Method for quickly detecting carbon deposition resistance performance of methane synthesis catalyst

A methane synthesis and catalyst technology, which is applied in chemical analysis, analysis materials, instruments, etc. by using catalysis, can solve the problems of long time consumption, high detection cost, and low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

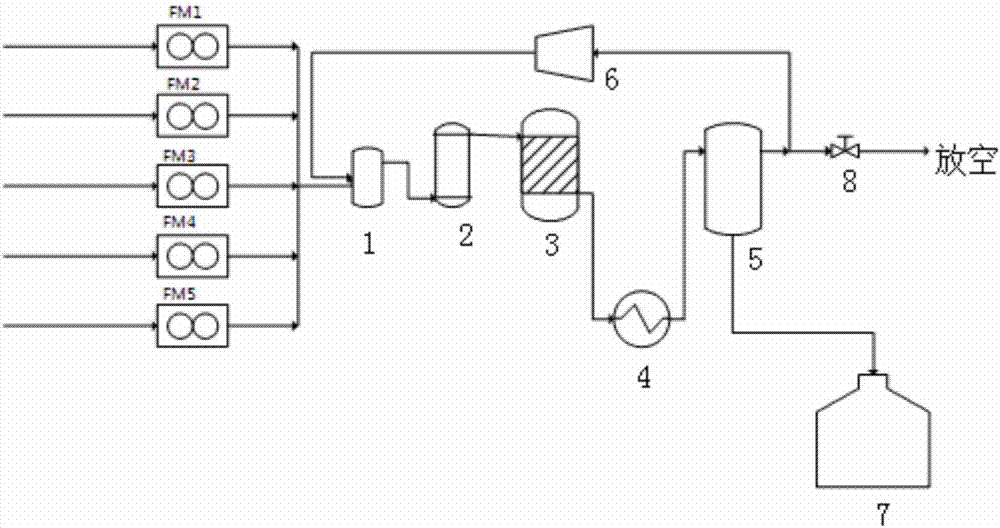

Method used

Image

Examples

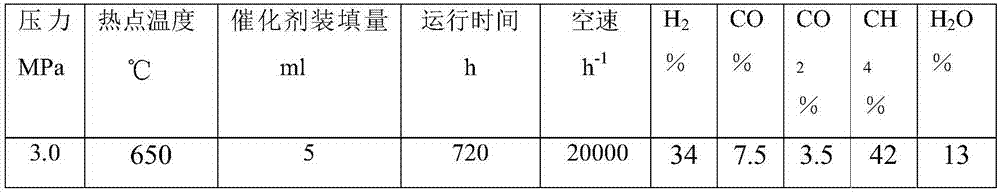

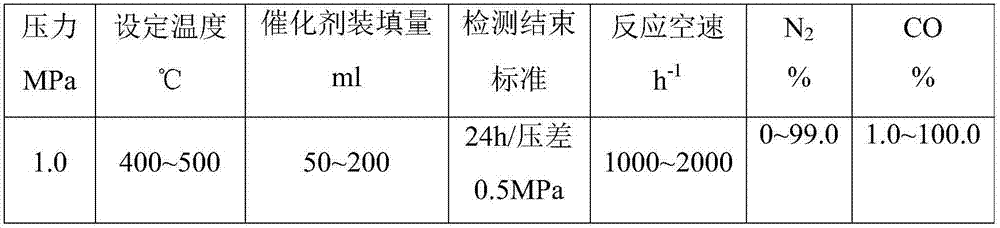

Embodiment 1

[0052] A foreign catalyst, product number CRG, uses the device described in patent ZL2016202013246. The catalyst is loaded in the constant temperature section of the reactor. Pressure leak test to 3.0MPa, observe whether the pressure before and after the reactor is consistent (the purpose is to check whether the pressure gauge is working normally). Introduce high-purity nitrogen to replace the air in the system. After confirming that all of the system is nitrogen, hold the pressure to 1.0-1.02MPa, stop nitrogen, and start to heat up by introducing hydrogen. It takes 1.5 hours to raise the temperature to 300°C, and keep at 300°C for 2 The catalyst is reduced in one hour, and the reduction space velocity is 500h -1 After the reduction, stop the flow of hydrogen, release the pressure to 0.2MPa, and replace the hydrogen in the system with nitrogen. During the process of replacing hydrogen with nitrogen, the temperature was raised to 500°C, and after confirming that no hydrogen wa...

Embodiment 2

[0058] Our company’s third-generation catalyst, the catalyst product number is XDJ-03 (can be purchased from Xindi Energy Engineering Technology Co., Ltd.), using the device described in the patent ZL2016202013246, the catalyst is loaded in the constant temperature section of the reactor, the catalyst must be installed flat, the catalyst The two sides are isolated with an appropriate amount of quartz wool, and the upper and lower sides are filled with ceramic balls. Pressure leak test to 3.0MPa, observe whether the pressure before and after the reactor is consistent (the purpose is to check whether the pressure gauge is working normally). Introduce high-purity nitrogen to replace the air in the system. After confirming that all of the system is nitrogen, hold the pressure to 1.0-1.02MPa, stop nitrogen, and start to heat up by introducing hydrogen. It takes 1.5 hours to raise the temperature to 300°C, and keep at 300°C for 2 The catalyst is reduced in one hour, and the reductio...

Embodiment 3

[0064] Our unit’s fourth-generation catalyst, the catalyst product number is XDJ-204 (can be purchased from Xindi Energy Engineering Technology Co., Ltd.), using the device described in the patent ZL2016202013246, the catalyst is loaded in the constant temperature section of the reactor, the catalyst must be installed flat, the catalyst The two sides are isolated with an appropriate amount of quartz wool, and the upper and lower sides are filled with ceramic balls. Pressure leak test to 3.0MPa, observe whether the pressure before and after the reactor is consistent (the purpose is to check whether the pressure gauge is working normally). Introduce high-purity nitrogen to replace the air in the system. After confirming that all of the system is nitrogen, hold the pressure to 1.0-1.02MPa, stop nitrogen, and start to heat up by introducing hydrogen. It takes 1.5 hours to raise the temperature to 300°C, and keep at 300°C for 2 The catalyst is reduced in one hour, and the reduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com