High-temperature-resistant and corrosion-resistant waterproof paint and preparation method thereof

A waterproof coating and anti-corrosion technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of low bonding strength, high temperature resistance, poor anti-corrosion performance, inconvenience, etc., and achieve good anti-alkali and salt corrosion performance. High temperature and corrosion resistance, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

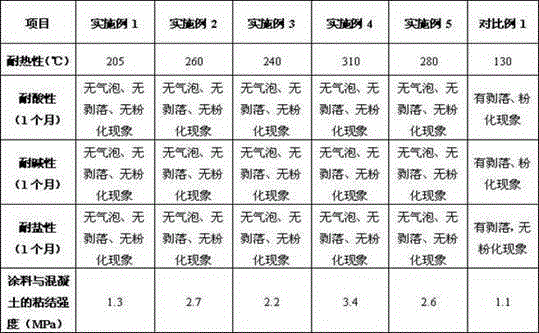

Examples

Embodiment 1

[0020] A high-temperature-resistant and corrosion-resistant waterproof coating, comprising the following components in parts by weight: 40 parts of phenolic resin, 32 parts of methyl acrylate emulsion, 23 parts of methyl acrylate emulsion, 5 parts of n-octyltrimethoxysilane, glycerin 6 parts of alcohol, 4 parts of calcium sulfate, 3 parts of aluminum chloride, 5 parts of aluminum oxide, 8 parts of talcum powder, 2 parts of sodium molybdate, 5 parts of short glass fiber, 2 parts of polyoxyethylene fatty alcohol ether, isophorone 3 parts of diamine, 1 part of allyl diglycol dicarbonate and 15 parts of deionized water.

[0021] Wherein, the particle size of the alumina is 200 mesh; the length of the short glass fibers is 0.5-1um.

[0022] The preparation method of the above-mentioned high-temperature-resistant and anti-corrosion waterproof coating comprises the following steps:

[0023] Step 1: taking the above-mentioned components by certain parts by weight;

[0024] Step 2: P...

Embodiment 2

[0029] A high-temperature-resistant and corrosion-resistant waterproof coating, comprising the following components in parts by weight: 46 parts of phenolic resin, 35 parts of methyl acrylate emulsion, 34 parts of methyl acrylate emulsion, 11 parts of n-octyltrimethoxysilane, glycerin 12 parts of alcohol, 8 parts of calcium sulfate, 6 parts of aluminum chloride, 9 parts of aluminum oxide, 12 parts of talcum powder, 6 parts of sodium molybdate, 12 parts of short glass fiber, 5 parts of polyoxyethylene fatty alcohol ether, isophorone 6 parts of diamine, 4 parts of allyl diglycol dicarbonate and 25 parts of deionized water.

[0030] Wherein, the particle size of the alumina is 200 mesh; the length of the short glass fibers is 0.5-1um.

[0031] The preparation method of the above-mentioned high-temperature-resistant and anti-corrosion waterproof coating comprises the following steps:

[0032] Step 1: taking the above-mentioned components by certain parts by weight;

[0033] Step...

Embodiment 3

[0038] A high-temperature-resistant and corrosion-resistant waterproof coating, comprising the following components in parts by weight: 53 parts of phenolic resin, 39 parts of methyl acrylate emulsion, 31 parts of methyl acrylate emulsion, 10 parts of n-octyltrimethoxysilane, glycerin 12 parts of alcohol, 7 parts of calcium sulfate, 8 parts of aluminum chloride, 7 parts of aluminum oxide, 12 parts of talcum powder, 5 parts of sodium molybdate, 10 parts of short glass fiber, 6 parts of polyoxyethylene fatty alcohol ether, isophorone 5 parts of diamine, 3 parts of allyl diglycol dicarbonate and 22 parts of deionized water.

[0039] Wherein, the particle size of the alumina is 200 mesh; the length of the short glass fibers is 0.5-1um.

[0040] The preparation method of the above-mentioned high-temperature-resistant and anti-corrosion waterproof coating comprises the following steps:

[0041] Step 1: taking the above-mentioned components by certain parts by weight;

[0042] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com