Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "No pulverization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Raw materials combustion adjuvant

Disclosed is a slurry sintering agent which is prepared by using oxidizing agent as the main raw material, and one or more selected from mineralization agent, seed crystal, grinding aid or packing material as the compatible auxiliary raw materials. The sintering agent can reduce deacidized material in the clinker aggregate and improve the sintering quality of the clinker aggregate.

Owner:尹小林

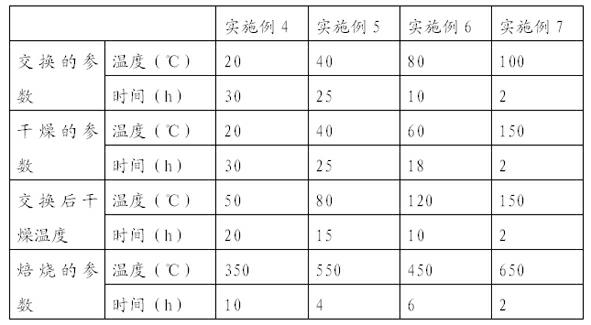

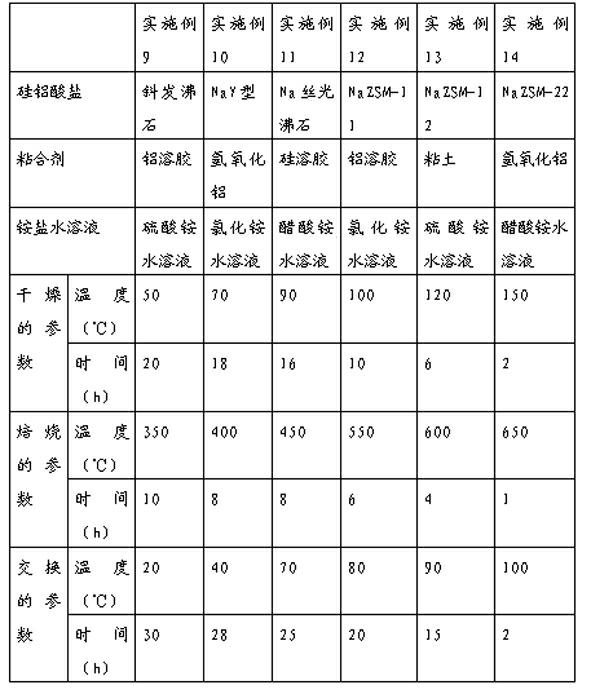

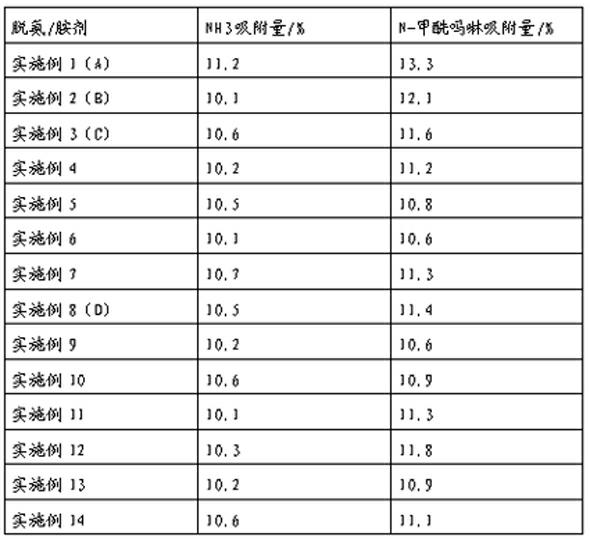

Deaminizing agent and preparation method thereof

InactiveCN101982232AIncreased ammonia capacityLow cleanlinessOther chemical processesAluminium silicatesAdhesiveIon exchange

The invention relates to a deaminizing agent and a preparation method thereof. The preparation method comprises the following steps: mixing and molding aluminosilicate and adhesive in the dry basis weight ratio of 90:10-70:30, and carrying out ion exchange with ammonium salt water solution to obtain the deaminizing agent. The deaminizing agent comprises the following raw materials in percentage by weight: 10-90% of SiO2, 5-10% of Al2O3 and 0.5-10% of MxO. The content of ammonia is greatly increased to higher than 10%, the degree of purification is lower than 0.3 ppm, the strength of adsorbentis very high, the phenomenon of efflorescence does not occur in the use process, and in addition, the adsorbent is reproducible and can be used for a long time.

Owner:YANTAI UNIV

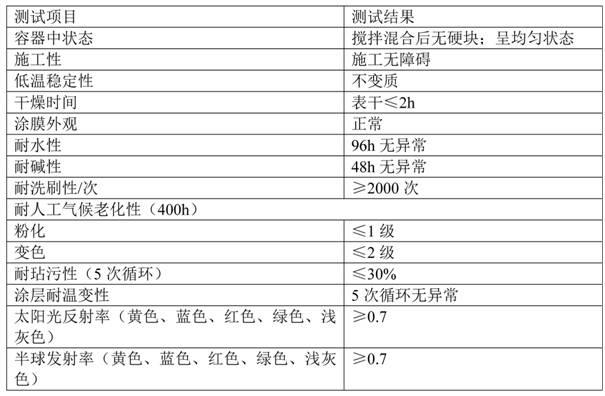

Colorful heat insulating and waterproof building paint

InactiveCN102675993AGood heat insulationReduce cooling energy consumptionNatural rubber coatingsGlass fiberSpray coating

The invention discloses colorful heat insulating and waterproof building paint, which comprises the components in parts by weight as follows: 20-30 parts of styrene-acrylic emulsion, 20-30 parts of natural rubber resin, 3-10 parts of paint dispersant, 10-15 parts of ethylene glycol, 0.5-1 parts of defoamer, 10-20 parts of pigment, 30-50 parts of low heat conductive coefficient filler, 4-8 parts of white carbon black and 10-15 parts of water. The colorful heat insulating and waterproof building paint is abundant in color, and can well meet the requirement of colorful outer wall paint of buildings with excellent heat insulating and waterproof effects which are same as those of white paint. The paint contains neither heavy metals nor formaldehyde and is relatively beneficial to health of human bodies. The paint is applicable for concrete pavements, asphalt pavements, plastic pavements, pavements of glass fiber reinforced plastics, and metal pavements, and is convenient to construct in ways of spray coating, brush coating and rolling coating.

Owner:开平市日固力涂料有限公司

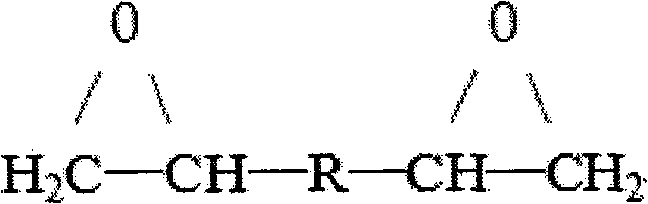

Fluoro olefin copolymerization fluororesin with fluoric lateral group or fluoric branched chain

The invention discloses a fluoro olefin copolymerization fluororesin with a fluoric lateral group or a fluoric branched chain, the resin is hexabasic copolymer which is formed by polymerizing fluoro olefin (trifluorochlor oethylene, tetrafluoroethylene), vinyl ether with a branched chain or a fluoric branched chain (lateral group) structure, alkyl vinyl ester, alkyl vinyl ether, hydroxyalkyl vinyl ether and olefine acid, the appearance of the fluoro olefin copolymerization fluororesin is colourless and faint yellow transparent liquid, the hydroxyl value (mgKOH / g) is 40-60, the acid value (mgKOH / g) is 6.5-13, dry resin fluorine content (%) is 35-45 percent, and the viscosity coefficient ((coating-4)25 DEG Cs) is 60-80. The fluoro olefin copolymerization fluororesin improves the solvent resistance of the fluorine coating, solves the technical problems of high-performance fluorine coating with good fluorine content and good dissolubility and constructability can not be synthesized originally and has the advantages of high fluorine content and low crystallinity.

Owner:UNIV OF JINAN

Iron-based catalyst prepared by sol-gel combustion method, and preparation method and applications of iron-based catalyst

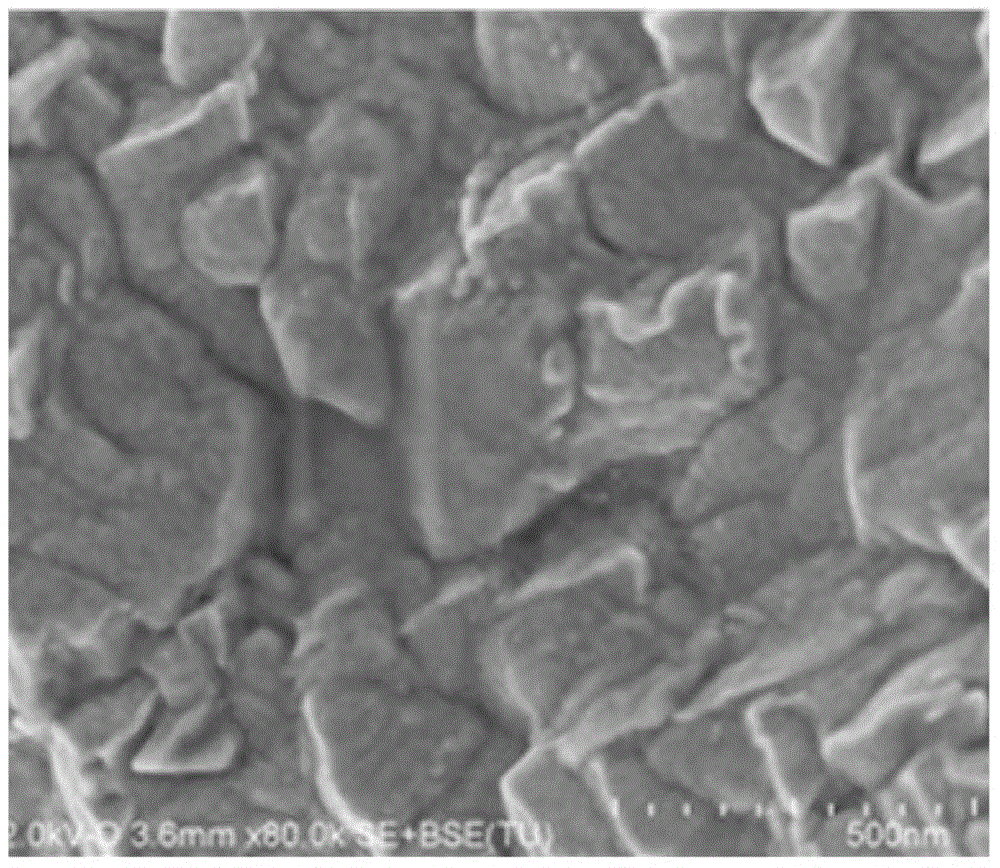

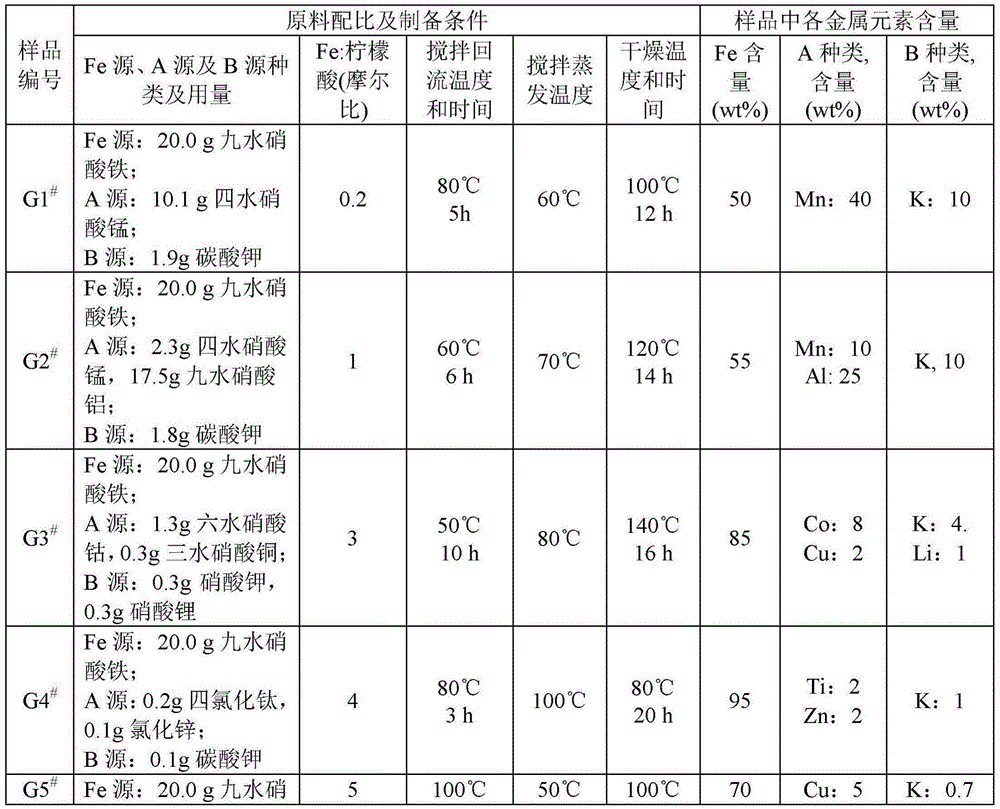

ActiveCN106311269AStrong ability to resist carbon depositionHigh selectivityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsCombustionMetal

The invention discloses an iron-based catalyst prepared by a sol-gel combustion method, which is characterized by containing a metal element Fe, a metal element A and a metal element B, wherein A is at least one selected from the group consisting of Mn, Co, Cu, Zn, Ti, Al, Cr, Ni, Ce, and Zr; B is at least one selected from the group consisting of Li, Na, K, Mg, and Ca; each metal element exists in the form of a metal simple substance and / or a metal oxide; and the content of the metal element A in the catalyst is 0.1-50 wt%, the content of the metal element B in the catalyst is 0.01-40 wt%, and the content of the metal element Fe in the catalyst is 50-99 wt%, based on the total amount of the metal elements contained in the catalyst. The catalyst has good resistance to carbon deposition, is used for reaction of preparation of low-carbon olefins by use of synthetic gas, and shows higher catalytic activity and low-carbon olefin selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

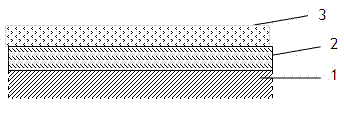

Coated type solar battery backboard

ActiveCN104505411AApparently uniformNo pulverizationFinal product manufacturePhotovoltaic energy generationWeather resistanceElectrical battery

The invention relates to a coated type solar battery backboard. At least one surface of a base material is coated with a first weather resisting layer, and the first weather resisting layer is coated with a second weather resisting layer. A coated type backboard produced according to the invention is excellent in performance and excellent in weather resistance; the coatings are uniform in appearance after double 85% damp-heat aging, free of pulverization and high in adhesive force.

Owner:乐凯胶片股份有限公司

Two-component polyurethane waterproof coating and preparation method thereof

InactiveCN110511662AAchieve solidificationNot easy to yellowPolyurea/polyurethane coatingsPolyolWeather resistance

The invention discloses a two-component polyurethane waterproof coating and a preparation method thereof. The raw materials of the two-component polyurethane waterproof coating comprise a component Aand a component B, the raw materials of the component A and the component B all comprise polyol, polyisocyanate, hydroxyl-terminated acrylate, an acrylate monomer mixture without hydroxyl, a filler and a thixotropic agent; according to the mass percentage content, the component A also comprises 0.1-1% of an accelerant, the mass ratio of hydroxyl-terminated acrylate to polyisocyanate is 0.6-0.95: 1, and the component B further comprises 0.1-1% of an initiator. The preparation method comprises the following steps: reacting the polyol with the polyisocyanate, then adding the hydroxyl-terminated acrylate and the acrylate monomer mixture without hydroxyl, adding the rest raw materials to prepare the component A, reacting the polyol with the polyisocyanate, then adding the hydroxyl-terminated acrylate and the acrylate monomer mixture without hydroxyl, adding the rest raw materials to prepare the component B, and then mixing the components A and B to obtain the product; the waterproof coatinghas the advantages of low cost, fast curing speed, good weather resistance, fast mechanical property rise and the like.

Owner:JIANGSU CANLON BUILDING MATERIALS

Colorful pavement brick and preparation method thereof

InactiveCN105220592ANo pulverizationSave resourcesSolid waste managementSingle unit pavingsCompressive resistanceBrick

The invention discloses a colorful pavement brick and a preparation method thereof. The colorful pavement brick is formed by compounding a base layer, a colorful surface layer and a covering layer, wherein the base layer of the colorful pavement brick is completely made of reclaimed building rubbish and RAP, so that waste materials are sufficiently utilized; the colorful surface layer is arranged on the base layer, so that a great quantity of resources are saved, and the preparation is simple. The colorful pavement brick is free from maintenance, is high in corrosion resistance and weather resistance, is economical and environmentally friendly, and beautifies the environment. The colorful pavement brick has the characteristics that the compressive strength is 15.8-16.7MPa, the wear resistant length is 7.6-8.4mm, and the freezing and thawing strength loss rate is 4.1-4.7%.

Owner:NANTONG ROAD & BRIDGE ENG CO LTD

A method of manufacturing self-cleaning polyurethane synthetic leather highly resistant to hydrolysis and highly resistant to ultraviolet light illumination aging

PendingCN105970663AReduce surface tensionLower free energyTextiles and paperGlycerolUltraviolet lights

A method of manufacturing self-cleaning polyurethane synthetic leather highly resistant to hydrolysis and highly resistant to ultraviolet light illumination aging is disclosed. The method includes steps of fluorine containing polyurethane modifying, transfer membrane preparing, adhering, and the like. The method includes modifying the polyurethane resin with fluorine containing polyether glycol, glycerol and polyisocyanate under functions of a catalyst to prepare the fluorine containing polyurethane, evenly coating the front surface of release paper with the fluorine containing polyurethane slurry, drying, evenly coating a surface film with fluorinated acrylate modified polyurethane prepolymer slurry comprising a solidification crosslinking agent as an adhesive layer, adhering to a woven fabric base, drying, cooling, sizing, stripping from the release paper to obtain a semi-finished product, and curing at room temperature to obtain a finished product. The product prepared by the method has excellent hydrolysis resistance and resistance to ultraviolet light illumination aging, and can be widely used for sofa furniture and shoe fabrics in high-temperature high-humidity using environments.

Owner:ANHUI ANLI MATERIAL TECH

Ferro-aluminum balls and preparation and application methods thereof

InactiveCN110387453AReduce energy consumptionSimple preparation processTurbinesOther manufacturing equipments/toolsAluminiumAdhesive

The invention discloses ferro-aluminum balls and preparation and application methods thereof. The ferro-aluminum balls are prepared from the following components in percent by mass: 40-45% of aluminumand the balance ferrum and inevitable impurities. The preparation method comprises the following steps: weighing metal aluminum powder and metal ferrum powder; uniformly stirring the powder by a stirrer; and pressing the powder into balls by using a high pressure ball press machine. The application method comprises the following steps: measuring components of molten steel in a later converter blowing stage and stopping smelting and tapping when the carbon content and the oxygen content reach process demands; and when 1 / 3 steel is tapped, determining the addition of the ferro-aluminum balls according to oxygen content in the molten steel and acid soluble aluminum of the molten steel and adding the ferro-aluminum balls into steel ladles through an overhead bunker. The ferro-aluminum balls have the advantages that (1) the product per ton is low in energy consumption and the preparation process is simple; (2) the content of impurities in the product is small, and no adhesives are added; (3) the product can be stored for a long time without a pulverizing phenomenon; (4) the product is moderate in density and is high in yield during use; and (5) the product is high in production efficiency and the balling rate can reach over 90%.

Owner:上海盛宝冶金科技有限公司

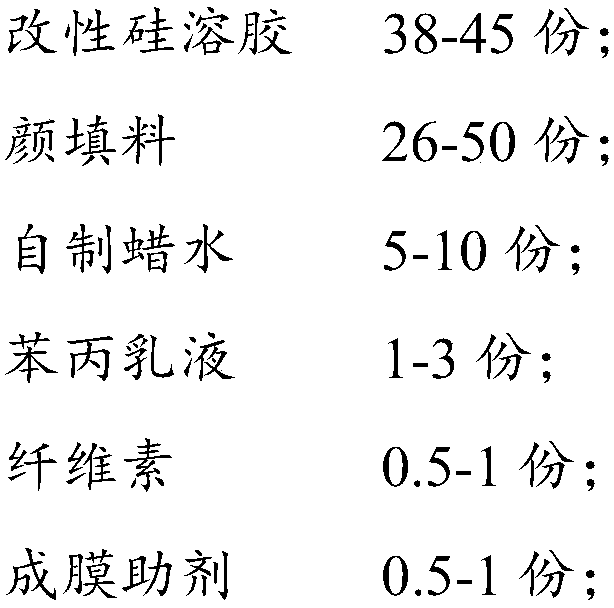

Inorganic composite modified interior wall flame-retardant and mildew-proof water paint and method for preparing same

PendingCN109439028AAvoid cracking of the paint filmGood acid and alkali resistanceFireproof paintsAntifouling/underwater paintsWaxEmulsion

The invention discloses inorganic composite modified interior wall flame-retardant and mildew-proof water paint and a method for preparing the same. The inorganic composite modified interior wall flame-retardant and mildew-proof water paint comprises, by weight, 38-45 parts of modified silica sol, 26-50 parts of pigment and fillers, 5-10 parts of self-made wax water, 1-3 parts of styrene-acrylic emulsion, 0.5-1 part of celluloses, 0.5-1 part of coalescing agents, 0.5-1 part of propylene alcohol, 0.3-1 part of dispersing agents, 0.5-1 part of defoaming agents, 0.2-0.8 part of thickeners, 0.3-0.6 part of multifunctional auxiliaries and 16-27 parts of water. The inorganic composite modified interior wall flame-retardant and mildew-proof water paint and the method have the advantages that theinorganic composite modified interior wall flame-retardant and mildew-proof water paint prepared by the aid of the method is good in acid and alkali resistance and water resistance and excellent in flame retardance and antibacterial and mildew-proof property; the inorganic composite modified interior wall flame-retardant and mildew-proof water paint does not contain formaldehyde or other organic solvents, is low in odor and is environmentally friendly and safe, heavy metal is omitted, and the VOC (volatile organic compound) content is close to zero.

Owner:丁贤勇

Inorganic slurry for thermosetting compound polystyrene board and preparation method thereof

The invention provides inorganic slurry for a thermosetting compound polystyrene board. The inorganic slurry is prepared from the following components in parts by weight: 80-100 parts of silicate cement, 0.1-10 part of enhancer, 0-10 parts of a suspending agent, 0-3 parts of a thickening agent, 0-5 parts of interface adhesive, 0-3 parts of water reducer, 0-1 part of surfactant, 0-2 part of retarder and 50-70 parts of water, wherein the enhancer is prepared from one or more of high-alumina cement, calcium sulphoaluminate and calcium formate. The invention further provides a preparation method of the inorganic slurry. The board produced from the inorganic slurry has a heat conductivity coefficient controlled to be 0.050 or less, is A-class non-combustible, has high strength and good integration with a substrate wall, does not have potential safety hazard, is relatively low in cost, and is easy to popularize and apply.

Owner:宁夏保利节能科技有限公司

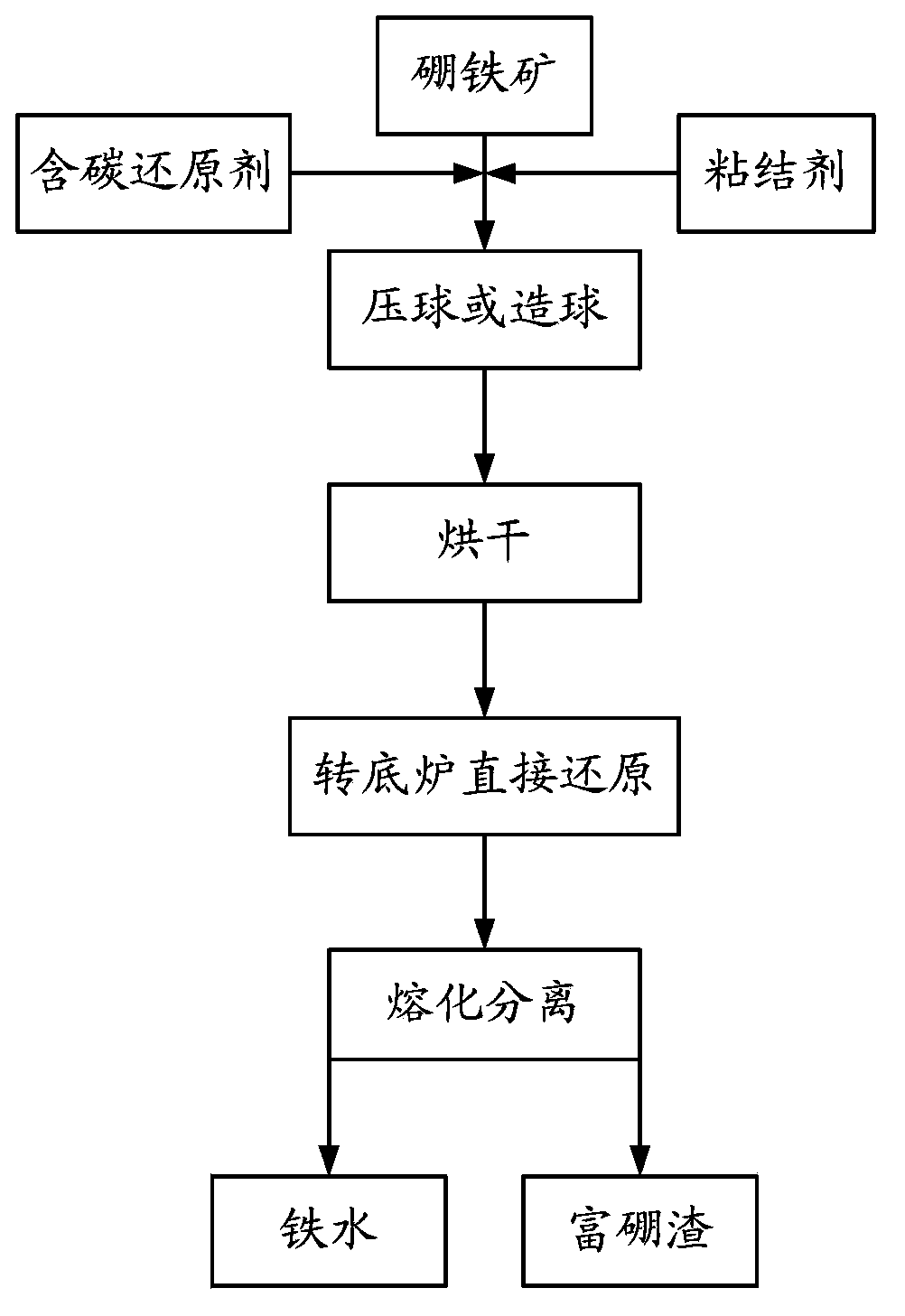

Method for performing boron and iron separation on paigeite

The invention discloses a method for performing boron and iron separation on paigeite, and the method comprises the following steps: pelletizing paigeite, a reducing agent and binders into pellets so as to obtain paigeite pellets; reducing and roasting the paigeite pellets in a rotary hearth furnace so as to obtain reduzate; melting and separating the reduzate so as to obtain molten iron and boron-rich slag containing boron trioxide. The boron and iron separation can be effectively performed on the paigeite by utilizing the method. Compared with the prior art, the method has the advantages of low requirements for rotary hearth furnace temperature and furnace bottom, high iron and boron recovery rates, high paigeite utilization ratio, less erosion to equipment, and can be used for obtaining reduced iron with good strength.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

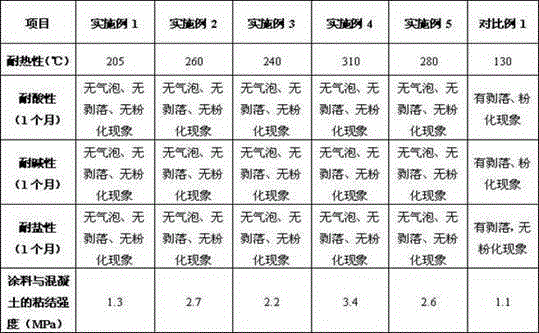

High-temperature-resistant and corrosion-resistant waterproof paint and preparation method thereof

InactiveCN105111883AImprove acid resistanceGood alkali resistanceAnti-corrosive paintsDicarbonateMaterials science

The invention discloses high-temperature-resistant and corrosion-resistant waterproof paint. The waterproof paint is prepared from, by weight, 40-65 parts of phenolic resin, 32-46 parts of methyl acrylate emulsion, 23-40 parts of methyl acrylate emulsion, 5-15 parts of n-Octyltrimethoxysilane, 6-18 parts of glycerin, 4-11 parts of calcium sulfate, 3-14 parts of aluminum chloride, 5-10 parts of aluminum oxide, 8-17 parts of talcum powder, 2-8 parts of sodium molybdate, 5-16 parts of short glass fibers, 2-10 parts of polyoxyethylene alcohol ether, 3-7 parts of isophorone diamine, 1-6 parts of diallyl 2,2'-oxydiethyl dicarbonate and 15-30 parts of deionized water. The invention further discloses a preparation method of the high-temperature-resistant and corrosion-resistant waterproof paint. The acid resistance, alkali resistance and salt corrosion resistance of the prepared waterproof paint are good, and the heat-resistance temperature ranges from 205 DEG C to 310 DEG C. The prepared waterproof paint has excellent high temperature resistance and corrosion resistance, and the application range of the waterproof paint can be expanded.

Owner:SUZHOU FAST INFORMATION TECH CO LTD

Auxiliary preparation process of spinnable and weavable long continuous zirconia fiber

InactiveCN104357954AGood flexibilityNo pulverizationInorganic material artificial filamentsWet spinning methodsAcetic acidFiber

The invention discloses an auxiliary preparation process of spinnable and weavable long continuous zirconia fiber. The auxiliary preparation process is characterized in that zirconia nanopowder is mixed with Y2O3 nanopowder, MgO nanopowder and Al2O3 nanopowder to obtain composite zirconia nanopowder, starch and water are added into the composite zirconia nanopowder, a glucosaminoglycan-polyvinyl alcohol-acetic acid mixed solution is added after the mixture is stirred, slurry is obtained, pressurized, heated and sprayed to form filaments by a spiral nozzle, and the filaments are wound after macromolecule polymerization, liquid bath and air cooling to obtain the long continuous zirconia fiber. The auxiliary preparation process is simple, doesn't contain complicated chemical technologies in the preparation process, and is lower in cost and high in product yield.

Owner:NANHUA UNIV

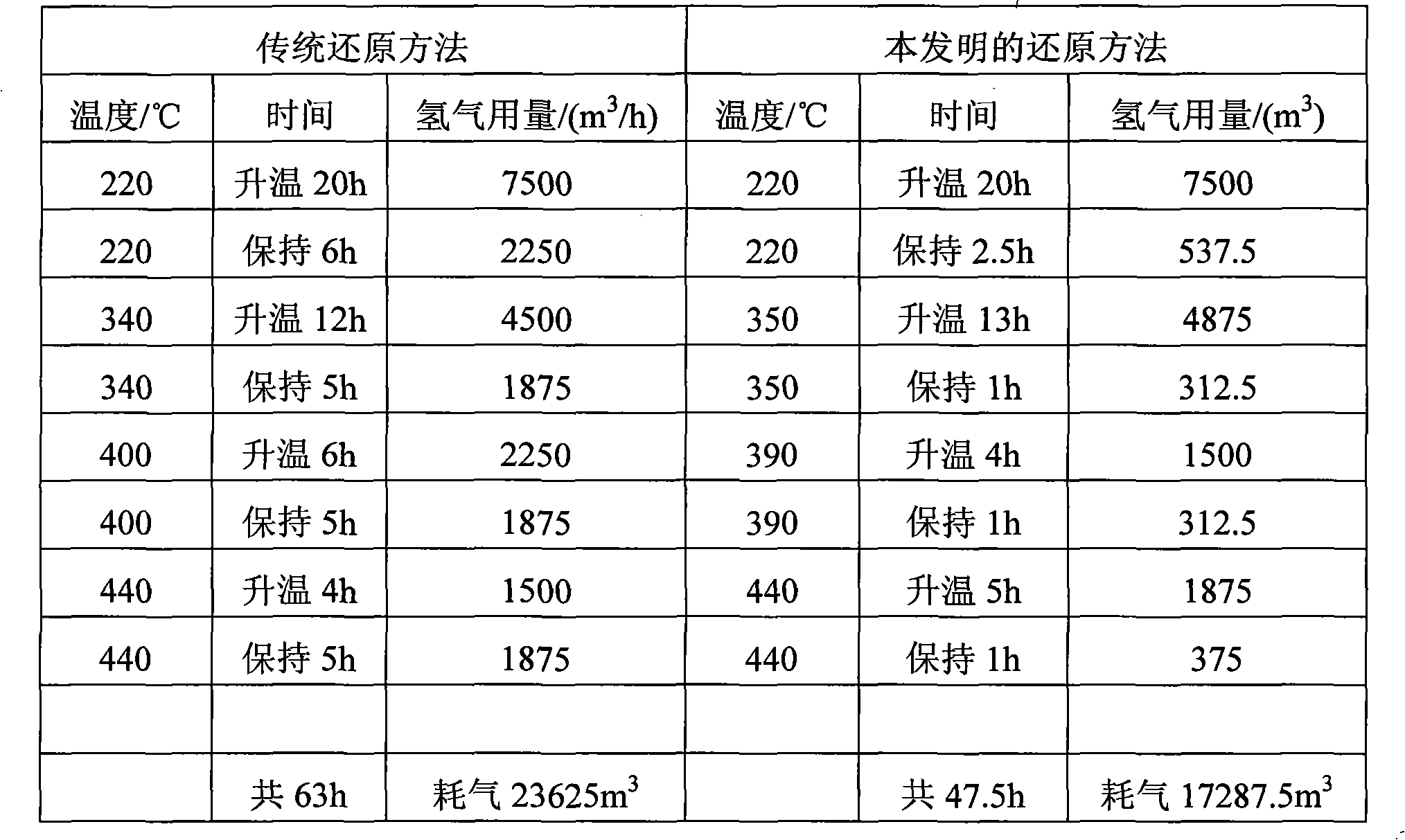

High-speed temperature programmed reduction method for catalyst

ActiveCN102335635ANo pulverizationShorten the timeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrogen concentrationSpace velocity

The invention relates to a high-speed temperature programmed reduction method for a catalyst. In order to solve the universal problems of long catalyst reduction time and great hydrogen consumption in present catalyst reduction equipment, the inventor puts forward the method of: during a catalyst reduction process, conducting on-line analysis for hydrogen concentrations in the inlet gas and outlet gas of a reduction furnace, and under a constant catalyst reduction space velocity, analyzing the difference of hydrogen concentrations at the inlet and outlet by a reduction control program, and adjusting the reduction temperature in the reduction furnace as well as the hydrogen concentration in the reduction gas. The method of the invention can guarantee the reduction of overall catalyst reduction time and the saving of hydrogen consumption based on fully reducing the catalyst, so that the overall processing period of the catalyst is substantially shortened and the catalyst production costis reduced, thus boasting extensive practical application value.

Owner:CHINA PETROLEUM & CHEM CORP +1

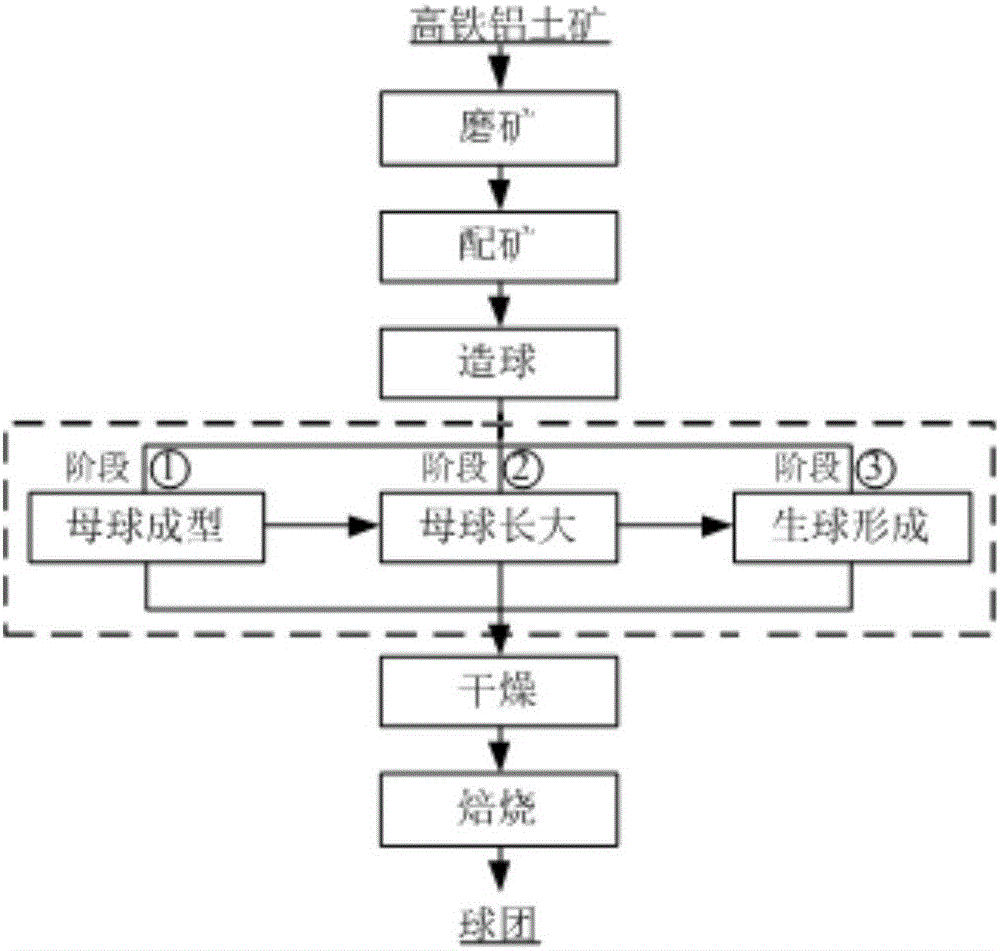

Method for preparing high-iron bauxite pellets

The invention relates to a method for preparing high-iron bauxite pellets. The method comprises the steps that bauxite is grinded, specifically, the high-iron bauxite is grinded to obtain bauxite powder; blending is carried out, specifically, 3-5 wt% of calcium hydroxide powder and 4.5-5.5 wt% of sodium hydroxide powder are added to the bauxite powder, and a mixed material is obtained; pelleting is carried out, specifically, the mixed material is added to a disc pelletizer, water is added to the mixed material, fresh pellets can be obtained through pelleting, the pelleting process sequentially comprises the three stages of formation of master pellets, growth of the master pellets and formation of the fresh pellets, and the inclination angle alpha of a disc of the disc pelletizer is 44-46 degrees, 48-52 degrees and 56-60 degrees in the stage of formation of the master pellets, the stage of growth of the master pellets and the stage of formation of the fresh pellets correspondingly; drying is carried out, specifically, the dried fresh pellets are obtained after drying; and calcination is carried out, specifically, the pellets are obtained by calcinating the dried fresh pellets. According to the method, the pelleting process is carried out by stages, the obtained fresh pellets are smooth in surface and compact inside, pulverization is avoided, and the high-iron bauxite pellets have high compressive strength and can be applied industrially on a large scale.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Test sample of gunning material containing calcium oxide and preparation method thereof

ActiveCN108007752ASolve the problem that the test specimen cannot be preparedStrong release strengthPreparing sample for investigationChemical compositionFreeze-drying

The invention relates to a test sample of a gunning material containing calcium oxide and a preparation method thereof. According to the technical scheme, the gunning material containing calcium oxideis stirred for 1-3 min, water accounting for 8-18wt% of the weight of the gunning material containing calcium oxide is added, mixing is conducted for 3-5 min, the mixture is placed in a mould, and vibration forming is conducted; maintenance is conducted under normal temperature conditions for 5-15 h, and demoulding is conducted; then the mixture is placed in a vacuum freeze-drying box, freeze drying is conducted till the mixture has a constant weight, and the test sample of the gunning material containing calcium oxide is obtained. The gunning material containing calcium oxide is mainly prepared from 60-93% of MgO, 1-33% of CaO, 5.5-6.5% of SiO2 and less than 0.5% of Na2O; the main material phases of the gunning material containing calcium oxide are periclase and free calcium oxide. The prepared test sample of the gunning material containing calcium oxide has no chalking phenomenon in the forming and freeze-drying stages, the demolding strength is high, and various physical propertiesof the gunning material containing calcium oxide can be detected.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method for producing ferroaluminium through flushed mixing of molten steel and aluminum ingot

The invention relates to a preparation method of ferroaluminium. A preparation method for producing the ferroaluminium through flushed mixing of molten steel and an aluminum ingot comprises the following steps that steel scrap containing 35%-70% of aluminum and the balance iron is prepared; glowstone is firstly added into the bottom of an intermediate frequency furnace, 2 / 3 of the total amount of the steel scrap is added, and temperature measurement is carried out after complete fusion; when the furnace temperature reaches 1550 DEG C to 1650 DEG C, power is off, and a slag collector is added for slag fishing; after surface slag is completely fished out, the remaining steel scrap is added to be heated, temperature measurement is carried out after complete fusion, the power is off after the furnace temperature reaches 1650 DEG C to 1680 DEG C, a slag collector is added for completely fishing out the surface slag, and then furnace discharging is carried out; the aluminum ingot is baked in a ladle brick to 600 DEG C; the aluminum ingot is carried to an opening of the aluminum ingot is, and the furnace discharging position is connected with the molten steel for molten steel; stirring is carried out after flushed mixing of the molten steel and the aluminum ingot so as to enable the aluminum ingot to be completely fused; two times of ladle-to-ladle operation is carried out, a slag selecting agent is thrown to the alloy liquid level, surface stirring is carried out, and the surface slag is fished completely; a casting ladle is hoisted to an automatic turnover casting platform for automatic casting, and preparation of the ferroaluminium is completed. The preparation method is simple in process, easy to implement and low in production cost.

Owner:江苏江南铁合金有限公司

Modified hydroxypropyl methyl cellulose ether dry powder material

The invention relates to a modified hydroxypropyl methyl cellulose ether dry powder material, which comprises, by weight, 870-940 parts of hydroxypropyl methyl cellulose ether, 38-70 parts of polyvinyl alcohol, 10-23 parts of polyacrylamide, 10-20 parts of white carbon black, 5-18 parts of a polycarboxylic acid water reducing agent and 5-15 parts of hydroxypropyl starch ether. Compared with the traditional hydroxypropyl methyl cellulose ether, the exterior wall external thermal insulation plastering mortar prepared from the modified hydroxypropyl methyl cellulose ether dry material of the invention has the advantages of high water retention rate, high early strength, no powdering phenomenon and no cracking.

Owner:南京钧正新材料有限公司

Film coating material as well as preparation method and application thereof

InactiveCN110713382AReduce chalkingHigh hardnessVacuum evaporation coatingSputtering coatingFilm-coated tabletFilm coating

The invention provides a film coating material as well as a preparation method and application thereof, and belongs to the technical field of film coating materials. The preparation method of the filmcoating material provided by the invention comprises the following steps: mixing trititanium pentoxide, aluminum oxide and a binder, and sequentially carrying out pressing, crushing, tabletting molding and vacuum sintering to obtain the film coating material. The film coating material prepared by the preparation method provided by the invention has the advantages of no pulverization phenomenon, ahigh and stable refractive index and a high coating material yield, and the preparation method is simple to operate and suitable for industrial production.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

Beta-dicalcium silicate and preparation method thereof

InactiveCN105712362ALow costHigh purityAlkaline-earth metal silicatesAir atmosphereCalcium bicarbonate

The invention relates to beta-dicalcium silicate and a preparation method thereof. The technical scheme comprises the following steps: mixing a calcium source, a silicon source and a barium source in a molar ratio of 1:(0.2-1):(0.02-0.05) to obtain a mixture; adding 80-120wt% of distilled water into the mixture and mixing uniformly; drying for 12-24 hours at 70-110 DEG C; performing fine grinding and mechanical pressing; preserving heat for 2-5 hours in an air atmosphere at 1,200-1,600 DEG C; and cooling along with the furnace to obtain beta-dicalcium silicate. In the technical scheme, the calcium source is one of calcium oxide, calcium hydroxide, calcium carbonate and calcium bicarbonate; the silicon source is silicon dioxide or metasilicic acid; and the barium source is one of barium carbonate, barium hydroxide and barium sulfate. The beta-dicalcium silicate has the characteristics of simple technology, low cost and easiness in operation; the prepared beta-dicalcium silicate has the advantages of no pulverization, high purity and few impurity phases; and a foundation is laid for widening the application of beta-dicalcium silicate in the field of silicate materials.

Owner:WUHAN UNIV OF SCI & TECH

Aluminum-manganese alloy deoxidizing agent and steelmaking deoxidizing method thereof

The invention discloses an aluminum-manganese alloy deoxidizing agent and a steelmaking deoxidizing method thereof. The aluminum-manganese alloy deoxidizing agent is characterized by comprising, by mass, 40-50% of aluminum, 30-40% of manganese, not more than 3% of inevitable impurity content, and the balance iron. The specific gravity range of the aluminum-manganese alloy deoxidizing agent is 3.0-4.5 g / cm<3>; and the aluminum-manganese alloy deoxidizing agent is in a shape of an ellipsoid, and the particle size range is 10-50 mm. The aluminum-manganese alloy deoxidizing agent has the advantages that (1) the ton product energy consumption is low, and a preparation process is simple; (2) the impurity content in products is small, and no adhering agents are added; (3) the products can be stored for a long time, and the pesting phenomenon is avoided; and (4) the products are large in specific gravity, oxygen in molten steel and top slag can be fast and efficiently removed, and meanwhile part alloying is performed on the molten steel; and compared with traditional deoxidizing agents such as titanium aluminum, silicon aluminum barium and aluminum iron, the deoxidizing capacity is high, and the purposes of purifying the molten steel and improving the molten steel quality can be achieved.

Owner:上海盛宝冶金科技有限公司

Ecological face brick construction process for old wall surface renovation

PendingCN114352056AShort production periodLow output durationCovering/liningsBuilding repairsEnvironmental resource managementBrick

The invention discloses an old wall surface renovating ecological face brick construction process which comprises the steps of construction starting pretreatment, base layer treatment, marking brick pasting, ecological face brick inlaying and pasting, seam wiping and cleaning, an old base surface does not need to be knocked off, construction is convenient, no garbage is produced, the construction period is short, cost is low, and ecological soft magnetic face bricks are light, thin, space-saving, cement-saving, anti-pollution and self-cleaning. The fireproof, anti-seismic, anti-cracking, good in texture, good in ductility, resistant to freezing and thawing, durable, resistant to acid and alkali, high in weather resistance, breathable, fireproof, ecological, safe, environment-friendly, healthy in living, capable of being completely regenerated and free of three-waste discharge.

Owner:SHANGHAI CONSTRUCTION GROUP

Aluminum manganese alloy deoxidizer for steelmaking, and steelmaking deoxidization method thereof

The invention discloses an aluminum manganese alloy deoxidizer for steelmaking, and a steelmaking deoxidization method thereof. The aluminum manganese alloy deoxidizer is characterized by comprising the following components: 60%-70% of aluminum, 15%-25% of manganese, no more than 3% of inevitable impurities and the balance iron; the specific gravity range of the aluminum manganese alloy deoxidizeris 3.0-4.5 g / cm<3>; and the aluminum manganese alloy deoxidizer is ellipsoidal, and the particle size range is 10-50 mm. The aluminum manganese alloy deoxidizer has the advantages that (1), the energy consumption per ton of products is low, and the preparation process is simple; (2), the content of the impurities in the products is low, and no binder is added; (3), the products can be stored fora long time, and no pulverization phenomenon occurs; (4), the specific gravity of the products is large, oxygen in molten steel and top slag can be removed quickly and efficiently; meanwhile, the molten steel is subjected to alloying partially; and compared with traditional titanium aluminum, silicon aluminum barium and ferro-aluminium deoxidizers, the aluminum manganese alloy deoxidizer has the beneficial effects that the deoxidizing capacity is high, and the purposes of purifying the molten steel and improving the molten steel quality can be achieved.

Owner:上海盛宝冶金科技有限公司

Fluoro olefin copolymerization fluororesin with fluoric lateral group or fluoric branched chain

InactiveCN101747464BGood chemical resistanceGood molecular flexibilityCoatingsVinyl etherPolymer science

The invention discloses a fluoro olefin copolymerization fluororesin with a fluoric lateral group or a fluoric branched chain, the resin is hexabasic copolymer which is formed by polymerizing fluoro olefin (trifluorochlor oethylene, tetrafluoroethylene), vinyl ether with a branched chain or a fluoric branched chain (lateral group) structure, alkyl vinyl ester, alkyl vinyl ether, hydroxyalkyl vinyl ether and olefine acid, the appearance of the fluoro olefin copolymerization fluororesin is colourless and faint yellow transparent liquid, the hydroxyl value (mgKOH / g) is 40-60, the acid value (mgKOH / g) is 6.5-13, dry resin fluorine content (%) is 35-45 percent, and the viscosity coefficient ((coating-4)25 DEG Cs) is 60-80. The fluoro olefin copolymerization fluororesin improves the solvent resistance of the fluorine coating, solves the technical problems of high-performance fluorine coating with good fluorine content and good dissolubility and constructability can not be synthesized originally and has the advantages of high fluorine content and low crystallinity.

Owner:UNIV OF JINAN

Epoxy-modified organic silicone resin for manufacturing composite glue, and processing technology thereof

The invention provides a processing technology of an epoxy-modified organic silicone resin. The technology comprises the steps of: heating epoxy resin A in a reactor to a temperature of 50 to 95 DEG C while stirring; dropping organic silicone resin B into the reactor, and adding a catalyst to the reactor; heating the mixture to a temperature of 110 to 135 DEG C, and allowing the mixture to react for 6 to 12 hours with the temperature maintained. The invention also provides an epoxy-modified organic silicone resin used for manufacturing composite glue manufactured with the method. According to the invention, with molecule designing and clipping methods, a type of multi-functional resin is synthesized. High strength and corrosion resistance of epoxy resin and weatherability of organic silicone resin are combined in the multi-functional resin. Modified composite glue manufactured from the modified organic silicone resin is greatly improved in flexibility and weatherability. Products employing the composite glue are greatly improved in weatherability, shock resistance and impact-resistance.

Owner:江苏力宝建材工业有限公司

Preparation method of composite film layer on surface of rare earth magnesium alloy structural part

ActiveCN112251790AMeet assembly dimensional tolerance requirementsReduce electrophoresis voltageAnodisationElectrophoretic coatingsElectrolytic agentMicro arc oxidation

The invention discloses a preparation method of a composite film layer on the surface of a rare earth magnesium alloy structural part. The preparation method sequentially comprises the steps of oil removal, primary water washing, micro-arc oxidation, secondary water washing, electrophoresis, tertiary water washing and drying and curing. A micro-arc oxidation electrolyte is an aqueous solution containing sodium silicate, sodium fluoride, sodium hydroxide, graphene, Cu(NO3)2 and triethanolamine, electrical parameters of micro-arc oxidation are as follows: the positive current density is 5-15A / dm<2>, the negative current density is 2-3A / dm<2>, the positive duty ratio is 25-70%, the negative duty ratio is 40-50%, the positive frequency is 200-800Hz, the negative frequency is 300-500Hz, the positive and negative stages are both one stage, the micro-arc oxidation time is 10-20 min, electrophoresis liquid for electrophoresis is an aqueous solution containing acrylate, a delustering agent andcarbon black pigment, and electrical parameters of electrophoresis are as follows: the voltage is 50-80V, and the time is 10-30s; and through the coordination effect of micro-arc oxidation and electrophoresis, the composite film layer meeting the requirements of high hardness, high bonding strength and ultraviolet aging resistance at the same time can be prepared.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

fbt-x series rare earth composite thermal insulation material and preparation method thereof

ActiveCN111592291BGood heat insulationGood heat insulation performance at high temperatureFiberThermal insulation

The invention discloses a novel FBT‑X series rare earth composite thermal insulation material and a preparation method thereof. Composite processing. The production process of this material utilizes the principles of physical and chemical effects such as material surface treatment, mechanochemical modification, and encapsulation modification, so that a large number of closed vacuum-like micropores are generated inside the product, which increases the porosity and specific surface area. The thermal insulation material presents a layered net-like stacked force unit and a filling structure, which endows the material with excellent thermal insulation performance and long service life. This material has a wide range of applications, and can be used for the insulation of various equipment and pipelines from -40°C to 800°C, especially for the insulation of special-shaped objects. The construction of this material is simple and easy, and it is convenient for inspection and maintenance. There is no asbestos in the material, no dust during construction, and the remaining materials can be recycled. It is a green and environmentally friendly product.

Owner:青岛启明环保节能技术有限公司

Eucalyptus wood board processing technique

InactiveCN106625949AImprove toughnessNo pulverizationWood treatment detailsWood heatingWood plankEnergy consumption

The invention discloses a eucalyptus wood board processing technique. The eucalyptus wood board processing technique comprises the steps that (1) eucalyptus wood boards are kept drying for 30-40 s at the temperature of 75-85 DEG C and under the pressure of 0.25-0.30 MPa, wherein a layer of quartz sand with the thickness being 0.05-0.1 mm is laid on a bottom layer where eucalyptus wood is placed firstly and used as a quartz sand layer, the eucalyptus wood boards are laid on the quartz sand layer, gauze is placed on the eucalyptus wood boards, and sawdust gauze with the thickness being 0.2-0.5 mm and sawdust are placed on the gauze, so that the eucalyptus wood boards are separated; and (2) dewatering is conducted, the total drying time in the whole dewatering process is 125 min, and the drying temperature is 55-65 DEG C. The eucalyptus wood boards obtained through the processing technique are free of cracks, good in tenacity and free of pulverization; the quartz sand and the sawdust are placed in the eucalyptus wood board drying process so that the drying water loss rate can be effectively increased, and the dried eucalyptus wood boards are better in quality and tenacity; and furthermore, the eucalyptus wood board processing technique is low in time consumption, energy consumption and cost.

Owner:天峨县全盛蜂业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com