Iron-based catalyst prepared by sol-gel combustion method, and preparation method and applications of iron-based catalyst

An iron-based catalyst, sol-gel technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of catalytic activity and low-carbon olefin selectivity decline , Serious blockage of catalytic bed and separation equipment, reduction of mechanical strength and other problems, to achieve good anti-carbon deposition ability, solve the phenomenon of catalyst carbon deposition and pulverization, and improve the effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

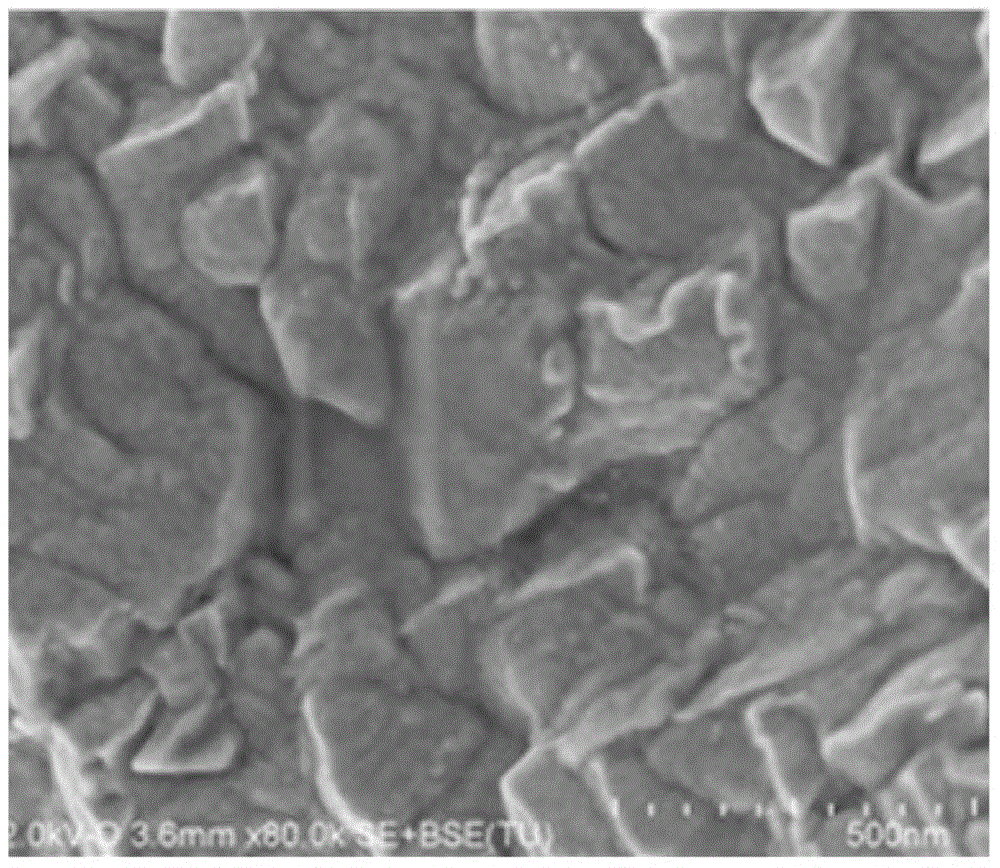

Image

Examples

Embodiment 1

[0038] The preparation of embodiment 1 catalyst sample

[0039] 20.0g ferric nitrate nonahydrate and 10.1g manganese nitrate hexahydrate are dissolved in 200ml deionized water, then add 0.25mol of citric acid (the mol ratio of Fe to citric acid is 0.2), stir to obtain mixed solution I; Add 20wt% ammonia water to the solution I, adjust the pH value of the system to 7, and stir and reflux at 80°C for 5h to ensure that the citric acid and metal ions are completely chelated to obtain a mixed solution II; the mixed solution II is continuously stirred and evaporated at 60°C to In the gel state, add 19g of 10% potassium carbonate, stir evenly, and dry at 100°C for 12 hours to obtain a dried sample, which is designated as sample G1 # .

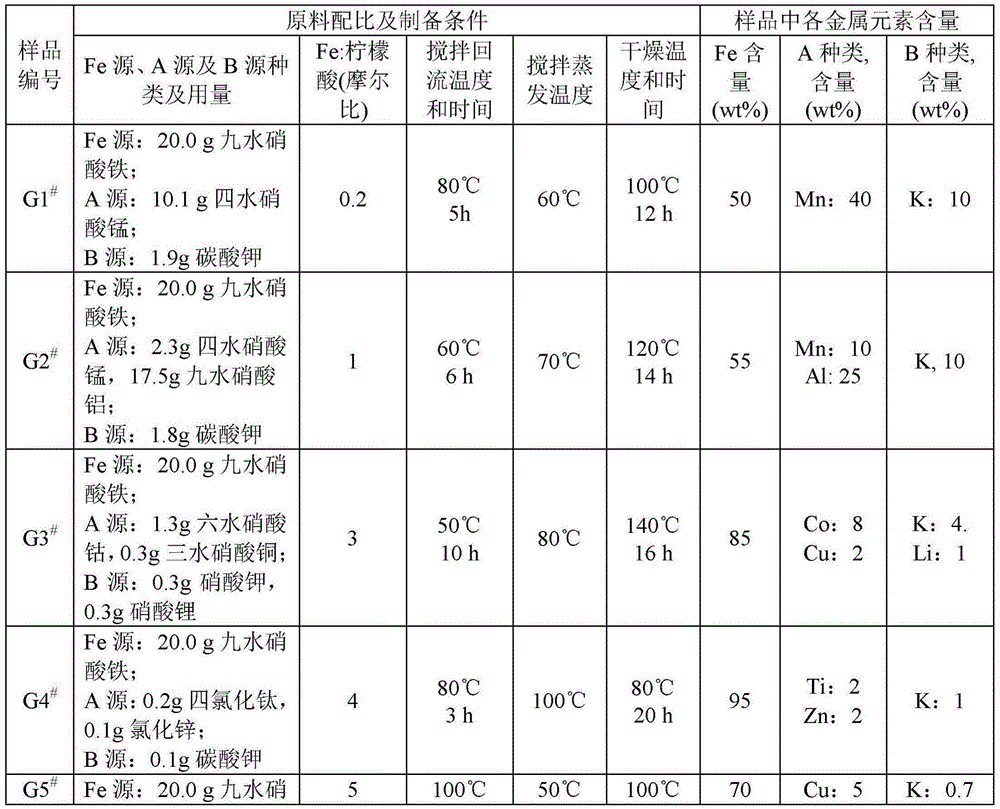

[0040] Sample G2 # ~G15 # The specific preparation steps are the same as sample G1 # , Fe source, A source and B source type and dosage and preparation conditions are shown in Table 1. Sample G1 after drying by XRF # ~G15 # The elemental compos...

Embodiment 2

[0045] The preparation of sample after embodiment 2 drying

[0046] Roasting embodiment 1 gained sample G1 in air # ~G15 #

[0047] The dried sample G1 # ~G15 # Put it in a muffle furnace, roast in an air atmosphere, raise the temperature to the roasting temperature at a certain heating rate, and after roasting for a period of time, the iron-based catalyst is obtained, which is designated as sample 1 # ~Sample 15 # .

[0048] sample 1 # ~Sample 15 # The specific roasting conditions are shown in Table 2.

[0049] Table 2

[0050]

[0051]

[0052] Roasting embodiment 1 gained sample G1 in non-reactive atmosphere # ~G15 #

[0053] The dried sample G1 # ~G15 # Put it in a muffle furnace, pass inactive gas, raise the temperature to the roasting temperature at a certain heating rate, after roasting for a period of time, cool down to 20°C; Gasification, passivation for a period of time, to obtain the iron-based catalyst, denoted as sample 16 # ~Sample 30 ...

Embodiment 4

[0061] Example 4 Sample 1 # ~Sample 15 # Reaction Performance Test of Syngas to Light Olefins

[0062] Take sample D1 separately # , sample 1 # ~Sample 15 # 2g each, put into a reaction tube, and combine the liner, quartz wool and quartz sand to keep the sample in a constant temperature section. Put the reaction tube into the fixed bed device, make the thermocouple at the height of the catalyst, connect other accessories, and check the air tightness of the device. Reduction treatment is carried out before the reaction, and the reduction gas is introduced, and the reduction is performed for a period of time at a certain temperature. After the reduction, the synthesis gas is introduced to test the reaction performance of the conversion of the synthesis gas to light olefins. The online chromatographic detection of the reaction product was carried out every 30 min. After 24 hours of reaction, each sample was taken out, and the amount of carbon deposited on the sample after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com