Method for performing boron and iron separation on paigeite

A boron iron ore and boron iron technology, applied in the fields of metallurgy and boron iron ore processing, to achieve the effect of improving utilization rate, improving efficiency, performance and reducing operation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

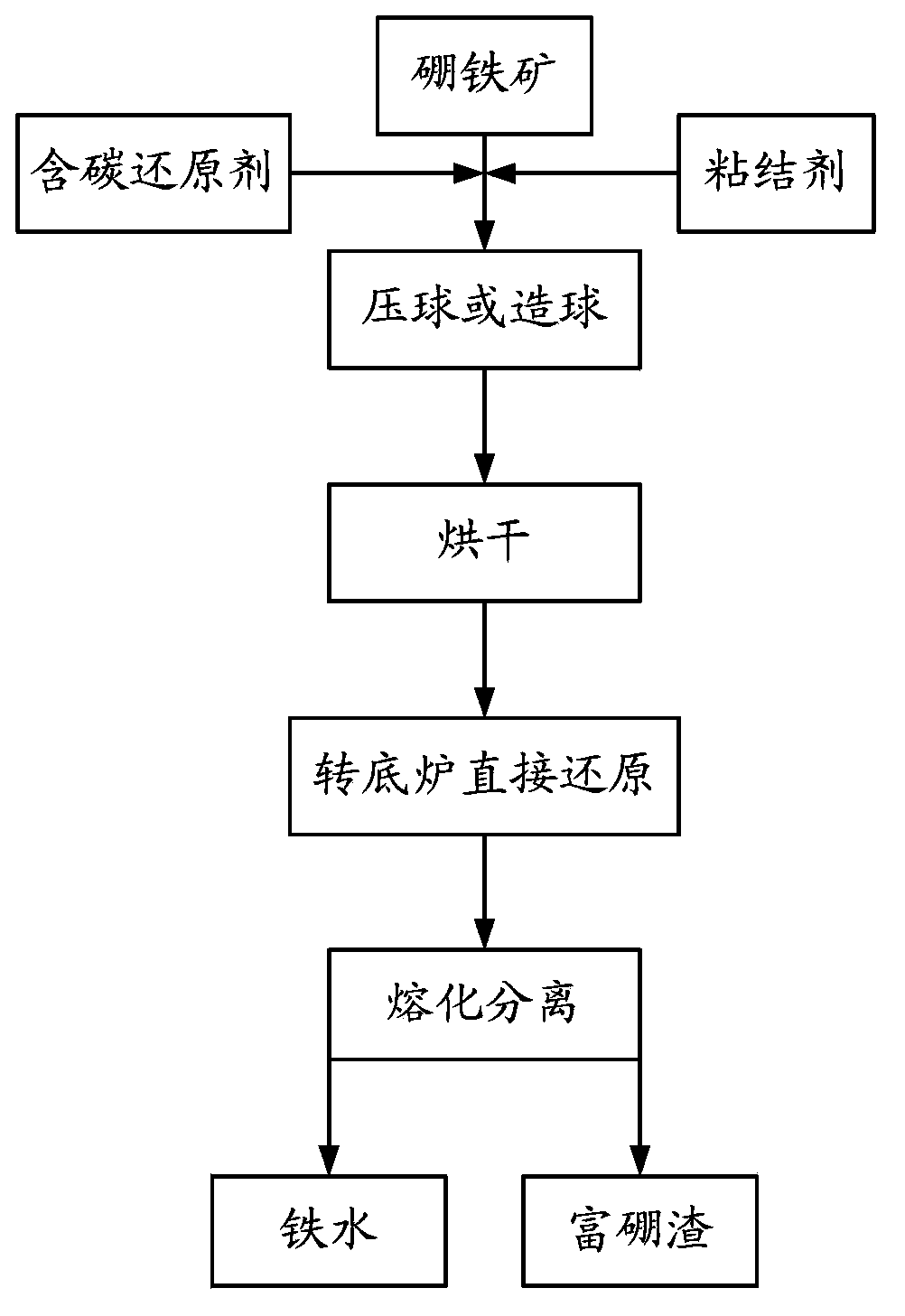

Method used

Image

Examples

Embodiment 1

[0053] Take 2Kg of boronite ore (with particle size below 2mm, main component: B 2 o 3 6.19%, TFe49.72%, FeO17.99%, CaO1.21%, MgO15.88%, SiO 2 6.75%, Al 2 o 3 0.27%, S0.11%, P0.05%), add 0.44Kg semi-coke, 0.18Kg starch and 0.2Kg bentonite, mix well, add 0.3Kg water and continue to mix until uniform, then press the mixture into balls or In the pelletizing process, after the pellets are dried, they are reduced and roasted in a rotary hearth furnace in order to obtain reduced products. Wherein, the reduction roasting temperature is 1350° C., and the reduction roasting time is 30 minutes. Then, the reduced product is put into an electric furnace in a hot state for melting and separation, so as to obtain 1.006Kg of molten iron with a total iron content of 96.86%, and a total iron content of 3.15%, B 2 o 3 0.624Kg of boron-rich slag with a content of 19.24%.

[0054] It can be known by calculation that the recovery rate of boron is as high as 97%.

Embodiment 2

[0056] Take 2Kg of boronite ore (with particle size below 2mm, main component: B 2 o 3 8.20%, TFe40.31%, FeO12.53%, CaO5.87%, MgO19.39%, SiO 2 9.22%, Al 2 o 3 0.96%, S0.08%, P0.052%), add 0.32Kg of anthracite, 0.18Kg of starch and 0.2Kg of bentonite, mix well, add 0.28Kg of water and continue to mix until uniform, and then press the mixture into balls or make Ball treatment, after the pellets are dried, they are reduced and roasted in a rotary hearth furnace in order to obtain reduced products. Wherein, the reduction roasting temperature is 1330° C., and the reduction roasting time is 30 minutes. Then, the reduction product is put into an electric furnace in a hot state for melting and separation, so as to obtain 0.825Kg of molten iron with a total iron content of 94.86%, and a total iron content of 3.09%, B 2 o 3 0.605Kg of rich boron with a content of 25.64%.

[0057] It can be known by calculation that the recovery rate of boron is as high as 94.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com