Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Single crystal form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

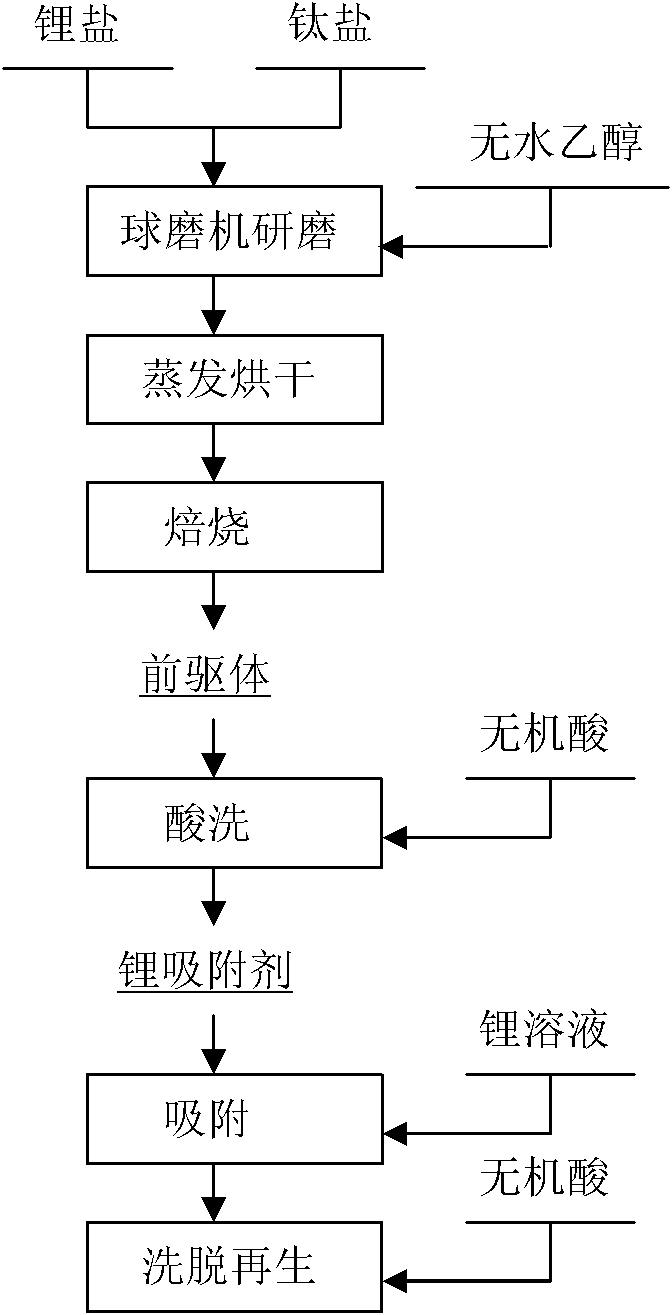

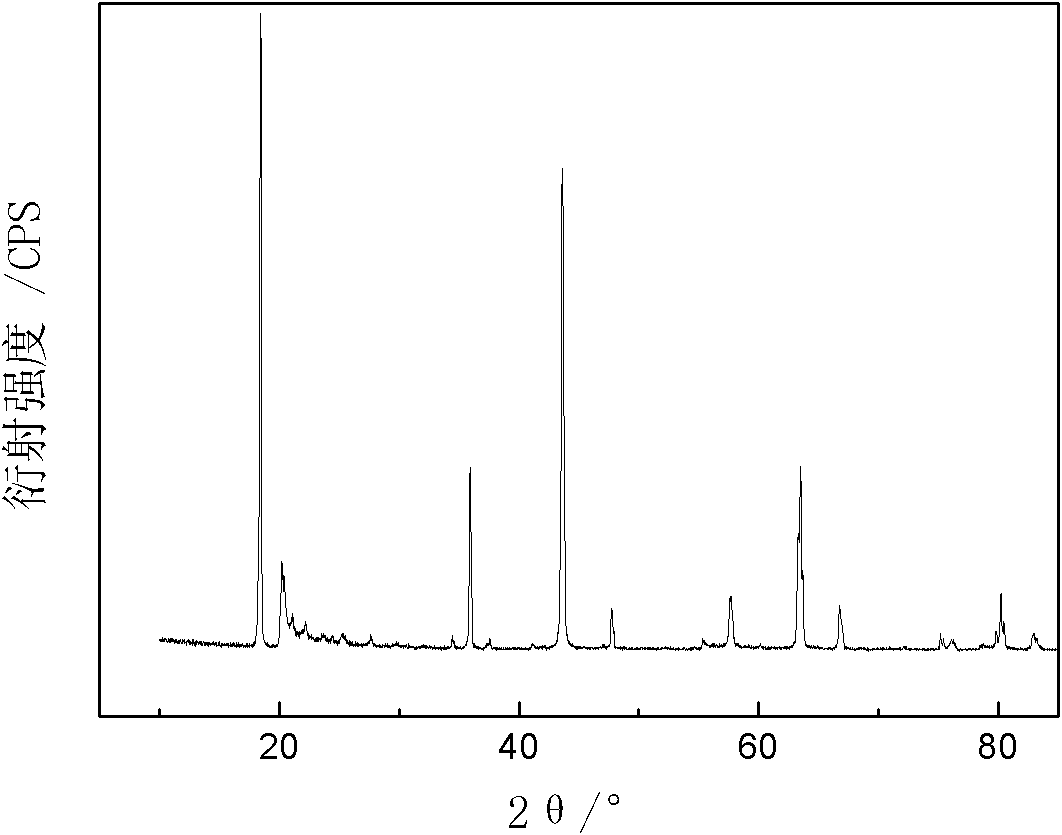

Lithium-titanium oxide type lithium ion sieve absorbent and method for preparing precursor thereof

InactiveCN101944600AWell mixedIncrease contact surfaceCell electrodesTitanium compoundsSalt lake brineTitanium oxide

The invention discloses a lithium-titanium oxide type lithium ion sieve absorbent and a method for preparing a precursor thereof, and relates to a method for preparing an inorganic absorbent for absorbing enriched lithium from salt lake brine, seawater and other liquid lithium resources. The method is characterized in that: titanium dioxide and lithium salt are taken as raw materials, ground by a ball grinder and dried so as to prepare a precursor Li2TiO3 of an ion sieve through a high-temperature solid-phase roasting method; and the lithium is eluted from the precursor Li2TiO3 by inorganic acid to prepare an ion sieve H2TiO3. The method has the advantage of simple technology, and the obtained ion sieve has the advantages of low solution loss and high adsorption capacity.

Owner:CENT SOUTH UNIV

Quzhazhigan crystal and preparation method and application thereof

ActiveCN102276666ASingle crystal formHigh purityOrganic active ingredientsSugar derivativesSolubilitySingle crystal

The invention relates to the pharmaceutical chemistry field, and discloses a quzhazhigan crystal and a preparation method and an application thereof. The quzhazhigan crystal of the invention has a single crystal form, high purity, good stability, high solubility and bioavailability. The preparation method of the quzhazhigan crystal of the invention has simple operation, easily available raw materials, low production cost, continuous operation, and is applicable to mass preparation of the quzhazhigan crystal.

Owner:KPC PHARM INC

Production method of ferrous oxalate special for ferrous lithium phosphate

InactiveCN1948259ASingle crystal formCarboxylic acid salt preparationReaction temperaturePhosphoric acid

The present invention relates to a method for preparing ferrous oxalate. Said method uses ferrous sulfate and oxalic acid as raw material, and includes the following steps: pretreatment of ferrous sulfate, said pretreatment includes: water-washing ferrous sulfate and inhibiting hydrolysis of its aqueous solution; mixing the pretreated ferrous sulfate with ammonium oxalate and oxalic acid according to the mole ratio of 3:7-8:2 to obtain their mixed solution; making said mixed solution produce reaction for 10-20 min at 65-95 deg.C, then standing still for 2-4 h, separating, washing and drying so as to obtain the invented product ferrous oxalate.

Owner:HEFEI ASIALON CHEM

Method for preparing doped perovskite structural material

The invention provides a method for preparing a doped perovskite structural composite oxide, which comprises two steps, namely preparation and sintering of sol-gel. The preparation of the sol-gel comprises the following steps of selecting an element containing Sr or Zr as a group A element and selecting an element containing three elements selected from Ti, Fe, Cu, Pd and Mn as a group B element to prepare perovskite structural composite oxide gel of which the general formula is AB1-x-yB'xB''yO3-epsilon, wherein x and y are more than 0 and less than 0.5; and epsilon is more than -0.5 and less than 0.5 and is an oxygen lattice defect number. The obtained gel is sintered in a muffle furnace of which the temperature can be controlled by a program to obtain a perovskite oxide material which has a high crystallization degree, a single crystal form and a compact surface. The perovskite oxide material can be applied to a piezoelectric material or an electronic apparatus and can also be made into a compact ion conducting oxygen-permeable membrane for oxygen separation.

Owner:CHINA PETROLEUM & CHEM CORP +1

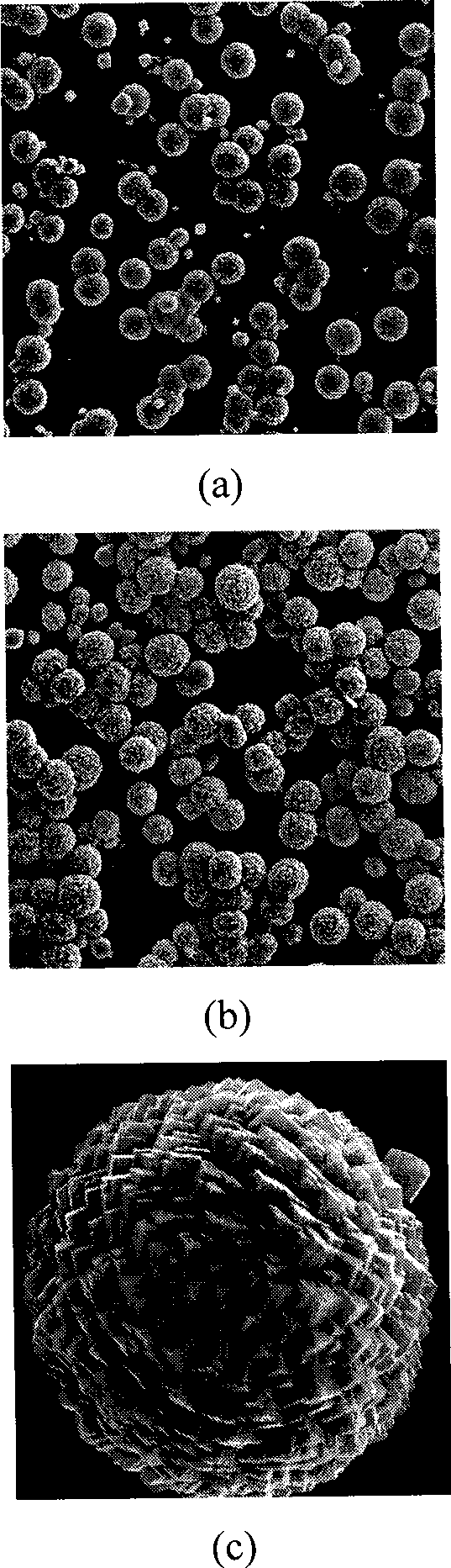

Preparation method of electrolytic manganese dioxide for positive material-lithium manganate of lithium battery

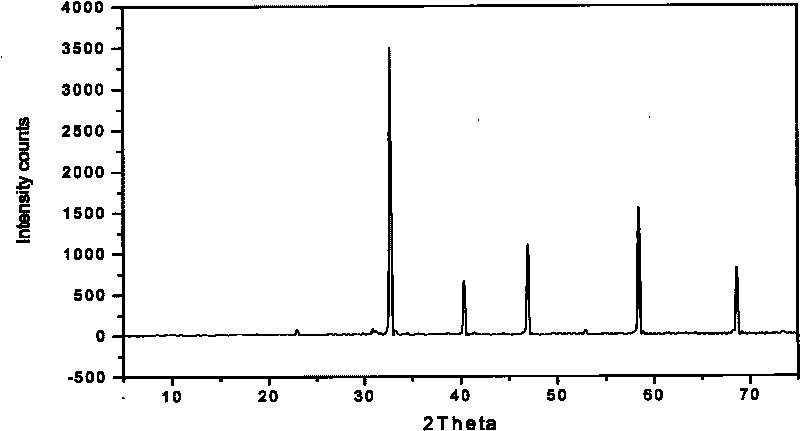

ActiveCN103579608ASingle crystal formHas a pure β-type structureElectrolysis componentsCell electrodesManganese sulphateElectrolysis

The invention discloses a preparation method of electrolytic manganese dioxide for positive material-lithium manganate of a lithium battery. The method comprises the steps of (1) mixing manganese oxide ore powder with pyrite powder, and then adding the mixture and sulfuric acid into a leaching tank with continuous stirring according to a certain material ratio for reacting, thus obtaining a manganese sulfate solution, wherein the process reaction temperature is 85-90 DEG C and the reaction time is 3h-4h; (2) removing potassium; (3) purifying to remove impurities; (4) carrying out electrolysis; (5) dissolving; (6) carrying out high-temperature calcination to obtain the electrolytic manganese dioxide product. The electrolytic manganese dioxide prepared by the method is single in crystal form and has a pure beta type structure, so that lithium can be easily embedded in and removed out from the electrolytic manganese dioxide; the electrolytic manganese dioxide is very low in the content of impurities, so that the lithium manganate produced from the electrolytic manganese dioxide has excellent electrical property and safety performance.

Owner:GUANGXI GUILIU CHEM CO LTD

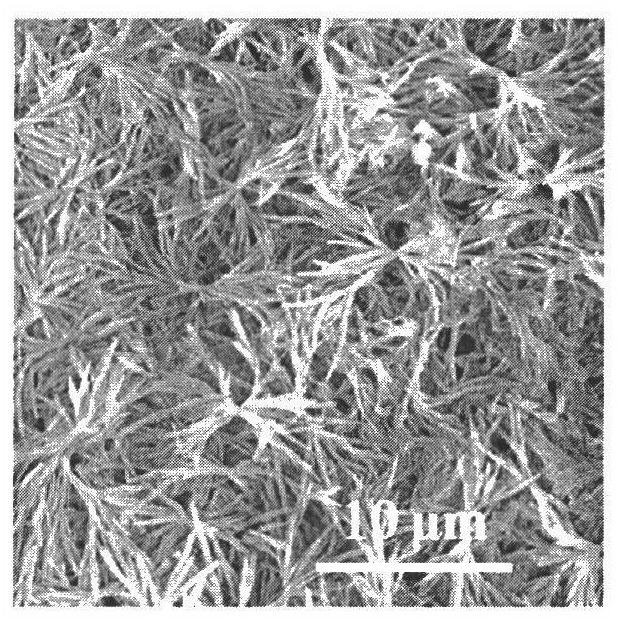

Preparation method of barium carbonate powder

InactiveCN102417198AComplex and uniqueUniform particle sizeCalcium/strontium/barium carbonatesNanotechnologyBarium saltSolvent

The invention, belonging to the technical field of inorganic salt materials, provides a preparation method of barium carbonate powder. The method comprises the following steps: selecting proper barium salt, adding a fresh prepared morphology regulator (water-soluble cellulose derivative), regulating the pH value to a proper value, using high pressure / supercritical carbon dioxide as a carbonic acid source (with certain temperature and pressure), reacting for different time to obtain a white turbid liquid; and separating and drying the white turbid liquid to obtain a required product. According to the invention, the batch production of barium carbonate powder with different morphologies (rodlike-type, dendritic-type, dumbbell-type, ball-type, symmetric-type and the like) and dimensions (500 nm-30 mu m) can be realized, the obtained barium carbonate product has good dispersibility and has a purity of more than 99.8 %; in addition, the method has the advantages of wide source of raw materials, low price, easy operation, little pollution of the used solvents, and no toxic and harmful effect, satisfies the requirement of green chemistry, and has the potential of large scale production.

Owner:FUDAN UNIV

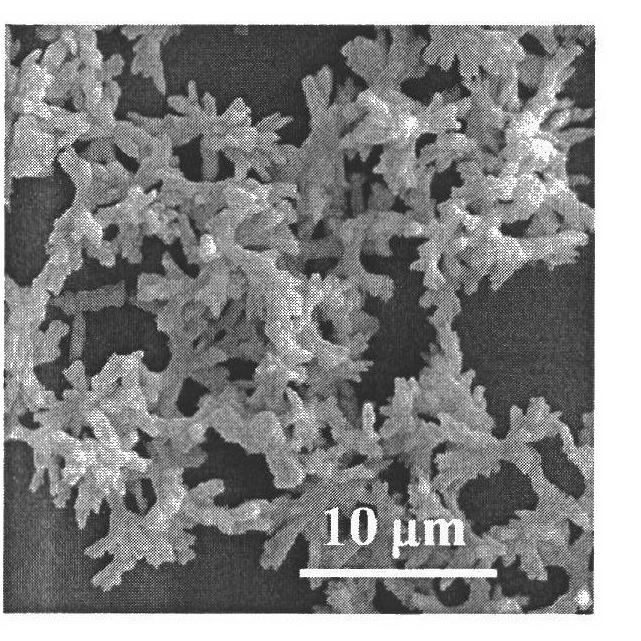

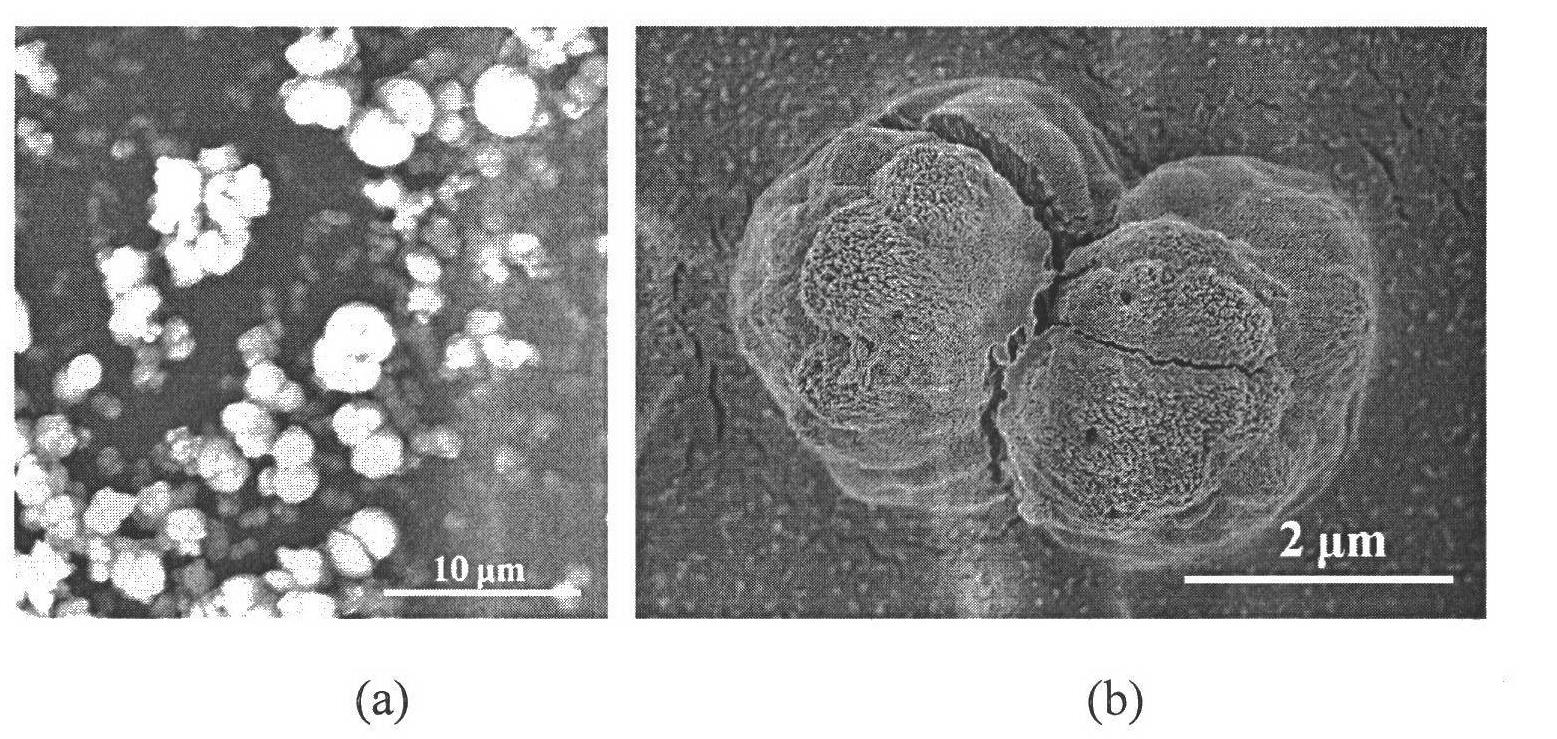

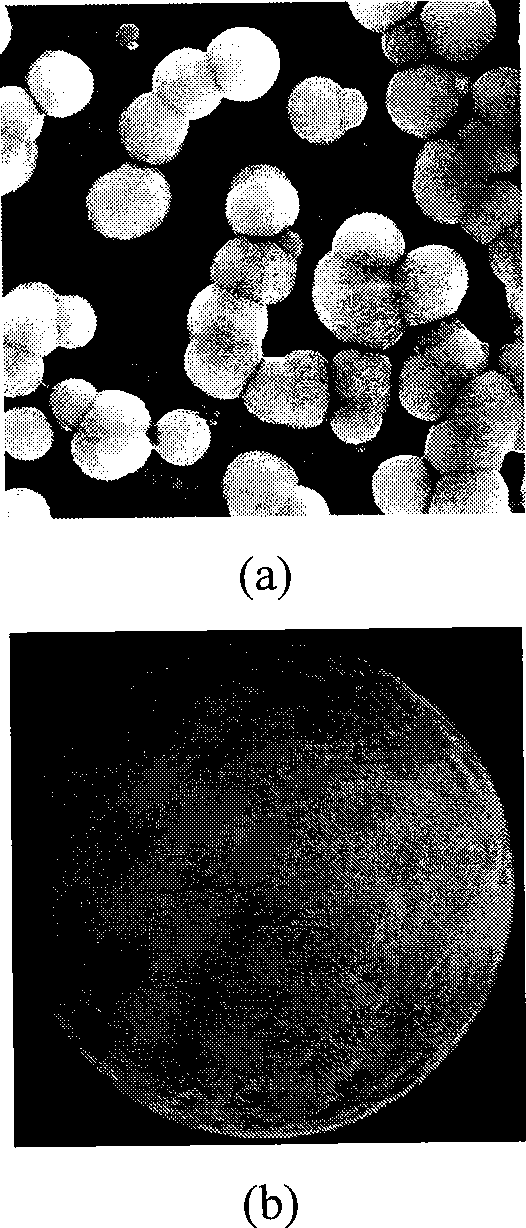

Process for producing monodisperse polymer/calcium carbonate composite fine particle

InactiveCN101429284AComplex and uniqueUniform particle sizePigment treatment with macromolecular organic compoundsPolymer scienceDecomposition

The invention belongs to the technical field of an organic and inorganic composite material, in particular to a method for preparing monodisperse polymer / calcium carbonate composite particles. The method comprises the following steps: a glass apparatus is pretreated, a polymer solution the concentration of which is between 0.001 and 10 grams per liter is prepared, and 0.001-1 mol / liter calcium salt is added into the polymer solution to prepare a calcium salt / polymer mixture; the mixture stands, the pH value of the mixture is adjusted to between 6 and 13, and 10<1> to 10<3> milliliters of the mixture is taken out and filled into a beaker; a beaker with grinded carbonate is arranged inside a sealing system at a temperature of between 10 and 60 DEG C, and a layer of film is coated on the beaker to control the speed of decomposition and generation of carbon dioxide; a layer of film is coated on a mouth of the beaker which is filled with the mixture, and is provided with a plurality of holes by a pin, and the beaker is placed into the sealing system, reacts for 0.5 hours to 15 days, is taken out for separation of products; and the products are separated and dried to obtain the required products. The raw materials have wide sources and low cost; the solvent adopted has small pollution and no toxic action; and the preparation method is simple and easy to operate, accords with the requirement of green chemistry, and has the potential of large-scale production.

Owner:FUDAN UNIV

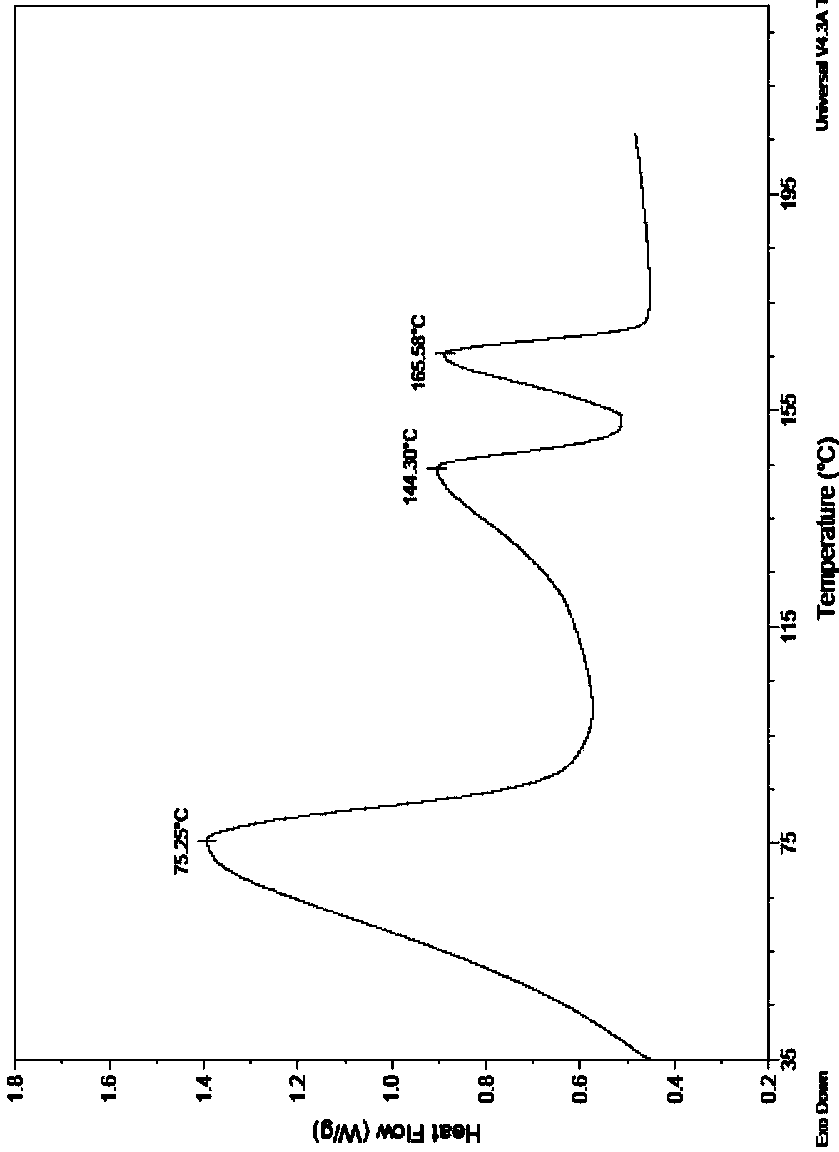

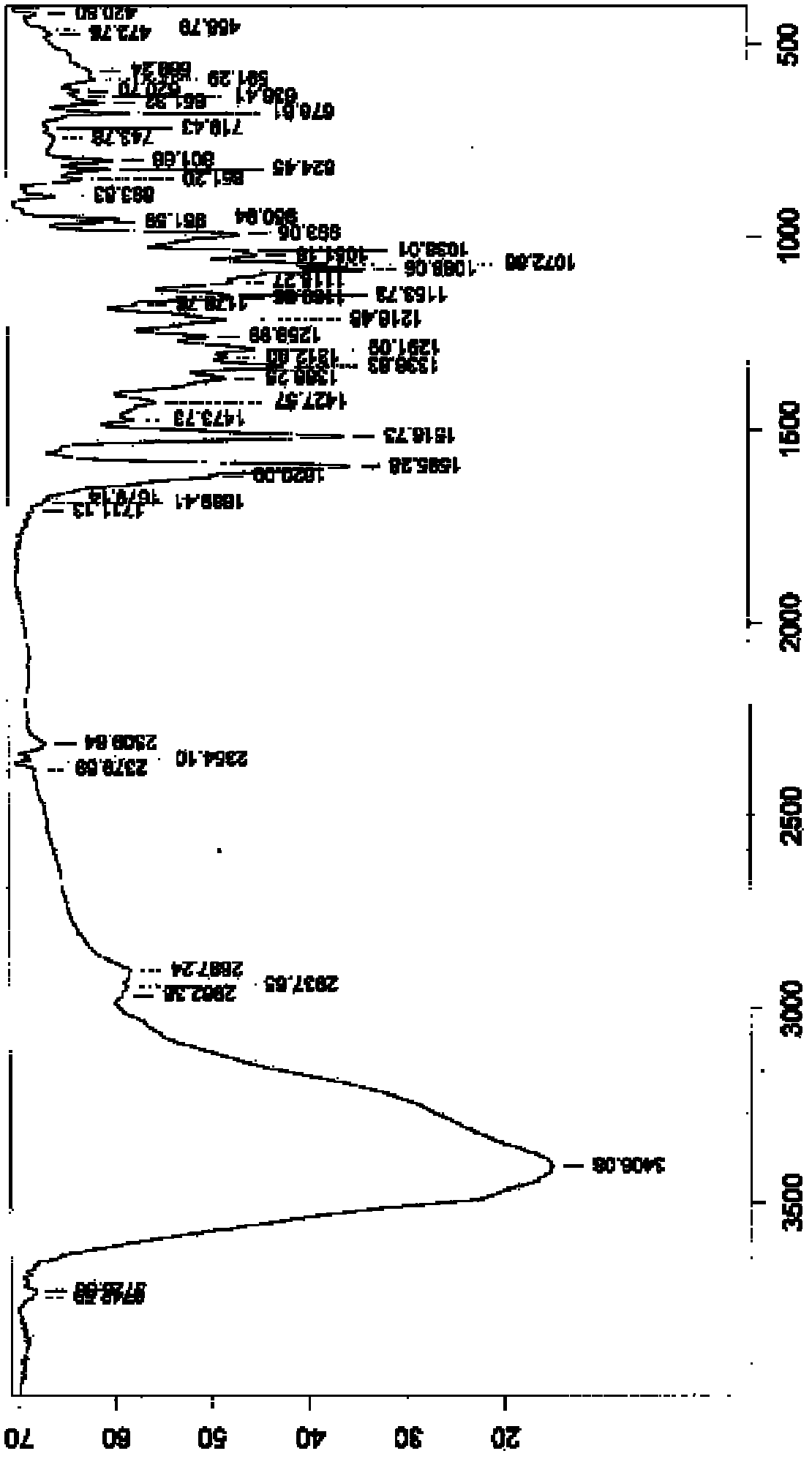

Preparation method of agomelatine I crystal form

The invention discloses a preparation method of agomelatine I crystal form. The preparation method comprises the following steps: heating and melting agomelatine at the temperature of 110-200 DEG C, then quickly cooling at the temperature of minus 20-30 DEG C and standing till crystallization. The method used by the invention is simple to operate, reaction conditions are easy to control, the yield is high, any organic solvent is not required, and the obtained crystal form is single, green, environment-friendly and very suitable for industrial production.

Owner:SUN YAT SEN UNIV

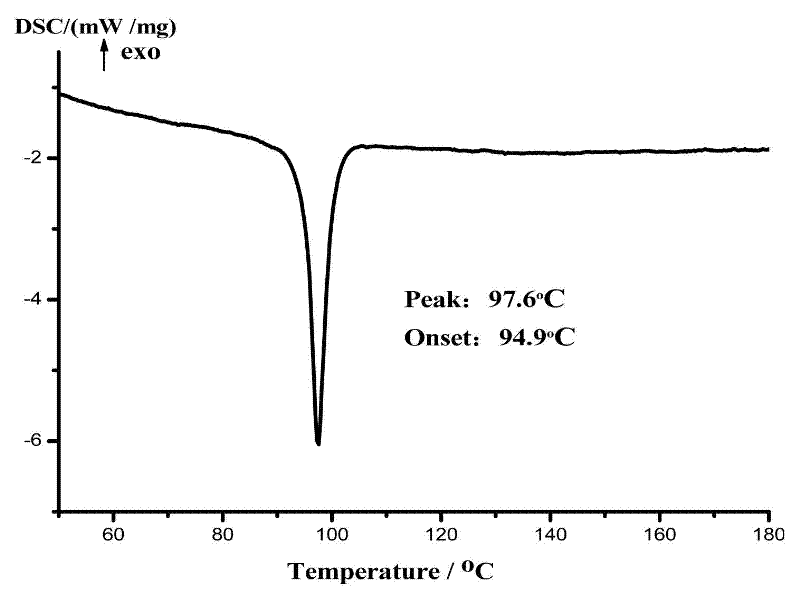

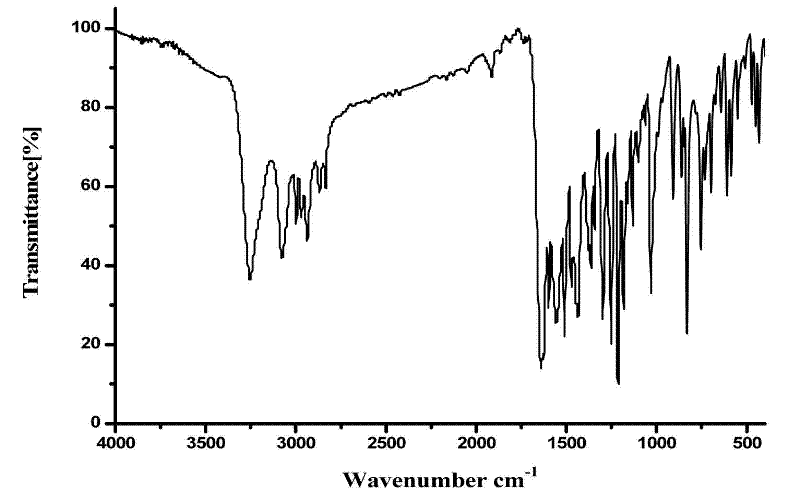

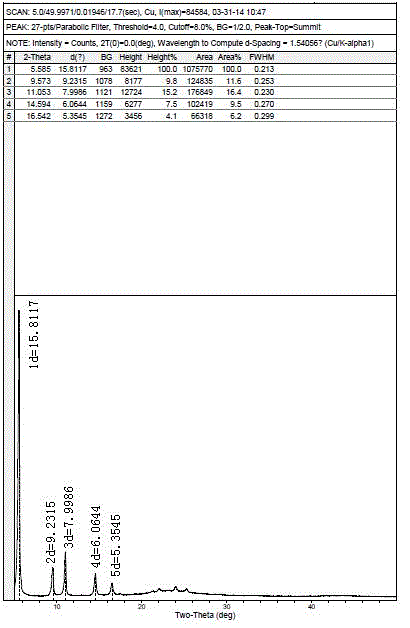

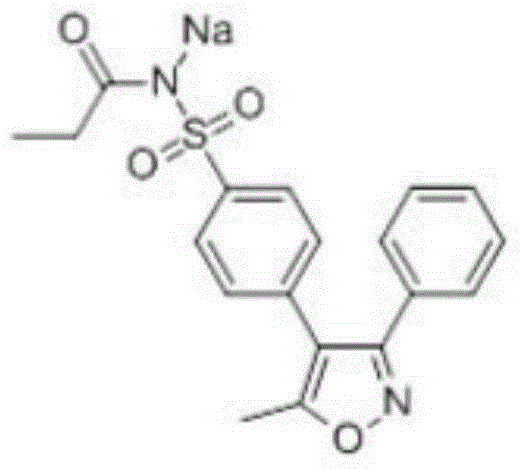

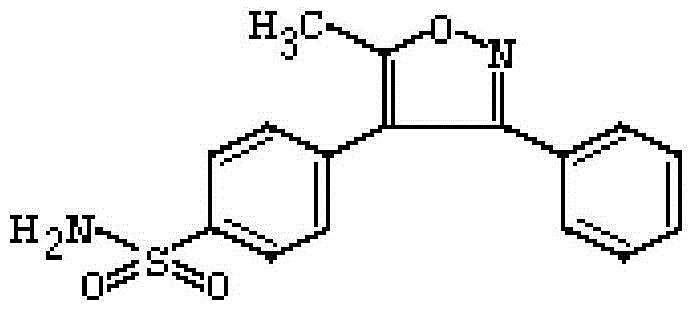

Preparation method of anhydrous and non-solvation A crystallization parecoxib sodium

InactiveCN104910091AHigh crystallinityImprove stabilityOrganic chemistrySodium acetateChlorosulfuric acid

The invention relates to a preparation method of anhydrous and non-solvation A crystallization parecoxib sodium. The method comprises the following steps: 1,2-phenylacetophenone and pyrrolidine are condensed to generate 1-(1,2-diphenylvinyl)pyrrolidine, then acetylation is carried out, and 4,5-dihydro-5-methyl-3,4-dibenzyl-5-isoxzzole alcohol are subjected to cyclization under sodium acetate and hydroxylamine hydrochloride. The compound is directly reacted to chlorosulfonic acid, dehydration and chlorine sulfonation reaction are carried out, and then valdecoxib can be obtained through ammonification, valdecoxib is refined, then is subjected to acetylation to obtain parecoxib, and salt forming is performed to obtain the target compound parecoxib sodium.

Owner:北京华睿鼎信科技有限公司

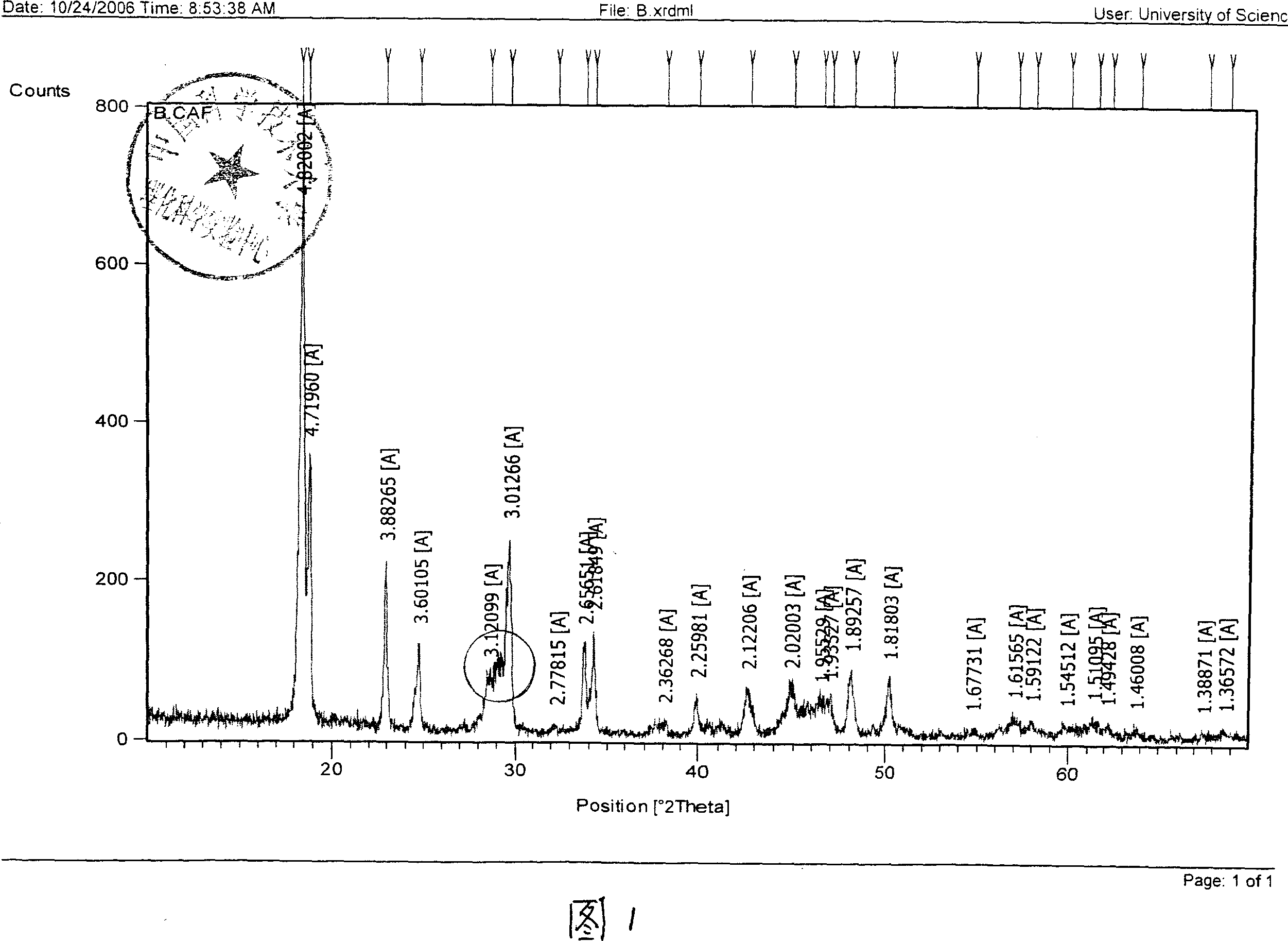

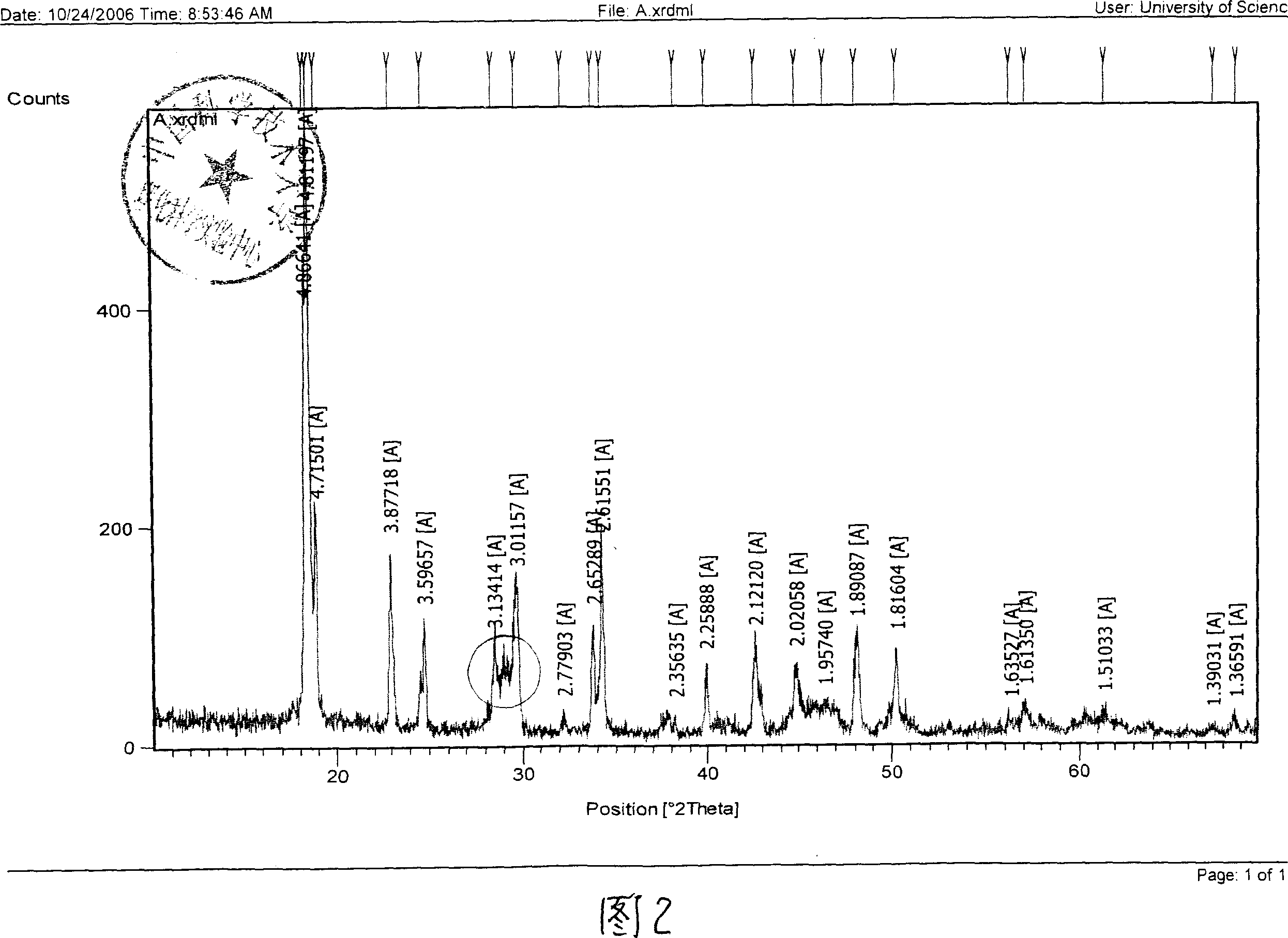

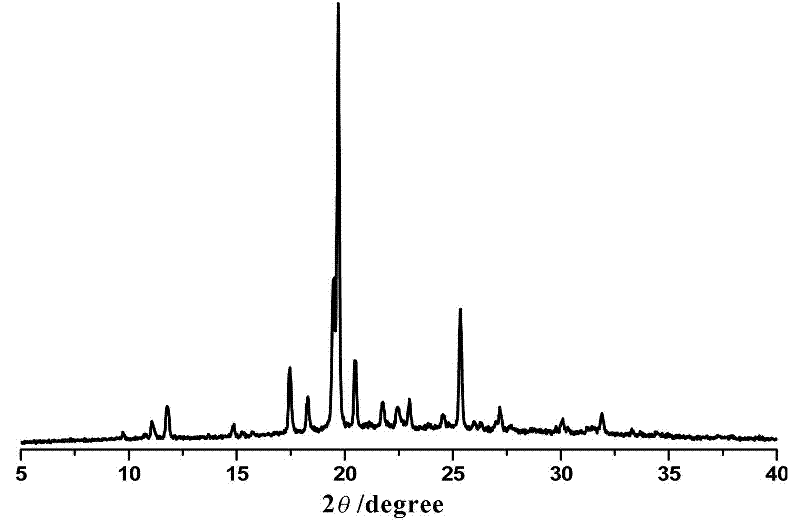

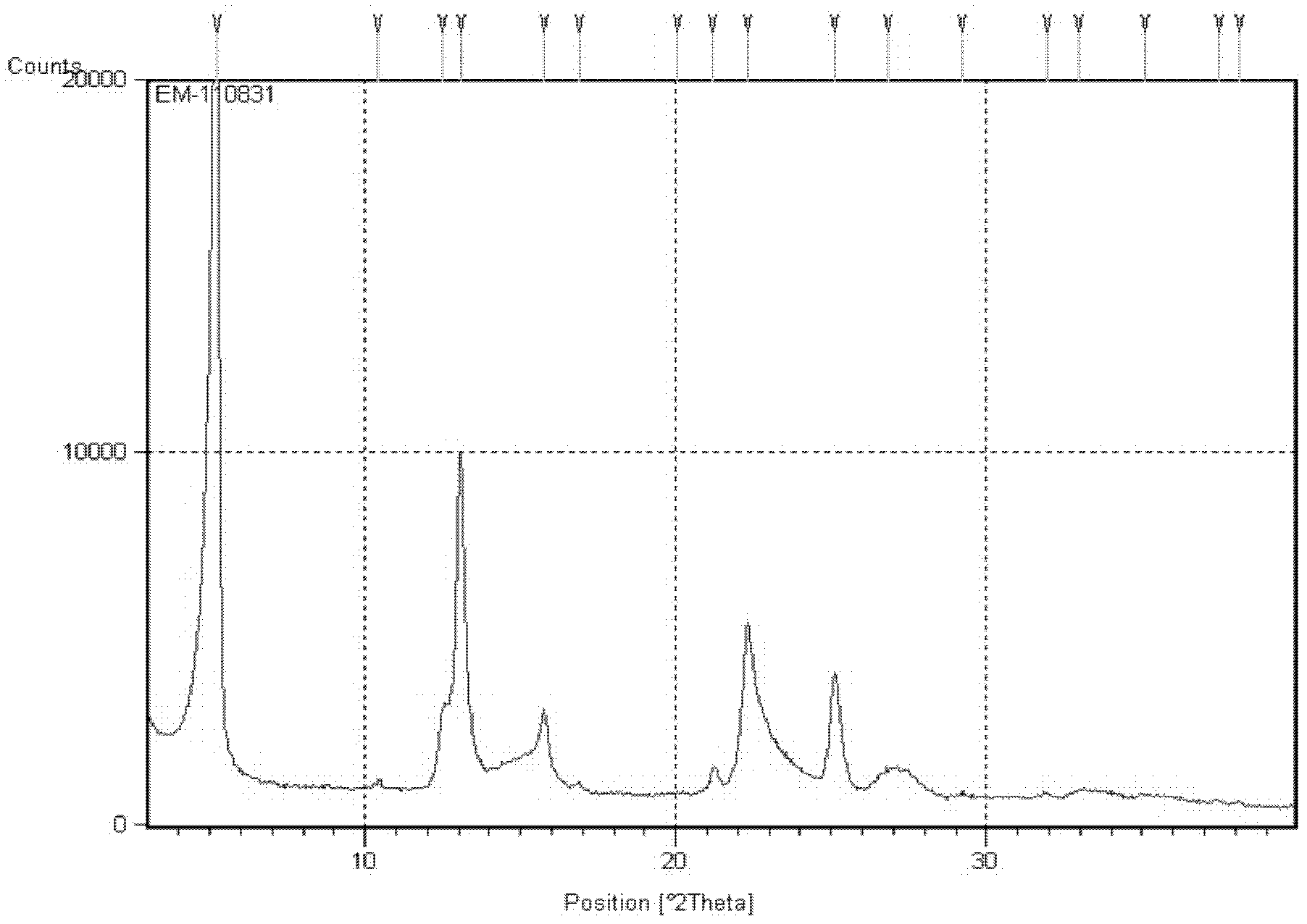

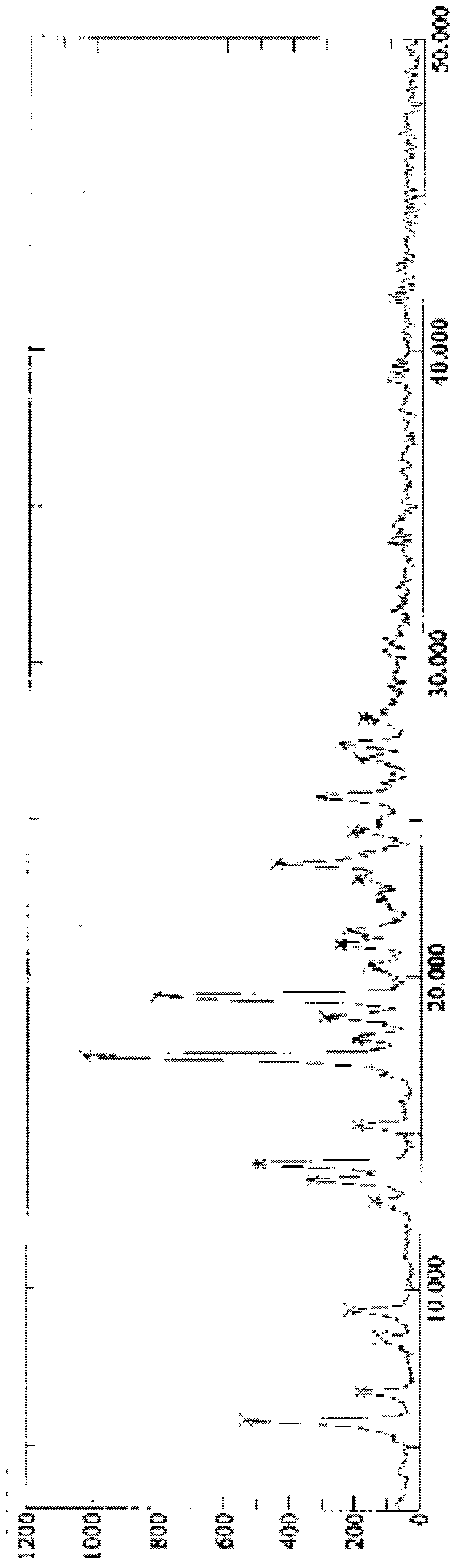

Acotiamide hydrochloride hydrate crystal form and preparation method thereof

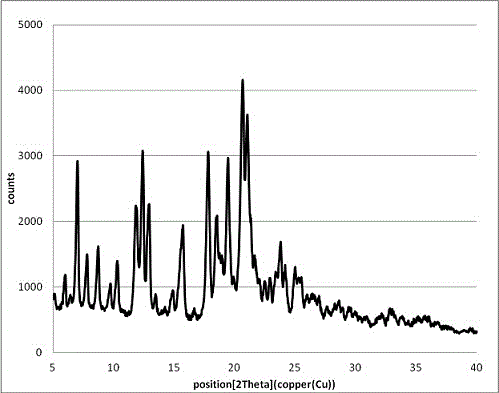

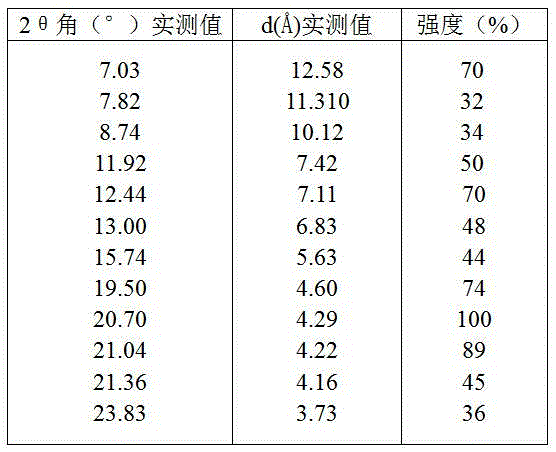

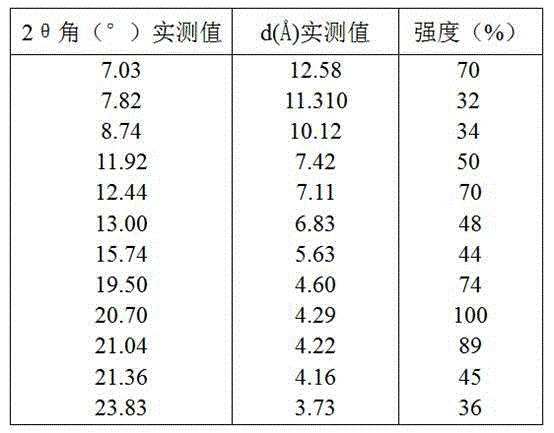

InactiveCN103980226ASingle crystal formStable in natureOrganic active ingredientsOrganic chemistrySingle crystalMedicinal chemistry

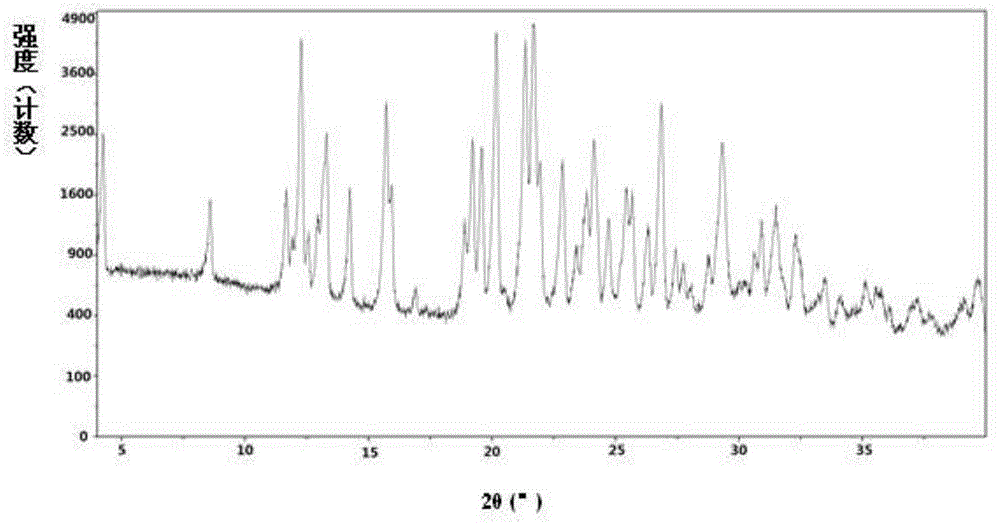

The invention relates to a crystal form of an acotiamide hydrochloride hydrate shown as a chemical formula (I) and a preparation method thereof. Specifically, the present invention discloses an acotiamide hydrochloride hydrate of crystal form A and a preparation method thereof, and the XRPD characteristic peak is shown as in a figure 1. The preparation method of the acotiamide hydrochloride hydrate of crystal form A provided by the invention is safe, simple and strongly operable, the prepared acotiamide hydrochloride hydrate of crystal form A has single crystal form, stable property and good repeatability, and suitable for drug development.

Owner:HANGZHOU XINBOSI BIOMEDICAL CO LTD

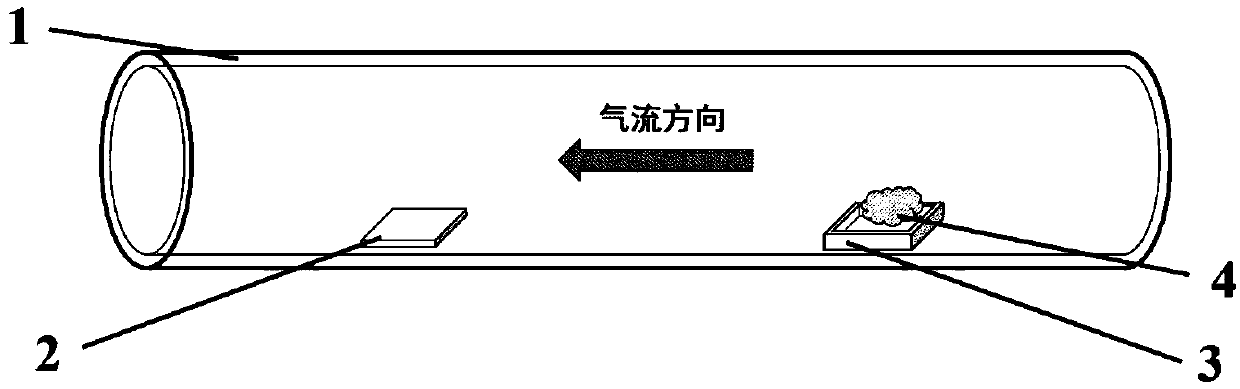

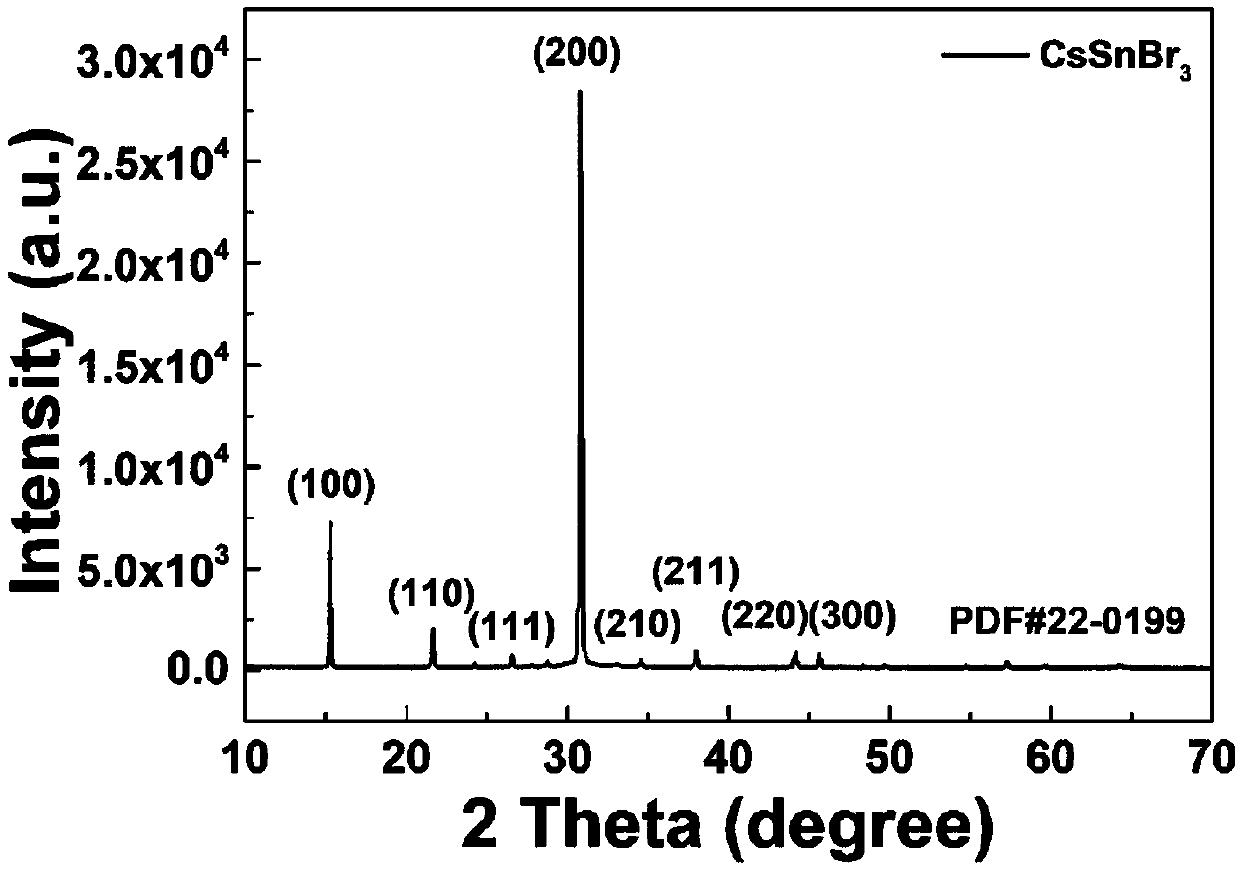

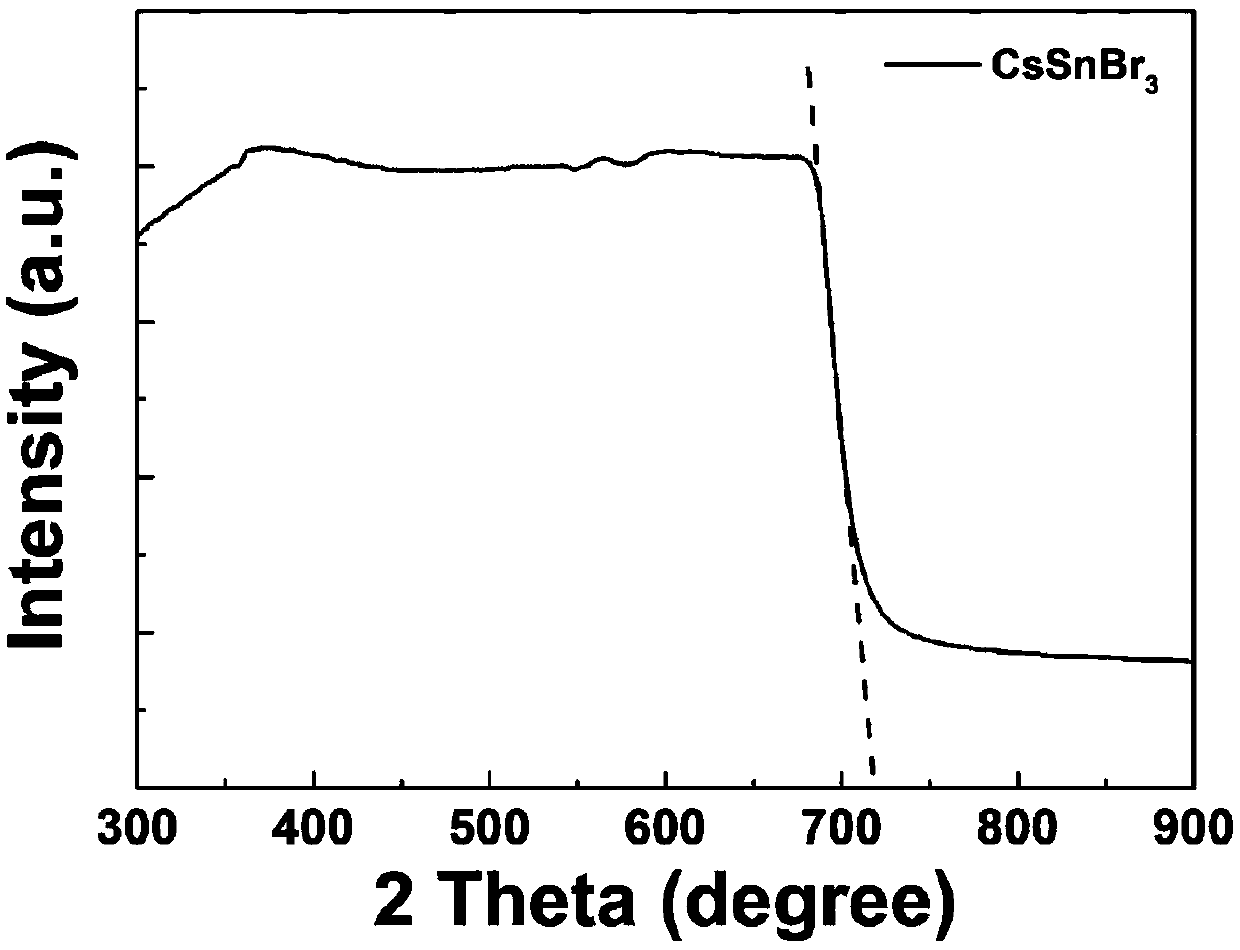

Preparation method for cesium-stannous halogen perovskite film material

InactiveCN109518161ASingle crystal formImprove crystal qualityChemical vapor deposition coatingHalogenTube furnace

The invention provides a preparation method for a cesium-stannous halogen perovskite film material. The method comprises the steps of placing mixed powder of CsX and SnX<2> and a substrate in a CVD tube furnace, vacuumizing, and feeding argon gas at the standard rate of 150-500 mL / min; holding the air pressure in a furnace chamber for 50-300 Pa, and then heating the interior of the furnace chamberto 500-800 DEG C for reaction; quenching upon completion of reaction, so that the cesium-stannous halogen perovskite film material is obtained; and the result shows that the cesium-stannous halogen perovskite film material prepared with the method is single in crystal form, and has high crystal quality and optical quality.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Clean production method of high-purity copper phthalocyanine

InactiveCN109504120AHigh puritySingle crystal formOrganic chemistryPorphines/azaporphinesSingle crystalSlurry

The invention provides a clean production method of high-purity copper phthalocyanine. The method comprises following steps: (1), synthesis: alkylbenzene is added to a condensation tank, phthalic anhydride is continuously added after the temperature is increased, urea, cuprous chloride and ammonium molybdate are added after phthalic anhydride is dissolved, the components are subjected to a reaction, and a crude copper phthalocyanine product is prepared; (2), refining: copper phthalocyanine slurry is prepared from the crude copper phthalocyanine product and added to a mixed solution N preparedfrom dilute sulfuric acid and a cosolvent, heating and stirring are performed until the crude copper phthalocyanine product is completely dissolved, then water is dropwise added until copper phthalocyanine crystals are not separated out, filtering is performed, a filter cake is subjected to ethanol washing, water washing, filtering and vacuum drying, and the high-purity copper phthalocyanine product is obtained; (2), waste liquor recovery: a large amount of filter liquor produced in a reaction process is adsorbed by ion exchange resin, neutralized, concentrated, evaporated and centrifuged, andan ammonium sulfate product is prepared. Copper phthalocyanine prepared with the method is high in purity and has single crystal form, good coloring effect and excellent color stability, meanwhile, tail gas and wastewater in the production are effectively treated, and economic benefits of energy conservation and emission reduction are obtained.

Owner:滨海康益医药化工有限公司

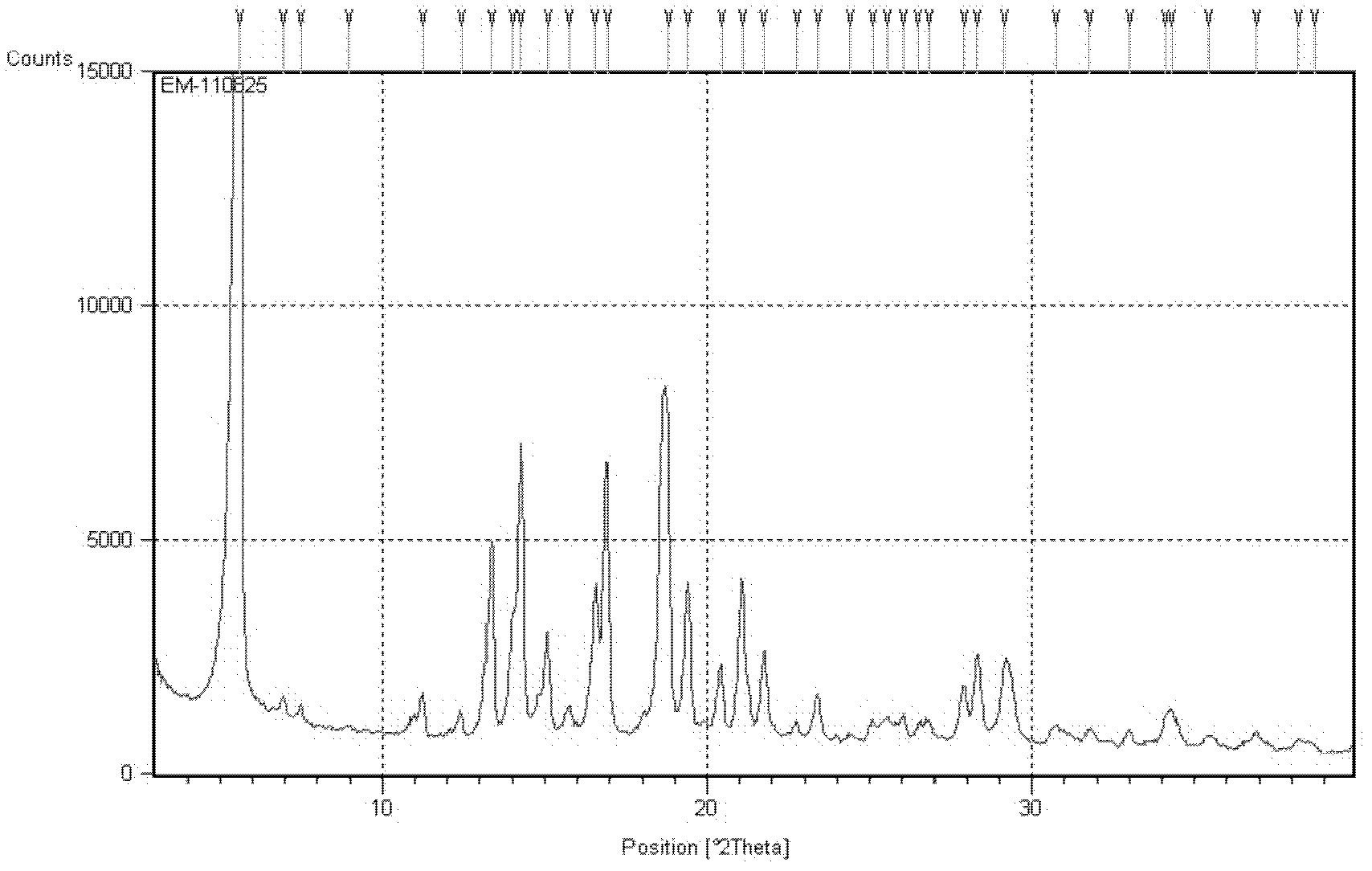

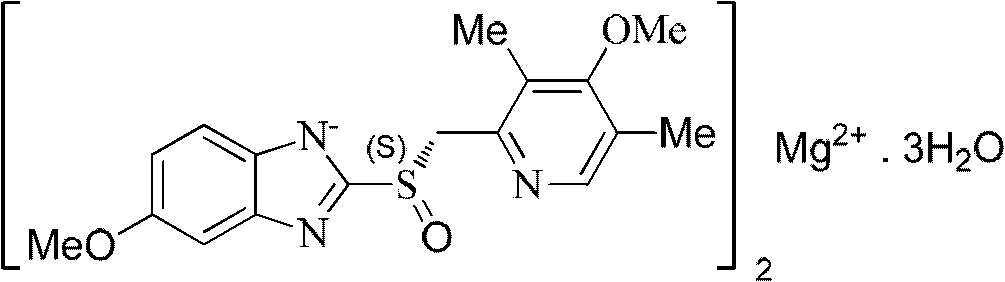

Esomeprazole magnesium dihydrate preparation method

The invention relates to an esomeprazole magnesium dihydrate preparation method. The method comprises the following steps: dissolving an esomeprazole magnesium trihydrate in a single or mixed solvent, adding an adverse solvent, stirring for precipitating a solid, separating the solid, washing the solid, and drying the solid to obtain an esomeprazole magnesium dehydrate having an A crystal form. The method has the advantages of economy, simple operation, single product crystal form, and high repeatability, and is suitable for the industrialized production.

Owner:SHANGHAI HUILUN BIOLOGICAL TECH CO LTD +1

Preparation method of antimony (III) trioxide cubic crystal

InactiveCN104512927ASave raw materialsSimple processAntimony oxides/hydroxides/oxyacidsFiberAntimony trioxide

The invention discloses a preparation method of an antimony (III) trioxide cubic crystal. The preparation method comprises the following steps: step one, dissolving antimony trichloride into glycol; step two, heating the solution to a temperature of 25-90 DEG C, and introducing ammonia gas into the solution until the pH value of the solution is greater than 8; step three, after the reaction, mixing the obtain solid-liquid mixture with distilled water, and stirring to carry out hydrolysis; step four, after the hydrolysis, carrying out centrifugal separation, washing the obtained substances until no chlorine ion exists on the substances, and drying so as to obtain the antimony (III) trioxide cubic crystals. The provided preparation method has the following advantages: (1) the raw materials are cheap, and the technology is simple; (2) the organic solvent can be recycle and reutilized, the recycling cost is low, and the production cost is reduced; (3) the crystal form of the obtained product is single, the crystallization is complete, and thus the crystals can be easily dispersed in plastic and paints and attached on fibers.

Owner:QINGDAO SHOUSHENG IND

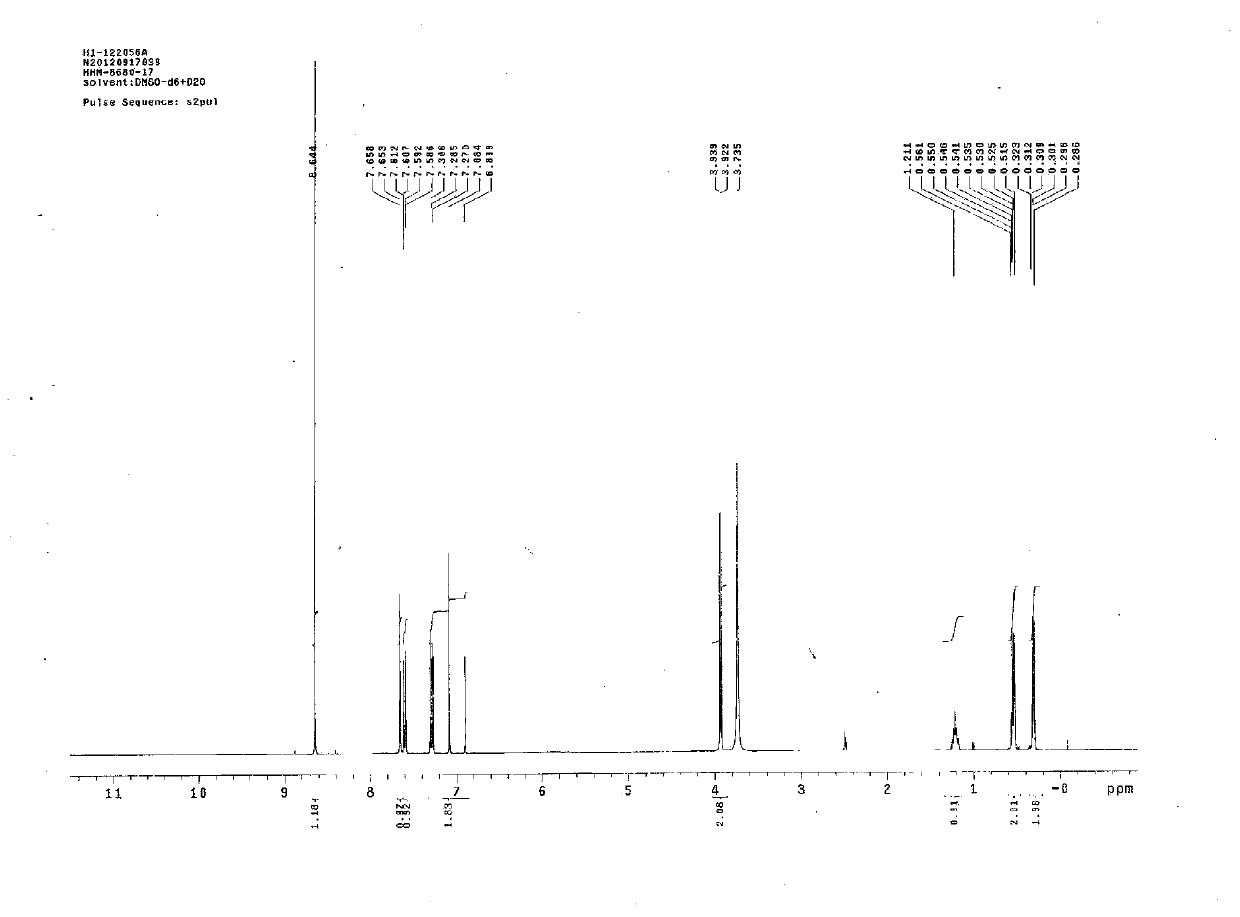

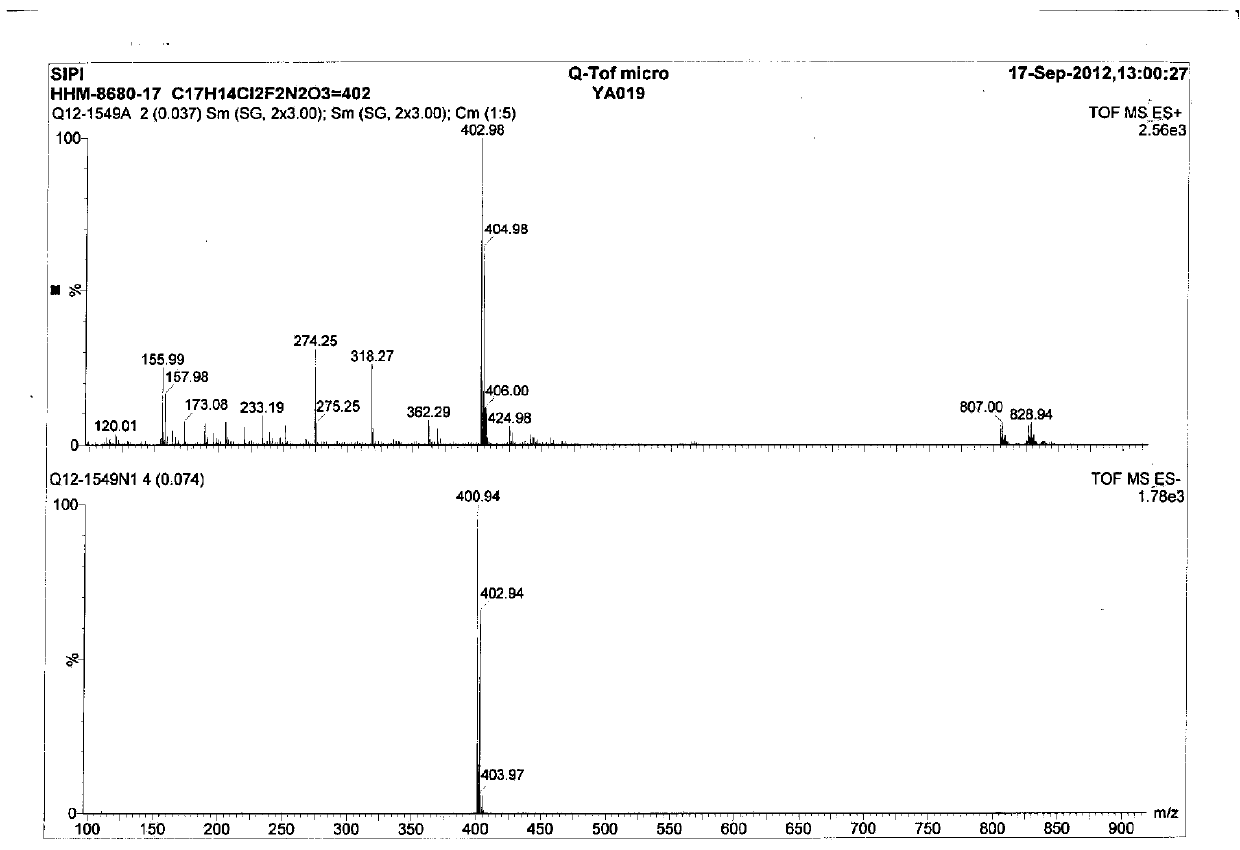

Betrixaban salt, preparation method and application thereof

InactiveCN105085387AEasy to prepareHigh purityOrganic chemistry methodsRespiratory disorderSolubilityBetrixaban

The present invention relates to betrixaban salts as shown by formula II, wherein the method for preparing these salts is simple, the crystal form is easy to control, the stability and solubility are good, and the salts are suitable for preparing a variety of preparations. The present invention also relates to the method for preparing these salts, pharmaceutical compositions comprising these salts, and the use of these salts in the preparation of medicaments for the prevention and treatment of diseases characterized by adverse thrombus formation in mammals.

Owner:SICHUAN HAISCO PHARMA CO LTD

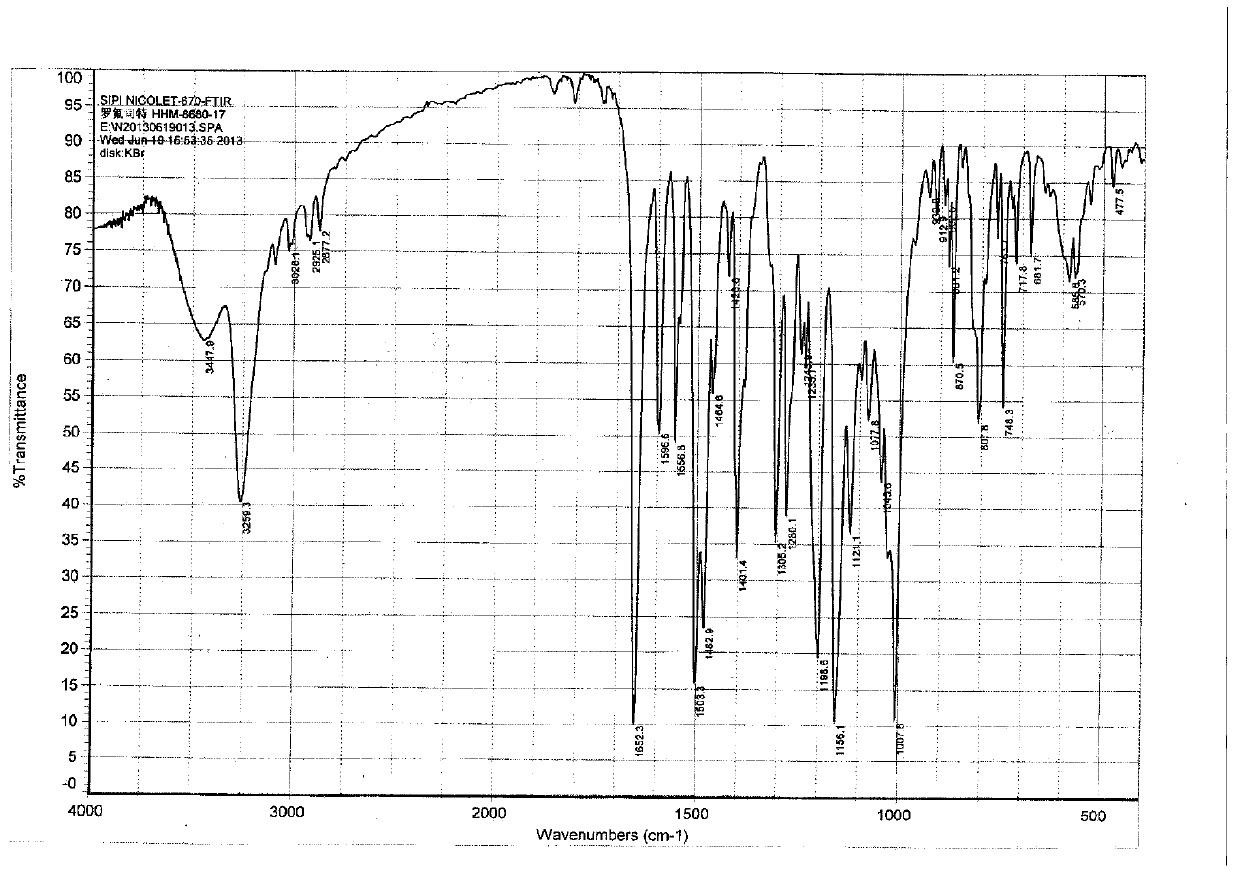

Refining method for high-purity roflumilast

The invention provides a refining method for high-purity roflumilast. The refining method includes: dissolving a crude product of the roflumilast into a solvent, adding activated carbon for decolorization processing, filtering, and subjecting filtered liquor to standing for crystallization prior to washing and drying to obtain roflumilast powder with the purity more than 99.5%. The solvent is selected from one or several of ethyl acetate, acetone, butanone, normal butanol, dioxane and isopropyl ether. The refining method is simple in process; the high-purity roflumilast can be obtained through primary crystallization, and the obtained roflumilast is good in appearance, high in yield, high in purity (single impurity is lower than 0.1%, and total impurity is lower than 0.5%), single in crystal form and applicable to industrial production.

Owner:国药集团致君(苏州)制药有限公司

Crystallization method of L-lysine hydrochloride

ActiveCN110092729AIncrease the rate of crystallizationImprove crystallization yieldOrganic compound preparationAmino-carboxyl compound preparationOrganic solventAqueous solution

The present invention provides a crystallization method of L-lysine hydrochloride. The crystallization method comprises the following steps: primarily concentrating an aqueous solution of L-lysine hydrochloride, then adding an organic solvent, and cooling the obtained solution while pumping in saturated steam to obtain the L-lysine hydrochloride. Compared with direct recrystallization or concentrating crystallization methods, the method in the invention, combining three processes of concentration, organic solvent and steam pump-in, can increase the crystallization rate and the crystallizationyield of the L-lysine hydrochloride on the premise of ensuring the crystallization purity, makes the highest crystallization yield reach up to 80% or above, allows the precipitated crystal form to besingle, and has great significance and values in the production and market application of L-lysine.

Owner:上海泰坦科技股份有限公司

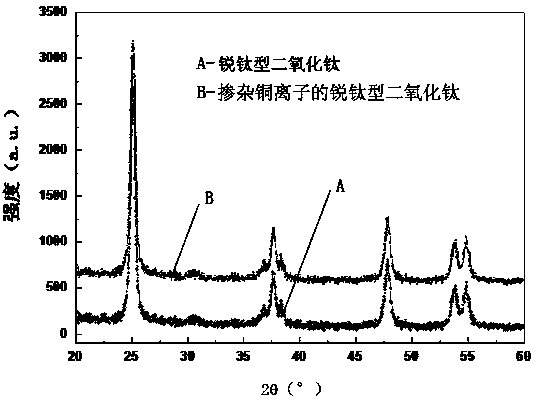

Preparation method of copper ion doped anatase titanium dioxide

ActiveCN104016406ASingle crystal formCrystal stableTitanium dioxideAnatase titanium dioxideOXALIC ACID DIHYDRATE

The invention discloses a preparation method of copper ion doped anatase titanium dioxide. The preparation process comprises the following steps: 1, adding concentrated sulfuric acid into a titanium tetrachloride aqueous solution, and then adding deionized water to obtain a first crude product; 2, adding an oxalic acid copper solution into the first crude product obtained in the step 1, adjusting the pH value to 7-8 by using ammonia, and washing with deionized water to obtain a secondary crude product; 3, washing the secondary crude product obtained in the step 2 with deionized water to obtain a third crude product; step 4, conducting pump filtration on the third crude product washed in the step 3 to obtain a filter cake, drying the filter cake in an air blast drying box, and conducting vacuum drying to obtain a fourth crude product; and step 5, grinding the forth crude product obtained in the step 4 get into particles, heating, calcining and cooling to room temperature to obtain copper ion doped anatase titanium dioxide. The preparation method provided by the invention has the advantages of simple operation, high controllability, and easiness for industrial popularization and application.

Owner:南京宁馨净化工程有限公司

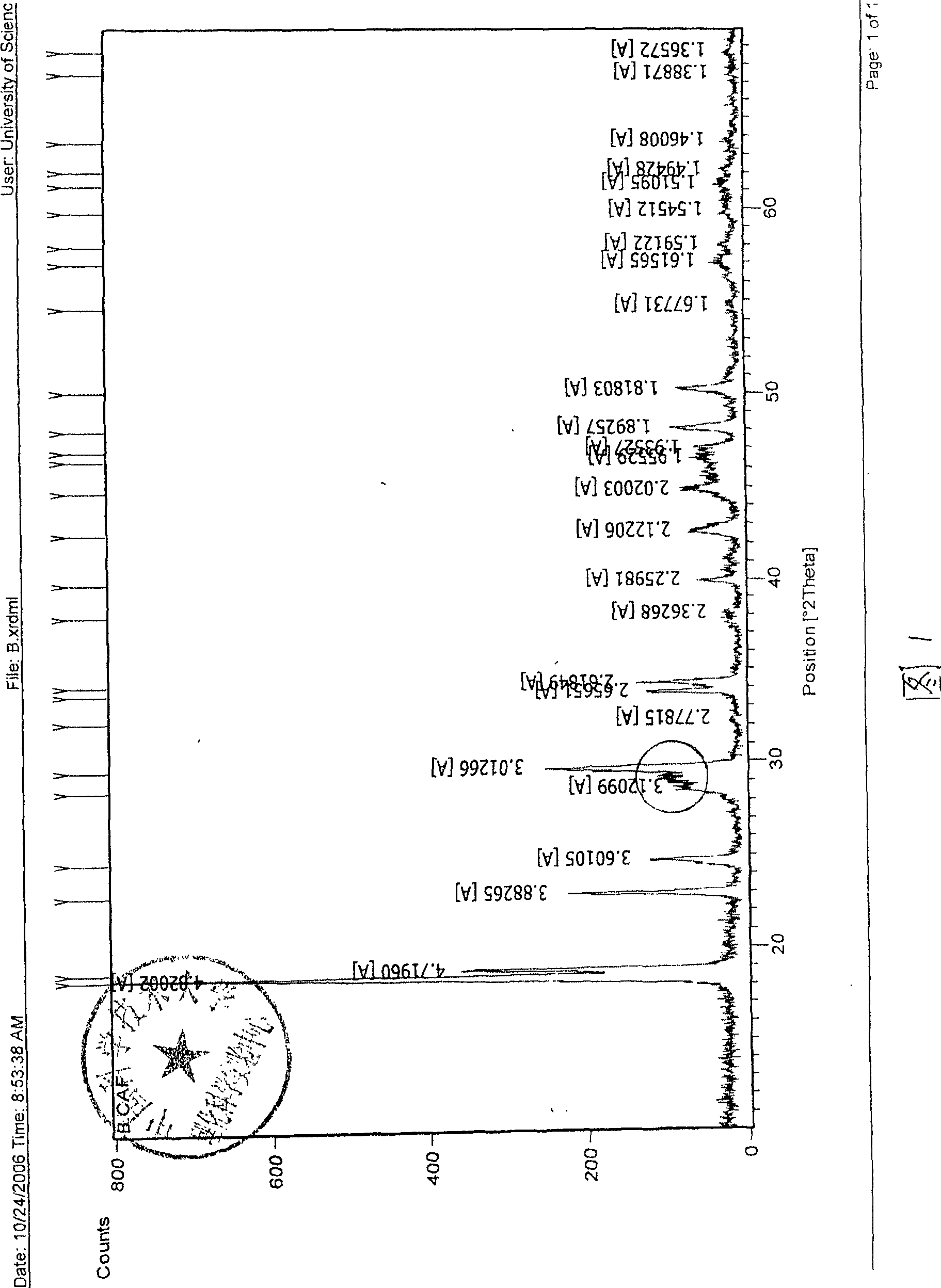

Quzhazhigan crystal and preparation method and application thereof

ActiveCN102276666BSingle crystal formHigh purityOrganic active ingredientsSugar derivativesSolubilitySingle crystal

Owner:KPC PHARM INC

Low-emission PP material and preparation method thereof

The invention provides a low-emission PP material and a preparation method thereof. The low-emission PP material is prepared from the following components in parts by weight: 50-60 parts of PP, 30-40parts of glass fiber, 2-5 parts of a compatilizer, 3 parts of black masterbatch, 1-5 parts of antibacterial agent and 0.2 part of an antioxidant through a double-screw extruder; the TVOC content of the low-emission PP material is less than 50 [mu] gC / g, and the odor is less than grade 4. According to the low-emission PP material and the preparation method thereof, the synergistic effect of all thecomponents in the formula achieves the low-emission effect, the added antibacterial agent nano magnesium oxide and nano zinc oxide mixture plays an unexpected role in effectively reducing the odor and TVOC of the PP material, the preparation method of the low-emission PP material is simple, the used equipment is a common water brace double-screw extruder, and large-scale production is easily realized.

Owner:太仓市华鼎塑料有限公司

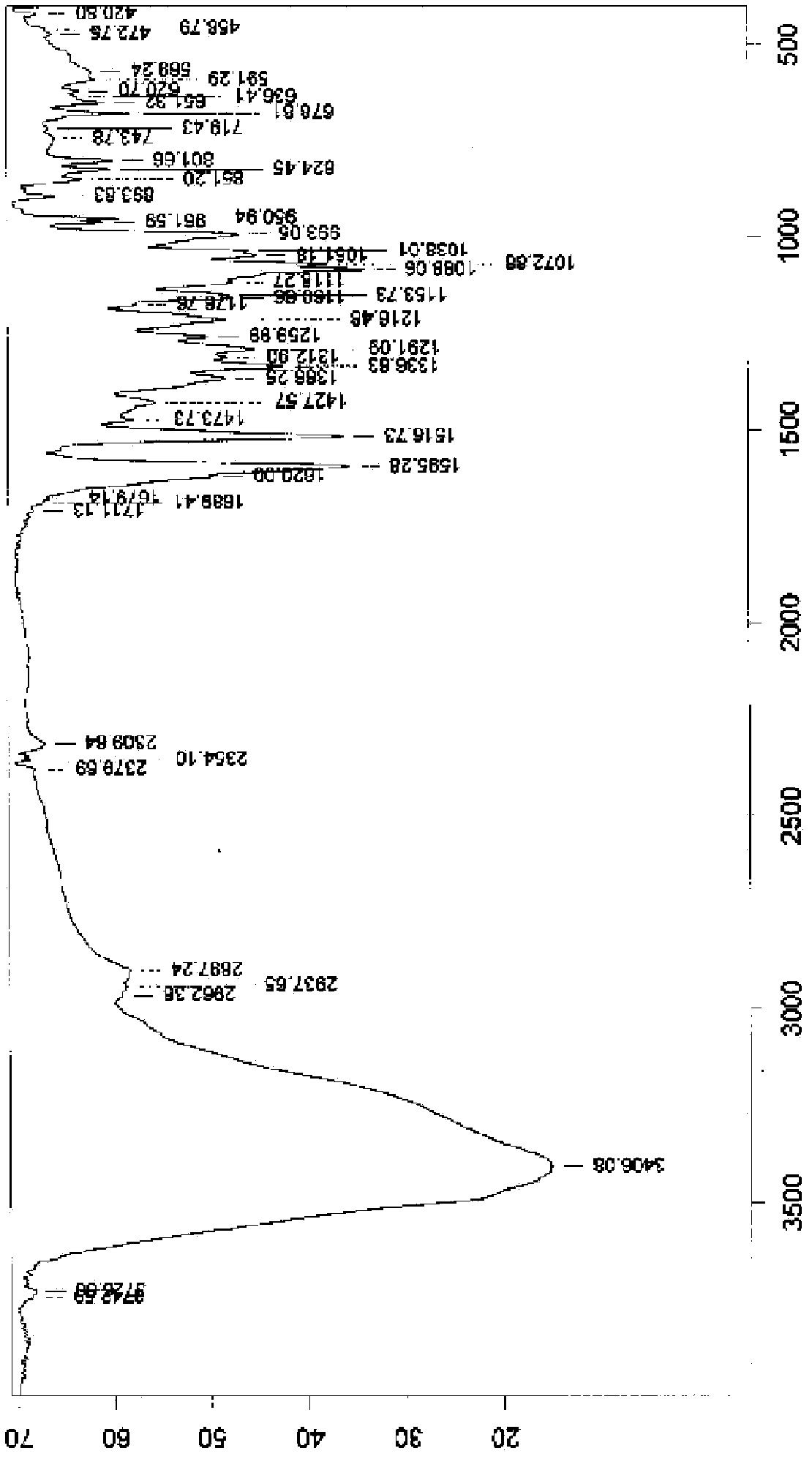

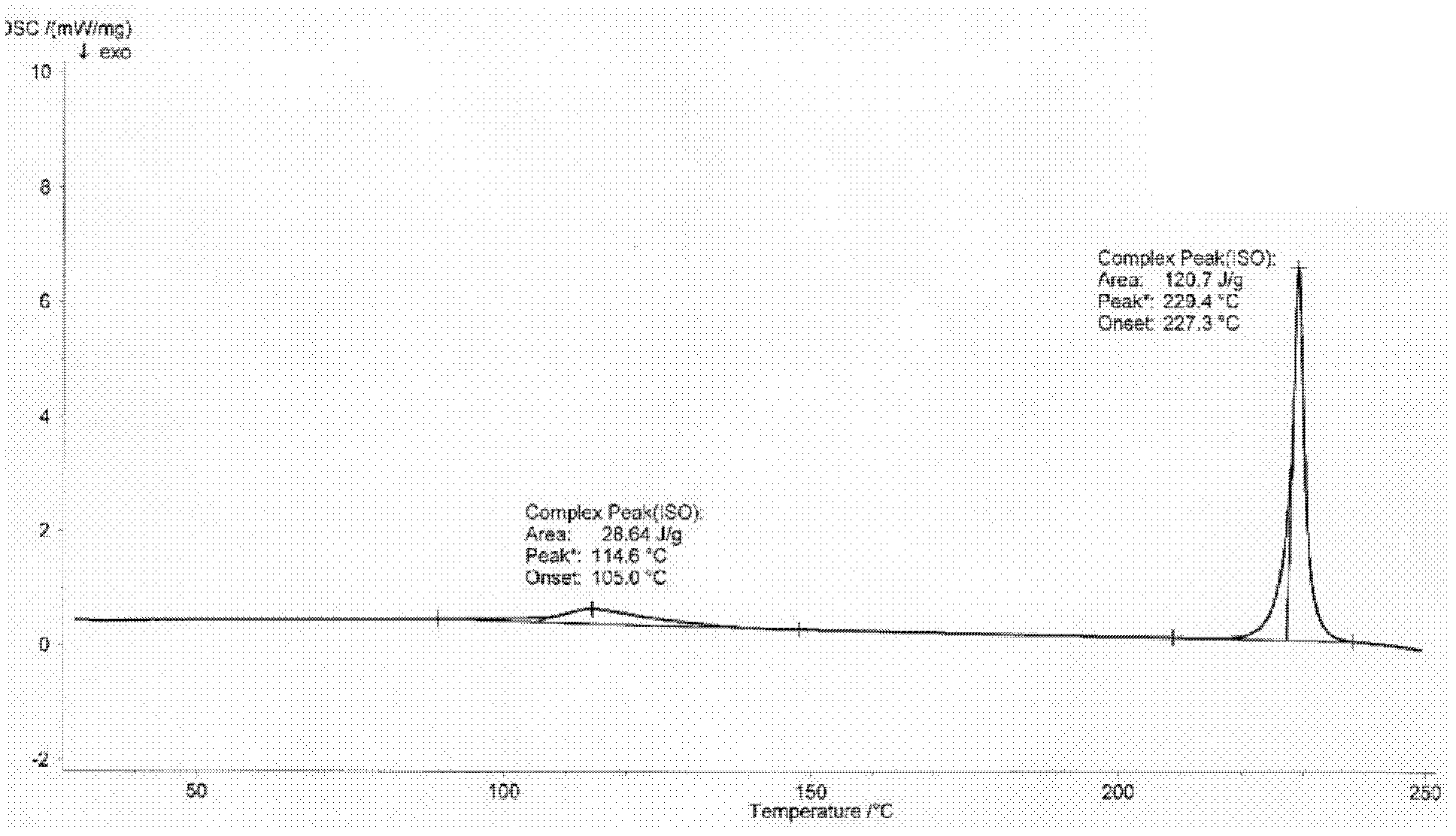

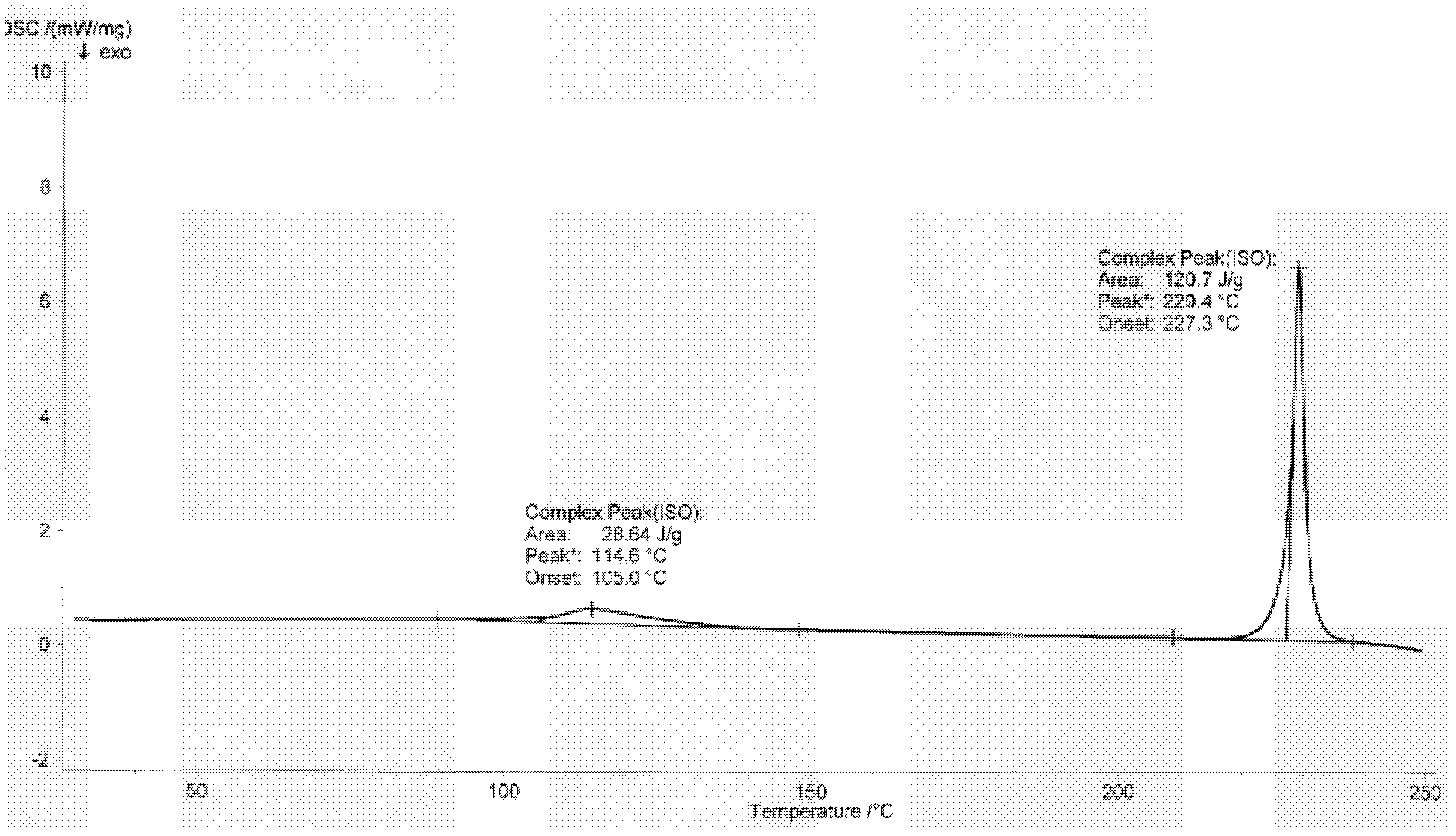

Preparation method of beta-crystal form silodosin

InactiveCN103980178AGood hygroscopicityIt is not easy to have the problem of excessive residueOrganic chemistryPhysical chemistryOrganosolv

The invention provides a preparation method of beta-crystal form silodosin. The preparation method comprises the following steps: adding silodosin into an organic solvent, heating in nitrogen till the refluxed solution is clear, naturally cooling to crystallize after 30 minutes, filtering to obtain white solid, and drying at about 40 DEG C in vacuum, wherein the X-ray powder diffraction spectrum shows that the crystal form of silodosin is beta, the purity is 99.6-99.7%, and the melting point is 105-106 DEG C. The method can stably prepare the beta-crystal form silodosin, and is high in yield and applicable to industrial production.

Owner:WUHAN SYNCHALLENGE UNIPHARM INC

A recovery process for preparing calcium sulfate by utilizing carbide slag

A recovery process for preparing calcium sulfate by utilizing carbide slag is provided. The process includes (1) adding a polymer surfactant into hot water and then adding the carbide slag into the mixture; (2) performing filtration with filter paper; (3) performing filtration with an ultrafiltration membrane; (4) performing degassing treatment by utilizing an ultrasonic instrument and a vacuum pump; (5) adding a saturated sodium chloride solution to precipitate calcium hydroxide solid; (6) performing a reaction with diluted sulfuric acid to form calcium sulfate; and (7) performing filtration and drying the calcium sulfate to obtain high-purity calcium sulfate crystals. The process is advantageous in that the polymer surfactant is added and ensures a stable colloid state of the calcium hydroxide; solid particle impurities such as ferrosilicon and coke are removed through filtration with the filter paper so that a product has good color; the polymer surfactant is removed through filtration with the ultrafiltration membrane; the product is free of odor through degassing treatment; and through adding the saturated sodium chloride solution, the calcium hydroxide solid is precipitated rapidly, a prepared calcium sulfate product has a single crystal form, regular shapes, uniform granularity and a high purity.

Owner:HWASU

Production method of ferrous oxalate special for ferrous lithium phosphate

InactiveCN100488937CSingle crystal formCarboxylic acid salt preparationReaction temperaturePhosphoric acid

Owner:HEFEI ASIALON CHEM

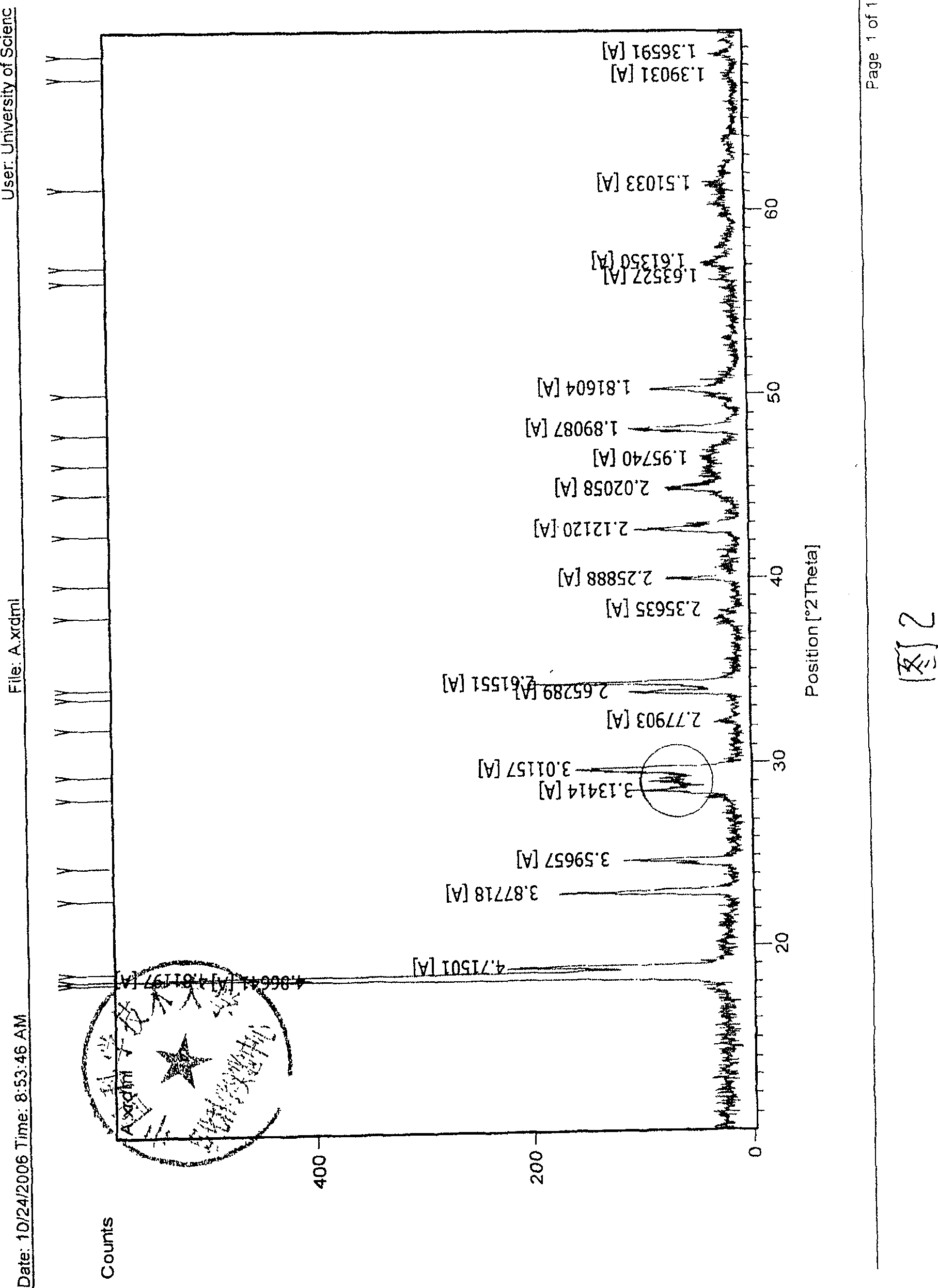

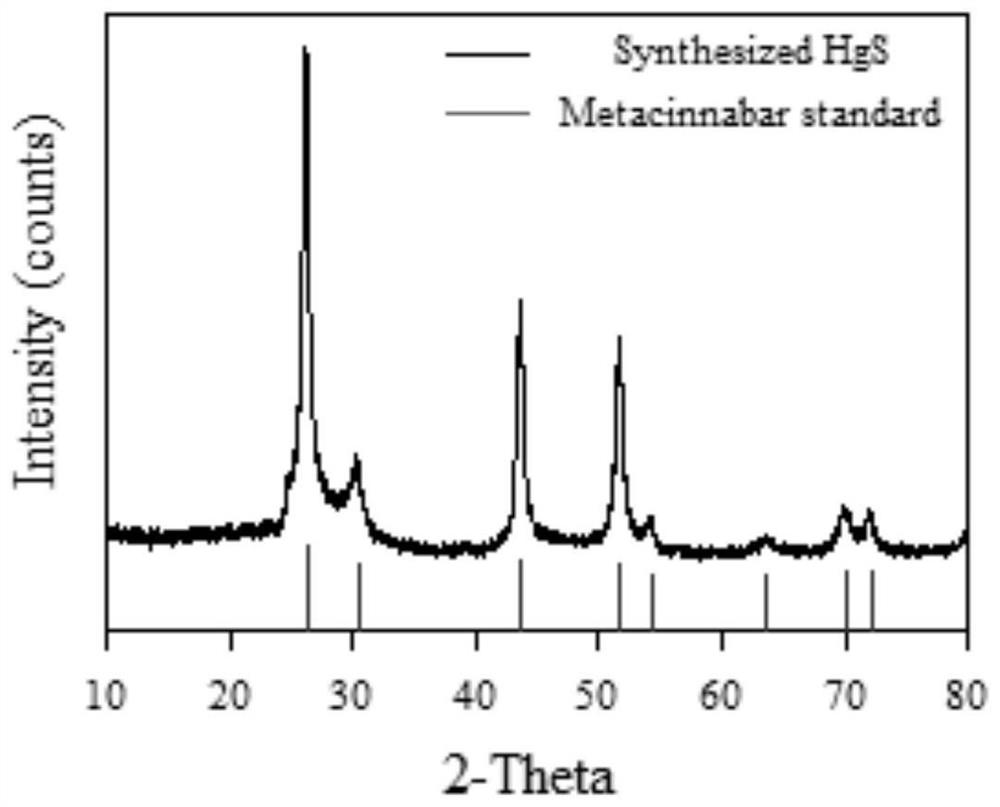

Method for rapidly preparing spherical mercury sulfide nanoparticles

ActiveCN112194172ASingle crystal formGood dispersionNanotechnologyMercury compoundsFreeze-dryingPyrrolidinones

The invention belongs to the field of preparation of semiconductor nano-materials, particularly relates to a method for rapidly preparing spherical mercury sulfide nanoparticles, and provides the following scheme aiming at the problems that energy and time cannot be saved and mercury sulfide nano-particles with uniform shape and size and good dispersity cannot be synthesized in the prior art. Themethod comprises the following steps: S1, preparing a reaction mixed solution, namely adding 0.5 mmol of mercury nitrate, 0.5 mmol of sulfur powder and 0.15 g of polyvinylpyrrolidone into 500g of ethylene glycol at room temperature to prepare the mixed solution; S2, synthesis of mercury sulfide nanoparticles: transferring the mixed solution into an oil bath pot containing simethicone, and performing magnetic stirring to enable the mixed solution to react for 2 hours; and S3, separating the mercury sulfide nanoparticles: taking out the mixed solution from the bath pot, adding ultrapure water with the same volume as the mixed solution, centrifuging for 15 minutes, removing the supernatant, reserving the precipitate, washing the precipitate with the ultrapure water, and freeze-drying the precipitate to obtain the spherical mercury sulfide nanoparticles. A solvothermal synthesis system adopted by the invention can be used for preparing spherical nano mercury sulfide; the obtained sphericalmercury sulfide nanoparticles are single in crystal form, good in dispersity, uniform in shape and high in stability; the method and the technological process are simple, short in time consumption, low in reaction temperature and low in energy consumption; the raw materials are low in cost, easy to obtain and beneficial to industrial production.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

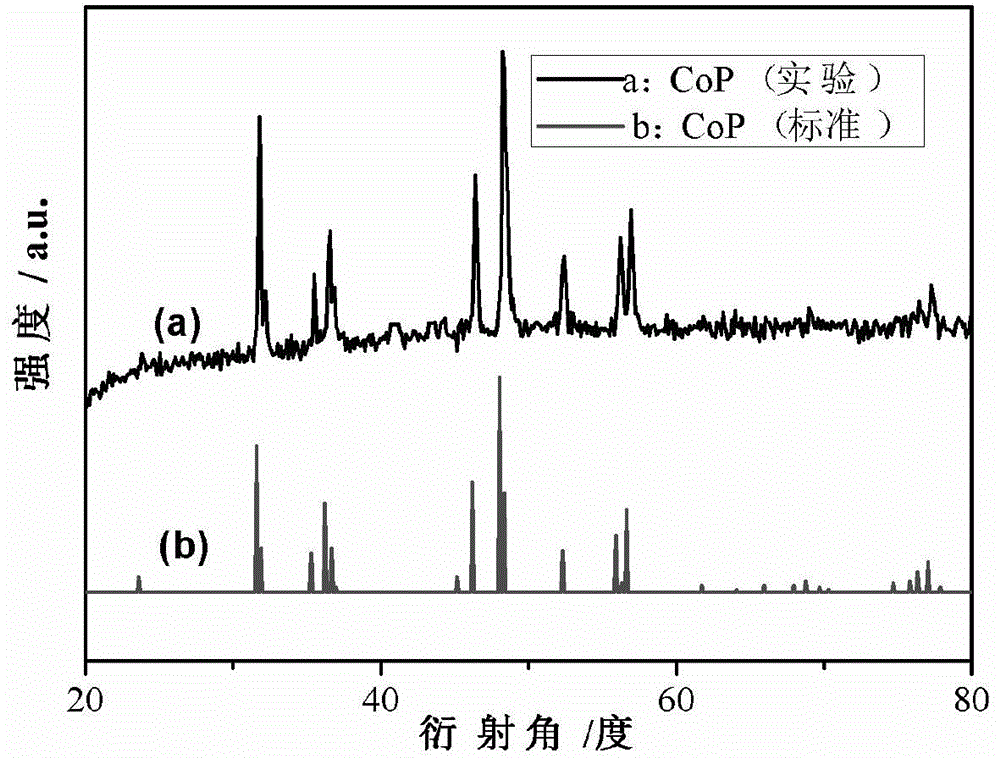

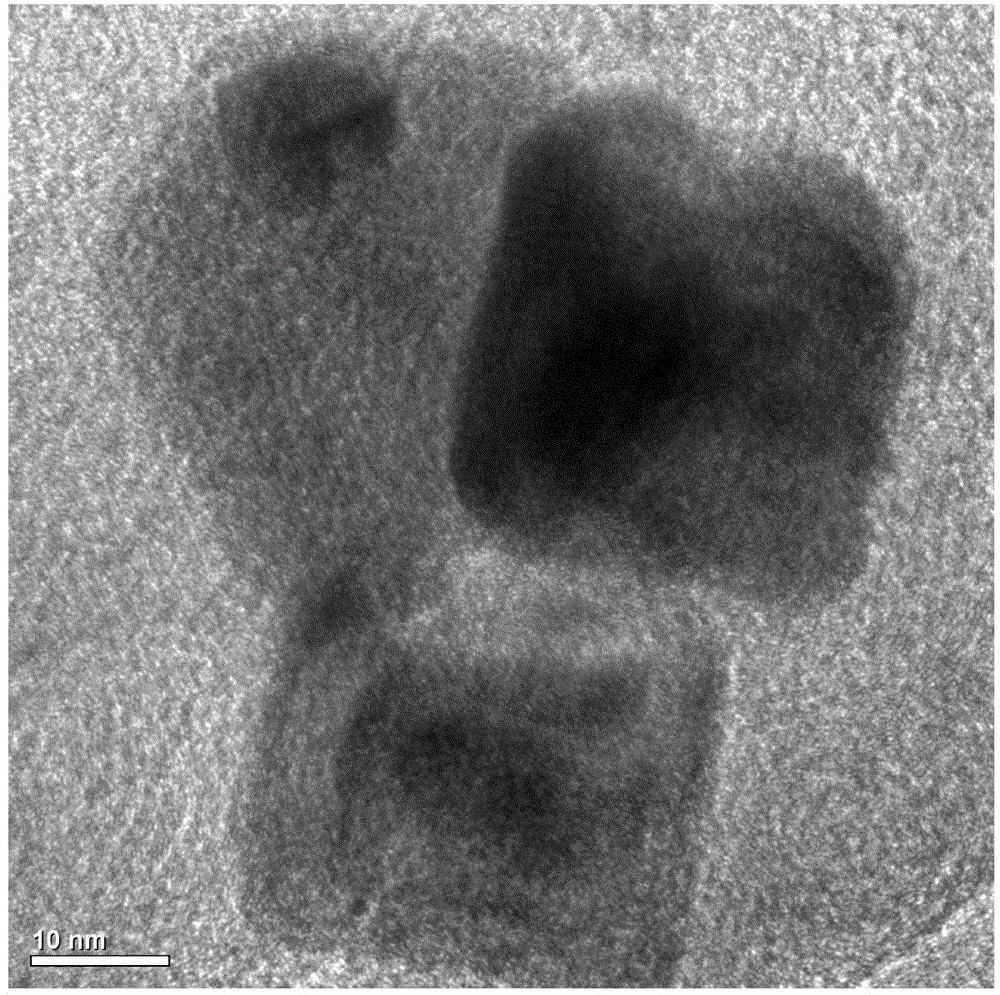

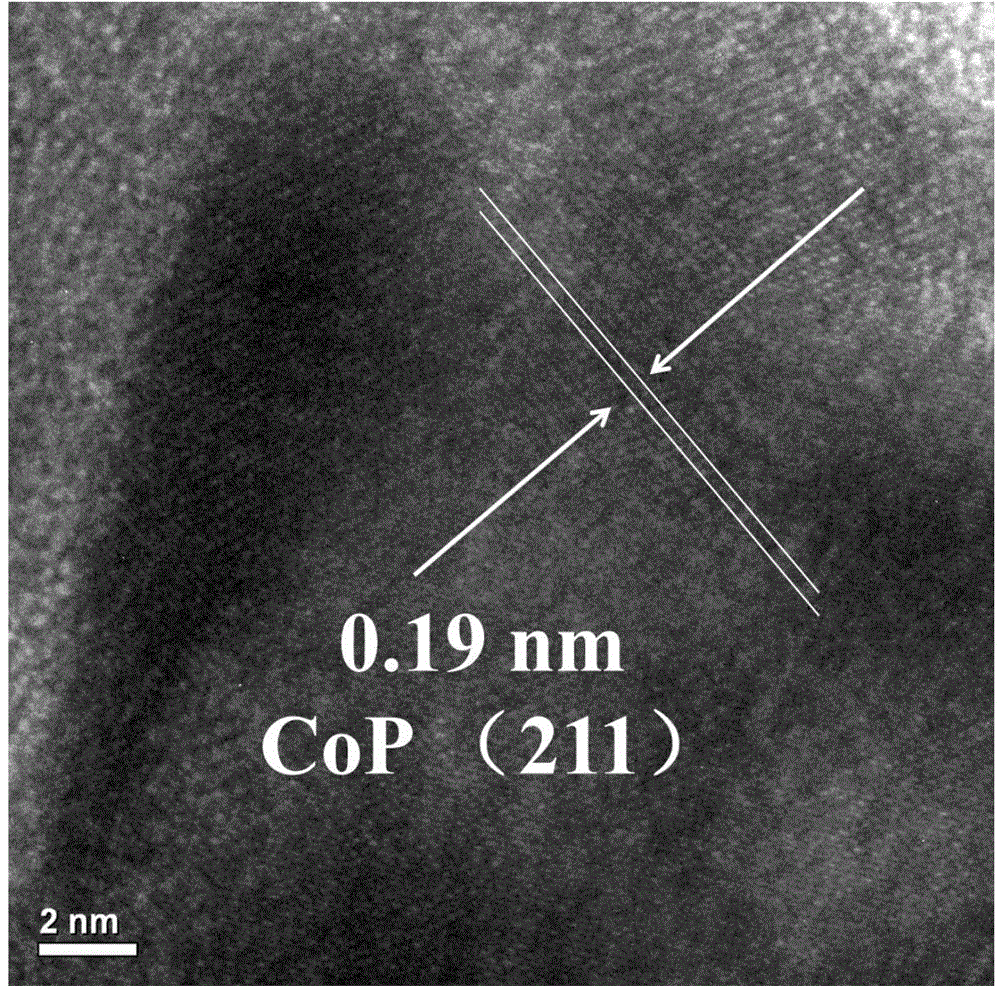

Preparation method of transition metal phosphide with good morphology

The invention relates to a preparation method of transition metal phosphide with good morphology, which is simple in process, and eliminates high temperature and high pressure complicated steps. The method comprises the following steps: taking a precursor of cobalt or nickel, and a precursor of phosphorus according to the molar ratio of (1:1)-(1:6); grinding and mixing the precursors uniformly; reacting for 60-240 minutes at 250-800 DEG C under the argon protection condition; porphyrizing the obtained product; using distilled water and absolute ethyl alcohol to respectively wash the product for three times; then drying the washed product at 60-80 DEG C for 12-24 hours, so as to obtain the product CoP or Ni2P. The main raw materials for the method are rich in sources and low in price, so that the cost is low; the synthetic method is novel, the process is simple, and the high temperature and high pressure complicated steps are not required, so as to simplify the preparation procedures and reduce the energy consumption; the prepared CoP and Ni2P are good in morphology, good in crystallization property, and have single crystal forms; the method disclosed by the invention cannot cause environment pollution during the preparation process, and is suitable for large-scale production.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

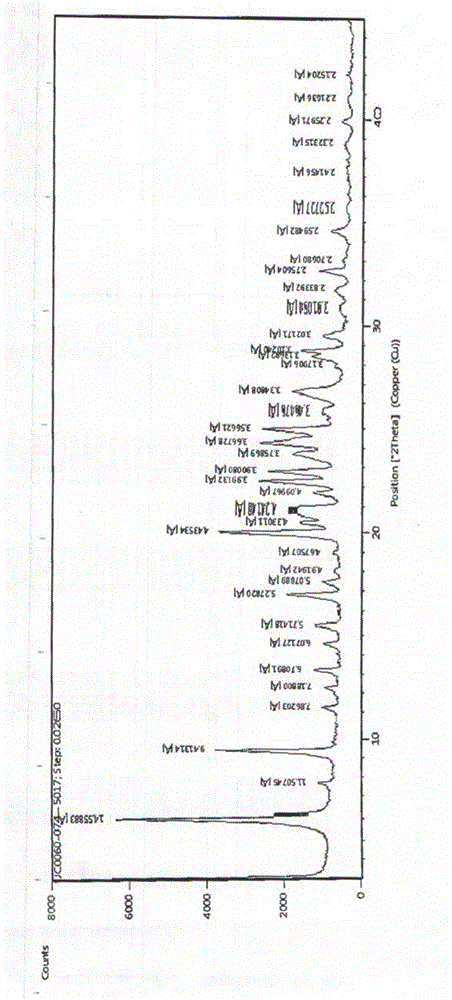

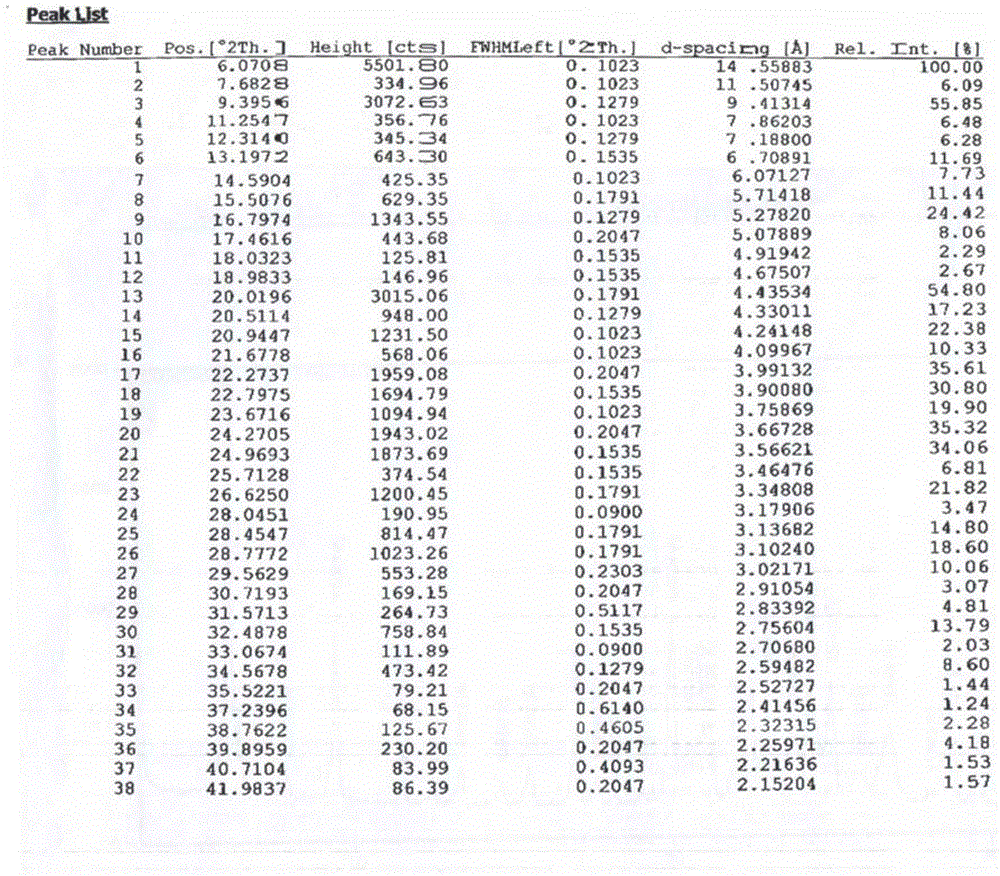

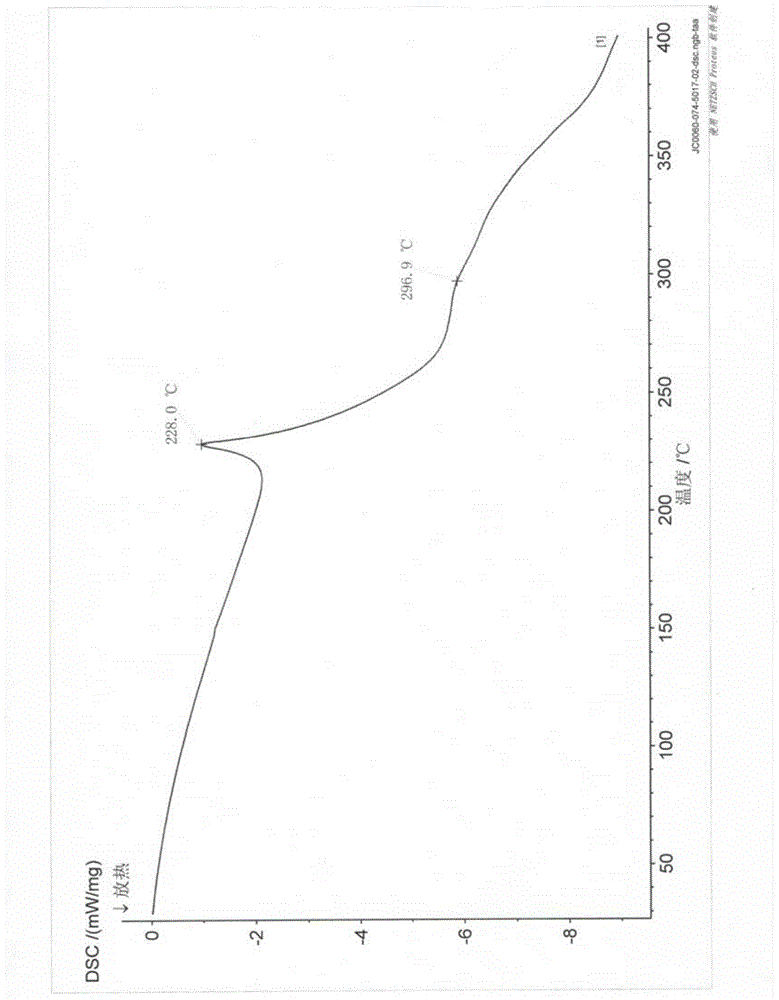

New erlotinib hydrochloride crystal form and preparation method thereof

The present invention relates to a new erlotinib hydrochloride crystal form and a preparation method thereof, wherein the 2theta characteristic peaks are positioned at 9.395+ / -0.2 DEG, 13.197+ / -0.2 DEG, 15.507+ / -0.2 DEG, 16.797+ / -0.2 DEG, 20.019+ / -0.2 DEG, 20.511+ / -0.2 DEG, 20.944+ / -0.2 DEG, 22.273+ / -0.2 DEG, 22.795+ / -0.2 DEG, 24.270+ / -0.2 DEG, and 24.969+ / -0.2 DEG in an x-ray powder diffraction pattern. The preparation method comprises: (1) adding erlotinib base to a solvent, and stirring until the erlotinib base is dissolved; (2) introducing dry HCl gas until no solid is precipitated, and stirring; (3) cooling under stirring to achieve a temperature of 0-10 DEG C; and (4) filtering and drying to obtain the product. According to the present invention, the crystal form is single, and stability is good; and the alcohol is adopted as a solvent, such that characteristics of low toxicity, simple method, high product purity and easy industrial production are provided.

Owner:SHANDONG JINCHENG PHARMACEUTICAL GROUP CO LTD

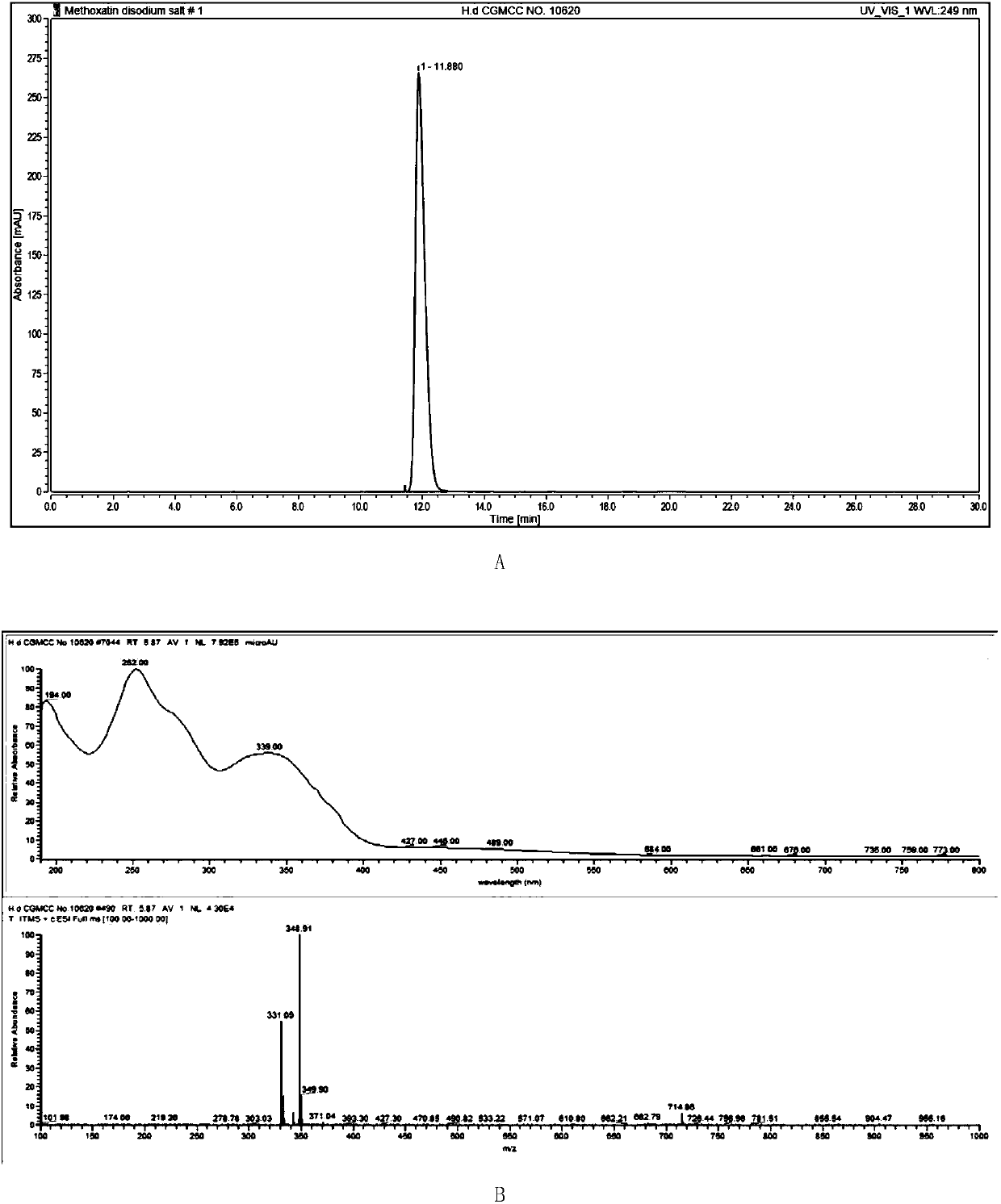

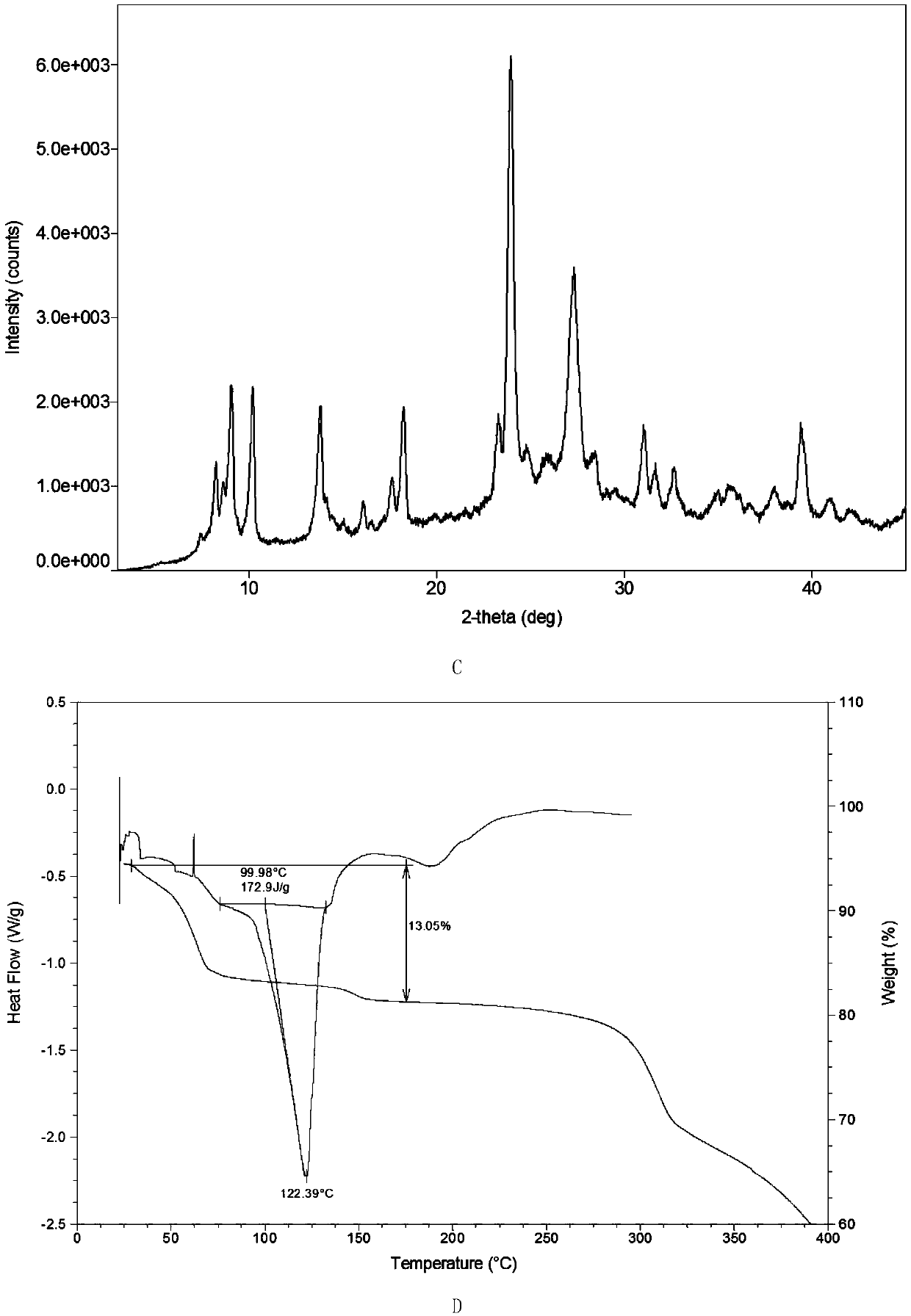

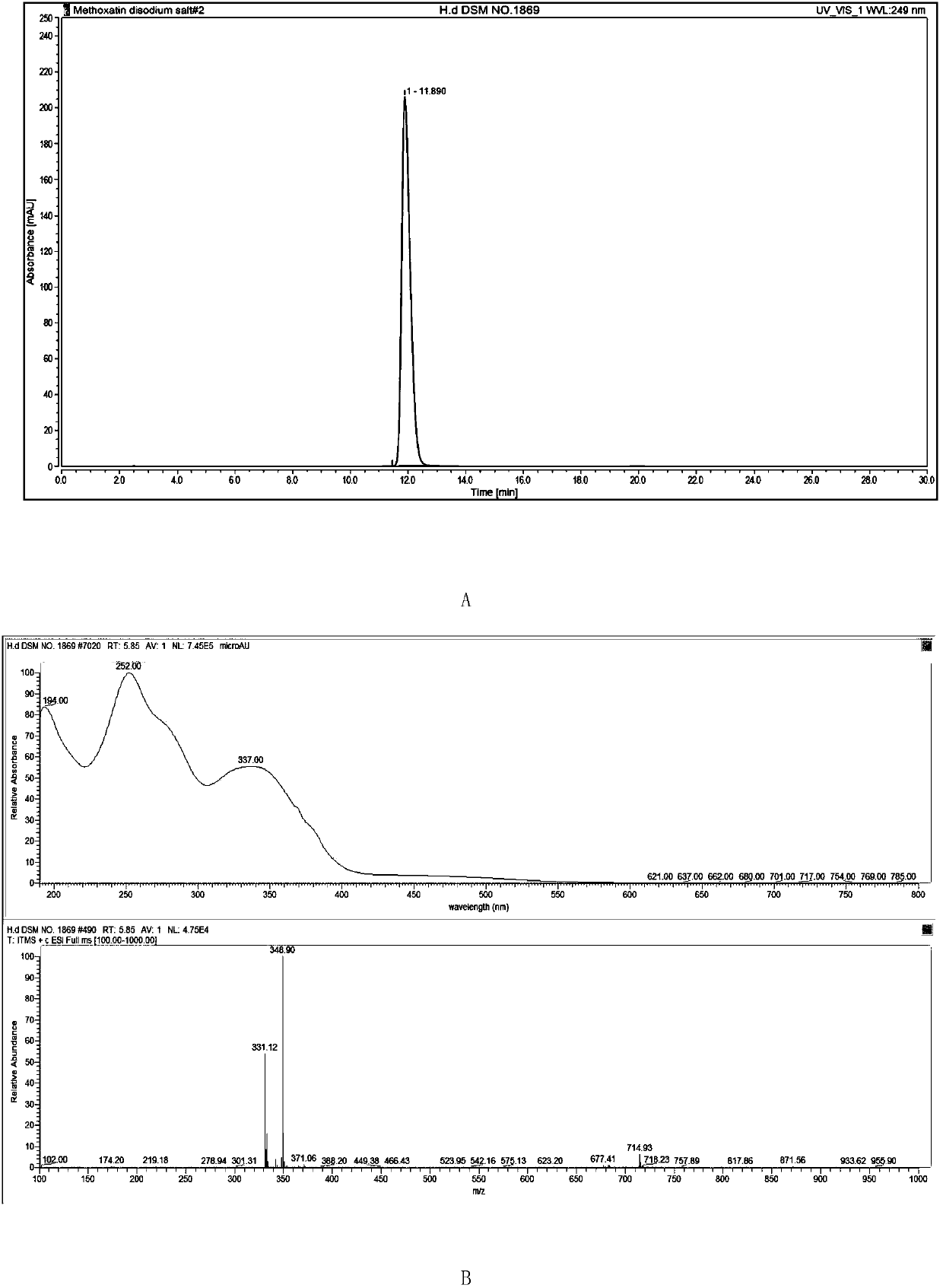

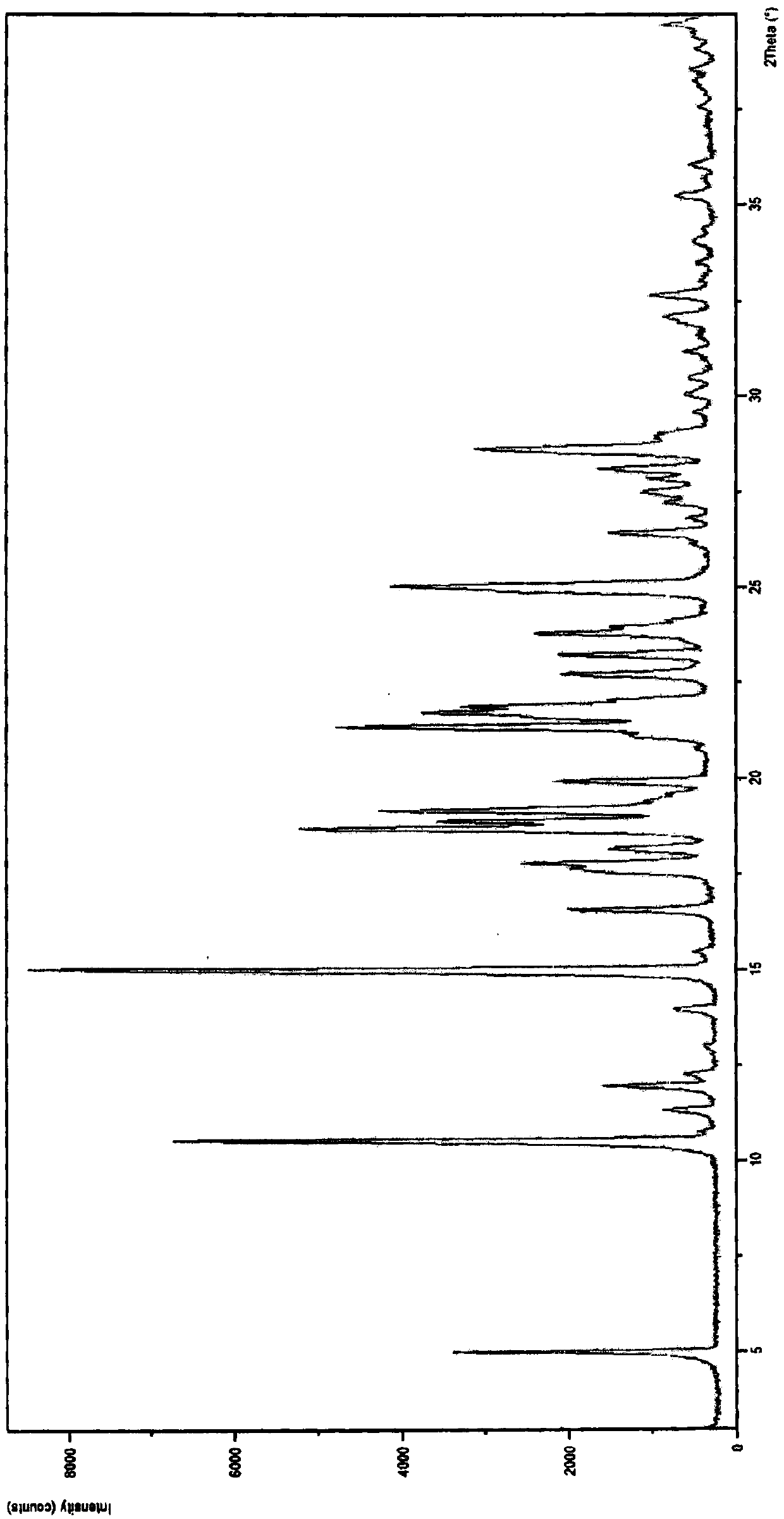

A kind of separation and purification method of pyrroloquinoline quinone in methylotrophic bacteria fermentation broth and its application

ActiveCN107056782BHigh purityEasy to operateBacteriaOrganic chemistry methodsPurification methodsQuinoline

The invention discloses a method for separating and purifying pyrroloquinoline quinone from a methylotrophic bacteria fermentation broth and an application thereof. The method of the present invention comprises the following steps: (1) enriching the fermented liquid through a macroporous resin, and then successively eluting through a buffer solution and water, collecting the eluent, and obtaining an enriched solution rich in pyrroloquinoline quinone; (2) purifying the enriched solution rich in pyrroloquinoline quinone through a hydrophilic silica gel filler to obtain a pyrroloquinoline quinone mother liquor; (3) separating out the pyrroloquinoline quinone crystallization in the pyrroloquinoline quinone mother liquor , to obtain pyrroloquinoline quinone crude crystals; (4) recrystallize the pyrroloquinoline quinone crude crystals by alkali-dissolving acid precipitation method to obtain pyrroloquinoline quinone. It is proved by experiments that the method of the present invention has the characteristics of simple process operation, high coherence, high product recovery rate and high purity, and can be used for large-scale industrial production to prepare pyrroloquinoline quinone.

Owner:FUJIAN NORMAL UNIV

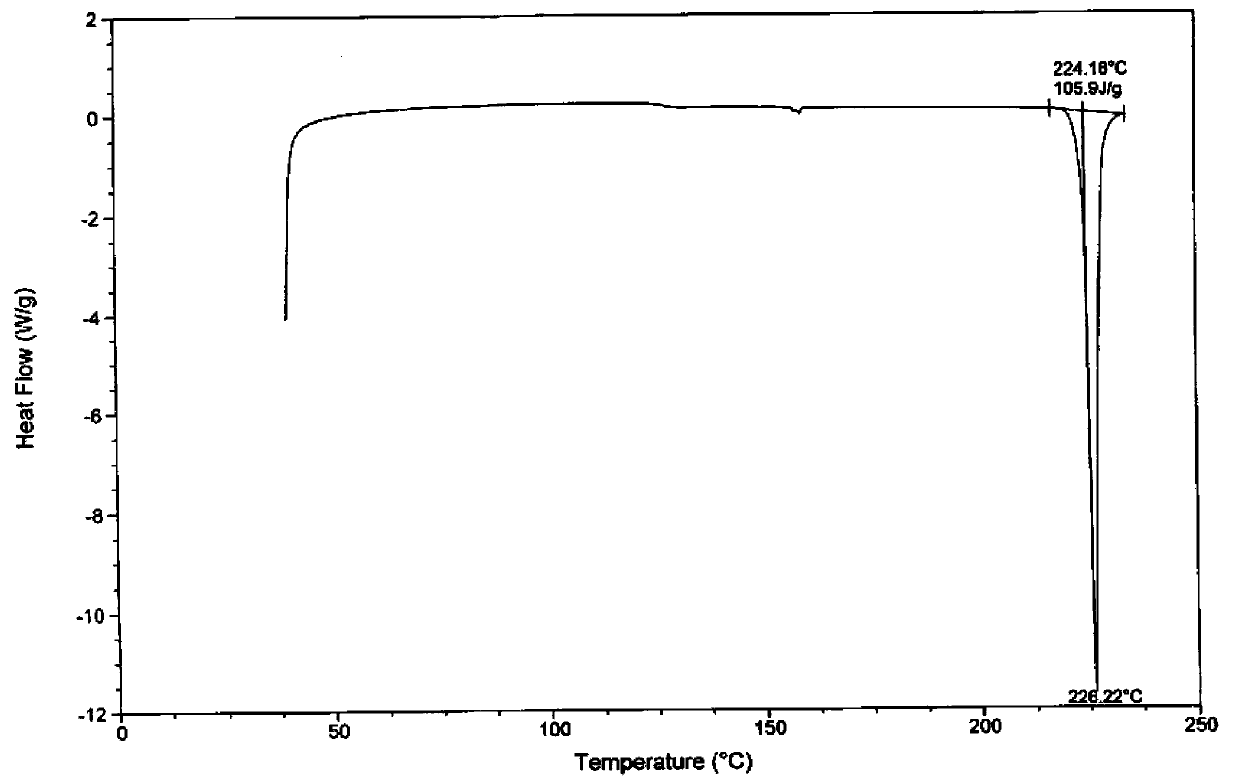

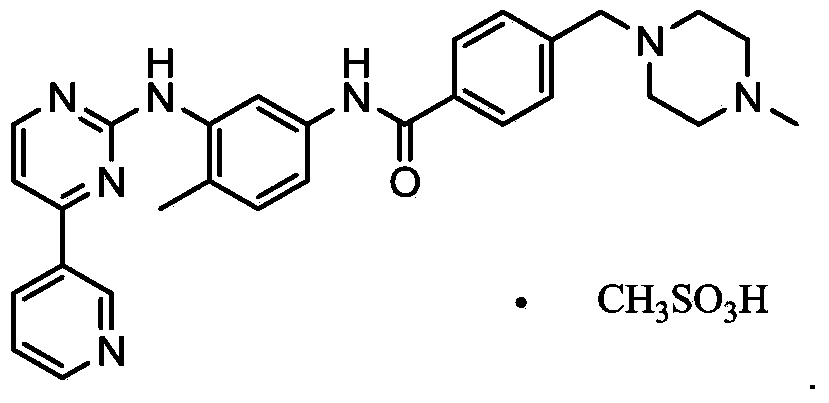

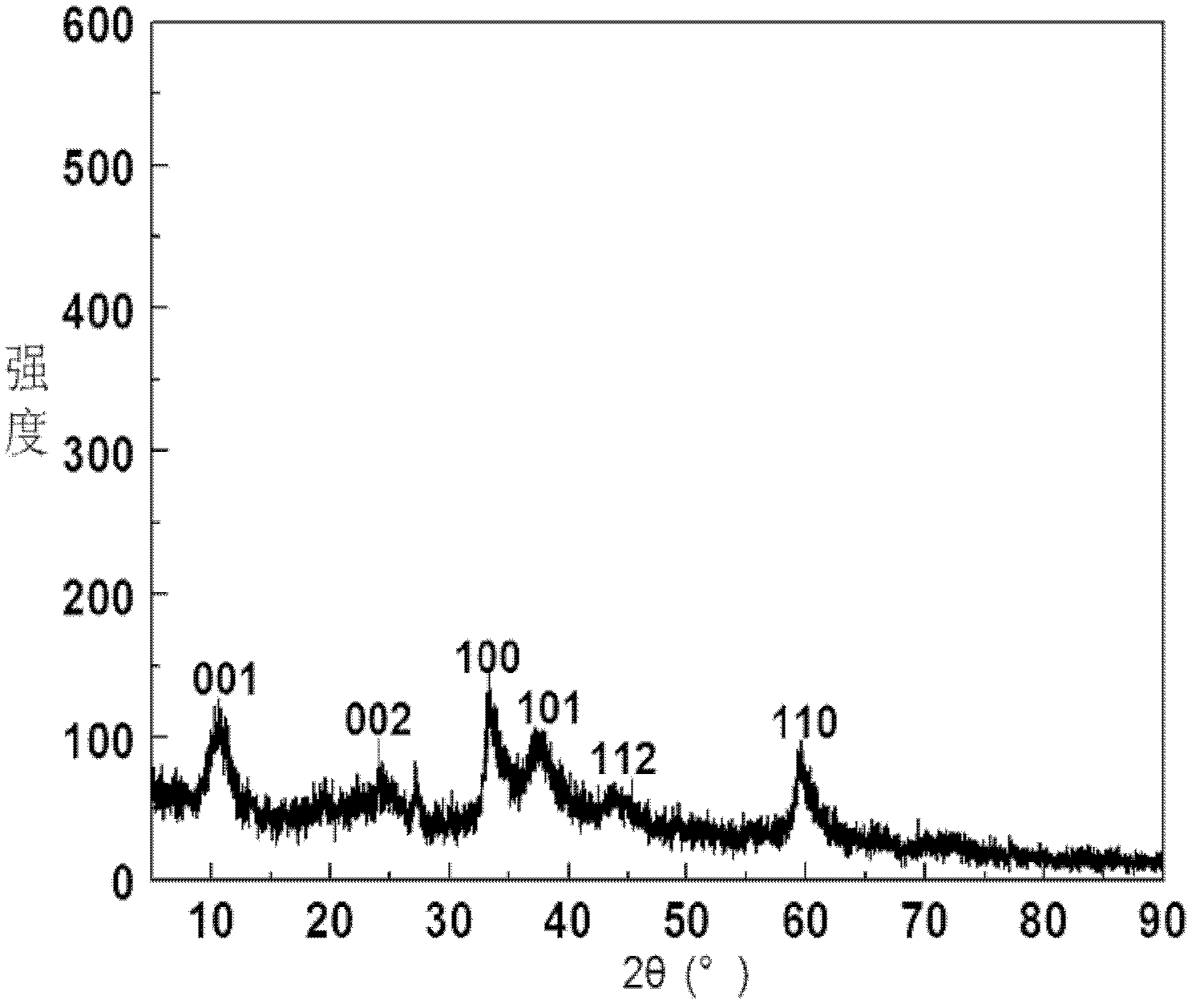

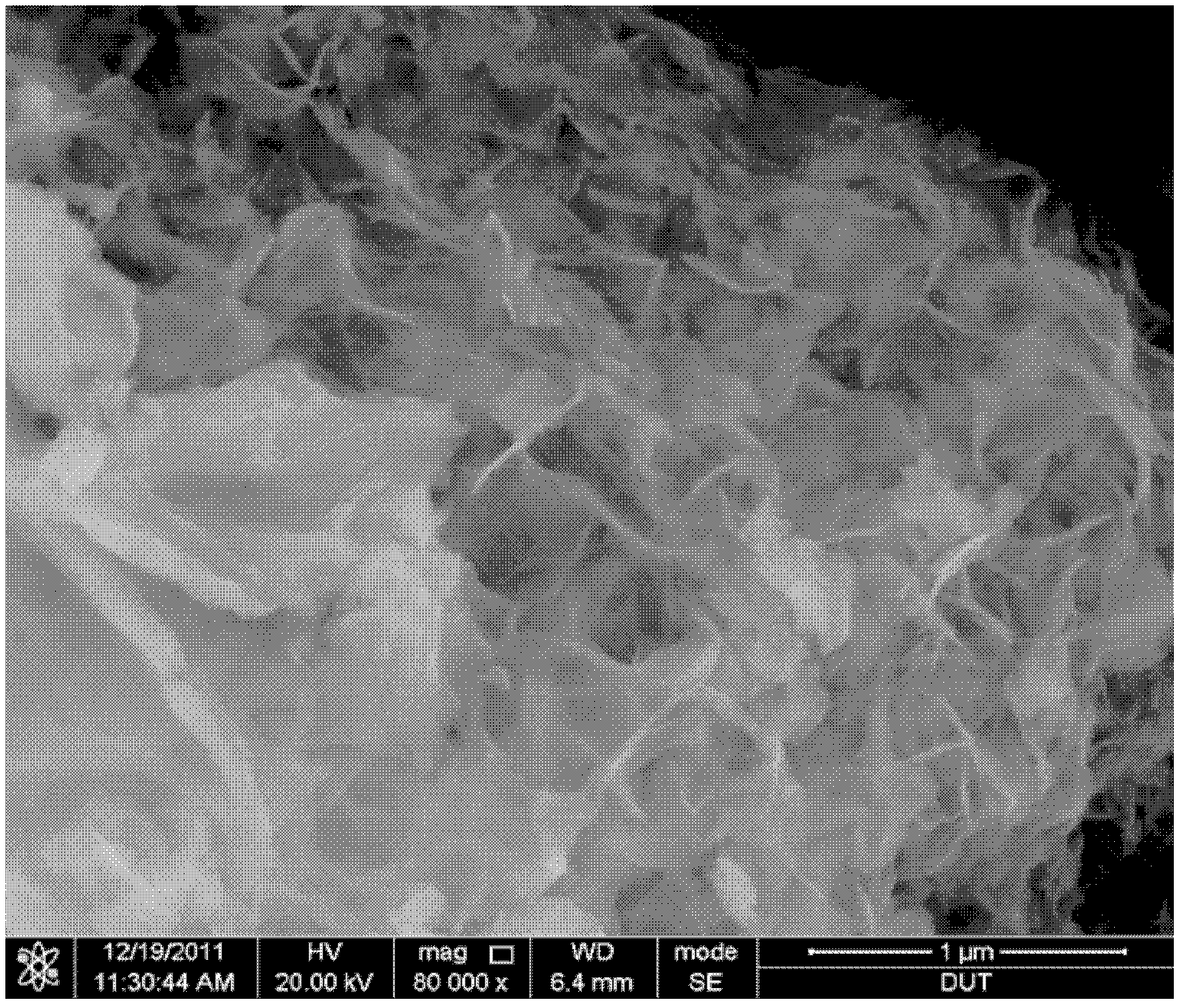

Preparation method of imatinib mesylate alpha crystal form

InactiveCN103467446ASingle crystal formEasy to operateSulfonic acids salts preparationAlcoholSingle crystal

The invention provides a preparation method of imatinib mesylate alpha crystal form. The preparation method comprises the following steps: adding imatinib base to dimethyl sulphoxide, heating for full dissolving, adding methanesulfonic acid for a reaction, adding imatinib mesylate of alpha crystal form as an initiation seed, and adding an alcohol solvent to obtain crystalline imatinib mesylate of the alpha crystal form. The imatinib mesylate of the alpha crystal form obtained through the preparation method has the characteristics of single crystal form, simple operation, stable technology, solving of a solvent residual problem, and high quality, and can completely satisfy demands of medicinal preparations.

Owner:SUNSHINE LAKE PHARM CO LTD

Method for preparing nickel hydroxide electrode material of supercapacitor

The invention discloses a method for preparing a nickel hydroxide electrode material of a supercapacitor, and belongs to the technical field of supercapacitors. The method is characterized in that: by controlling a speed of separating out a precipitator, namely controlling the thickness of quartz sand in an isolation and dilution area and the heating temperature of a main reaction chamber, a reaction speed is controlled. The method comprises the following steps of: heating the main reaction chamber to generate vapor, and making the vapor enter the isolation and dilution area through a condensation reflux system to obtain a diluted precipitator solution; and slowly dripping the diluted solution into the main reaction chamber to make a nickel hydroxide precipitate slowly separated out. The method has the advantages that: a dispersing agent is not required, the preparation method is simple, raw materials are low in prices and easy to obtain, the preparation method is easy to implement, and the prepared nickel hydroxide has a scaly appearance, single crystal form and high specific surface area, and has the characteristics of high specific capacitance and long cycle life through an electrochemical test.

Owner:DALIAN UNIV OF TECH

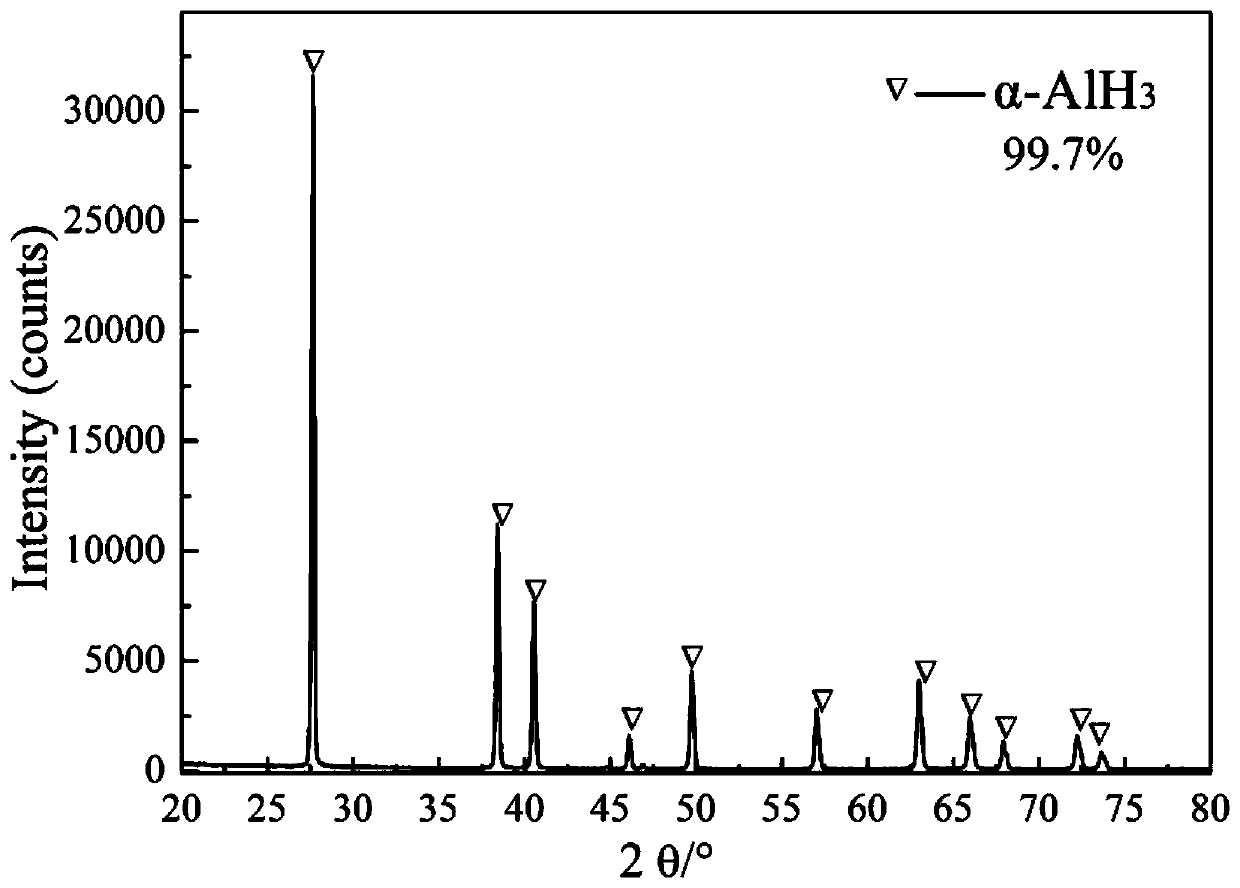

Method for preparing α-aluminum hydride by mixed catalysis of lithium aluminum hydride and lithium borohydride

The invention discloses a method for preparing alpha-aluminum trihydride by carrying out mixed catalysis of lithium aluminum hydride and lithium borohydride. The method comprises the following steps: (1) preparing mixed catalyst solutions; (2) synthesizing alpha-aluminum trihydride; (3) refining and drying a product. The method for preparing alpha-aluminum trihydride by carrying out the mixed catalysis of lithium aluminum hydride and lithium borohydride provided by the invention can be carried out at a relatively low reaction temperature under constant pressure; the method is simple in processes, easy to operate, simple in device, and can be applied to industrial production. The method disclosed by the invention is economical and high-efficient, and is low in production cost; a crystal form of the obtained alpha-aluminum trihydride is single, the purity of the product is so high to be up to 99.8%, and the product is high in stability and easy to store; moreover, the chemical stability performance of the product is beneficial for being applied to energetic materials, propellants, fuel cells and the like.

Owner:河南纳宇新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com