Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "The process route is green and environmentally friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

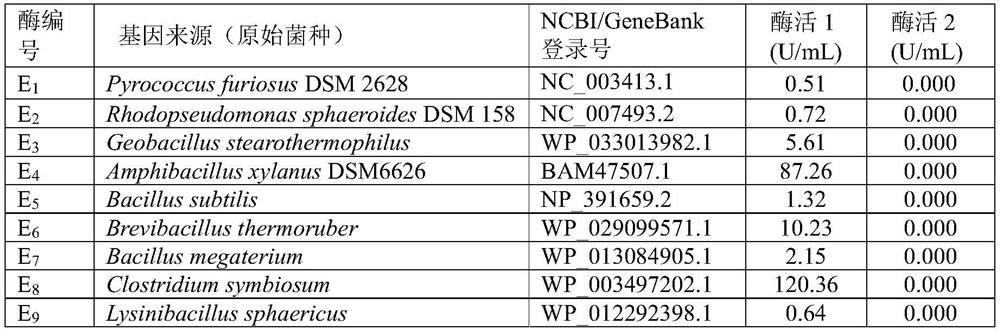

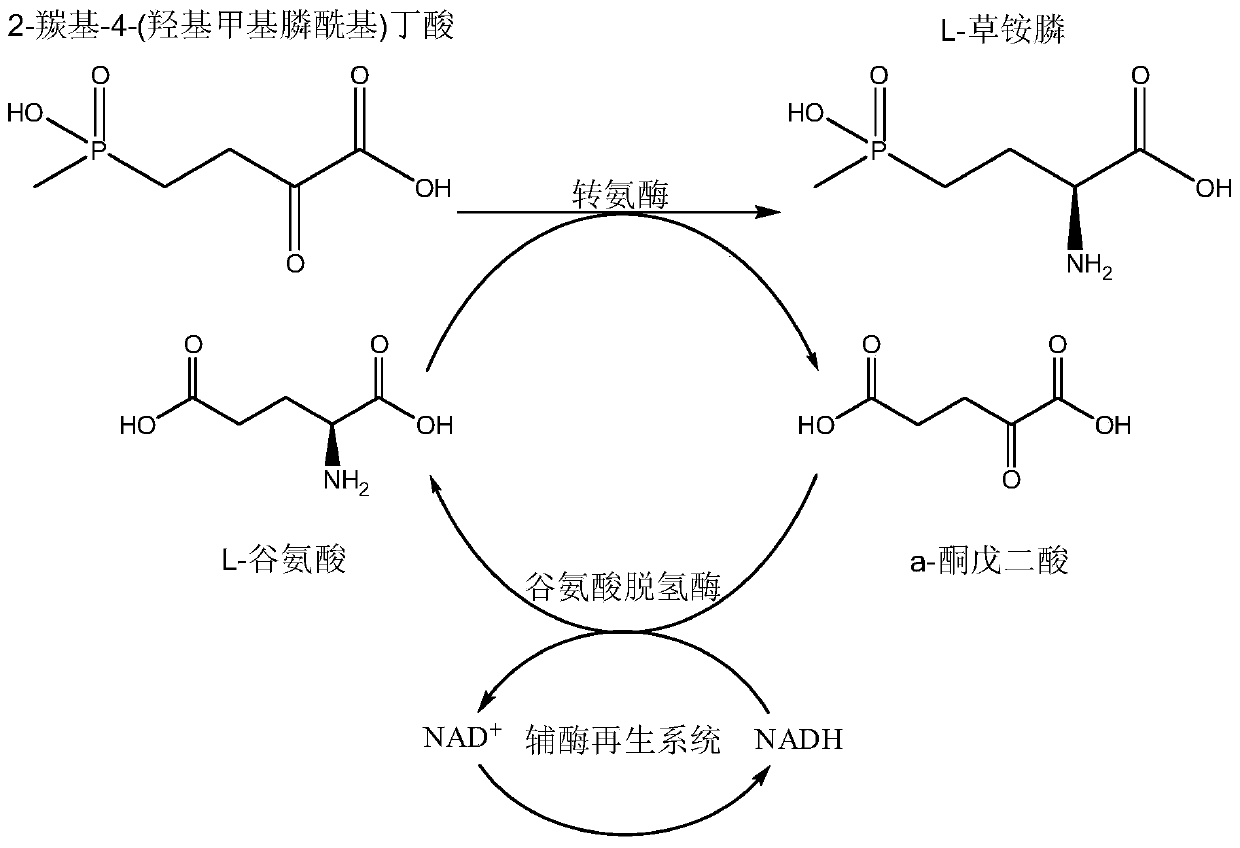

Production method of L-phosphinothricin

ActiveCN106916857AHigh catalytic activityStereoselectiveFermentationButyric acidGlutamate dehydrogenase

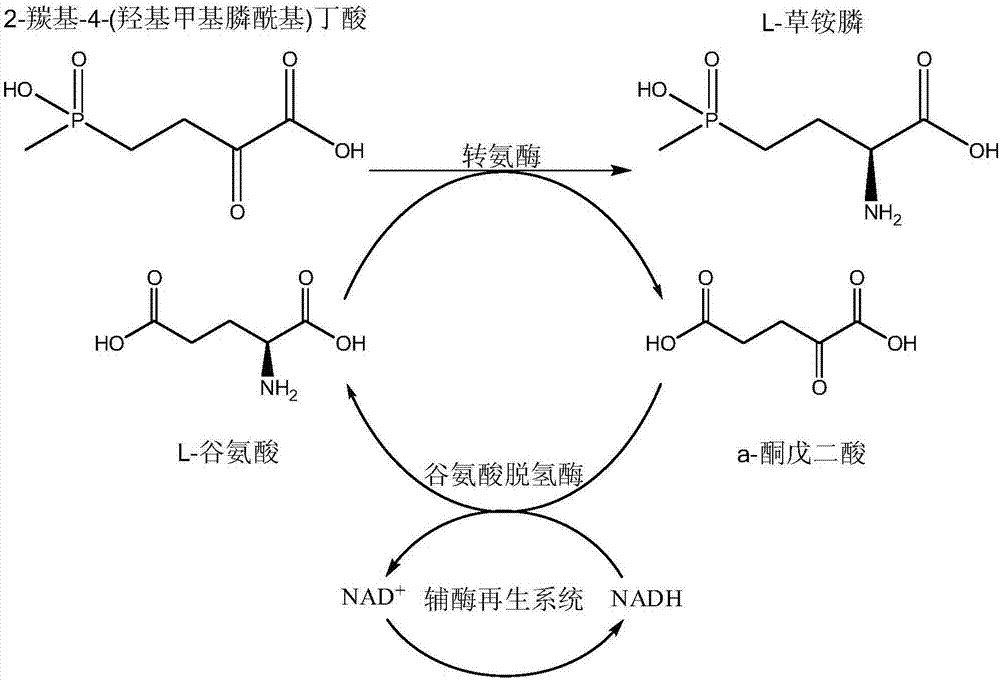

The invention discloses a production method of L-phosphinothricin. According to the method, 2-carbonyl-4-(hydroxymethylphosphonyl)butyric acid is used as a substrate and is catalyzed by an enzyme catalytic system to obtain L-phosphinothricin, and the enzyme catalytic system is composed of gamma-aminobutyric acid / alpha-ketoglutarate transaminase, glutamate dehydrogenase and a coenzyme regeneration system. The method utilizes the advantages of high catalytic activity, strong stereoselectivity and the like of transaminase, and also solves the problem of incomplete transaminase catalytic reaction, so that the catalytic reaction can completely convert the substrate 2-carbonyl-4-(hydroxymethylphosphonyl)butyric acid into L-phosphinothricin, and the conversion rate can reach 100%; no by-product alpha-ketoglutarate is accumulated in the final product of the method, and the residual amount of other substances such as the raw material glutamic acid in the product after the end of the reaction is extremely low, so the subsequent refining process of L-phosphinothricin is greatly simplified, and the total yield of the product is increased.

Owner:ZHEJIANG UNIV

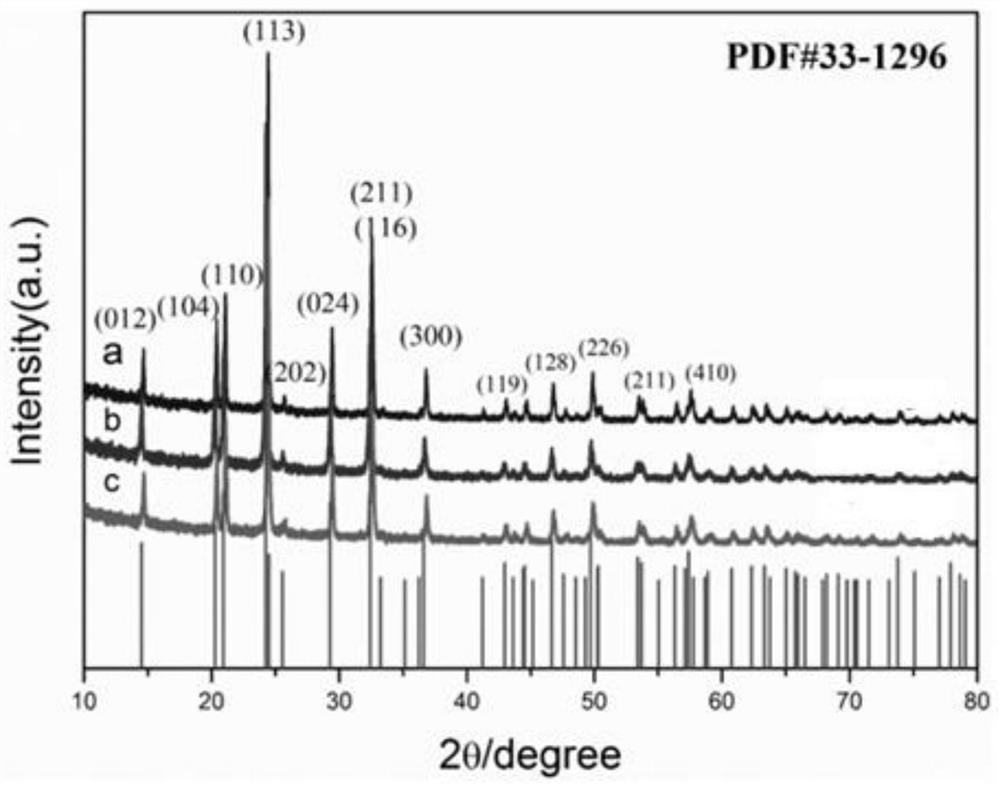

Lithium ion battery silicon-based negative material and preparation method thereof

InactiveCN103236517ASmall particle sizeAlleviate volume effectCell electrodesSilicon monoxideSilicon oxide

The invention relates to a lithium ion battery silicon-based negative material and a preparation method thereof, which belong to the technical field of lithium ion battery negative materials. The lithium ion battery silicon-based negative material is prepared from silicon monoxide; the macroscopic particle diameter of the negative material is 10-25 micrometers; according to a microstructure, the negative material is composed of nanometer silicon particles covered with silica; the internal silicon particle diameter of the negative material is 20-30 nanometers; and at 0.1C discharge rate, the first discharge capacity of the negative material reaches 2010-2640 mAh / g, and is 420-790 mAh / g after 50 cycles. The negative materials with the structure characteristic combines the dispersion and the reduction of silicon particles; and on one hand, the silicon particles can be dispersed by a pore channel structure of silica so as to provide a space for the expansion of silicon in charge and discharge processes, on the other hand, the particle diameter of silicon can be reduced, and therefore, a volume effect of silicon in the charge and discharge processes can be weakened.

Owner:中国东方电气集团有限公司

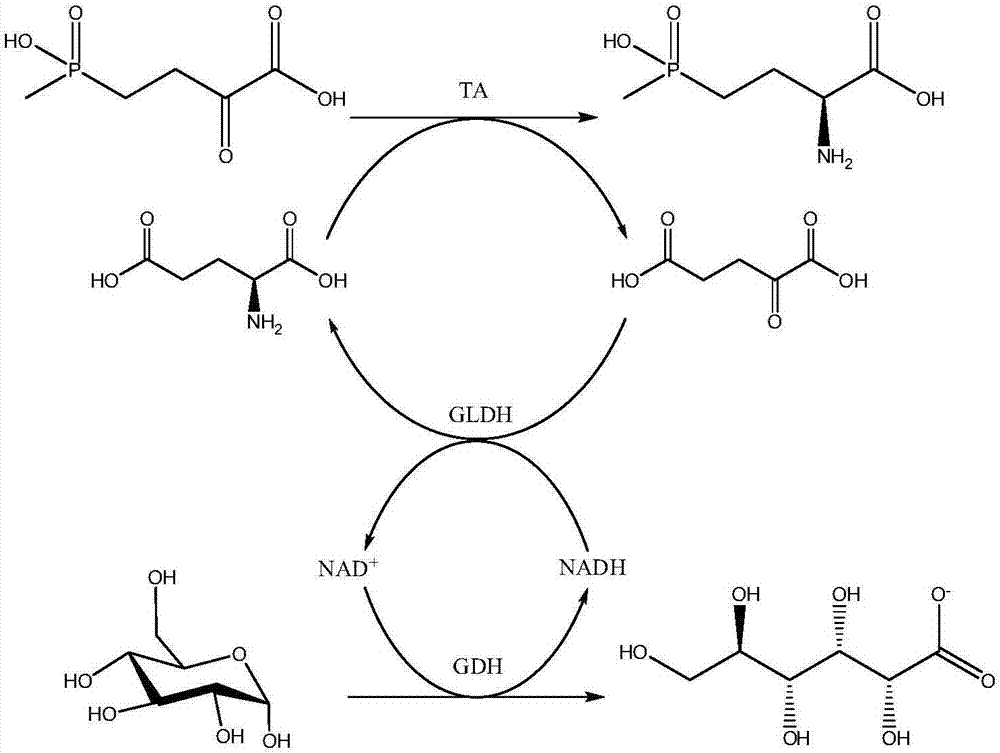

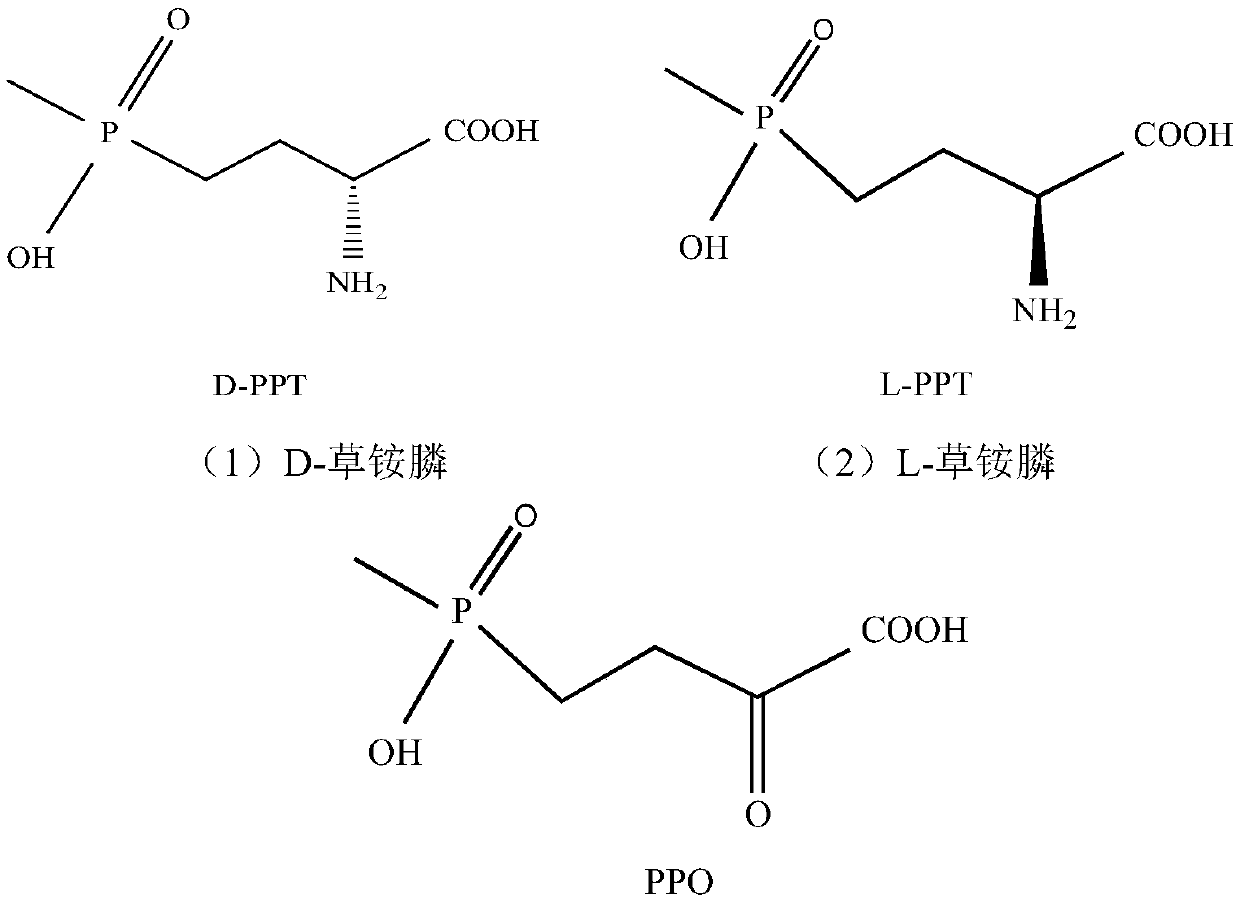

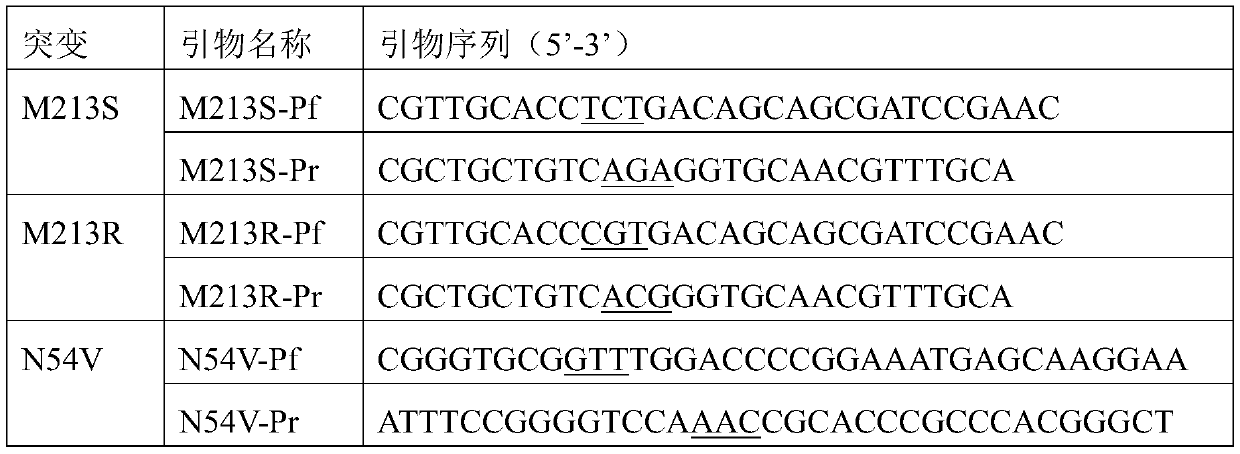

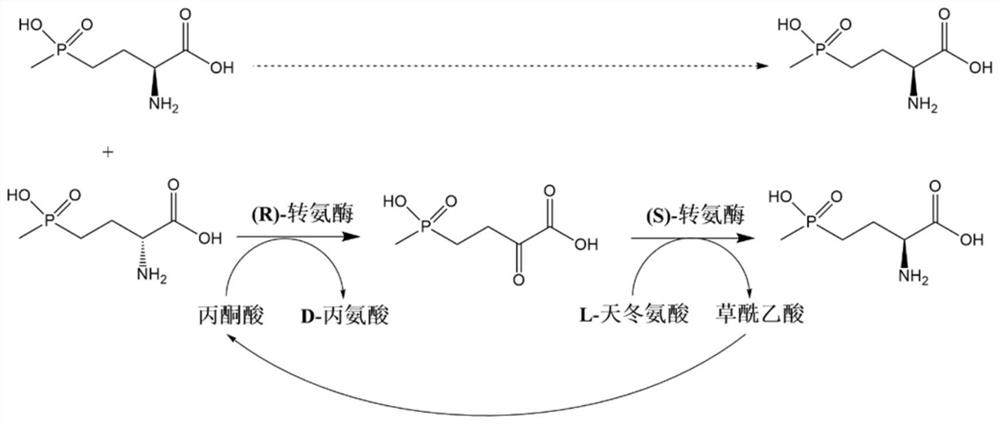

Redox asymmetrical method for preparing L-phosphinothricin by biological multi-enzyme coupling

The present invention discloses a redox asymmetrical method for preparing L-phosphinothricin by biological multi-enzyme coupling. D, L-phosphinothricin is used as a raw material, the L-phosphinothricin is obtained through catalysis of an enzyme catalysis system, the enzyme catalysis system comprises a D-amino acid oxidase mutant for catalyzing D-phosphinothricin in the D, L-phosphinothricin into 2-carbonyl-4-[hydroxy (methyl) phosphonyl] butyric acid and a transaminase for catalyzing and reducing the 2-carbonyl-4-[hydroxy (methyl) phosphonyl ] butyric acid into the L-phosphinothricin, the D-amino acid oxidase mutant is obtained by mutation of D-amino acid oxidase in wild rhodotorula taiwanensis, and mutation sites are selected from one of the following four types: (1) M213S; (2) M213S-N54V-F58E; (3) M213S-N54V-F58E-D207A; and (4) M213S-N54V-F58E-D207A-S60T. The D-amino acid oxidase mutant has better catalytic efficiency, a conversion rate is far higher than that of wild enzyme when theracemic D, L-phosphinothricin is used as a substrate, and yield of PPO is also greatly improved.

Owner:ZHEJIANG UNIV OF TECH

Method for separating and extracting cepharanthine

The invention relates to a method for separating and extracting cepharanthine, which comprises the following steps of: taking a dry stephania tuberous root, crushing, adding 2 to 3L of water and 0.5 to 5ml of mixed bio-enzyme liquid into each kilogram of crushed material, soaking for 1 hour, adding 9 to 11L of 1 to 2 mass percent aqueous solution of HCL, heating to 90DEG C, and soaking for 3 hours; and separating out a liquid medicine, adding 9 to 11L of 1 to 2 percent aqueous solution of HCL into dregs, decocting for 3 hours, filtering, mixing filtrate, adsorbing by adopting a cation exchange column or cation cellulose column, enriching the cepharanthine, eluting by using solution that sodium hydroxide is added into 60 to 90 percent aqueous solution of ethanol until the saturation state as eluent, collecting eluent of a cepharanthine section, regulating the pH value to be 7, concentrating for recovering ethanol, filtering, dissolving a precipitate by using absolute ethanol, eluting and purifying by using an anion column, collecting eluent of a cepharanthine section, concentrating, crystallizing, and drying to obtain the cepharanthine. The method has the advantages of simple operation, light pollution, low cost, high yield, high purity of cepharanthine, and suitability for industrial production.

Owner:YUNNAN HANDE BIO TECH

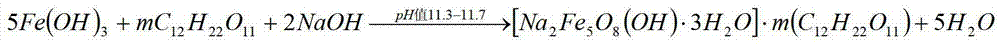

Preparation method of raw medicine of environment-friendly iron sucrose

InactiveCN103059072AHigh yieldQuality improvementSugar derivativesDisaccharidesEnvironmental resistanceSucrose

The invention relates to the technical field of a raw medicine preparation, and particularly relates to a preparation method of the raw medicine of environment-friendly iron sucrose. The weight-average molecular weight (Mw) of the raw medicine of the environment-friendly iron sucrose obtained by the technical scheme is 34000-60000, and the distribution coefficient (MW / Mn) is less than 1.7. The exceeding chloride Cl<-> in an iron sucrose solution is removed by selecting an anion exchange resin, and the content of Cl<-> in products is controlled at between 0.012% and 0.025%. The products are qualified by titratable alkali indexes after the products are processed by a cation exchange resin. The residual large particle impurities in the iron sucrose solution are filtered out by selecting a 0.8mu m filter membrane. The preparation method is simple and environment-friendly in technology route, high in product yield, good in quality, simple in production equipment, and easy to operate and the whole production process is easy to control, so the preparation method is suitable for scale production.

Owner:CHANGZHOU VOCATIONAL INST OF ENG +1

Catalyst for catalyzing 5-hydroxymethylfurfural to prepare furan-2,5-dicarbaldehyde in water phase, and preparation method and application of catalyst

ActiveCN107417649AEasy to recycleThe process route is green and environmentally friendlyOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFuranHydroxymethylfurfural

The invention discloses a Catalyst for catalyzing 5-hydroxymethylfurfural to prepare furan-2,5-dicarbaldehyde in a water phase. The catalyst comprises a carrier, an active metal component and an auxiliary agent metal, by a final catalyst weight, the mass fraction of the active metal component is 1%-20%, the mass fraction of the auxiliary agent metal component copper is 0-10%, and the balance is that of the carrier, wherein the carrier is one selected from graphene, silicon carbide, aluminium oxide, silicon dioxide, activated carbon and carbon nitride, and the active metal component is one or two selected from gold, palladium, platinum, silver, ruthenium and rhodium. A preparation method provided in the invention has the advantages that the method is mild in reaction conditions, friendly to environments, high in conversion efficiency and good in selectivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

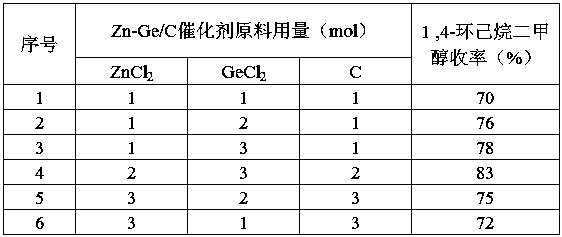

Synthesis process of 1,4-cyclohexane diisooctoate

InactiveCN107778175ASimple processEasy to controlOrganic compound preparationCarboxylic acid esters preparationCyclohexanedimethanolOctanoic Acids

The invention relates to a method for synthesizing esters, in particular to a method for synthesizing 1,4-cyclohexanedimethanol diisocaprylate. The preparation steps include: adding terephthalic acid and (4-methylcyclohexyl)methanol into a reaction kettle under superatmospheric pressure at a temperature of 250-400°C, stirring evenly, and fully reacting to obtain terephthalic acid diacetate (4‑methylcyclohexyl) methyl ester; add Zn‑Ge / C catalyst to the reaction system, feed hydrogen, charge hydrogen to carry out hydrogenation reaction, during the hydrogenation reaction, control the hydrogenation rate so that the temperature in the reactor Keep at 100-150°C and pressure at 1-3Mpa, after the hydrogenation reaction, cool to 90-100°C, slowly open the exhaust port to obtain 1,4-cyclohexanedimethanol; the 1 prepared in step 1 , 4-cyclohexanedimethanol and isooctanoic acid are added to the reaction vessel, then superacid catalyst SO42- / TiO2 / Ce is added, the reaction temperature is 100-200 ° C, the reaction is 5-15 h, and the reaction is completed and the heating is stopped to obtain the crude product; Post-processing. The synthetic route is suitable for industrial production.

Owner:PANJIN HONGDING CHEM CO LTD

Synthesis method for 4-methyl-5-(2-ethoxyl)-thiazole

ActiveCN102584740AHigh yieldMeet market quality requirementsOrganic chemistrySynthesis methodsDistillation

The invention provides a preparation method for 4-methyl-5-(2-ethoxyl)-thiazole. The 4-methyl-5-(2-ethoxyl)-thiazole is synthesized from 2-acetylbutyrolactone serving as a raw material through amination, chloration, condensation and oxidative reaction. The preparation method comprises the following steps of: introducing chlorine into 2-acetylbutyrolactone and hydrolyzing to obtain 3-acetyl chloride propyl alcohol; introducing ammonia gas into carbon bisulfide to obtain ammonium salt; oxidizing a condensation product of 3-acetyl chloride propyl alcohol and the ammonium salt with hydrogen peroxide or oxygen to obtain a product; extracting with dichloromethane; removing the dichloromethane; then performing reduced pressure distillation; and collecting fraction at 120-127 DEG C under the pressure of 395-400 Pa. The synthesis method has the advantages of readily available raw material, low production cost, simple process, mild reaction conditions and yield of reaching up to 82 percent.

Owner:WUTONG AROMA CHEM CO LTD

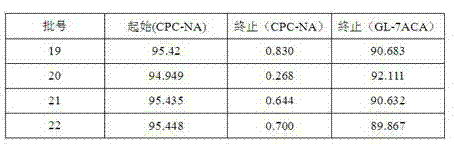

A kind of method for preparing 7-aminocephalosporanic acid

The invention is a method for preparing 7-aminocephalosporanic acid. Add cephalosporin C sodium salt solution in the enzyme reactor, then add D-amino acid oxidase to oxidize, after hydrogen peroxide conversion, add GL-7 aminocephalosporanic acid acylase to cleavage, then crystallize, centrifugal filter, wash, Dry and test to get 7-aminocephalosporanic acid. The production process is greatly simplified. The cephalosporin C obtained by fermentation can be used for enzymolysis without crystallization. No toxic solvent is used in the production process, and steps such as adding and removing protective agents are omitted. The product can achieve high yield and high yield. quality while reducing costs and pollution.

Owner:FUJIAN FUKANG PHARMA

Method for preparing and purifying nebivolol intermediate

The invention relates to a method for preparing and purifying a nebivolol intermediate and in particular relates to an improved method for preparing and purifying 2-chloro-1-(6-fluro-3,4-dihydro-2H-1-benzopyran-2-yl) acetone shown in a formula (I) as shown in the specification. The 2-chloro-1-(6-fluro-3,4-dihydro-2H-1-benzopyran-2-yl) acetone compound is a key intermediate for synthesizing nebivolol. By adopting the method provided by the invention, a high-purity solid of the key intermediate is obtained with high yield (more than 85%) and high purity (more than 99%), operation is easy, and industrial production can be easily realized.

Owner:PHARMA CHANGZHOU PHARMA FACTORY NO 4

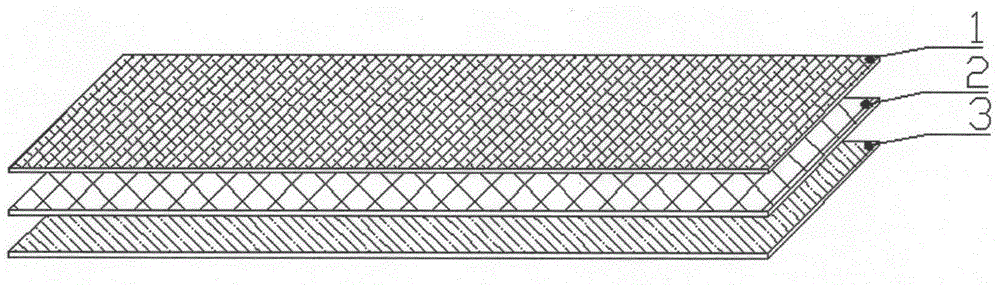

High-efficiency low-resistance air filter material prepared from special-shaped melt-blown fiber

InactiveCN104785019AEasy to operateLow costLayered productsFiltration separationFiberPolymer science

The invention discloses a high-efficiency low-resistance air filter material prepared form special-shaped melt-blown fiber and a preparation method of the high-efficiency low-resistance air filter material. The high-efficiency low-resistance air filter material is characterized in that a coarse filtration part, a supporting part and a fine filtration part are sequentially arranged from top to bottom to form a filter material adopting a sandwich structure; needling is performed under the conditions that the needling depth ranges from 5 mm to 7 mm and the needling density ranges from 390 needles per cm<2> to 480 needles per cm<2>, and all parts of the filter material are connected to form the high-efficiency low-resistance air filter material; the coarse filtration part and the fine filtration part are made from chemical fiber and combed into net-shaped structure, and the supporting part is made from the special-shaped melt-blown fiber. The high-efficiency low-resistance air filter material has high filter efficiency, the filter resistance is lower, the manufacturing cost is low, and the process is simple and environment-friendly; the special-shaped melt-blown fiber is used for preparing the filter material for the first time, and a great breakthrough is made in the field of filter materials.

Owner:DONGHUA UNIV

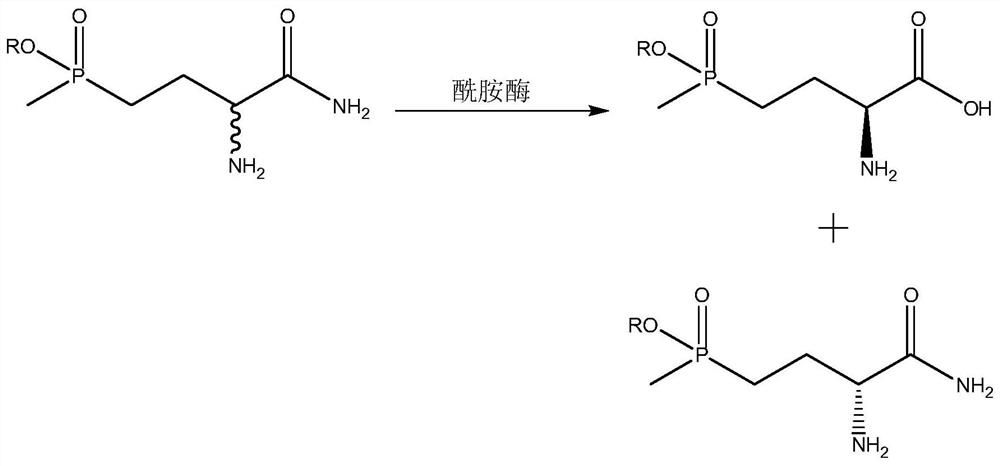

Method for preparing L-glufosinate ammonium by using biological multi-enzyme coupling method

ActiveCN112410383AImprove conversion rateThe separation and refining process is simpleTransferasesFermentationReceptorAmmonium glufosinate

The invention relates to a method for preparing L-glufosinate ammonium by using a biological multi-enzyme coupling method. The method comprises converting D, L-glufosinate ammonium into L-glufosinateammonium in a presence of (R)-transaminase, (S)-transaminase, an amino receptor and an amino donor. The method can realize a high-efficiency resolution of high-concentration D, L glufosinate ammoniumto prepare the L-glufosinate ammonium.

Owner:YONGNONG BIOSCI +2

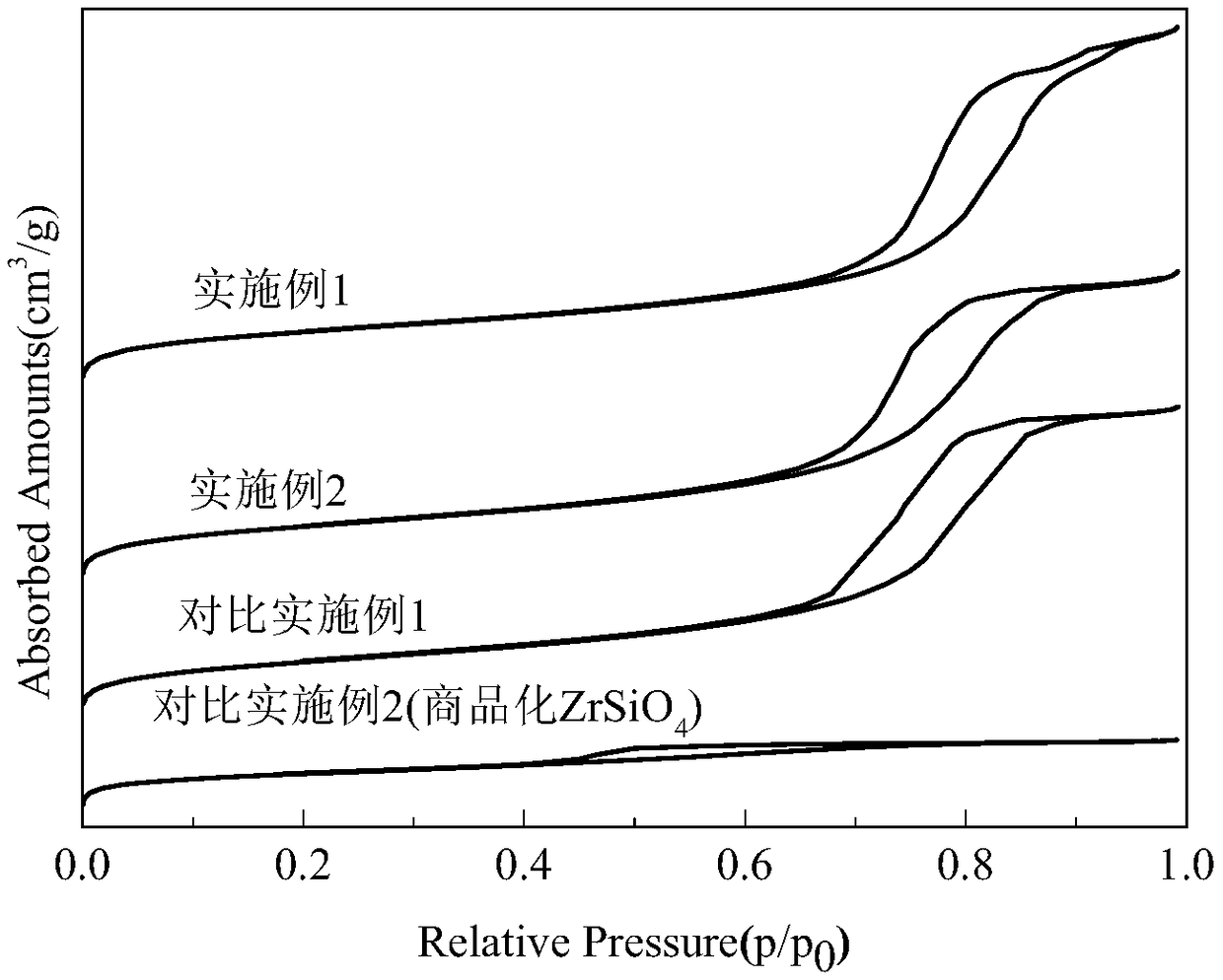

Zirconium silicate-modified mesoporous silicon oxide catalyst as well as preparation method and application thereof

ActiveCN108786778AImprove thermal stabilityReduce dosageOrganic compound preparationCarboxylic acid esters preparationButeneAlcohol

The invention discloses a zirconium silicate-modified mesoporous silicon oxide catalyst as well as a preparation method and application thereof. The catalyst is prepared by one-step hydrothermal condensation after a template agent, a structure directing agent, a silicon source and a zirconium source are added. The invention further discloses a method for synthesizing 3-methyl-butene-1-alcohol carboxylate by adopting the zirconium silicate-modified mesoporous silicon oxide catalyst. The method is that the 3-methyl-butene-1-alcohol carboxylate is generated by the condensation and the esterification of carboxylic acid, isobutene and formaldehyde. The zirconium silicate-modified mesoporous silicon oxide catalyst disclosed by the invention is mild in preparation condition, simple in preparationprocess and high in catalytic activity, is used for the catalytic synthesis of the 3-methyl-butene-1-alcohol carboxylate and has the advantages of being good in reaction activity, high in product yield, green, environmentally-friendly and the like.

Owner:NANJING UNIV OF TECH

Glutamate dehydrogenase mutant for producing L-glufosinate-ammonium and L-glufosinate-ammonium production method

ActiveCN113088501AMild reaction conditionsGreen Process RouteBacteriaMicroorganism based processesNiacinamideNucleotide

The invention discloses a glutamate dehydrogenase mutant for producing L-glufosinate-ammonium, and belongs to the technical field of gene engineering, and the amino acid sequence after mutation is shown as SEQ ID NO.1-SEQ ID NO.11. The invention also discloses a production method of L-glufosinate-ammonium, which comprises the following steps: by taking 2-carbonyl-4-[hydroxyl (methyl) phosphonyl]-butyric acid as a raw material, adding NH4<+> and coenzyme NADH / NAD<+>, then catalyzing by using the glutamate dehydrogenase mutant, and reducing and aminating the 2-carbonyl-4-[hydroxyl (methyl) phosphonyl]-butyric acid into L-glufosinate-ammonium by using glutamate dehydrogenase. A large number of glutamate dehydrogenase mutant genes are developed through the method, L-glufosinate-ammonium can be prepared from glutamate dehydrogenase mutants by using nicotinamide adenine dinucleotide (NADH or NAD<+>) which is low in price as coenzyme, the substrate conversion rate is larger than or equal to 99%, the optical purity of the product exceeds 99%, reaction conditions are mild, and the method is a green, environment-friendly and low-carbon process route, and is suitable for large-scale industrial production and application.

Owner:ZHEJIANG UNIV

Genetically engineered bacterium for producing L-aspartic acid through fermentation and construction method and application thereof

InactiveCN109370971AHigh yieldIncrease concentrationBacteriaStable introduction of DNAEscherichia coliL-Aspartate

The invention discloses a genetically engineered bacterium for producing L-aspartic acid through fermentation and a construction method and application thereof. The bacterial strain is classified andnamed ad Escherichia coli deltaiclR, and its preservation number is CCTCC NO: M2018521. The construction process mainly includes the steps that a repressor gene iclR of an aceBAC operon in a recombinant bacterium with the preservation number CCTCC NO: 2301 is knocked out so as to open glyoxylic acid pathway for sharing the flux, acetic acid accumulated in the fermentation process is fully utilizedand is used as a raw material, fumaric acid is obtained by fermentation, the utilization efficiency of a carbon source is improved, and thus the yield of L-aspartic acid is further improved. The invention also discloses a culture medium of the L-aspartic acid by the genetically engineered bacterium through fermentation and culture conditions. The route of adopting only glucose as the raw materialfor fermentation to prepare the L-aspartic acid is realized, the yield of L-aspartic acid is improved, and the genetically engineered bacterium is friendly to the environment and economical.

Owner:NANJING UNIV OF TECH

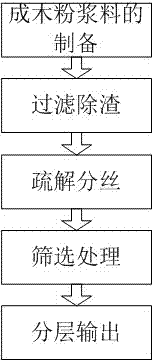

Preparation process and treatment system for papermaking wood flour

ActiveCN105442367AGood quality and stabilityEnsure consistencyPretreatment with water/steamFibrous raw materialsFiberEnvironmental resistance

The invention discloses a reparation process and a treatment system for papermaking wood flour. The preparation process comprises processes of preparing of log slurry, filtering for slag removal, untwining and devillicate, screening and layered output. The treatment system comprises a preparation tank, a slag remover, a deflaker, a first slurry pool, a UV flow rising pressurized screen and a second slurry pool. The reparation process and a treatment system for the papermaking wood flour have the advantages of being high in quality consistency and binding force between fibers, low in cost and green and environmentally friendly in process.

Owner:DONGGUAN NINE DRAGONS PAPER IND

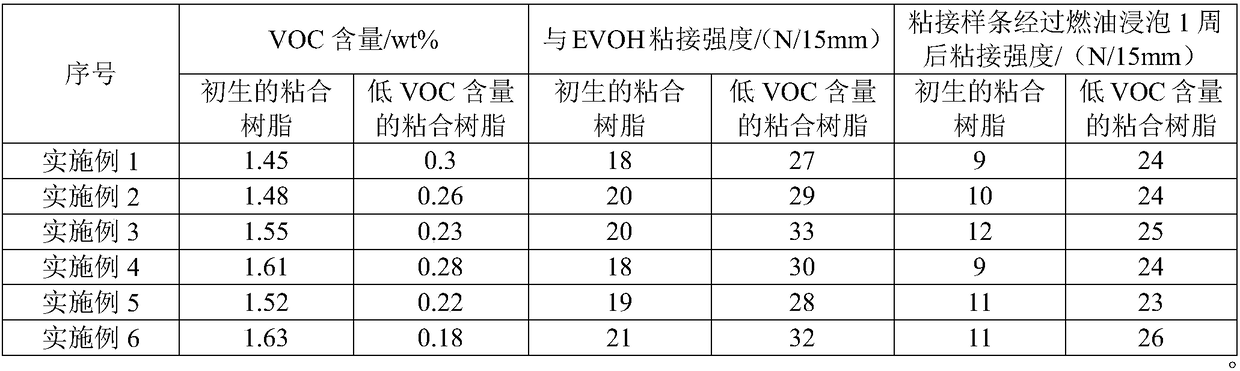

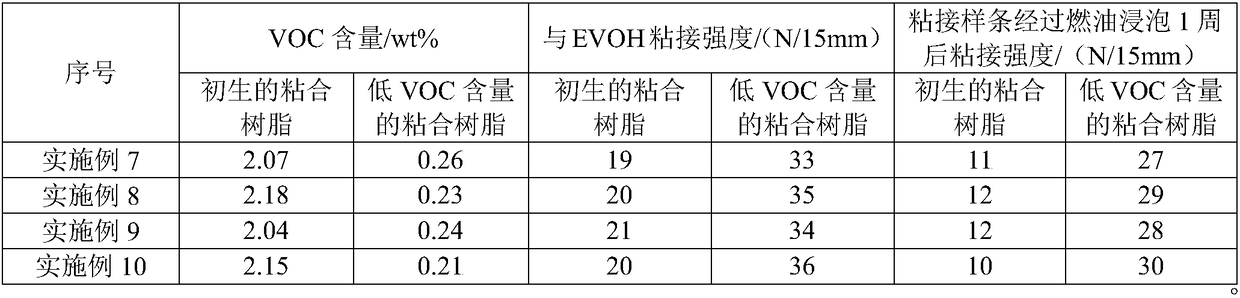

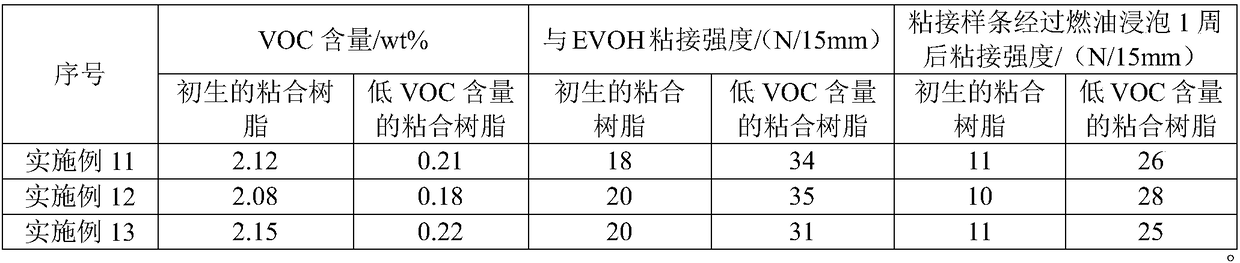

Preparation method of low-VOC bonding resin

ActiveCN108546531ALow VOC contentImprove performanceMacromolecular adhesive additivesBulk chemical productionAging resistanceTetrachloroethane

The invention relates to the technical field of bonding resins, and concretely relates to a preparation method of a low-VOC bonding resin. The preparation method comprises the following steps: preparing a primary bonding resin from a matrix resin, a graft monomer, an initiator, a tackifying resin and a functional assistant through a double screw extruder, feeding the primary bonding resin into a supercritical device, and removing VOCs from the primary bonding resin by a purifying solvent to obtain the low-VOC bonding resin, wherein the purifying solvent is one or more of carbon dioxide, 1,1,1,2-tetrachloroethane, methane, ethane, propane, ethylene and propylene. The supercritical fluid purification of the primary bonding resin in the method greatly reduces the content of the VOCs in orderto effectively improve the use performance and the safety performance of an automobile plastic fuel tank; and the preparation method has the advantages of environmentally-friendly and efficient preparation process, and simple process route, and the tackifying resin and the functional assistant can improve the flowability, the adhesion and the aging resistance of the bonding resin.

Owner:NINGBO NENGZHIGUANG NEW MATERIALS TECH

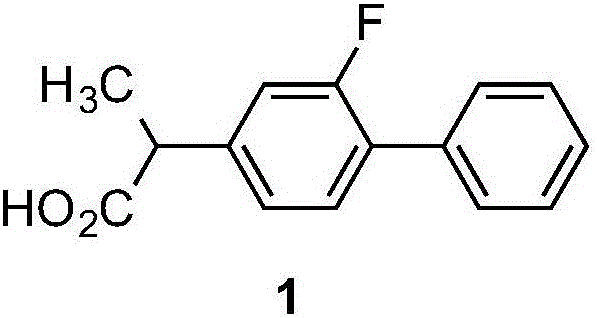

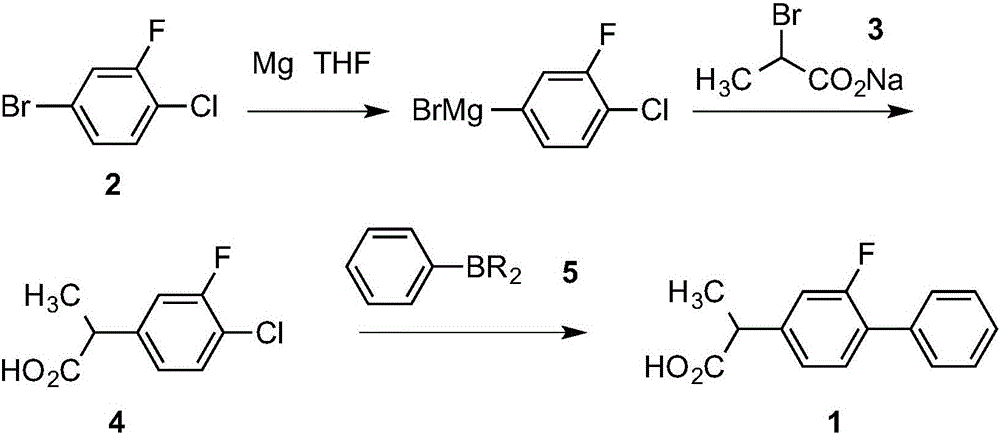

Flurbiprofen synthesis method

ActiveCN106496016AAvoid security issuesAvoid environmental pollutionOrganic compound preparationMagnesium organic compoundsPropanoic acidOrganic solvent

The invention relates to a flurbiprofen synthesis method and belongs to the technical field of pharmaceutical synthesis. According to the flurbiprofen synthesis method, Suzuki coupling reaction is utilized, the flurbiprofen can be obtained from 2-(3-fluoro-4-bromophenyl) propionic acid and phenyl boron reagent in organic solvent in the alkali condition through palladium catalytic Suzuki coupling reaction; the mole ratio between the 2-(3-fluoro-4-bromophenyl) propionic acid and the phenyl boron reagent is 1: (0.9 to 1.1). The synthesis method is simple, and the obtained flurbiprofen is high in yield and high in purity.

Owner:MAISON CHEM

Preparation method of carbon-coated sodium titanium phosphate composite material and preparation method of negative pole piece

InactiveCN113697789ASave raw materialsSimple equipment requirementsElectrode carriers/collectorsElectrode collector coatingTitanium phosphateSlurry

The invention discloses a preparation method of a carbon-coated sodium titanium phosphate composite material and a preparation method of a negative pole piece. The preparation method of the carbon-coated sodium titanium phosphate composite material comprises the following steps: (1) adding a carbon source, a sodium source, a phosphorus source and a titanium source into a dispersing agent, and stirring to obtain slurry; (2) stirring and refluxing the slurry, removing part of the dispersing agent under reduced pressure, and drying to obtain a powdery precursor; and (3) pressing the precursor into a rough blank, calcining in an inert atmosphere, and cooling to obtain the carbon-coated sodium titanium phosphate composite material. The preparation method of a carbon-coated sodium titanium phosphate negative pole piece comprises the following steps: S1, mixing water-based conductive slurry, water-based glue and a solvent, adding a conductive agent and the carbon-coated sodium titanium phosphate composite material, and uniformly stirring to obtain water-based coating slurry; and S2, coating a hydrophobic carbon-coated aluminum foil with the water-based coating slurry, drying, compacting and slitting to obtain the carbon-coated sodium titanium phosphate negative pole piece. According to the methods, no harmful or corrosive gas is discharged, the methods are green and environment-friendly production processes, and the used raw materials are common and cheap.

Owner:JIANGSU UNIV OF TECH

A preparing method of flurbiprofen

ActiveCN106496015AAvoid security issuesAvoid environmental pollutionOrganic compound preparationMagnesium organic compoundsPhenylboronic acidOrganic solvent

A preparing method of flurbiprofen is disclosed and belongs to the technical field of medicine preparation. A Suzuki coupling reaction is adopted. 2-(3-fluoro-4-chloro-phenyl)-propionic acid and a phenylboronic acid reagent are subjected to the palladium catalyzed Suzuki coupling reaction in an organic solvent under existence of an alkali to obtain the flurbiprofen, wherein the mole ratio of the 2-(3-fluoro-4-chloro-phenyl)-propionic acid to the phenylboronic acid reagent is 1:(0.9-1.1). The method is simple. The prepared flurbiprofen is high in yield and high in purity.

Owner:MAISON CHEM

Preparation method and application of polyoxometalate crystal

ActiveCN106957313AEasy to makeNo need for harsh reaction conditionsOrganic chemistryMolecular sieve catalystsMANGANESE ACETATEVilanterol trifenatate

The invention belongs to the technical field of organocatalysis and in particular relates to a preparation method and application of a polyoxometalate crystal. The preparation method disclosed by the invention comprises the following steps: by taking Na2WO4.2H2O, NaVO3.2H2O, disodium hydrogen phosphate, manganese acetate and benzyl tri-n-butylammonium chloride as raw materials, preparing the heteropolyacid crystal. Catalyzed preparation of an anti-asthma drug vilanterol trifenatate intermediate is realized by taking the polyoxometalate crystal as a catalyst. The defect in the conventional process that a strong base is adopted is overcome, the pressure for environmental protection is alleviated, the process route is green and environment-friendly, and the requirements on the conventional industrial production are met.

Owner:山东本源晶体科技有限公司

A kind of solid acid catalyst and its preparation method and application

InactiveCN103934027BHigh activityEasy to produceOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation by compound dehydrationCarbon layerEther

Owner:NANJING DECAN CHEM

Extracting process regulating grease ratio of colza oil

InactiveCN105462681AHigh nutritional valueRaise the ratioFatty-oils/fats productionOil and greaseOrganic solvent

The invention discloses an extracting process regulating grease ratio of colza oil, comprising: drying the water content of rapeseed to 5-15%, adding into an extruding bulking machine to extrude grease, and forming the rapeseed into grains; adding the grains into water, heating, adding composite enzyme, and stirring for reaction; heating to destroy the enzyme, filtering, and collecting filter slag; adding water into the filter slag for leaching, heating and stirring, then centrifuging to separate oil, sewage and solid sediment; combining obtained oil with the grease in step (1) to obtain grease. By controlling the water content of the rapeseed and extracting process parameters, the process improves the ratio of linoleic acid to linolenic acid in the grease obtained by extruding, and improves nutrient value of the grease. According to the extracting process, the rapeseed is not required to be peeled, no organic solvent is adopted in the whole process, the obtained grease is safe, and a process route is green and environment-friendly and high in grease yield.

Owner:刘家容

Method for synthesizing hydrofluoroether by gas phase method

ActiveCN112250551AReduce manufacturing costImprove stabilityEther preparation by compound additionPtru catalystOrganosolv

The invention discloses a method for synthesizing hydrofluoroether by a gas phase method, which comprises the following steps: putting a catalyst into a fixed bed reactor, heating to a specified temperature, introducing a mixed gas of methanol and fluorine-containing olefin in a molar ratio of 1-10: 1, controlling the reaction temperature to be 150-350 DEG C, the reaction pressure is normal pressure, the whole reaction process is monitored on line by GC-MS, and the product is cooled and rectified to obtain the corresponding hydrofluoroether product. According to the method for synthesizing theseries of hydrofluoroethers, a fixed bed reactor is adopted, use of strong base, organic solvents and the like is avoided, the method has good effect on reaction equipment, the cost is greatly reduced, and the method is simple in process, free of solvent pollution, mild in reaction condition, low in cost, good in product quality and very good in industrial application prospect.

Owner:浙江诺亚氟化工有限公司

A kind of preparation method of green environmental protection iron sucrose bulk medicine

InactiveCN103059072BHigh yieldQuality improvementSugar derivativesDisaccharidesSucroseSaccharophagus degradans

The invention relates to the technical field of a raw medicine preparation, and particularly relates to a preparation method of the raw medicine of environment-friendly iron sucrose. The weight-average molecular weight (Mw) of the raw medicine of the environment-friendly iron sucrose obtained by the technical scheme is 34000-60000, and the distribution coefficient (MW / Mn) is less than 1.7. The exceeding chloride Cl<-> in an iron sucrose solution is removed by selecting an anion exchange resin, and the content of Cl<-> in products is controlled at between 0.012% and 0.025%. The products are qualified by titratable alkali indexes after the products are processed by a cation exchange resin. The residual large particle impurities in the iron sucrose solution are filtered out by selecting a 0.8mu m filter membrane. The preparation method is simple and environment-friendly in technology route, high in product yield, good in quality, simple in production equipment, and easy to operate and the whole production process is easy to control, so the preparation method is suitable for scale production.

Owner:CHANGZHOU VOCATIONAL INST OF ENG +1

A kind of method of producing L-glufosinate-ammonium

ActiveCN106916857BHigh catalytic activityStereoselectiveFermentationGamma-Aminobutyric acidButyric acid

The invention discloses a production method of L-phosphinothricin. According to the method, 2-carbonyl-4-(hydroxymethylphosphonyl)butyric acid is used as a substrate and is catalyzed by an enzyme catalytic system to obtain L-phosphinothricin, and the enzyme catalytic system is composed of gamma-aminobutyric acid / alpha-ketoglutarate transaminase, glutamate dehydrogenase and a coenzyme regeneration system. The method utilizes the advantages of high catalytic activity, strong stereoselectivity and the like of transaminase, and also solves the problem of incomplete transaminase catalytic reaction, so that the catalytic reaction can completely convert the substrate 2-carbonyl-4-(hydroxymethylphosphonyl)butyric acid into L-phosphinothricin, and the conversion rate can reach 100%; no by-product alpha-ketoglutarate is accumulated in the final product of the method, and the residual amount of other substances such as the raw material glutamic acid in the product after the end of the reaction is extremely low, so the subsequent refining process of L-phosphinothricin is greatly simplified, and the total yield of the product is increased.

Owner:ZHEJIANG UNIV

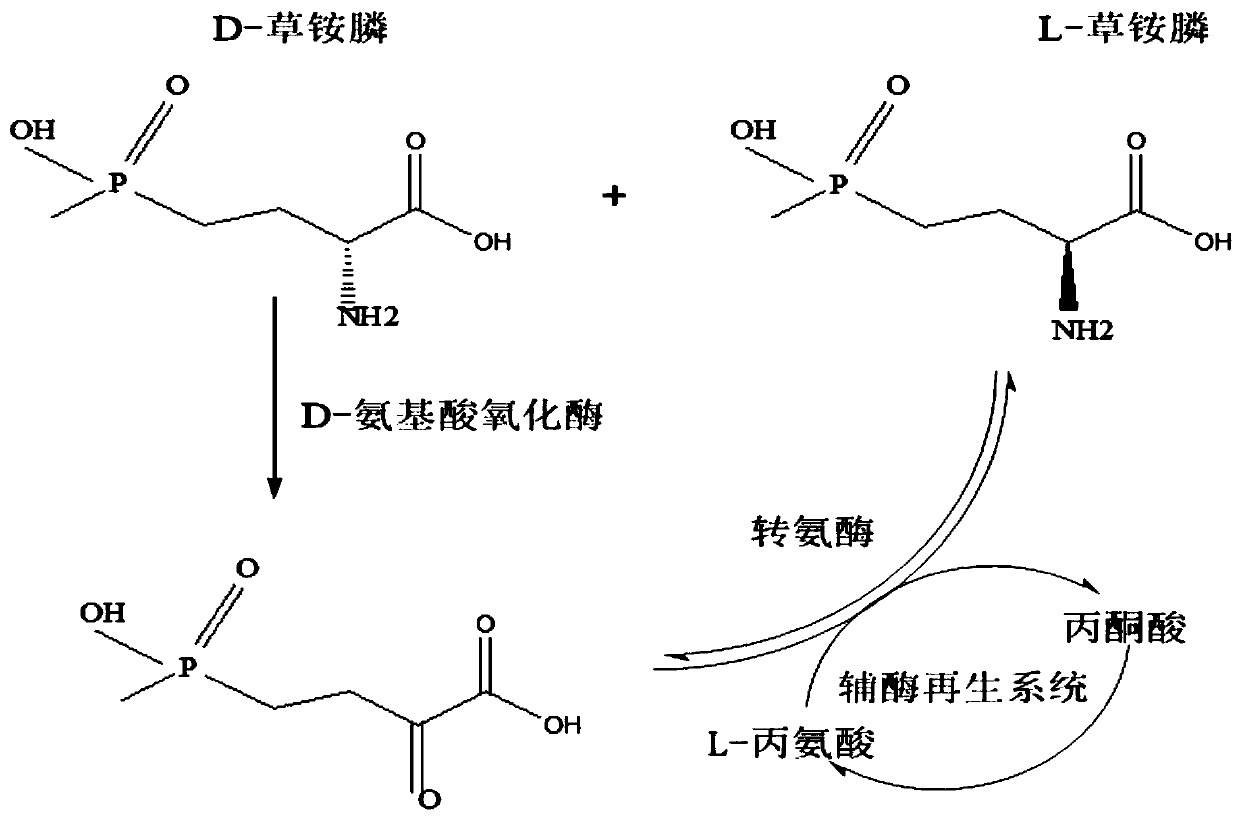

A kind of method for the preparation of l-glufosinate-ammonium by deracemization of biological enzymatic method

ActiveCN107502647BAchieve in situ deracemizationSimplify the disassembly processChemical recyclingFermentationAcyl groupOxidative enzyme

The invention discloses a method for preparing L-phosphinothricin through deracemization and by a biological enzyme method. According to the method, the L-phosphinothricin is obtained by taking D,L-phosphinothricin as a raw material and through catalysis by an enzyme catalysis system, and the enzyme catalysis system consists of D-amino acid oxidase, amino acid dehydrogenase and coenzyme regeneration systems. By the method, racemized D,L-phosphinothricin serves as the raw material, the D-phosphinothricin is oxidized into 2-carbonyl-4-(hydroxymethylphosphonyl)-butyric acid by the D-amino acid oxidase, and the L-phosphinothricin does not take part in the reaction and is completely retained; but the 2-carbonyl-4-(hydroxymethylphosphonyl)-butyric acid is catalytically reduced into the L-phosphinothricin by the amino acid dehydrogenase, so that in-situ deracemization of the D,L-phosphinothricin is realized, the obtained L-phosphinothricin does not contain other side products, the total yield of the products is more than or equal to 99 percent, and the optical purify can exceed 99 percent.

Owner:ZHEJIANG UNIV

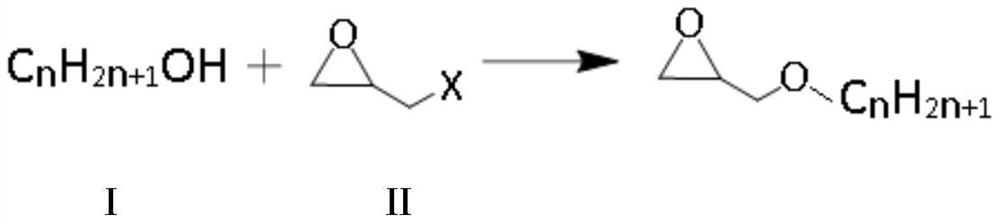

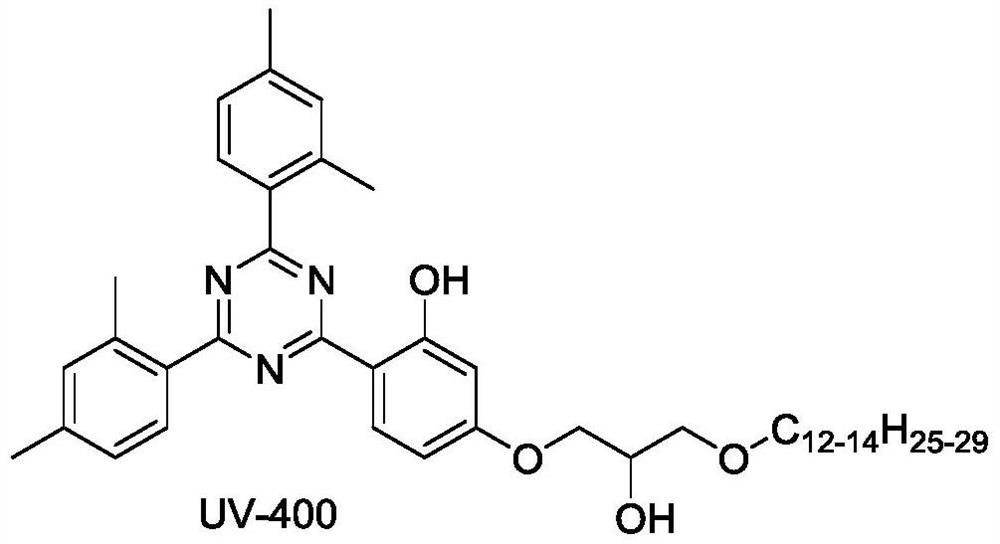

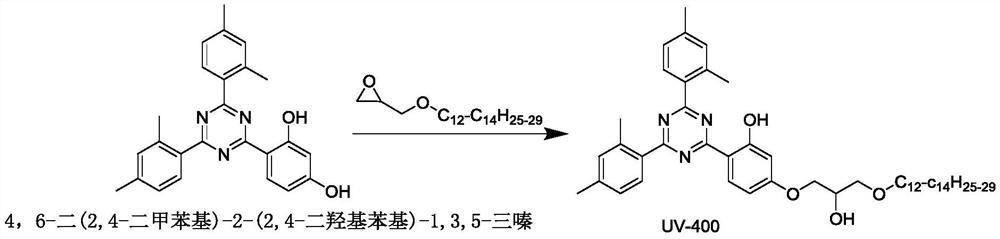

Preparation method of alkyl glycidyl ether

ActiveCN112250646AImprove securityImprove efficiencyOrganic chemistryChemical/physical/physico-chemical microreactorsPolymer scienceAlcohol

The invention provides a preparation method of alkyl glycidyl ether. The preparation method comprises the following steps: carrying out the following continuous flow substitution reaction on alkyl alcohol and epoxy halogenated propane in a micro-channel reactor to obtain alkyl glycidyl ether; wherein the alkyl alcohol comprises one or a mixture of more of compounds CnH<2n+1>OH shown as a formula I, and n in the formula I is 12-14; the epoxy halopropane has a structure shown as a formula II, and X in the formula II is a halogen atom. The invention solves the problems that in the prior art, whenalkyl glycidyl ether is prepared, reaction safety is poor, the number of byproducts is large, and the product yield and purity cannot be considered at the same time; the preparation method is simplein operation process, high in product purity, efficient, safe, environmentally friendly and suitable for industrial production.

Owner:RIANLON ZHONGWEI NEW MATERIAL CO LTD +1

A method for preparing 4-oxoisophorone by solid-liquid two-phase catalytic oxidation of β-isophorone

ActiveCN108440262BSimple processEasy to operateCarbonyl compound preparation by oxidationChemical recyclingIsophoronePtru catalyst

The invention discloses a method for preparing 4-oxoisophorone by solid-liquid two-phase catalytic oxidation of β-isophorone. The method adopts γ-alumina supported metal composite oxide (CuO-Co 2 o 3 ‑Fe 2 o 3 ‑MgO / Al 2 o 3 ) as a catalyst. The method comprises the following steps: β-isophorone is oxidized with hydrogen peroxide in the presence of a solvent and a catalyst to prepare 4-oxoisophorone. The method has mild reaction conditions, simple process, high product yield, environmental protection, no waste liquid containing heavy metal elements, and can effectively solve the problem of non-recyclable catalyst preparation in the prior art.

Owner:WANHUA CHEM GRP CO LTD

Method for circularly preparing iron oxyhydroxide from ferric trichloride

PendingCN113800570AHigh purityReduce manufacturing costIron oxides/hydroxidesFerric oxyhydroxidePhysical chemistry

The invention belongs to the technical field of environmental protection, and provides a method for circularly preparing iron oxyhydroxide from ferric trichloride, wherein the method comprises the steps: using a ferric trichloride solution as a raw material, carrying out replacement reaction on the ferric trichloride solution and an iron source in a reaction tank, and filtering to obtain a high-purity ferrous solution; sequentially carrying out oxygen oxidation, filtration separation and filtration on the ferrous solution to obtain an iron salt solution, and further washing filter residues to obtain a washing solution and iron oxyhydroxide; and respectively sending the ferric salt solution and the washing solution back to the reaction tank, continuously reacting, and circularly dissolving the iron source. The whole process does not consume ferric trichloride, ferric oxyhydroxide is obtained by circularly dissolving the iron source through ferric trichloride and oxidizing with oxygen, the process route is simple and environment-friendly, and remarkable economic and social benefits are achieved.

Owner:3R ENVIRONMENTAL TECH CO LTD +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com