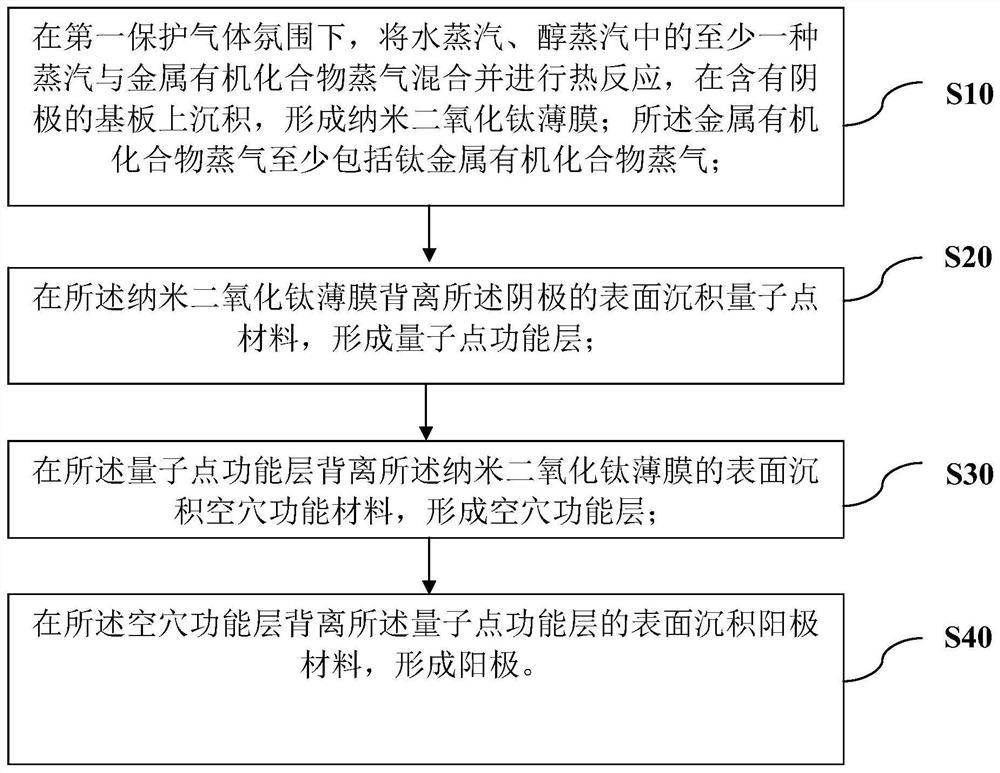

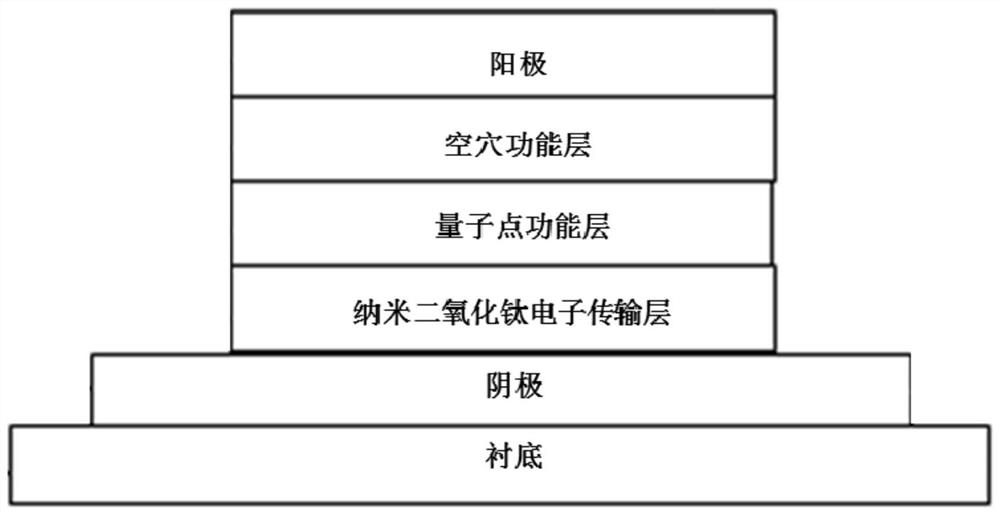

[0029] as attached figure 1 As shown, the first aspect of the embodiment of the present application provides a method for preparing a nano-titanium dioxide film, comprising the following steps:

[0030] S10. Obtaining at least one of water vapor, alcohol vapor, and metal-organic compound vapor respectively; the metal-organic compound vapor includes at least titanium metal-organic compound vapor;

[0031] S20. Under the atmosphere of the first protective gas, at least one vapor of water vapor and alcohol vapor is mixed with metal-organic compound vapor and thermally reacted to deposit and form a nano-titanium dioxide film.

[0032]The first aspect of the present application provides a method for preparing a nano-titanium dioxide film, using titanium metal organic compound vapor and water vapor and / or alcohol vapor as reaction raw materials, so that each raw material component reacts in a gas phase state, and each raw material component can be more uniform The distribution and ...

Embodiment 1

[0085] (1) A nano-titanium dioxide electron transport layer, comprising the steps of:

[0086] The cleaned ITO conductive glass substrate is transferred to the furnace body of the vapor deposition furnace, and high-purity argon gas is introduced to remove the air in the furnace body. Next, the temperature of the furnace body was raised and stabilized at 550°C. Then, add butyl titanate and deionized water into the steam generator, and adjust the temperature of butyl titanate and deionized water to 115°C and 100°C respectively, and wait for the temperature of butyl titanate and deionized water to stabilize , switch the protective gas circuit, make the high-purity argon flow into the steam generating device respectively equipped with butyl titanate and deionized water at a flow rate of 100ml / min, and generate corresponding butyl titanate steam and water vapor by bubbling. Steam is loaded into the vapor deposition furnace body. After continuing the reaction for 30 minutes, switc...

Embodiment 2

[0092] (1) A nano-titanium dioxide electron transport layer, comprising the steps of:

[0093] The cleaned ITO conductive glass substrate is transferred to the furnace body of the vapor deposition furnace, and high-purity argon gas is introduced to remove the air in the furnace body. Next, the temperature of the furnace body was raised and stabilized at 550°C. Then, add isopropyl titanate and deionized water into the steam generator, and adjust the temperature of isopropyl titanate and deionized water to 105°C and 100°C respectively. After the temperature stabilizes, switch the protective gas circuit so that the high-purity argon enters the steam generating device equipped with isopropyl titanate and deionized water at a flow rate of 100ml / min, and generates corresponding isopropyl titanate steam and steam, and load the steam into the vapor deposition furnace body. After continuing to react for 30 minutes, switch the gas path, turn off the steam generator, and stop the loadi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com