Preparation method of copper ion doped anatase titanium dioxide

An anatase-type titanium dioxide and copper ion technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve problems such as difficult to scientifically control the crystal form of titanium dioxide, weaken the catalytic efficiency of titanium dioxide, and not easy to form a film. Stable, easy to operate, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

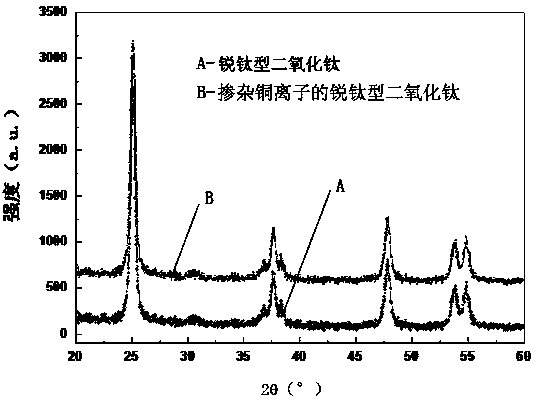

Image

Examples

Embodiment 1

[0024] (1) Preparation of crude product: Wash and dry the 1L beaker, add 0.6ml of concentrated sulfuric acid into it, in a fume hood, add concentrated sulfuric acid to 15mL of titanium tetrachloride aqueous solution; under constant stirring, add 585mL of deionized water , stirred for 0.5h until titanium tetrachloride was hydrolyzed; added oxalic acid solution containing 0.47g copper oxalate, stirred for 0.5h, added 33mL of ammonia water until the pH value of the solution was 7.5, then stirred for 2h to obtain crude product A; Wash with deionized water, test the chloride ion in the solution with 0.02mol / L silver nitrate until no obvious white precipitate occurs; filter with suction, put the obtained filter cake into a blast drying oven, and dry at 100°C for 4 hours; then Put it into a vacuum drying oven to dry, and the vacuum degree is maintained at 10 -1 Pa, the temperature was maintained at 80°C, and dried for 6 hours.

[0025] (2) Grind the dried crude product A into a fine...

Embodiment 2

[0028] (1) Preparation of crude product: Wash and dry the 2L beaker, add 2ml of concentrated sulfuric acid into it, and add concentrated sulfuric acid to 25mL of titanium tetrachloride aqueous solution in a fume hood; add 973mL of deionized water under constant stirring, Stir rapidly for 0.5h until titanium tetrachloride is hydrolyzed, add oxalic acid solution containing 0.7834g of copper oxalate, stir for 0.5h, add 70mL of ammonia water until the pH value of the solution is 7.5, then stir for 2h to obtain crude product A; deionize with 6L Wash with water, and use 0.02mol / L silver nitrate to test the chloride ion in the solution until no obvious white precipitate occurs; filter with suction, put the obtained filter cake into a blast drying oven, and dry it at 100°C for 4 hours; Dry in a vacuum oven with a vacuum of 10 -1 Pa, the temperature was maintained at 80°C, and dried for 6 hours.

[0029] (2) Grind the dried crude product A into a fine powder with a radius of 40-50 μm,...

Embodiment 3

[0032] (1) Preparation of crude product: wash and dry the 3L beaker, add 1.6ml of concentrated sulfuric acid into it, in a fume hood, add concentrated sulfuric acid to 30mL of titanium tetrachloride aqueous solution; under constant stirring, add 2970mL of deionized water , stirred for 0.5h until titanium tetrachloride was hydrolyzed; added oxalic acid solution containing 1.5g of copper oxalate, stirred for 0.5h, added 125mL of ammonia water until the pH of the solution was 7.5, then stirred for 2h to obtain crude product A; Wash with deionized water, test the chloride ion in the solution with 0.02mol / L silver nitrate until no obvious white precipitate occurs; filter with suction, put the obtained filter cake into a blast drying oven, and dry at 100°C for 4 hours; then Put it into a vacuum drying oven to dry, and the vacuum degree is maintained at 10 -1 Pa, the temperature was maintained at 80°C, and dried for 6 hours.

[0033] (2) Grind the dried crude product A into a fine p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com