Inorganic composite modified interior wall flame-retardant and mildew-proof water paint and method for preparing same

An inorganic compounding and modification technology, which is applied in the field of interior wall decorative coatings, can solve the problems of hidden dangers to health, single functionality of latex paint, and lack of fire, flame and mildew resistance in latex paint, and achieve excellent acid and alkali resistance, avoid Cracking of the paint film to ensure the effect of sanitation and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

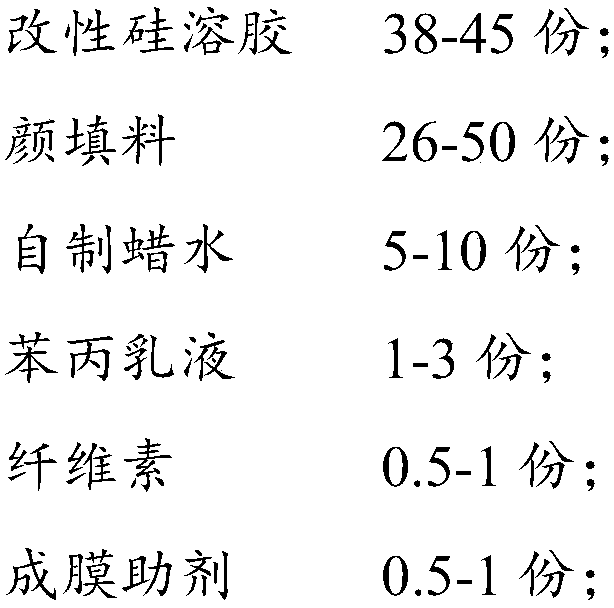

[0044] An inorganic composite modified interior wall flame retardant anti-mold water paint, which is prepared by the following components calculated in parts by weight:

[0045]

[0046] The preparation process of the inorganic composite modified interior wall flame-retardant mildew-proof water paint is as follows:

[0047] S1: Add 15 parts of water, dispersant, defoamer, and multifunctional additives into the disperser in sequence, and disperse at 500-600r / min for 5-8min;

[0048]S2: Add titanium dioxide, light calcium carbonate and silicon micropowder to the disperser, disperse at 800-1000r / min for 20-25min; then add cellulose, disperse at 1000-1200r / min for 20-25min;

[0049] S3: Add modified silica sol to the disperser, disperse at 600-800r / min for 20min, then add film-forming aids alcohol ester 12 and propylene glycol in turn, and disperse for 5-8min;

[0050] S4: Add styrene-acrylic emulsion to the disperser, disperse at 600-800r / min for 8-10min; then add the mixture...

Embodiment 2

[0053] An inorganic composite modified interior wall flame retardant anti-mold water paint, which is prepared by the following components calculated in parts by weight:

[0054]

[0055] The preparation process of the inorganic composite modified interior wall flame-retardant mildew-proof water paint is as follows:

[0056] S1: Add 20 parts of water, dispersant, defoamer, and multifunctional additives into the disperser in sequence, and disperse at 500-600r / min for 5-8min;

[0057] S2: Add titanium dioxide, light calcium carbonate and silicon micropowder to the disperser, disperse at 800-1000r / min for 20-25min; then add cellulose, disperse at 1000-1200r / min for 20-25min;

[0058] S3: Add modified silica sol to the disperser, disperse at 600-800r / min for 20min, then add film-forming aids alcohol ester 12 and propylene glycol in turn, and disperse for 5-8min;

[0059] S4: Add styrene-acrylic emulsion to the disperser, disperse at 600-800r / min for 8-10min; then add the mixtur...

Embodiment 3

[0062] An inorganic composite modified interior wall flame retardant anti-mold water paint, which is prepared by the following components calculated in parts by weight:

[0063]

[0064] The preparation process of the inorganic composite modified interior wall flame-retardant mildew-proof water paint is as follows:

[0065] S1: Add 15 parts of water, dispersant, defoamer, and multifunctional additives into the disperser in sequence, and disperse at 500-600r / min for 5-8min;

[0066] S2: Add titanium dioxide, light calcium carbonate and silicon micropowder to the disperser, disperse at 800-1000r / min for 20-25min; then add cellulose, disperse at 1000-1200r / min for 20-25min;

[0067] S3: Add modified silica sol to the disperser, disperse at 600-800r / min for 20min, then add film-forming aids alcohol ester 12 and propylene glycol in turn, and disperse for 5-8min;

[0068] S4: Add styrene-acrylic emulsion to the disperser, disperse at 600-800r / min for 8-10min; then add the mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com