Process for producing monodisperse polymer/calcium carbonate composite fine particle

A technology of composite particles and polymers, applied in the treatment of dyed macromolecular organic compounds, fibrous fillers, etc., can solve the problems of incompatibility and high experimental cost, and achieve the effects of less pollution, easy separation and purification, and convenient recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

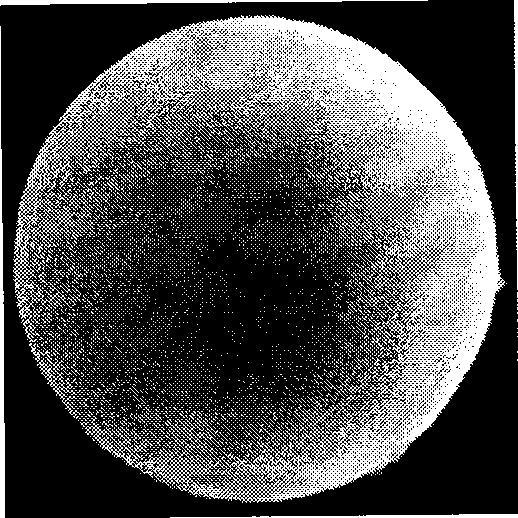

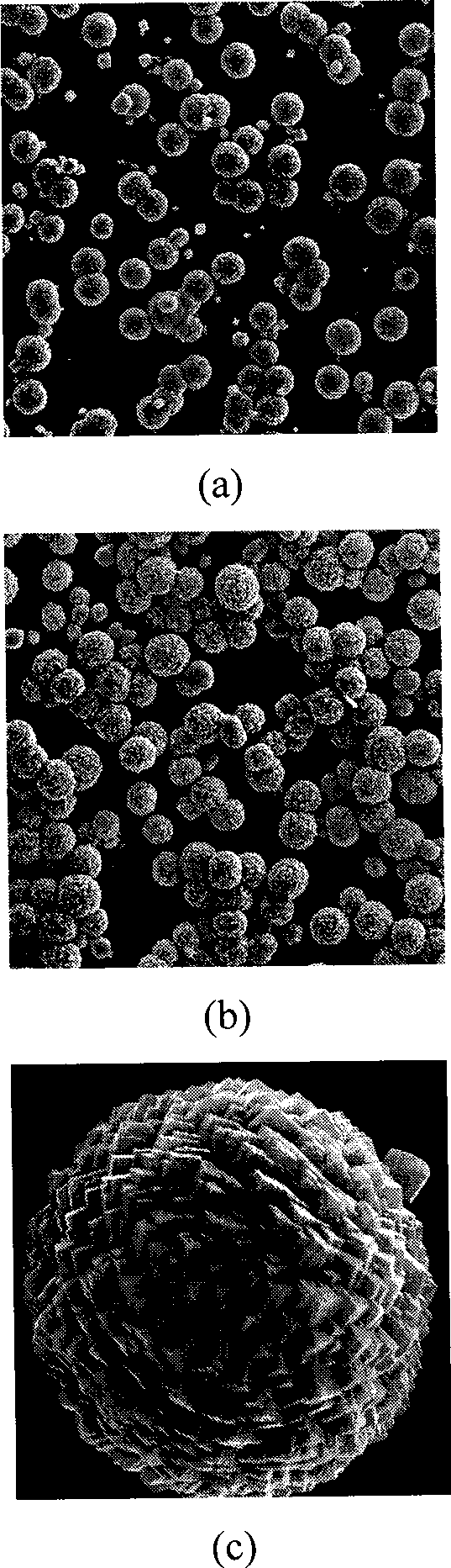

[0037] All glass instruments used in the experiment were pretreated as follows: firstly, they were sonicated in ethanol for 15 minutes, and then removed and rinsed with deionized water. Soak in a mixed solvent of concentrated nitric acid / hydrogen peroxide / water at a volume ratio of 1:1:1 for 2 days, take it out, wash it with acetone, and dry it at room temperature. Prepare 100 milliliters of 5 g / L carboxymethyl cellulose aqueous solution, then add a certain amount of calcium acetate to prepare 0.01 mol / L calcium chloride solution, and adjust the pH of the solution to 8. Cover the beaker containing the solution with aluminum foil, and make 8 pinholes on the aluminum foil. Take 20 grams of ammonium carbonate, grind it to a powder with a fineness of 100 mesh, put it in a 50 ml beaker, cover the mouth of the beaker with a polyethylene film, and prick 4 holes with a needle. Then put it into a desiccator with a volume of about 10 liters together with the above-mentioned beaker cont...

Embodiment 2

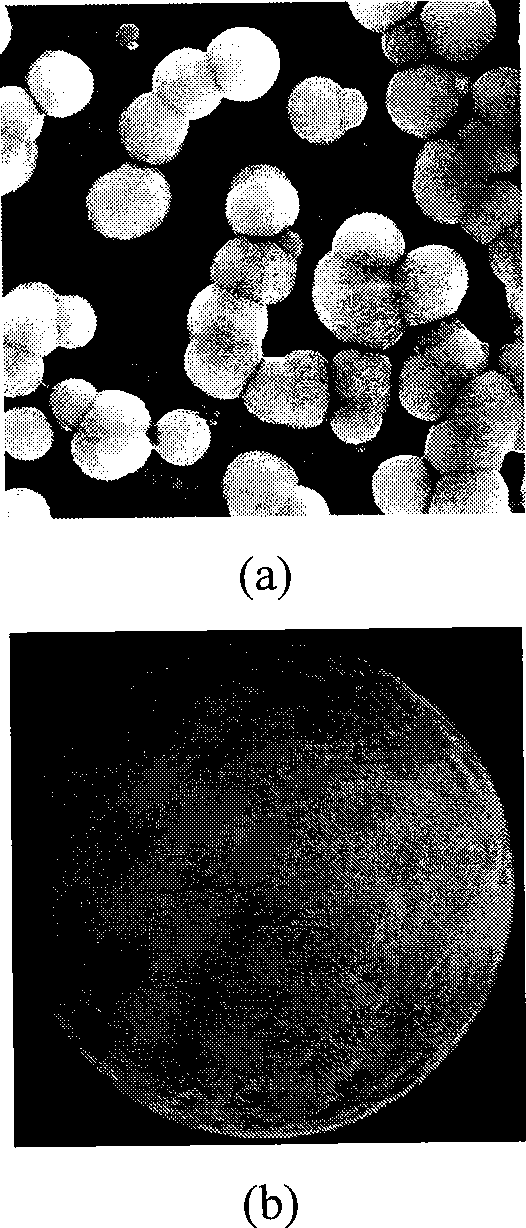

[0039] The glass instrument processing method is the same as in Example 1. Prepare 100 ml of 0.5 g / L carboxymethyl cellulose aqueous solution, add a certain amount of calcium chloride to prepare 0.01 mol / L calcium chloride solution, adjust the pH of the solution to 7.5, cover the beaker containing the solution with aluminum foil , Prick 8 pinholes on the aluminum foil. Take 20 grams of ammonium carbonate, grind it to a powder with a fineness of 100 mesh, put it in a 50 ml beaker, cover the mouth of the beaker with a polyethylene film, and prick 4 holes with a needle. Then put it into a desiccator with a volume of about 10 liters together with the above-mentioned beaker containing the solution, seal it, and start the reaction at a temperature of 30±1°C. After reacting for 12 hours, the resulting suspension was centrifuged and washed alternately with water and ethanol three times each. The obtained powder was dried at 50° C. for 12 hours under a vacuum of about 10 Pa. Get the...

Embodiment 3

[0041] The glass instrument processing method is the same as in Example 1. Prepare 100 ml of 1 g / L carboxymethyl cellulose aqueous solution, add a certain amount of calcium chloride to prepare a 0.1 mol / L calcium chloride solution, adjust the pH of the solution to 9, and cover the beaker containing the solution with aluminum foil , Prick 8 pinholes on the aluminum foil. Take 20 grams of ammonium carbonate, grind it to a powder with a fineness of 100 mesh, put it in a 50 ml beaker, cover the mouth of the beaker with a polyethylene film, and prick 4 holes with a needle. Then put it into a desiccator with a volume of about 10 liters together with the above-mentioned beaker containing the solution, seal it, and start the reaction at a temperature of 20±1°C. After reacting for 12 hours, the resulting suspension was centrifuged and washed alternately with water and ethanol three times each. The obtained powder was dried at 25° C. for 12 hours under the condition of a vacuum of abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com