Lithium ion battery silicon-based negative material and preparation method thereof

A silicon-based negative electrode material and lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of rapid volume change and capacity attenuation, and achieve the effect of simple and environmentally friendly process routes, good stability, and weakened volume effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

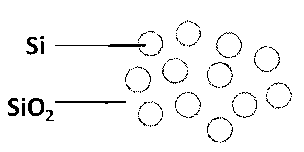

[0037] A silicon-based negative electrode material for a lithium-ion battery, characterized in that: the silicon-based negative electrode material for a lithium-ion battery is made of silicon monoxide, the macroscopic particle size is 10 μm, and the microscopic structure is nano-silicon particles coated with silicon dioxide , The internal silicon particle size is 20nm.

[0038] The above-mentioned negative electrode material has an initial discharge capacity of 2010mAh / g at a rate of 0.1C, and 420mAh / g after 50 cycles.

Embodiment 2

[0040] A silicon-based negative electrode material for a lithium-ion battery, characterized in that: the silicon-based negative electrode material for a lithium-ion battery is made of silicon monoxide, the macroscopic particle size is 25 μm, and the microscopic structure is nano-silicon particles coated with silicon dioxide , The internal silicon particle size is 30nm.

[0041] The above-mentioned negative electrode material has an initial discharge capacity of 2640mAh / g at a rate of 0.1C, and 790mAh / g after 50 cycles.

Embodiment 3

[0043]A silicon-based negative electrode material for lithium-ion batteries, characterized in that: the silicon-based negative electrode material for lithium-ion batteries is made of silicon monoxide, the macroscopic particle size is 18 μm, and the microscopic structure is nano-silicon particles coated with silicon dioxide , The internal silicon particle size is 25nm.

[0044] The above-mentioned negative electrode material has an initial discharge capacity of 2325mAh / g at a rate of 0.1C, and 605mAh / g after 50 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com