Preparation method of beta-crystal form silodosin

A technology of silodosin and beta crystal form, applied in the field of preparation of beta crystal form silodosin, can solve problems such as low yield, loss of silodosin, etc. type single effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 5 g of crude silodosin crystals into 20 ml of 2-methyltetrahydrofuran, heat to about 80° C. under a nitrogen atmosphere and reflux for 30 minutes, then cool down naturally. After reaching room temperature, it was filtered and sucked dry. After vacuum drying at 40°C, 4.7g of off-white solid was obtained, with a yield of 94%, a purity of 99.6%, and a melting point of 105-106°C.

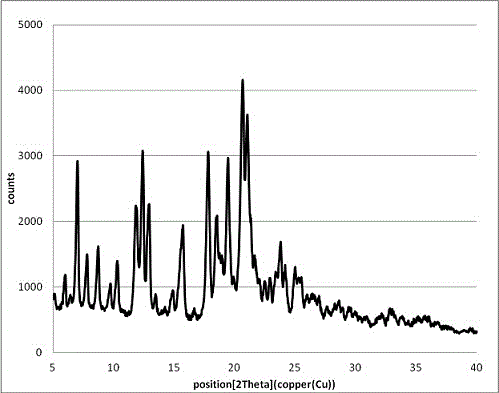

[0021] The obtained crystals were measured by X’Pert PRO X-ray diffractometer of PANalytical B.V. company in the Netherlands, Cu target, tube voltage 40 kV, tube current 40 mA, and its X-ray powder diffraction is shown in the attached figure 1 shown

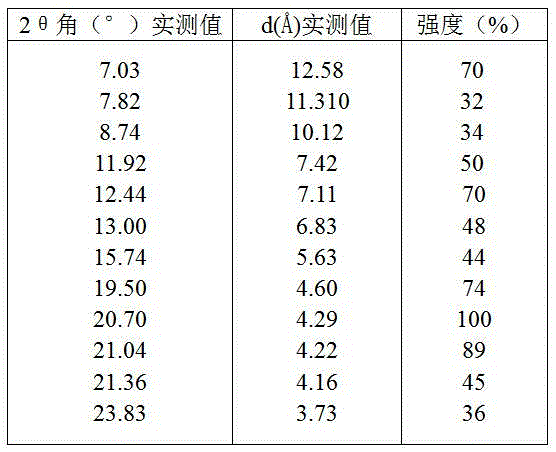

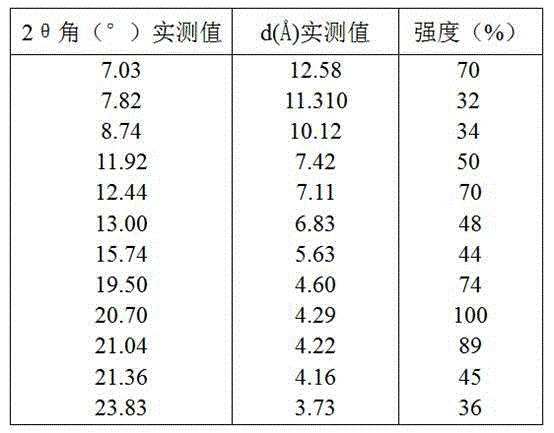

[0022]

Embodiment 2

[0024] Add 4.5 g of crude silodosin crystals to a mixture of 9 ml ethanol and 27 ml 2-methyltetrahydrofuran, heat to about 70° C. under nitrogen atmosphere and reflux for 30 minutes, then cool down naturally. After reaching room temperature, it was filtered and dried, and dried under vacuum at 40°C to obtain 4.1 g of an off-white solid with a yield of 91%, a purity of 99.76%, and a melting point of 105-106°C.

[0025] The obtained crystals were measured by X’Pert PRO X-ray diffractometer of PANalytical B.V. company in the Netherlands, Cu target, tube voltage 40 kV, tube current 40 mA, and its X-ray powder diffraction is shown in the attached figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com