Zirconium silicate-modified mesoporous silicon oxide catalyst as well as preparation method and application thereof

A mesoporous silica and catalyst technology, which is applied in catalyst activation/preparation, physical/chemical process catalyst, carboxylate preparation, etc., can solve the problems of non-compliance with green environmental protection, waste acid waste water pollution, large catalyst consumption, etc. Less catalyst dosage, less by-products, and the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

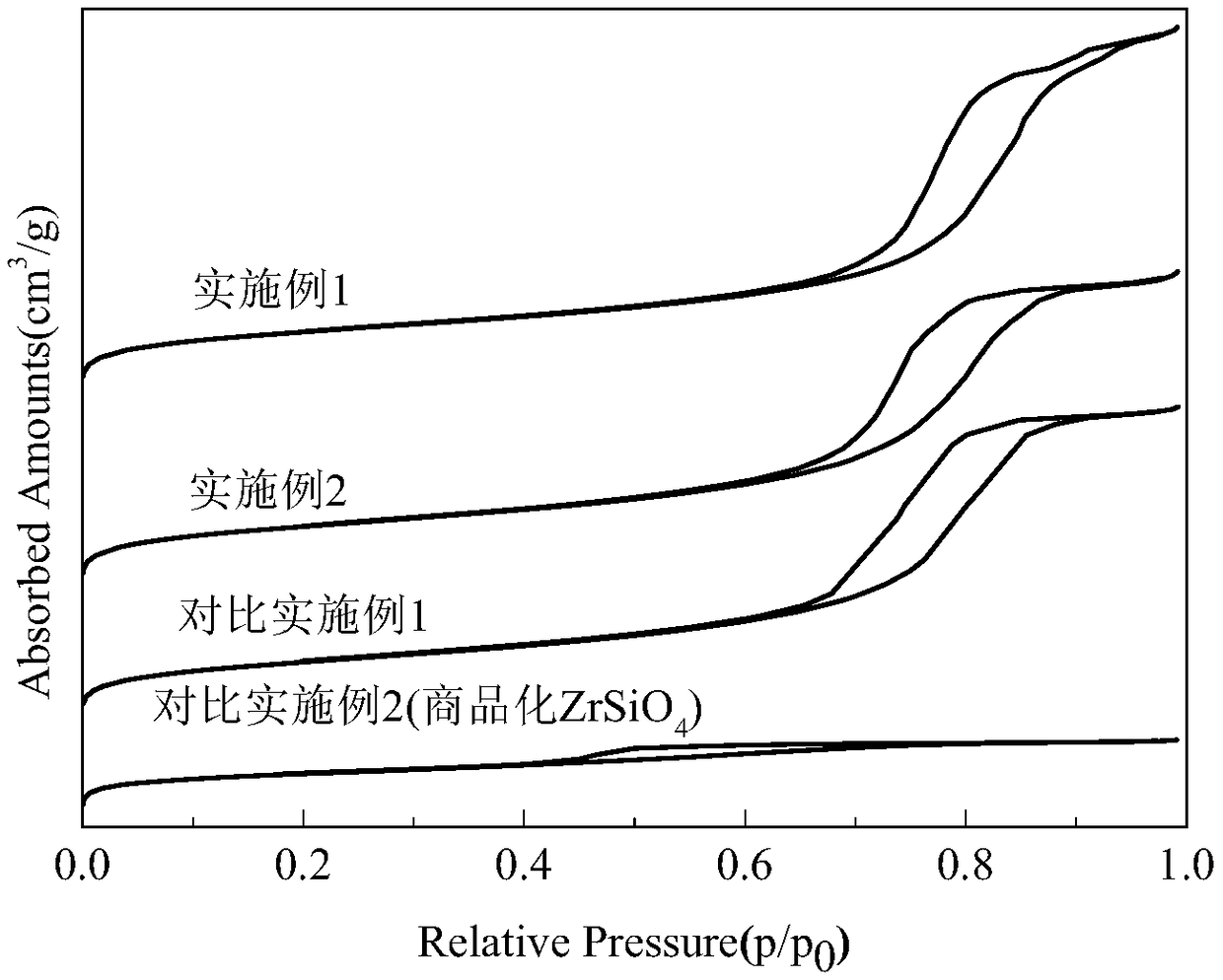

[0030] Add 4g of P123, 140mL of 0.4mol / L hydrochloric acid solution into the three-necked flask in turn, stir at 40°C to dissolve P123 completely, then add 4g of n-butanol, stir at 40°C for 1h, then add 2.60g of oxychloride octahydrate Zirconium ZrOCl 2 ·8H 2 O, 8.50g tetraethyl orthosilicate (TEOS), uniformly stirred at 40°C for 20h, put the mixed liquid into a stainless steel hydrothermal synthesis kettle with a polytetrafluoroethylene liner, at 130°C After crystallization for 1 day, cool down to room temperature, take out the crystallization solution, filter, put the filter cake after filtration in an oven to dry at 60°C, and place the dried item in a muffle furnace at 550°C for 6 hours. Prepared zirconium silicate modified mesoporous silica catalyst, denoted as 0.2ZrSiO 4 - MS-T130 (wherein MS refers to mesoporous silica, 0.2 refers to the molar ratio of Zr to Si, and T130 refers to a crystallization temperature of 130° C.). From the XRD pattern of the catalyst (see fi...

Embodiment 2

[0032] Add 4g of P123, 140mL of 0.8mol / L hydrochloric acid solution into the three-necked flask in turn, stir at 40°C to completely dissolve P123, then add 4g of n-butanol, stir at 40°C for 1h, then add 5.2g of octahydrate oxychloride Zirconium ZrOCl 2 ·8H 2 O, 8.50g tetraethyl orthosilicate (TEOS), uniformly stirred at 40°C for 20h, put the mixed liquid into a stainless steel hydrothermal synthesis kettle with a polytetrafluoroethylene liner, at 130°C After crystallization for 1 day, cool down to room temperature, take out the crystallization solution, filter, put the filter cake after filtration in an oven to dry at 60°C, and place the dried item in a muffle furnace at 550°C for 6 hours. Prepared zirconium silicate modified mesoporous silica catalyst, denoted as 0.4ZrSiO 4 - MS-T130 (wherein MS refers to mesoporous silica, 0.4 refers to the molar ratio of Zr to Si, and T130 refers to a crystallization temperature of 130° C.). From the XRD pattern of the catalyst (see fig...

Embodiment 3

[0034] Add 6.3g of F127 and 140mL of 0.9mol / L hydrochloric acid solution into the three-necked flask in turn, stir at 40°C to dissolve F127 completely, then add 6.18g of n-butanol, stir at 40°C for 1 hour, then add 4.7g of zirconium chloride ZrCl 2 , 14.20g of sodium silicate, stirred evenly at 40°C for 20h, put the mixed liquid into a stainless steel hydrothermal synthesis kettle with polytetrafluoroethylene lining, crystallized at 110°C for 1 day, cooled To room temperature, take out the crystallization solution, filter, put the filtered filter cake in an oven to dry at 60°C, place the dried article in a muffle furnace and roast at 550°C for 6h to prepare the catalyst 0.4ZrSiO 4 - MS-T110 (wherein MS refers to mesoporous silica, 0.4 refers to the molar ratio of Zr to Si, and T110 refers to a crystallization temperature of 110° C.).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com