Growth method of p-type SiC with high doping uniformity

A growth method and uniformity technology, which is applied in the growth field of p-type SiC with high doping uniformity, can solve the problems of p-type SiC doping inhomogeneity, and achieve uniform resistivity, high quality and resistivity uniformity, The effect of maintaining crystal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for growing p-type SiC with high doping uniformity, the steps are as follows:

[0035] 1) Weigh 1500g of C powder and Si powder in a molar ratio of 1:1, and 2g of Al 4 C 3 Mix uniformly with Si powder and C powder for 2h to obtain a mixture;

[0036] 2) Put the mixture in a graphite crucible, heat it up to 1600°C, and keep it at 600mbar for 4h, the synthesis temperature is not easy to be too high to prevent Al 4 C 3 Premature gasification occurs to ensure that the Al element can be integrated into the SiC grains, and the SiC grains (Al-Si-C) containing the Al growth source are obtained;

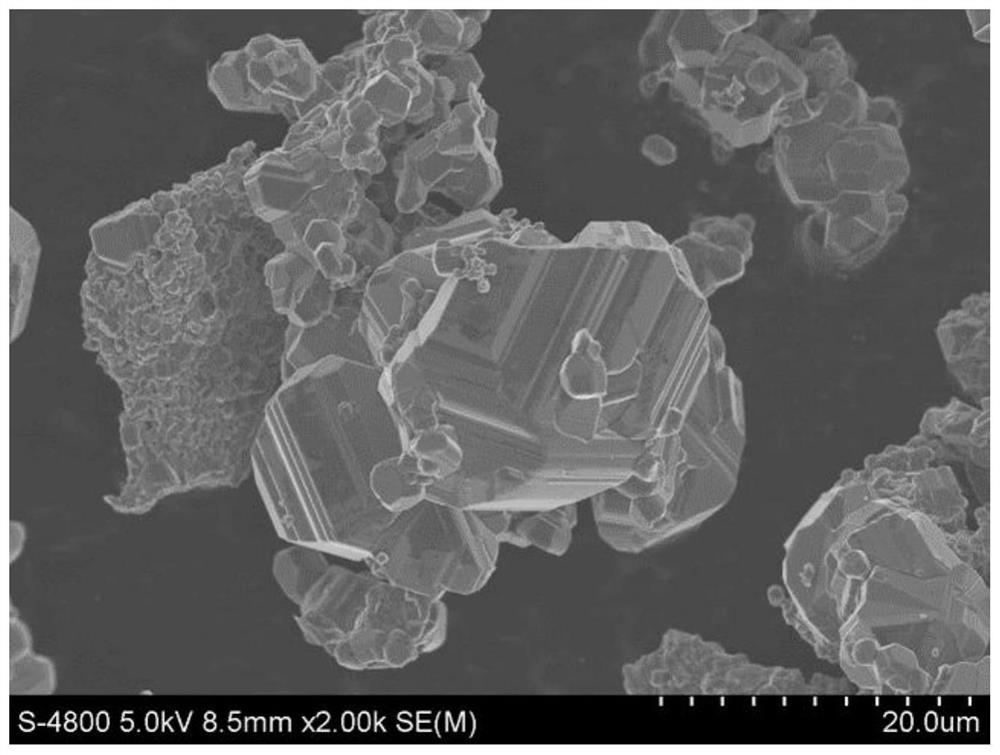

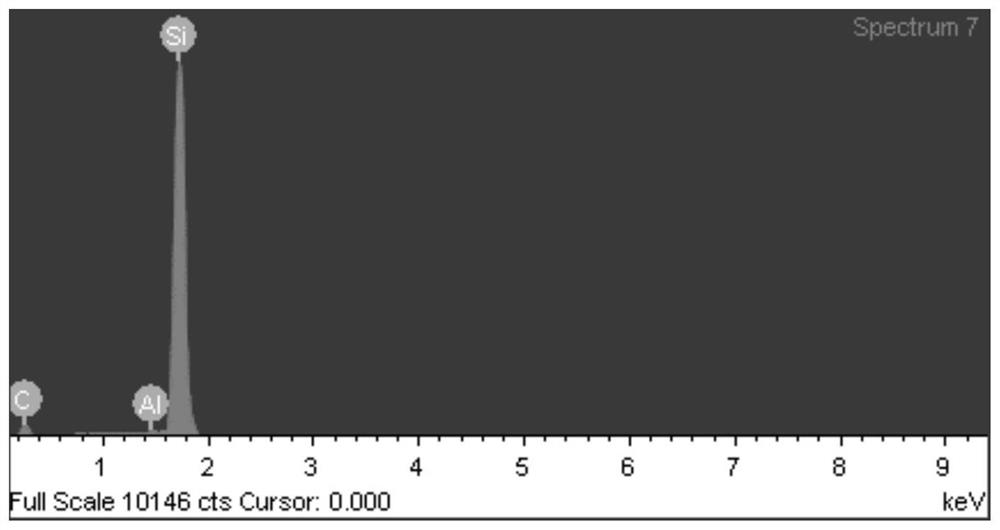

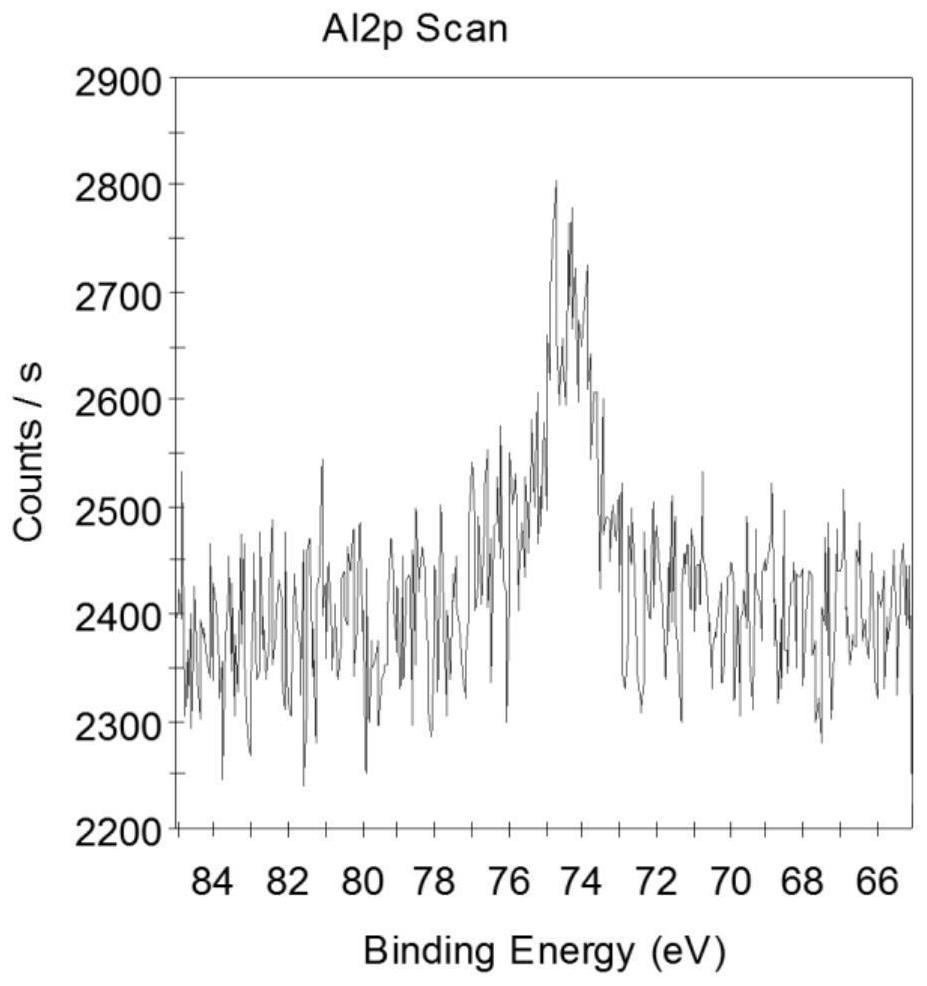

[0037] The SEM images and EDS images of the prepared SiC grains (Al-Si-C) containing Al growth source are shown in figure 1 , figure 2 As shown, the Al element XPS pattern of the SiC grain containing the Al growth source is shown in image 3 As shown, XPS testing of Al element indicates the formation of Al-C bonds in the grains.

[0038] 3) Then the synthesized SiC cry...

Embodiment 2

[0044] A method for growing p-type SiC with high doping uniformity, the steps are as follows:

[0045] 1) Weigh 3000g of C powder and Si powder in a molar ratio of 1.4:1, and 60g of Al 2 O 3 Mix uniformly with Si powder and C powder for 1 h to obtain a mixture;

[0046] 2) Put the mixture in a graphite crucible, heat it up to 2000°C, and keep it at 900mbar for 8h. The synthesis temperature should not be too high to prevent Al 2 O 3 Premature gasification occurs to ensure that the Al element can be integrated into the SiC grains, and the SiC grains (Al-Si-C) containing the Al growth source are obtained;

[0047] 3) Then the synthesized SiC crystal grains (Al-Si-C) containing the Al growth source are taken out.

[0048] 4) Load the SiC grains (Al-Si-C) containing the Al growth source into the growth crucible, without adding Al dopant into the powder;

[0049] 5) Put the loaded crucible into the growth chamber of the PVT single crystal furnace to grow p-type crystals; obtain...

Embodiment 3

[0051] A method for growing p-type SiC with high doping uniformity, the steps are as follows:

[0052] 1) Weigh 1500g of C powder and Si powder in a molar ratio of 1:1, and 3g of Al 4 C 3 Mix uniformly with Si powder and C powder for 3h to obtain a mixture;

[0053] 2) Put the mixture in a graphite crucible, heat it up to 2100 ° C, and keep it at 1 mbar for 60 hours. The synthesis temperature should not prevent Al 4 C 3 Premature gasification occurs to ensure that the Al element can be integrated into the SiC grains to obtain SiC polycrystalline ingots containing Al growth sources (Al-Si-C); SiC polycrystalline ingots containing Al growth sources such as Image 6 shown.

[0054] 3) Then the synthesized SiC polycrystalline ingot (Al-Si-C) containing the Al growth source is taken out.

[0055] 4) The SiC polycrystalline block (Al-Si-C) containing the Al growth source is loaded into the growth crucible, and there is no need to add Al dopant into the powder;

[0056] 5) Put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com