Method for preparing high-iron bauxite pellets

A technology of high-iron bauxite and pellets, which is applied in the field of ironmaking, can solve the problems of high-iron bauxite being difficult to form pellets, low sample strength, and rough surface of pellets, so as to achieve large-scale industrial application and high compressive strength Large, Smooth Surface Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

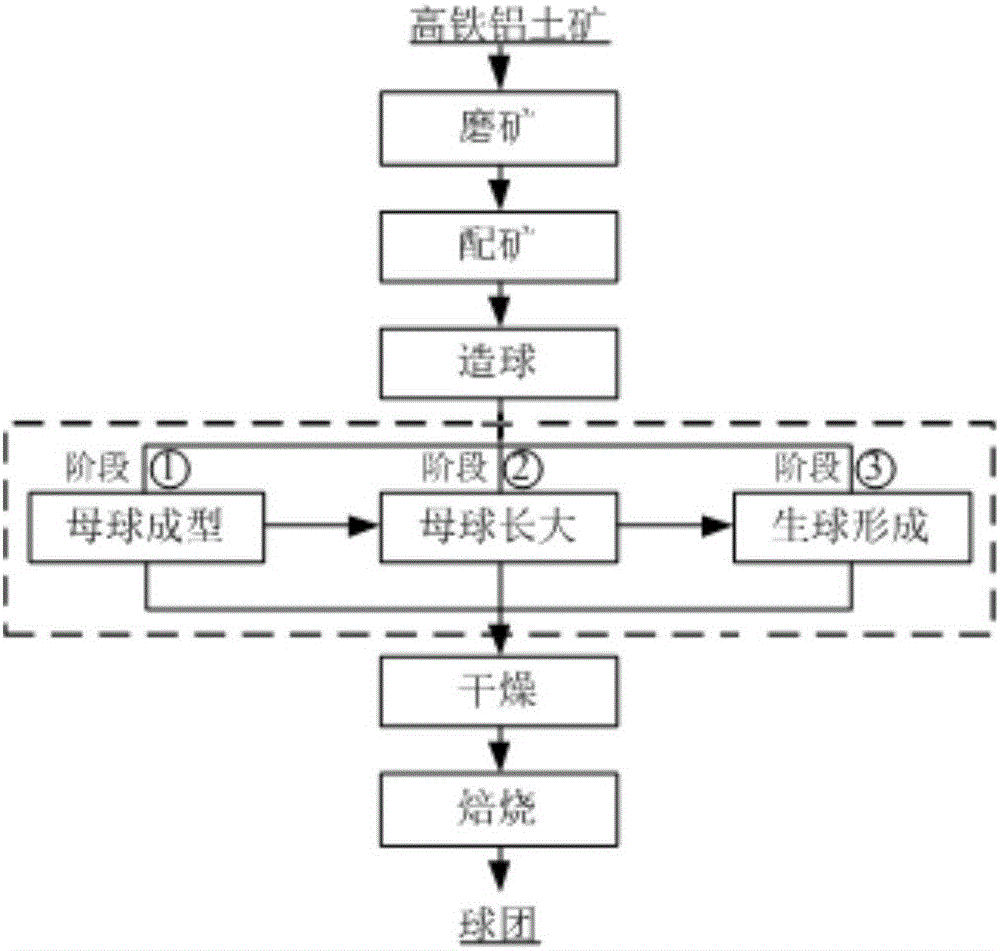

Method used

Image

Examples

Embodiment 1

[0054] The high-iron bauxite in the A area is selected, wherein the TFe content is 22.54wt%, Al 2 o 3 Content is 44.76wt%, SiO 2 The content is 7.32wt%. The mass percentage of the mass of the high-iron bauxite ground to a particle size of ≤74 μm to the total mass of the ore powder is 67%. Add 3.5wt% calcium hydroxide powder and 5wt% sodium hydroxide powder to the mineral powder, and mix uniformly to obtain a mixed material.

[0055] Get 5wt% mixed material, add in the disc of disc granulator in the mode of continuous feeding. Adjust the inclination angle α of the disk to 44° and the rotation speed to 15r / min. The mix and water were added to the disc every 3 minutes. When the average particle size of the cue ball is greater than 2 mm, stop adding the mixed material to the disc, and only add water.

[0056] Screen out the cue balls with a particle size of 2-5 mm, and keep the cue balls with a particle size > 5 mm. In this embodiment, cue balls with a particle size of 2-5 ...

Embodiment 2

[0060] Select the high-iron bauxite in B area, wherein the TFe content is 22.34wt%, Al 2 o 3 Content is 43.19wt%, SiO 2 The content is 4.92wt%. The mass of the high iron bauxite ground to a particle size of ≤74 μm accounts for 71% of the total mass of the ore powder. Add 5wt% calcium hydroxide powder and 5.5wt% sodium hydroxide powder to the mineral powder, and mix uniformly to obtain a mixed material.

[0061] Get 5wt% mixed material, add in the disc of disc granulator in the mode of continuous feeding. Adjust the inclination angle α of the disc to 45°, and the rotation speed to 16r / min. The mixture and water were added to the disc every 3 minutes. When the average particle size of the cue ball is greater than 2 mm, stop adding the mixed material to the disc, and only add water.

[0062] Screen out the cue balls with a particle size of 2-5 mm, and keep the cue balls with a particle size > 5 mm. In this embodiment, cue balls with a particle size of 2-5 mm account for ≥9...

Embodiment 3

[0066] Select the high-iron bauxite in C area, wherein TFe content is 23.15wt%, Al 2 o 3 Content is 43.88wt%, SiO 2 The content is 5.13wt%. The mass of the high-iron bauxite ground to a particle size of ≤74 μm accounts for 75% of the total mass of the ore powder. Add 3wt% calcium hydroxide powder and 4.5wt% sodium hydroxide powder to the mineral powder, and mix uniformly to obtain a mixed material.

[0067] Get 5wt% mixed material, add in the disc of disc granulator in the mode of continuous feeding. Adjust the inclination angle α of the disk to 46° and the rotation speed to 17r / min. The mixture and water were added to the disc every 3 minutes. When the average particle size of the cue ball is greater than 2 mm, stop adding the mixed material to the disc, and only add water.

[0068] Screen out the cue balls with a particle size of 2-5 mm, and keep the cue balls with a particle size > 5 mm. In this embodiment, cue balls with a particle size of 2-5 mm account for ≥95% of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com