Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Less amount of catalyst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

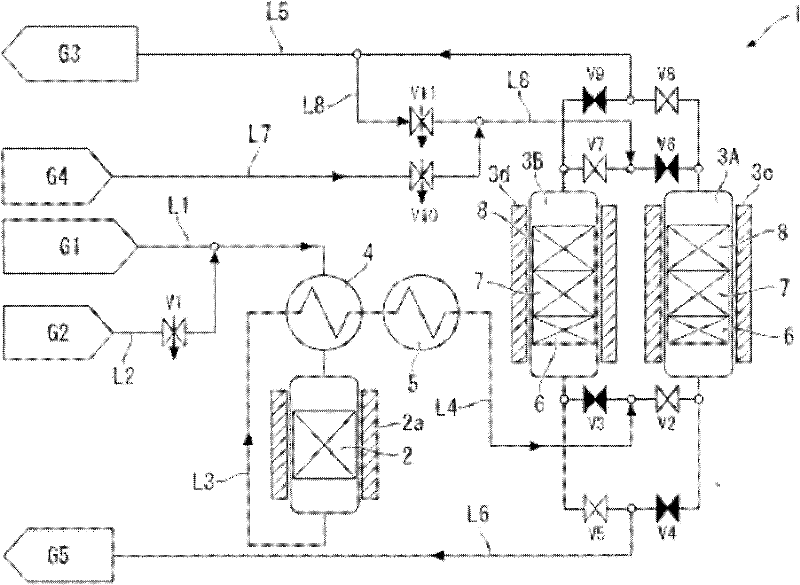

Gas purifying method and gas purifying apparatus

InactiveCN102380313AReactiveCheap and readily availableNitrogen purification/separationProductsNoble gasPurification methods

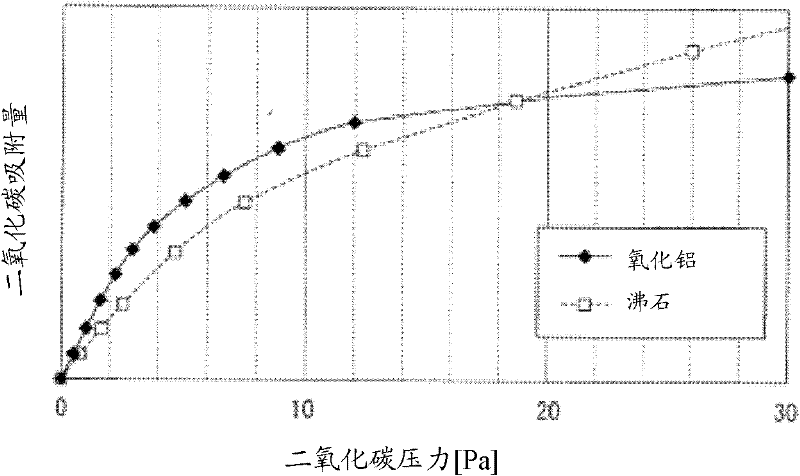

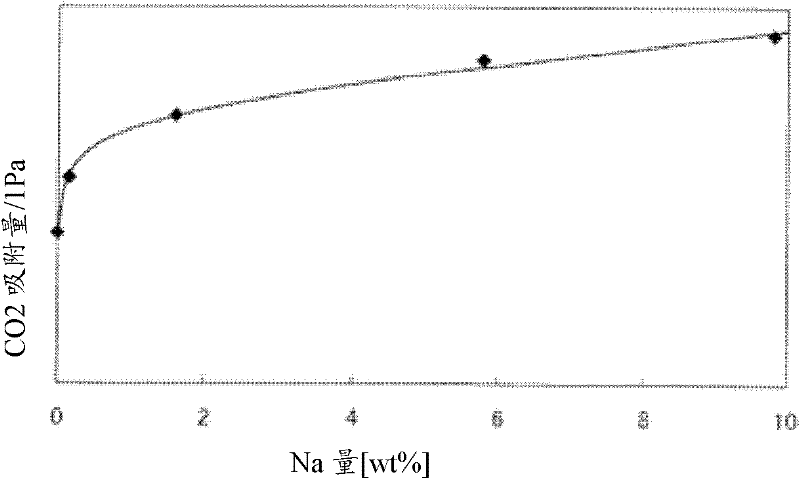

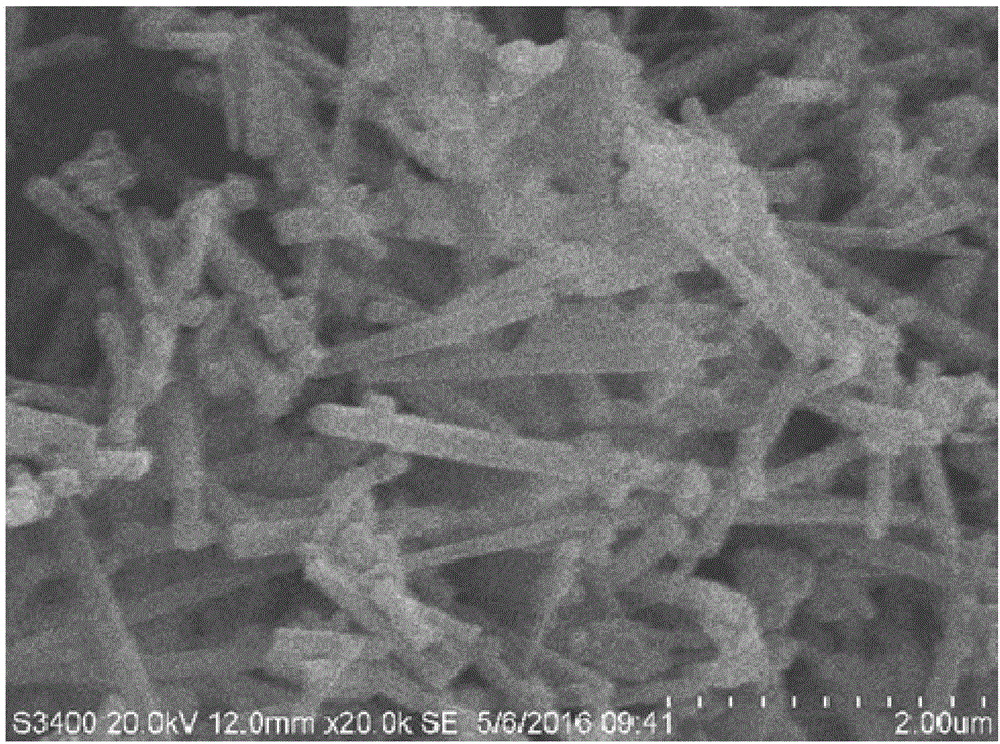

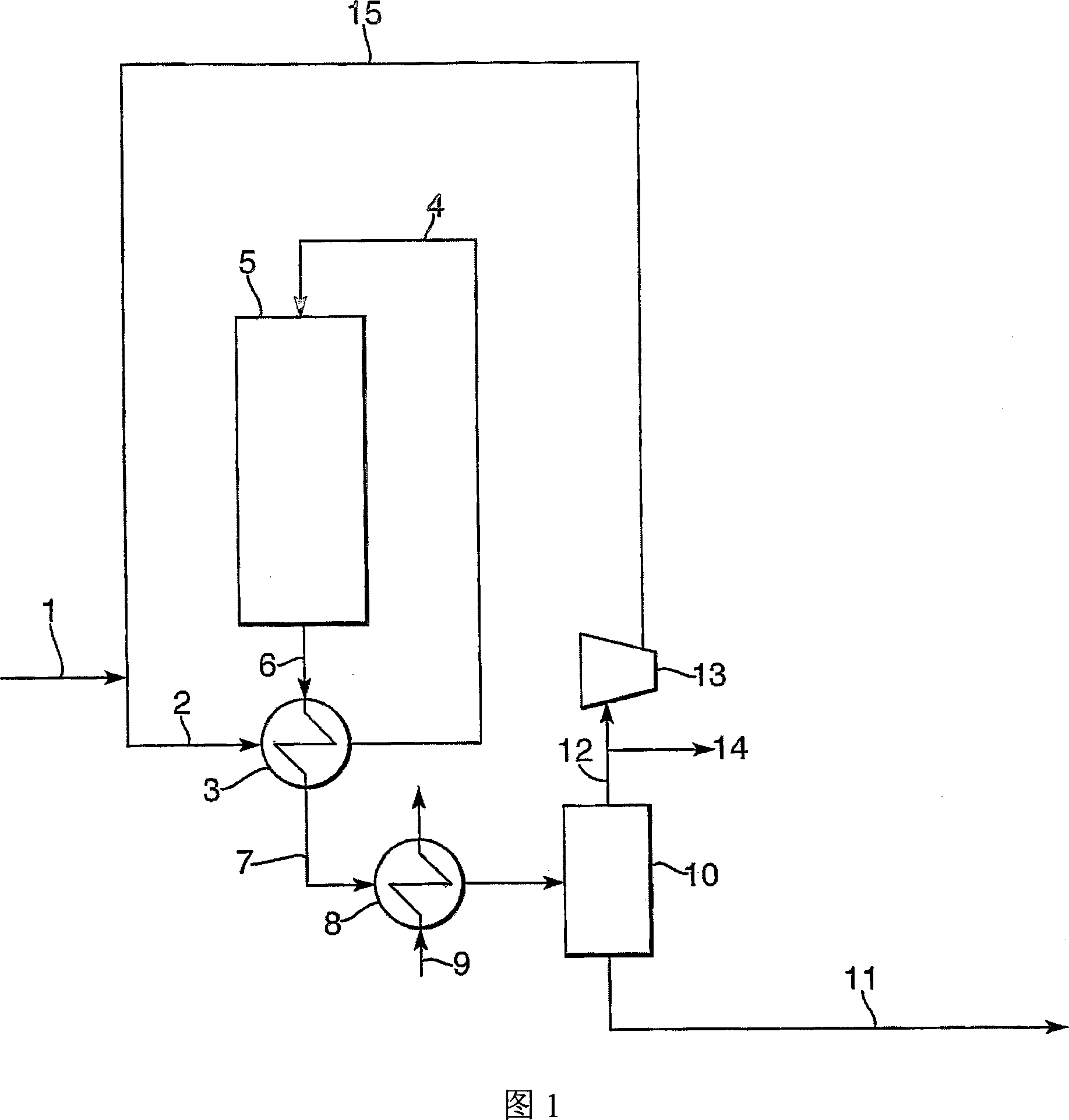

The present invention provides a gas purifying method, characterized by comprising the steps of contacting a raw material gap with a catalyst to form carbon dioxide and water; contacting the raw material gas after contacting with the catalyst with a water adsorbent for removing the water; contacting the raw material gas with the water removed with a nickel catalyst for removing reaction residuum oxygen; and contacting the raw material gas with the oxygen removed with an aluminum oxide containing 0.1-10 wt% sodium for removing the carbon dioxide. According to the present invention, the gas purifying method and the gas purifying apparatus can remove hydrocarbon, hydrogen, carbon monoxide, carbon dioxide, oxygen and water contained in the raw material gas containing nitrogen or rare gas, thereby enabling the purifying apparatus to be miniaturized, reducing the filling amount of the costly nickel catalyst, and reducing the purification cost.

Owner:NIPPON SANSO CORP

Mesoporous manganese ferrite Fenton-like catalyst and preparation method and application thereof

InactiveCN106391042ALarge specific surface areaGood mesoporous structureWater treatment compoundsWater contaminantsFenton reactionWastewater

Owner:NANJING UNIV

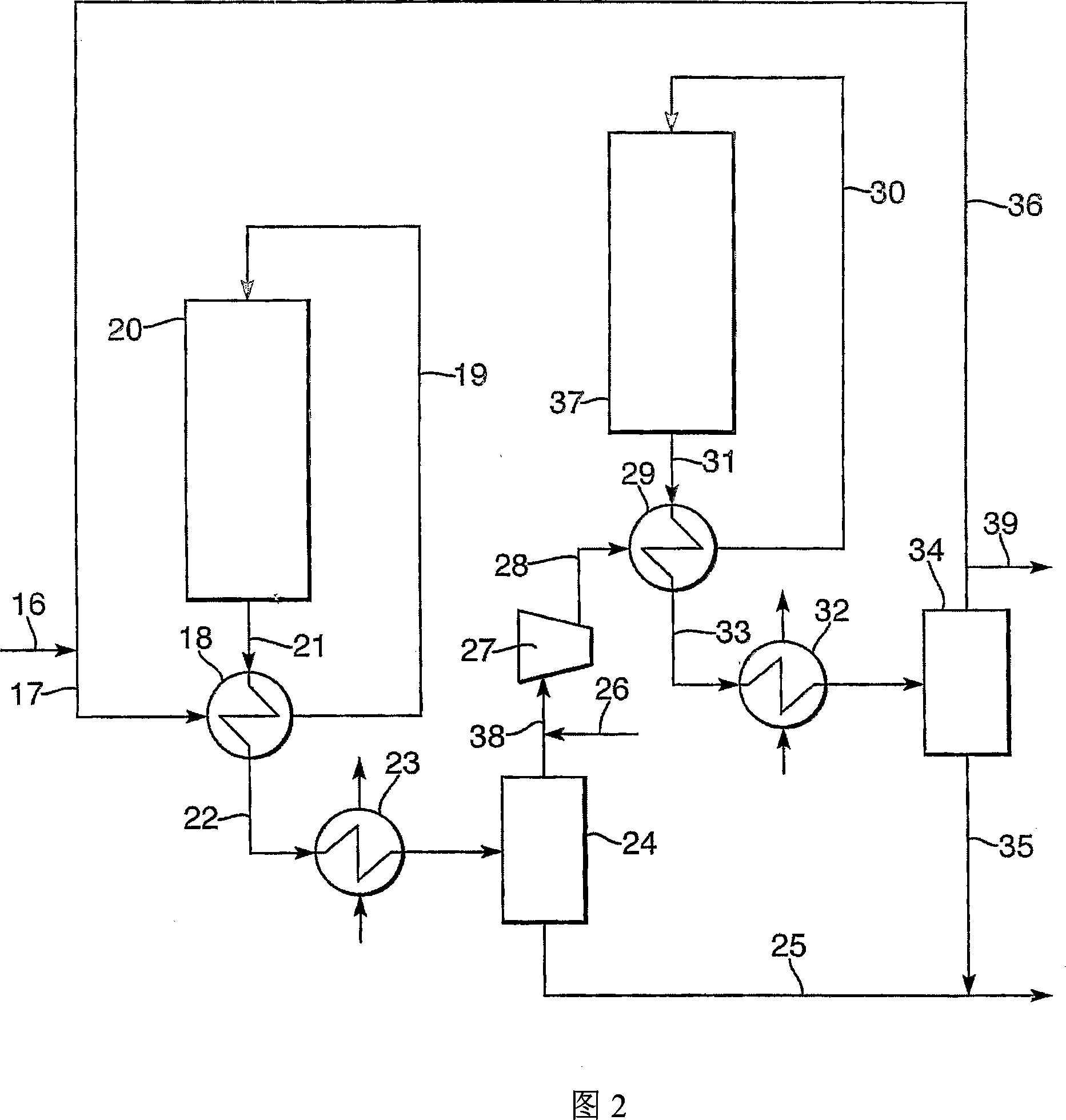

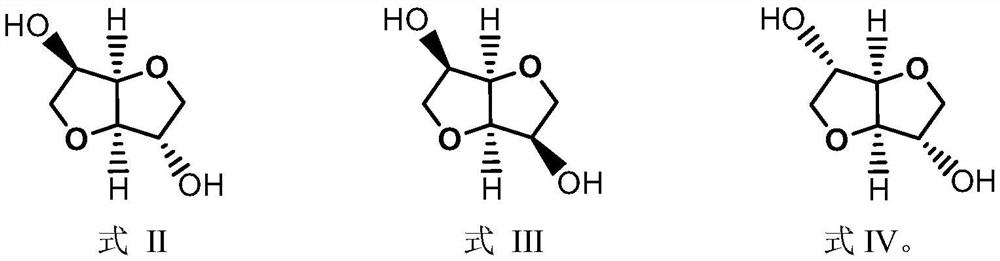

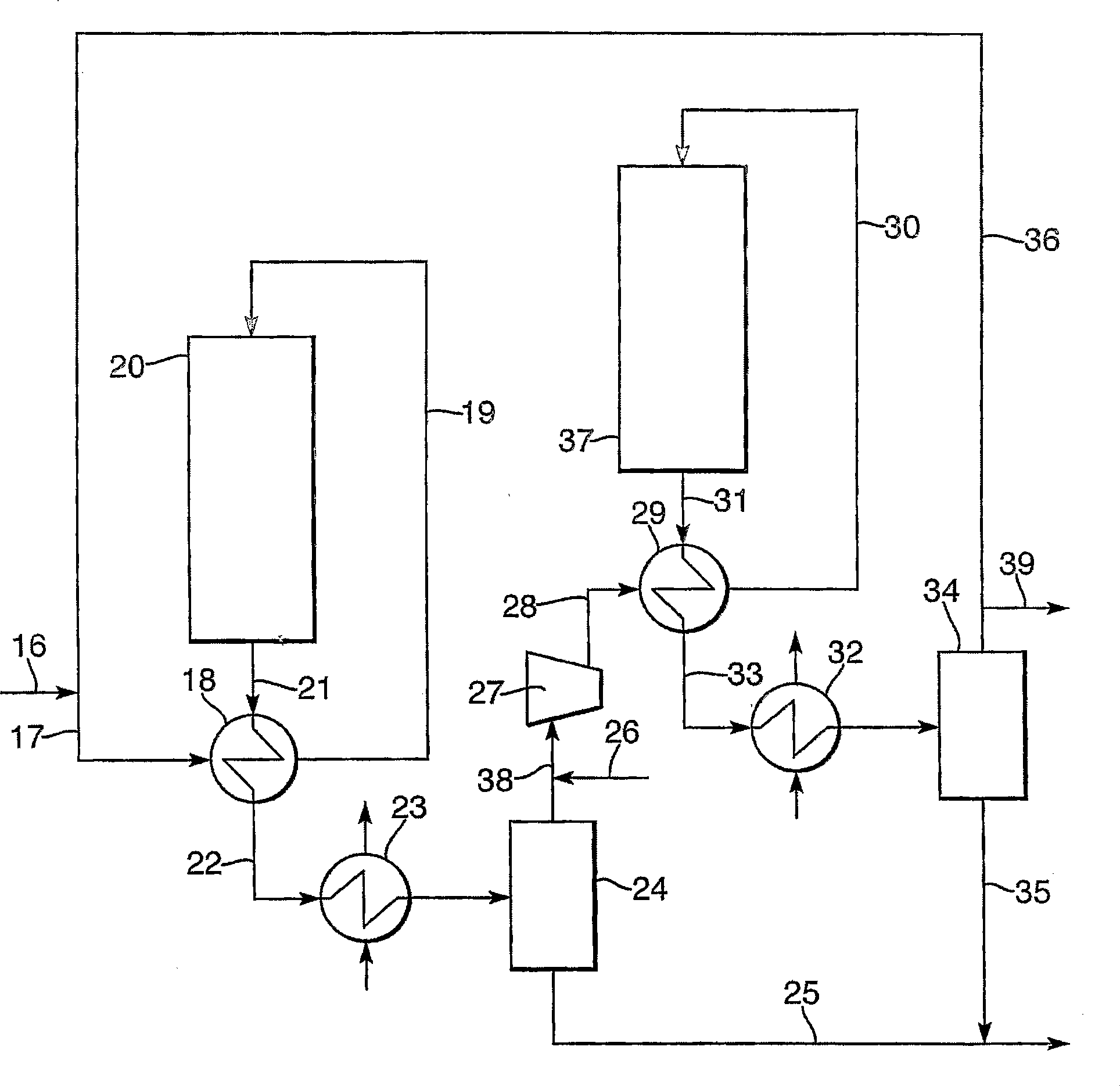

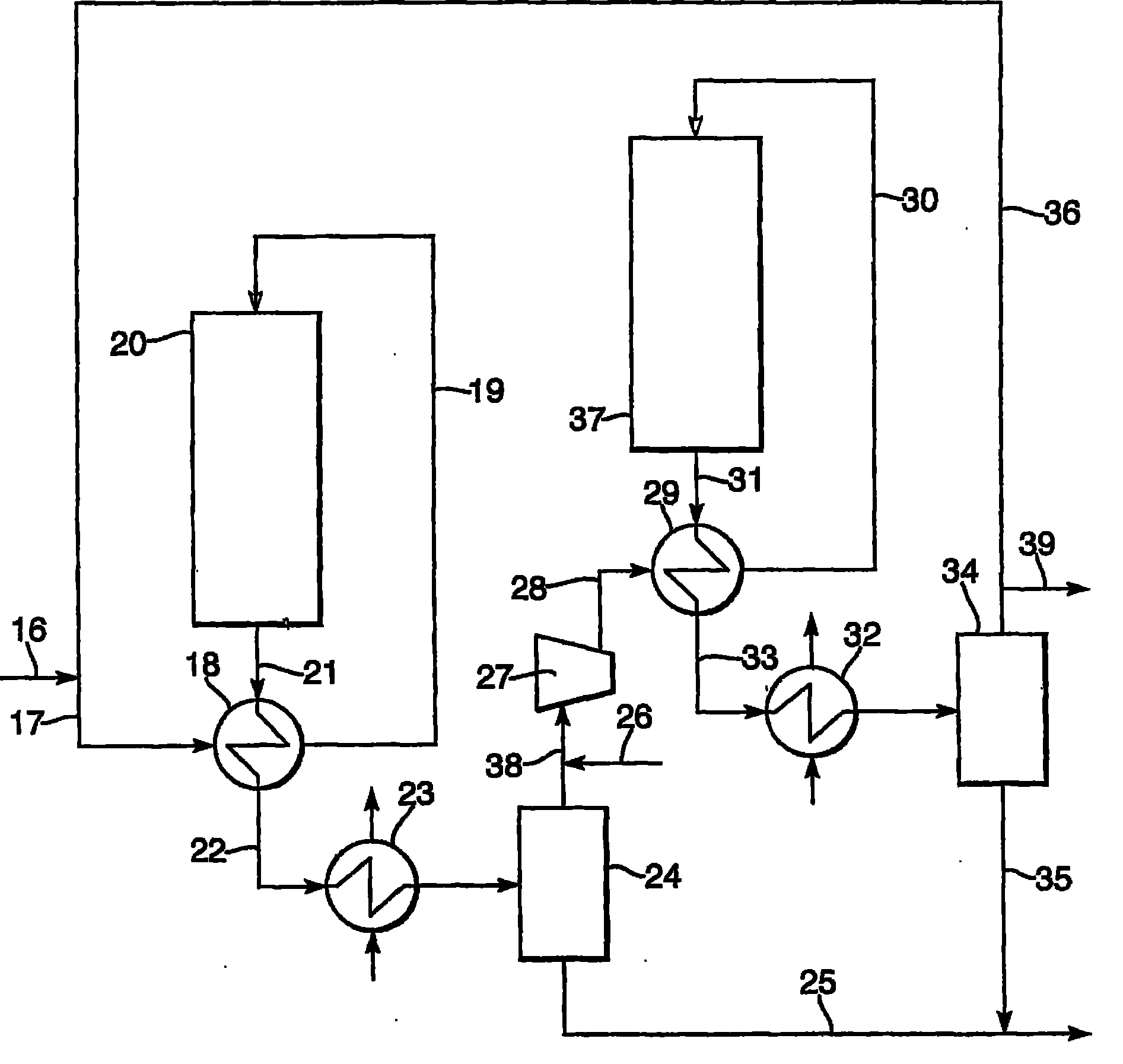

Process for use in gas phase reactions

ActiveCN1989092AReduce cycle ratioTemperature controlOrganic compound preparationHydroxy compound preparationGas phaseLiquid phase

A process for use in equilibrium exothermic gas phase reactions comprising the steps of (a) providing a recycle stream with the addition of make-up gas, to form a feed gas stream; (b) heating the feed gas stream; (c) passing the heated feed gas stream to a first reactor containing a catalyst for the exothermic gas phase reactions at conditions suitable for the reaction; (d) removing a product stream comprising product and unreacted gases from the first reactor; (e) cooling and partially condensing the product stream to form a gas phase and a liquid phase; (f) separating the liquid phase containing the desired product from the product stream and removing said liquid phase; (g) separating the gas phase from the product stream to form a gas stream; (h) optionally mixing the gas stream from the product stream with additional make-up gas; (i) heating the gas stream; (j) passing the heated gas stream to a final reactor containing a catalyst for the exothermic gas phase reactions at conditions suitable for the reaction; (k) removing a final product stream comprising product and unreacted gases from the final reactor; (l) cooling and partially condensing the final product stream to form a final gas phase and a mal liquid phase; (m) separating the final liquid phase containing the desired product from the final product stream and removing said final liquid phase; and (n) separating the gas phase from the final product stream and recycling the gas to step (a); and in which the gas stream from step (g) is compressed prior to heating in step (i).

Owner:JOHNSON MATTHEY DAVY TECH LTD

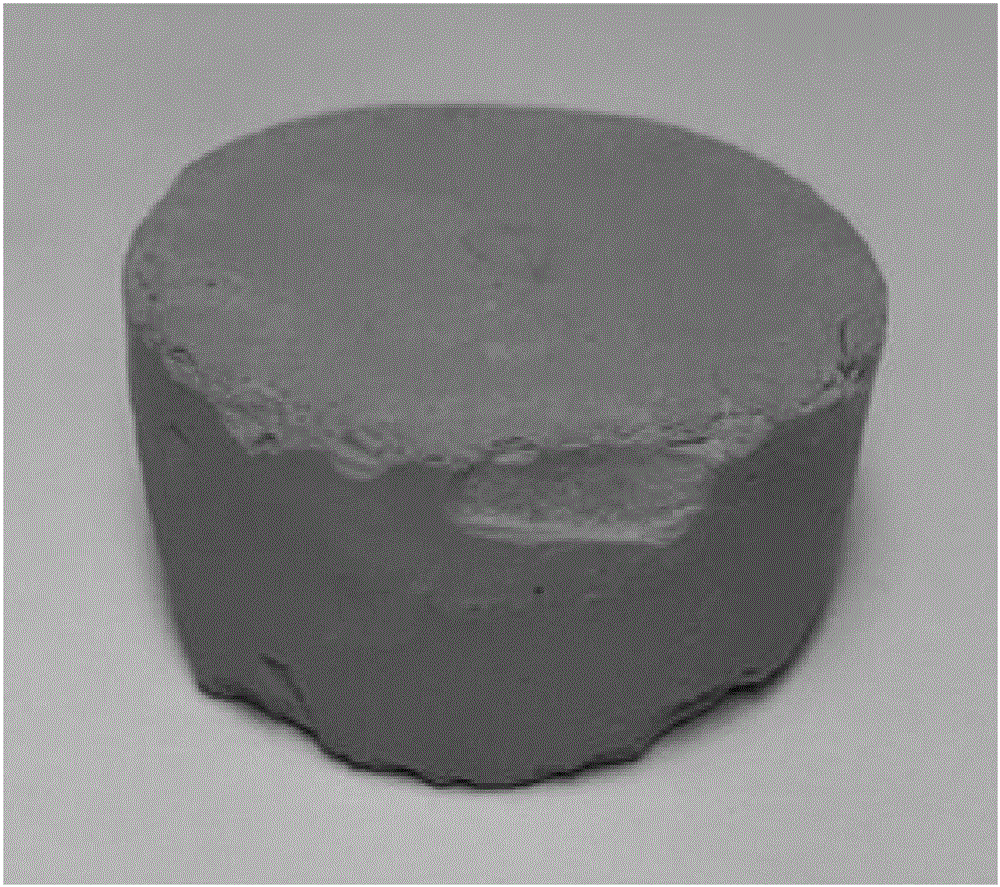

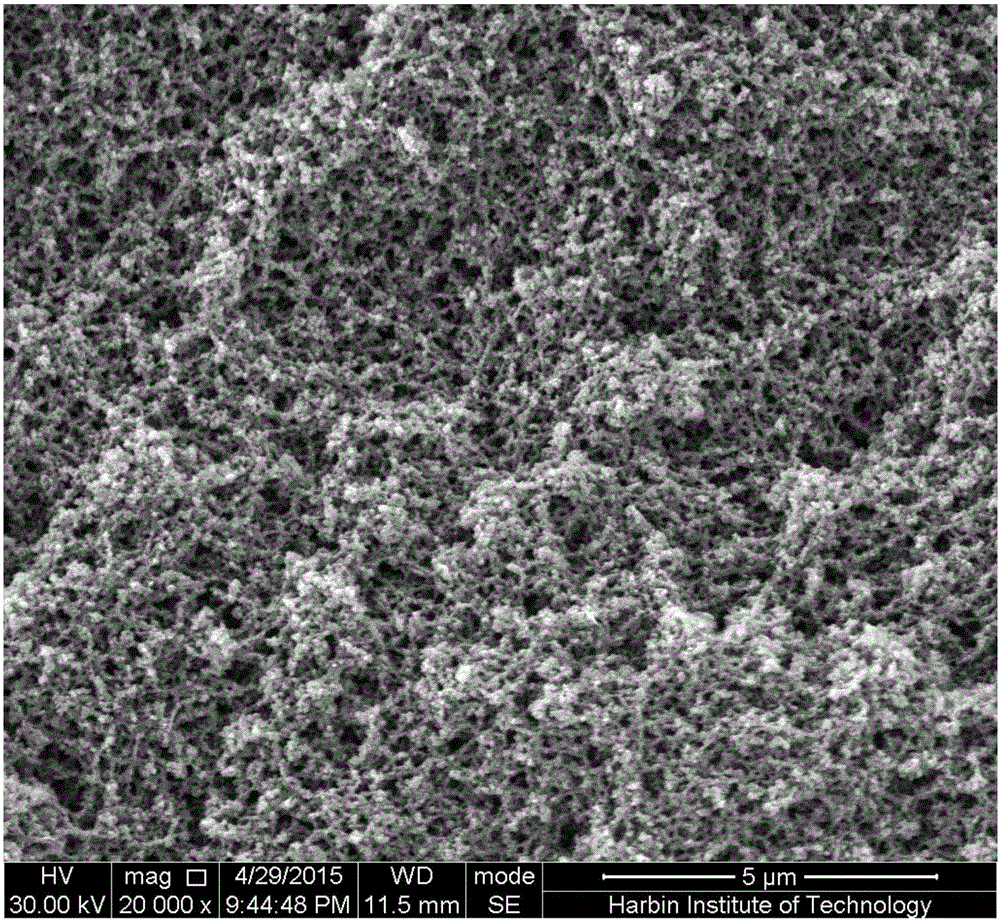

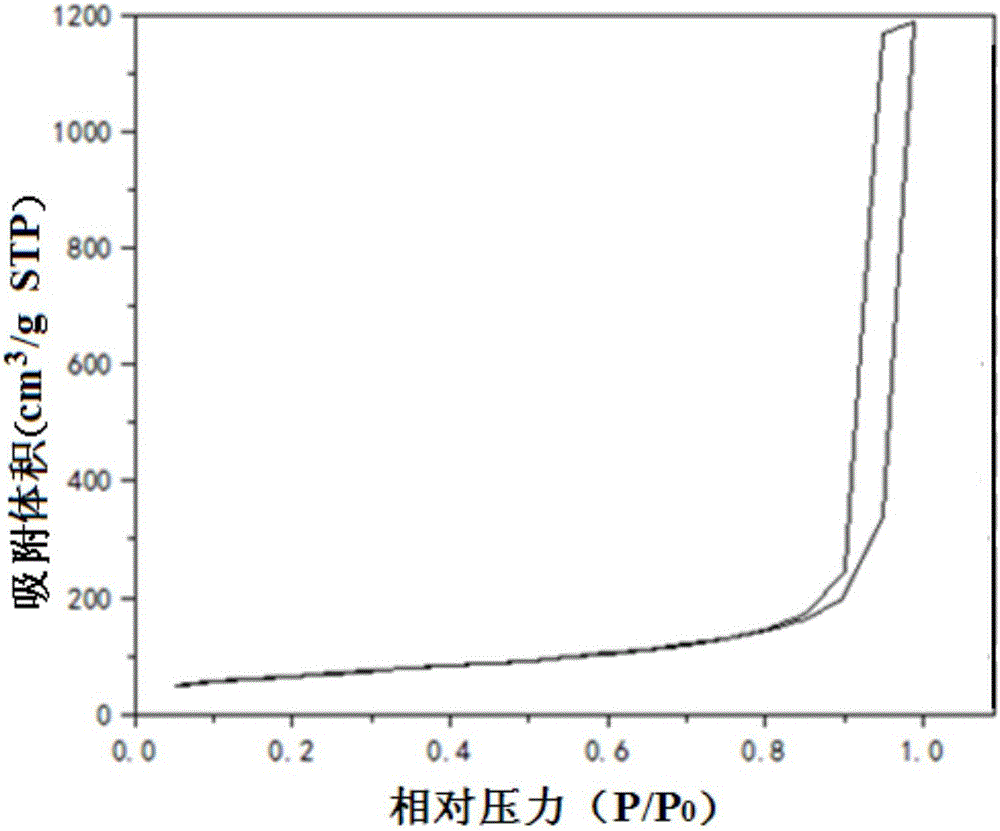

Preparation method of resorcinol-formaldehyde/silicon dioxide aerogel

The invention relates to an aerogel preparation method, and discloses a preparation method of resorcinol-formaldehyde / silicon dioxide aerogel. The preparation method is used for solving problems of conventional one-step sol method used for aerogel hybridization that the composition structure of a polymer prepared from sol can not be controlled, independence of hybridized aerogel components is lost, component performance is difficult to maintain. Two-step sol method is complicated, many catalysts are needed, and sol-gel time is relatively long. The preparation method comprises following step: 1, resorcinol-formaldehyde sol colloidal nucleuses are prepared; 2, a mixed soil precursor of the resorcinol-formaldehyde / silicon dioxide aerogel is prepared; and 3, the resorcinol-formaldehyde / silicon dioxide aerogel is prepared. Compared with the prior art, the preparation method is simple, and is convenient to control; the amount of needed catalyst is small; preparation time is shortened; sample strength is increased; cost is reduced; the preparation method is convenient for large-scale and industrialized production, and possesses significant importance on promotion of applications of hybridized aerogel.

Owner:HARBIN INST OF TECH

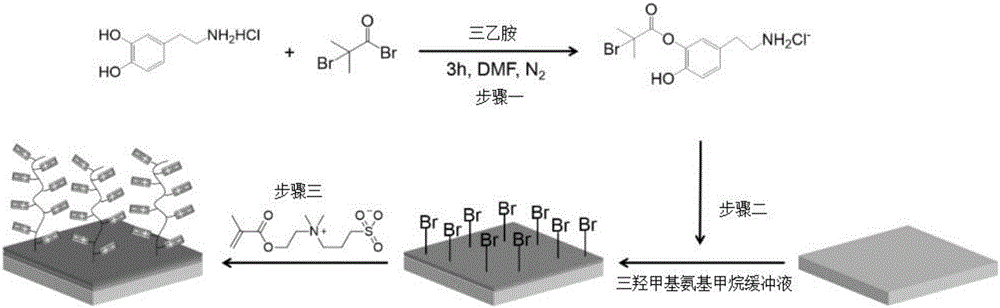

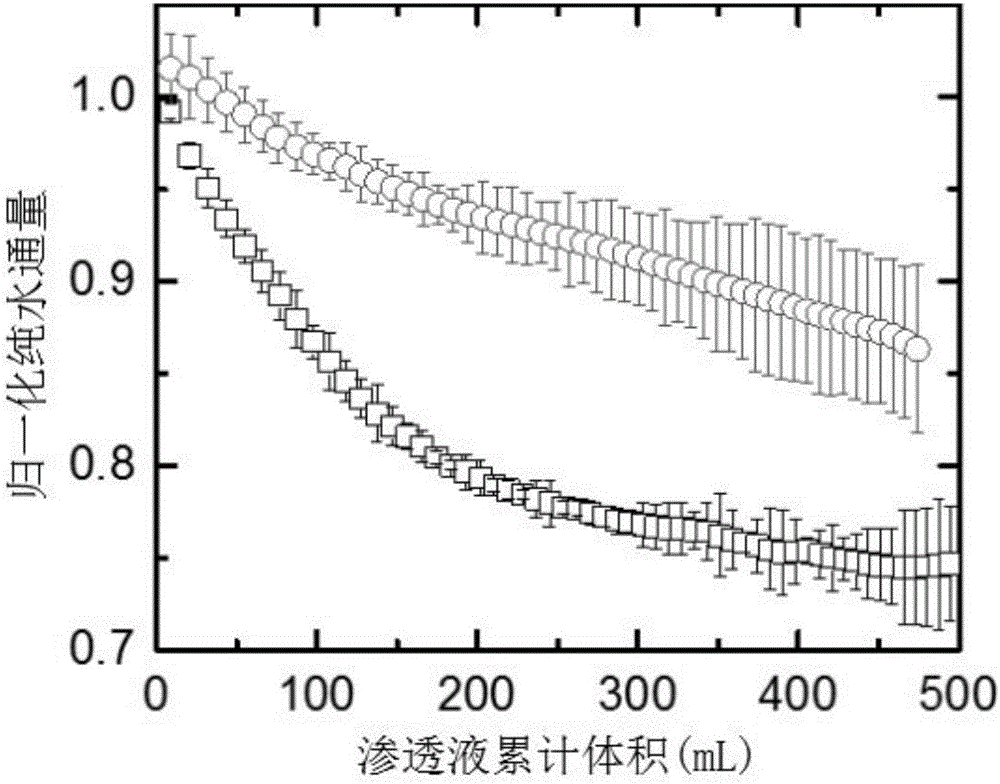

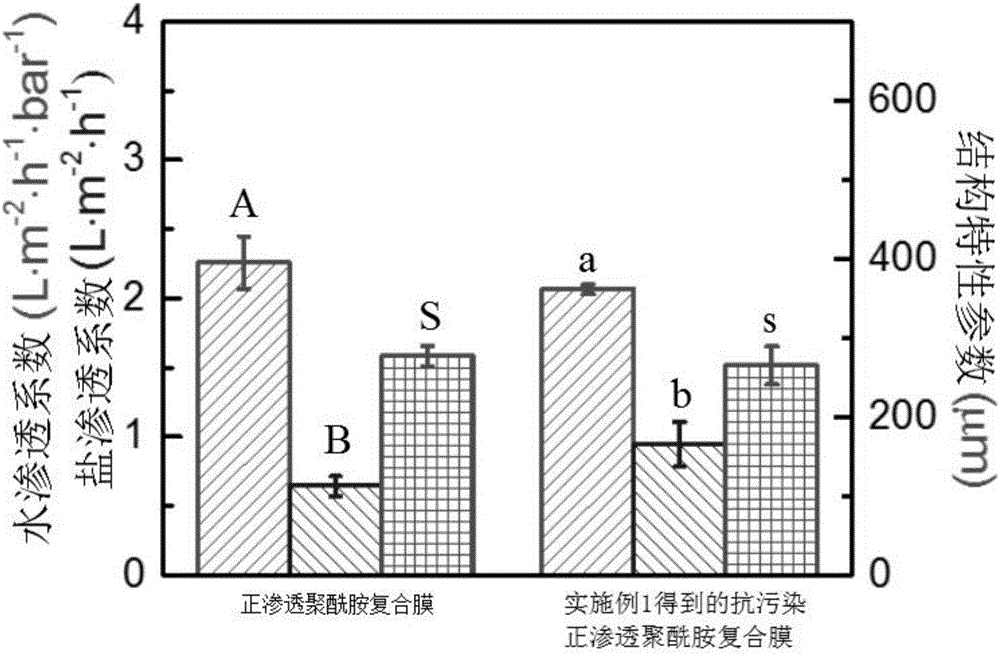

Method for preparing anti-pollution forward-permeating polyamide composite film through aftertreatment

InactiveCN106823805AImprove anti-pollution performanceKeep waterSemi-permeable membranesComposite filmPolyamide

The invention relates to a method for improving pollution resistance of a forward-permeating polyamide composite film through aftertreatmetn modification, in particular to a method for preparing an anti-pollution forward-permeating polyamide composite film through aftertreatment. The method aims at solving the problem that an existing forward-permeating polyamide film is likely to be organically polluted in the water treatment process, and consequently the treatment efficiency of a forward-permeating process is reduced. The method for preparing the anti-pollution forward-permeating polyamide composite film through aftertreatment comprises the steps that 1, coupling of dopamine hydrochloride, 2-bromobutyl bromide and triethylamine is completed in dimethylformamide, and a coupling solution is obtained; 2, the surface of an active layer on the surface of a forward-permeating polyamide composite film is grafted with an initiator; 3, zwitter-ion polymers are grafted, and the anti-pollution forward-permeating polyamide composite film is obtained. The method has the advantages that the anti-pollution performance is greatly improved, and the water passing performance and selectivity on salt of the composite film can be kept. The method can be used for modifying treatment of the forward-permeating polyamide composite film.

Owner:HARBIN INST OF TECH

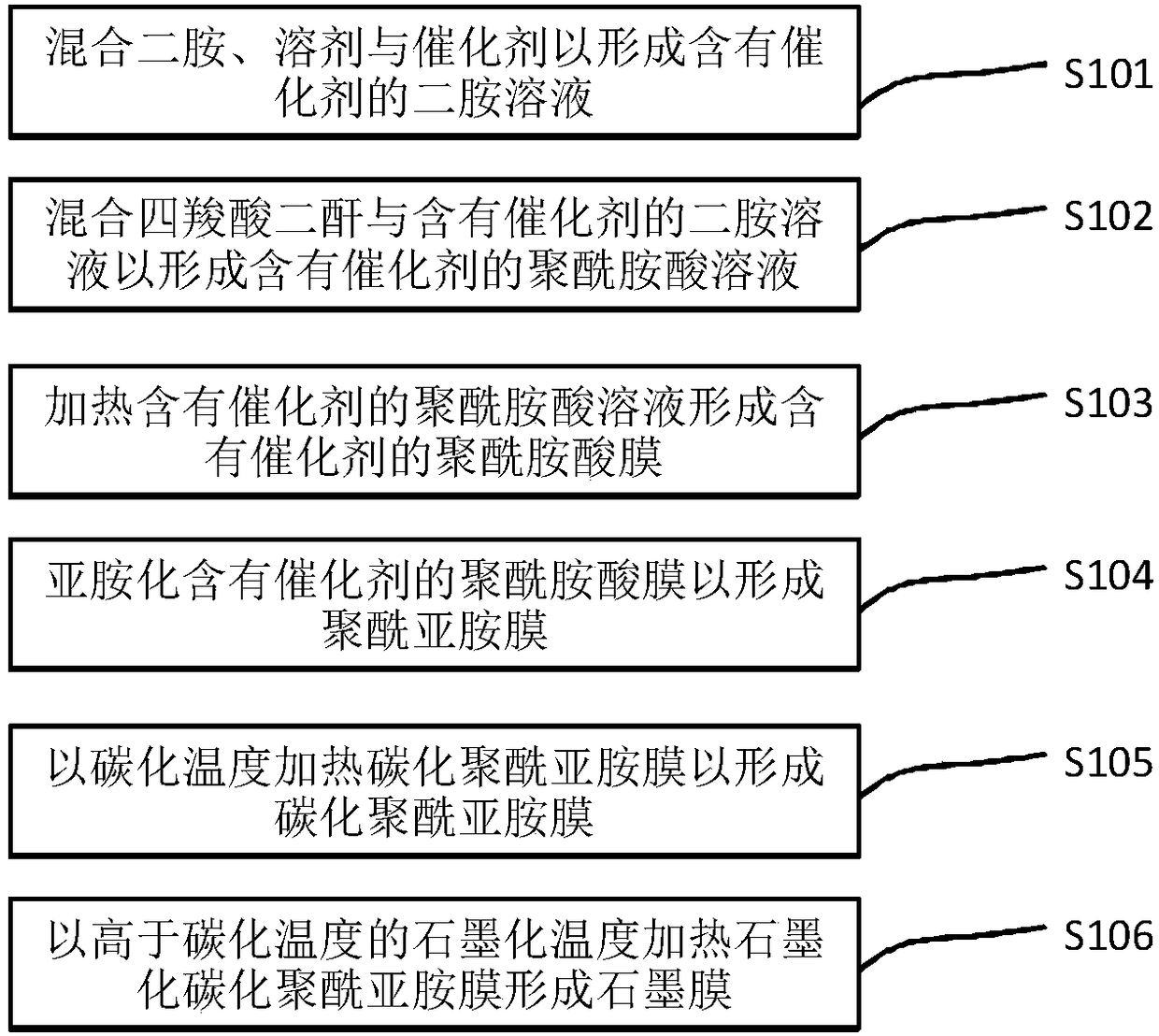

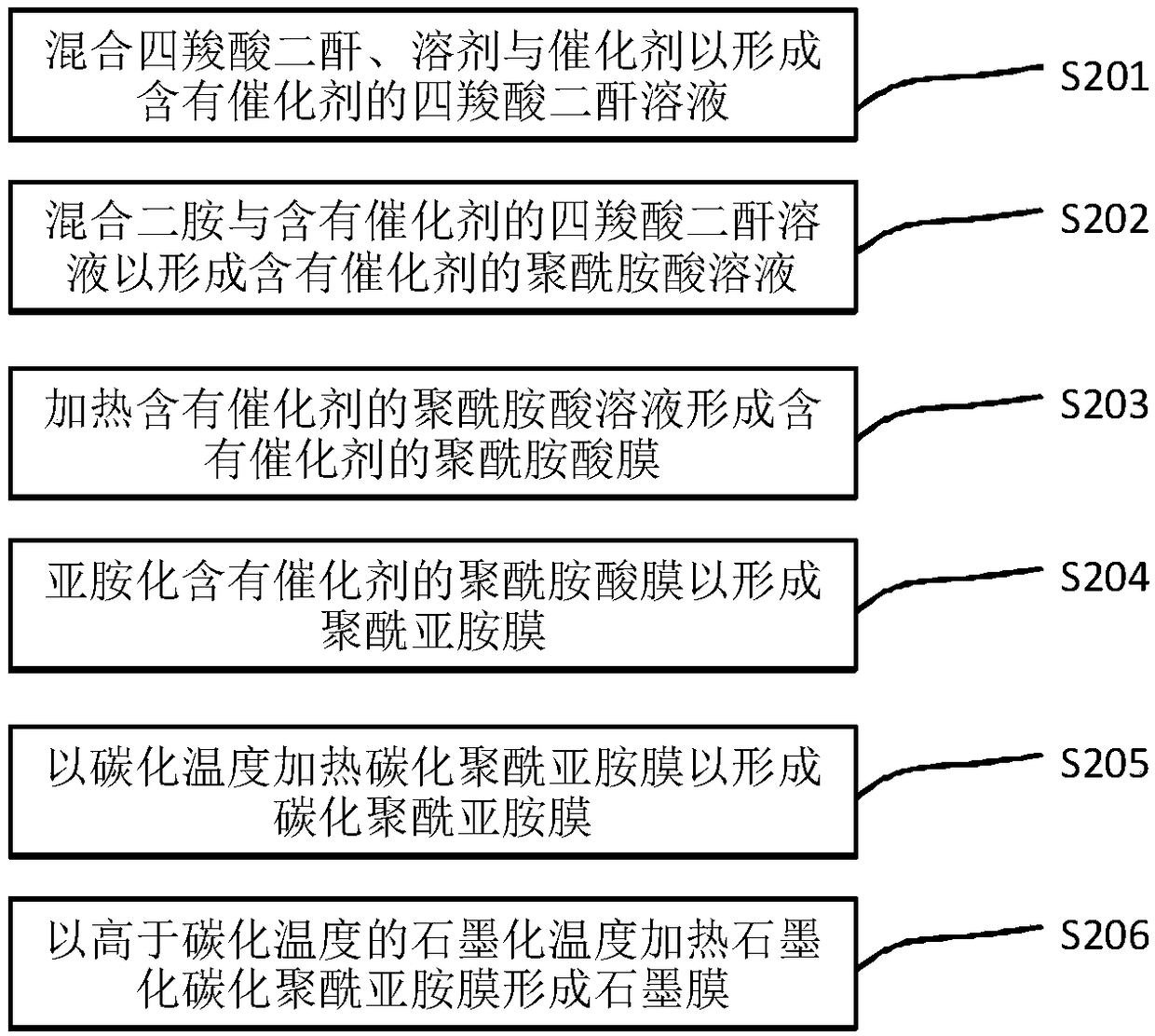

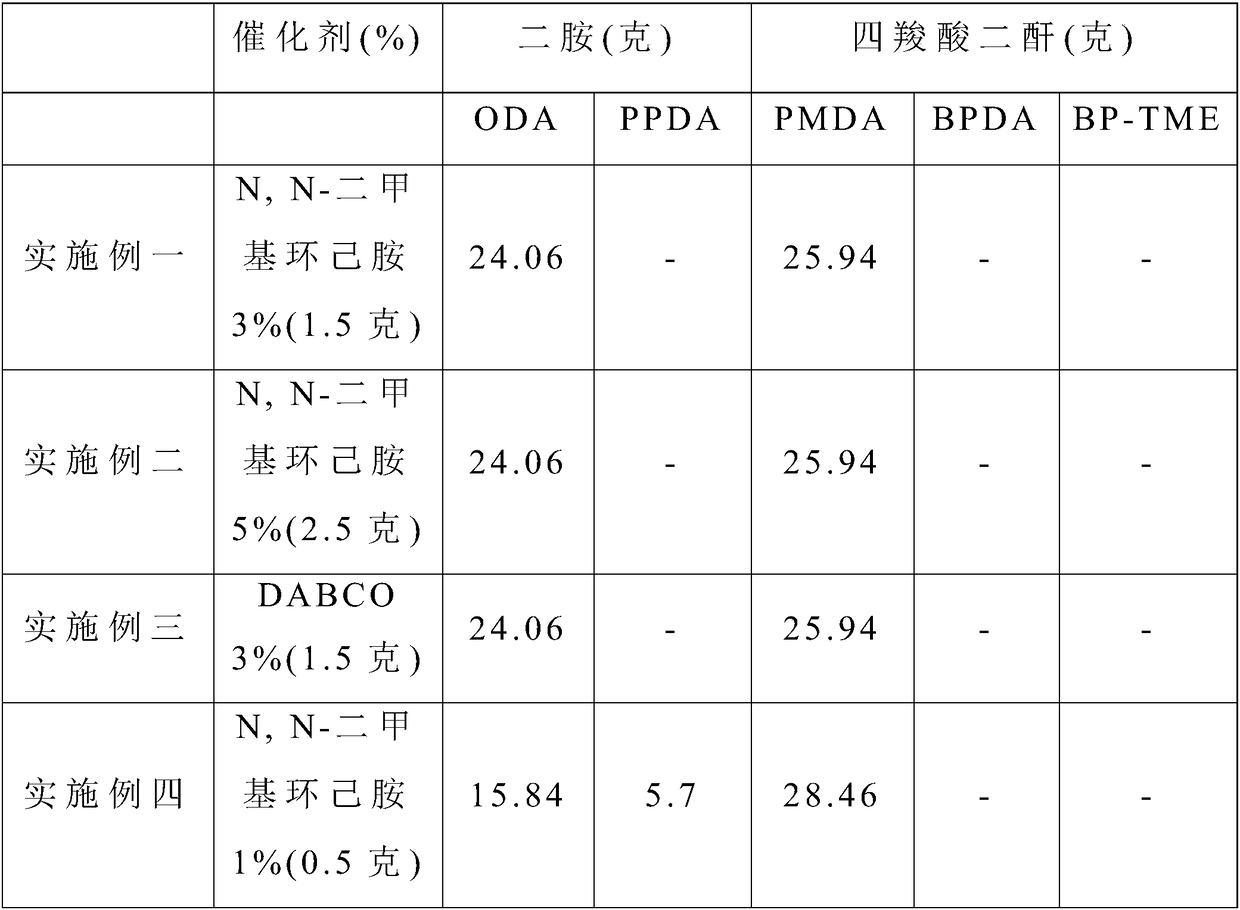

Manufacturing method of polyimide film and manufacturing method of graphite film using the same

InactiveCN108148201AFast heat conductionSolve the problem of insufficient thermal conductivityCarbon compoundsPolyamic acidGraphite

The present invention discloses a method for producing a graphite film by using a method for producing a polyimide film. According to the method, firstly, a diamine, a solvent and a catalyst are mixedup to form a diamine solution containing a catalyst. Next, a tetracarboxylic dianhydride and a catalyst-containing diamine solution are mixed to form a catalyst-containing polyamic acid solution. Next, the polyamic acid solution containing a catalyst is heated to form a polyamic acid film containing a catalyst. Next, a polyamic acid film containing a catalyst is imidized to form a polyimide film.Finally, the polyimide film is heated to form a graphite film. The step of imidizing the polyamic acid film containing the catalyst to form a polyimide film is catalyzed by a catalyst, and the catalyst is a tertiary amine.

Owner:MORTECH CORP

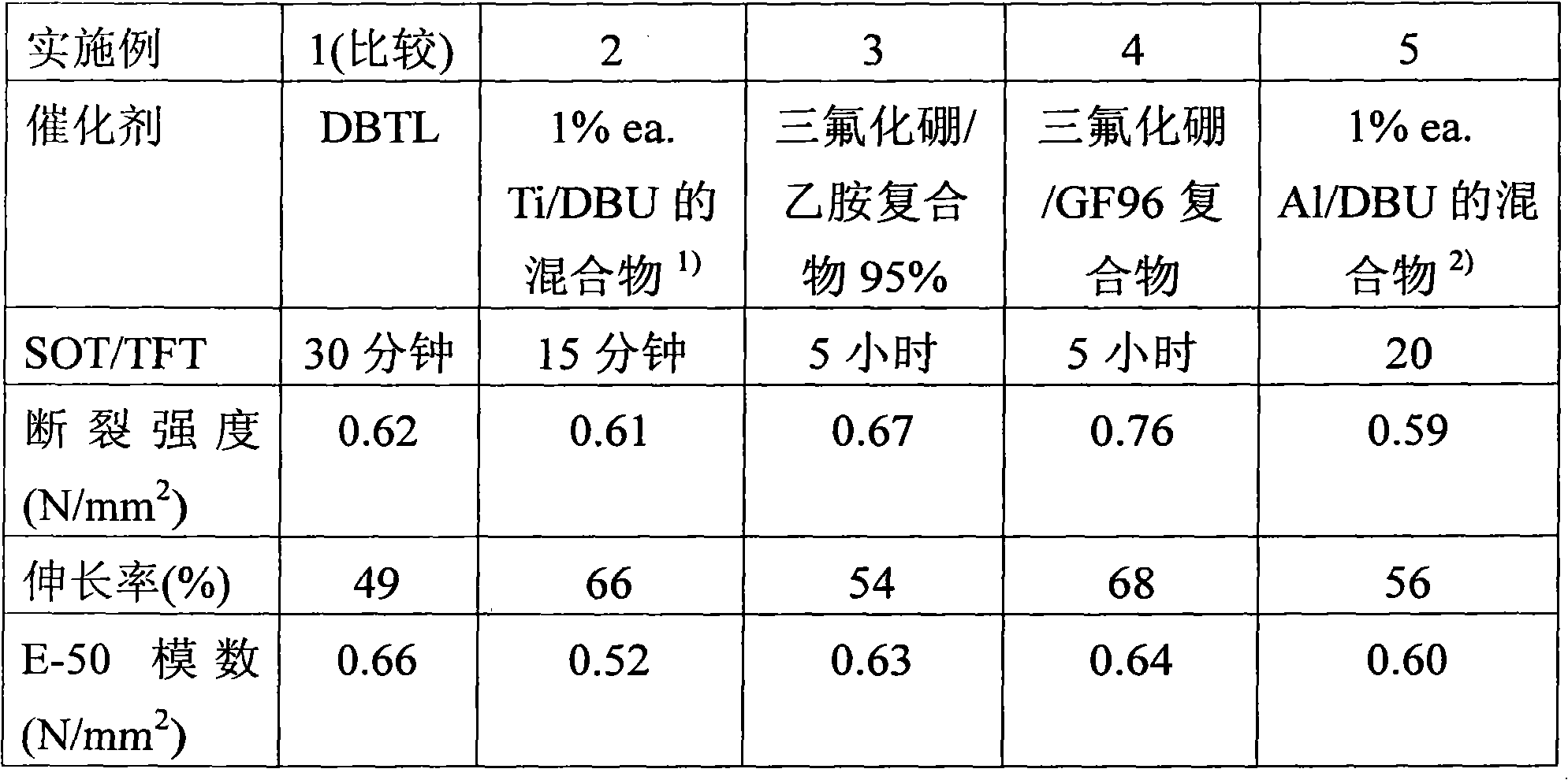

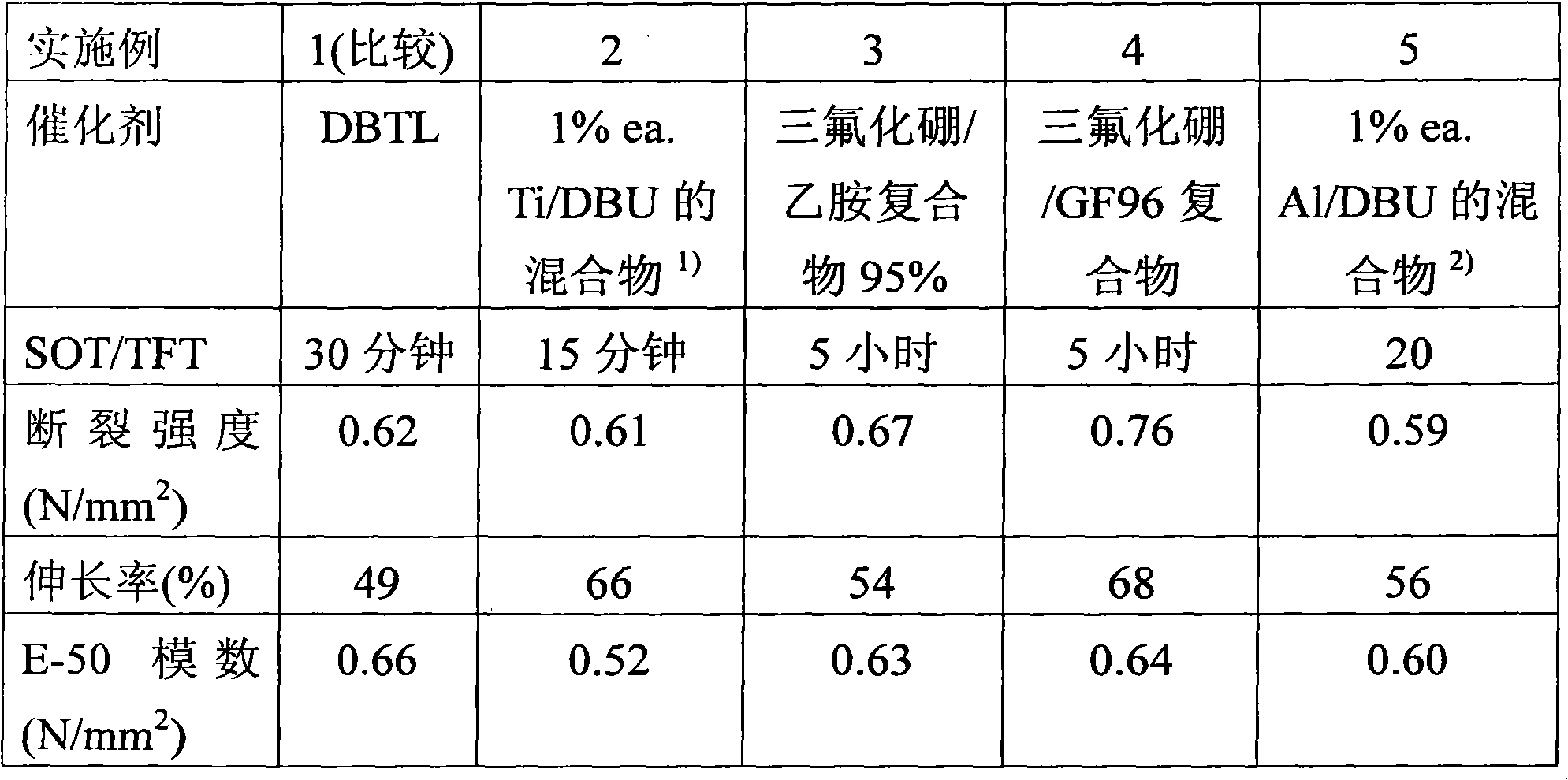

Hardenable compositions based on silylated polyurethanes

InactiveCN102037039AIncrease the degree of cross-linkingFast crosslinkingPolyureas/polyurethane adhesivesIndiumSilylene

The invention relates to a method for producing cross-linkable formulations. In a first step of the method, at least one alpha, omega-difunctional organic polymer of formula (1) X-A-X (1) is converted into organyloxysilyl-terminated polymers P1, using organofunctional silanes of formula (2) Y-R-Si-(R1)m(-OR2)3-m (2) in the presence of catalysts (A) selected from the group consisting of potassium,iron, indium, zinc, bismuth and copper compounds. In said formulae, R is a bivalent, optionally substituted hydrocarbon group which comprises between 1 and 12 carbon atoms and can be interrupted withheteroatoms, R1 and R2 are the same or different, monovalent, optionally substituted hydrocarbon groups which comprise between 1 and 12 carbon atoms and can be interrupted with heteroatoms, A is a bivalent, optionally substituted hydrocarbon group which comprises at least 6 carbon atoms and can be interrupted with heteroatoms, m is equal to 0, 1 or 2, X is a hydroxyl group, and Y is an isocyanategroup, or X is an isocyanate group and Y is a hydroxyl group or a primary or secondary amino group. In a second step, the polymers P1 obtained in the first step are mixed with a silane condensation catalyst (B) selected from the group consisting of compounds of elements of the third main group and / or fourth secondary group and heterocyclic organic amines, amine complexes of the element compounds,or the mixtures thereof. Optionally, said mixture is mixed with other substances (C). The formulations do not contain organic tin compounds, and are suitable for using as adhesives, sealants or coating agents.

Owner:HENKEL KGAA

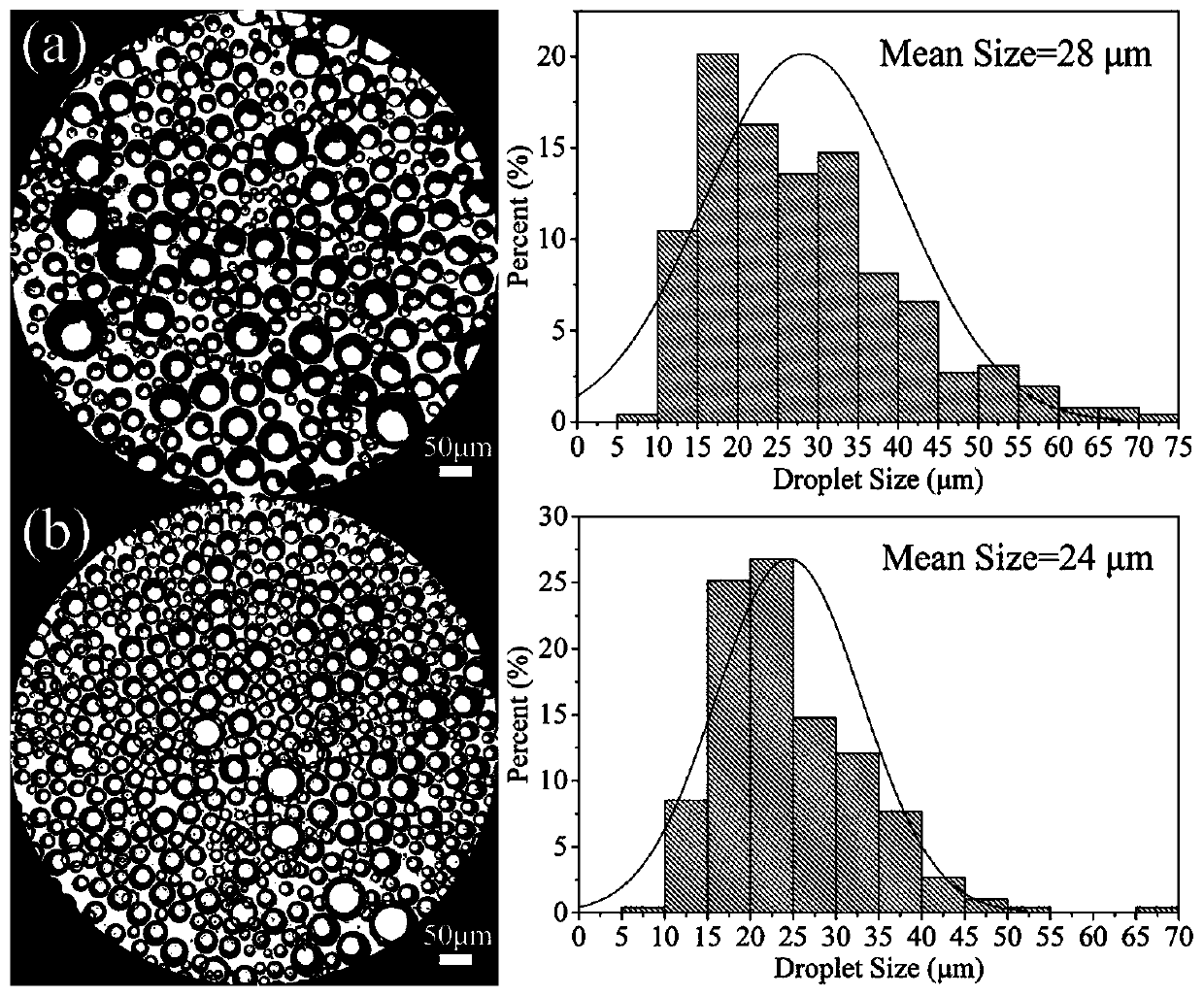

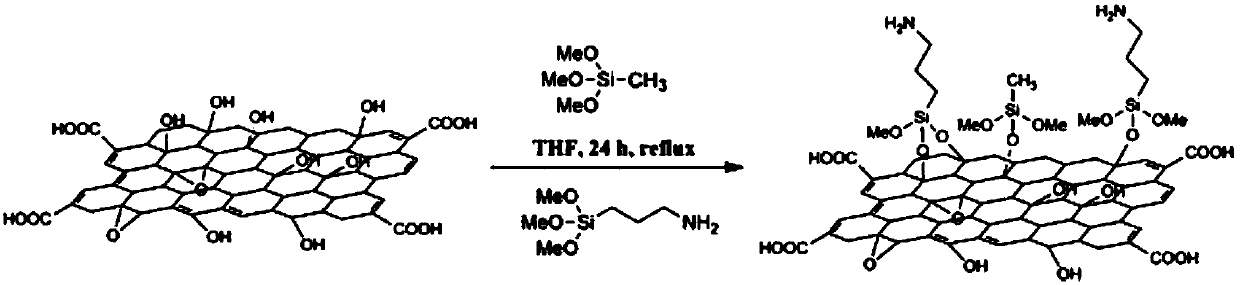

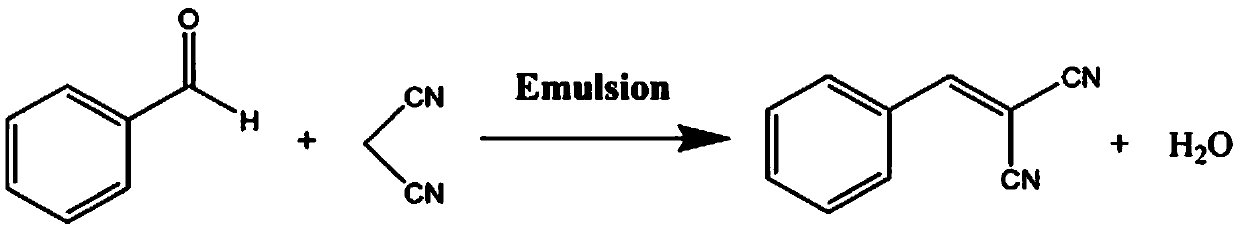

Preparation method of bifunctional Pickering emulsion catalyst

PendingCN111195528AHigh catalytic activityRegulating lipophilicity and hydrophobicityCarboxylic acid nitrile preparationOrganic compound preparationPolymer sciencePtru catalyst

The invention belongs to the field of chemical engineering, and relates to a preparation method of a bifunctional Pickering emulsion catalyst, which comprises the following steps of: carrying out ultrasonic treatment and mechanical stirring on a bifunctional graphene oxide material, benzaldehyde and water to prepare the bifunctional Pickering emulsion catalyst. The bifunctional graphene oxide (GO-NH2-Si) is prepared by simultaneously modifying graphene oxide (GO) by utilizing 3-aminopropyltrimethoxysilane (APTMS) and 3-methyltrimethoxysilane (MTMS). The preparation method of the Pickering emulsion catalyst is simple, the preparation cost is low, the catalytic activity is high, and compared with an emulsion catalyst prepared by only utilizing APTMS modified GO (GO-NH2) in the prior art, theconversion rate of benzaldehyde is increased by about 24% in a Knoevenagel reaction.

Owner:CHANGZHOU UNIV

Preparation method for perfluorohexyl acetate

InactiveCN104844446AHigh yieldLess amount of catalystOrganic compound preparationCarboxylic acid salt preparationReaction temperatureSolvent

The invention discloses a preparation method for perfluorohexyl acetate. The method includes the steps of: (a) reacting perfluorohexyl ethanol, a catalyst and an oxidant in a mole ratio of 1:0.01-0.2:1-5 in a solvent at 50-80DEG C for 10-24h, at the end of reaction, conducting standing layering to obtain an upper layer organic phase and a lower layer aqueous phase, and subjecting the organic phase to solvent separation to obtain a white solid; and (b) adding the white solid obtained in step (a) into deionized water, conducting neutralizing with an alkali solution to a PH value of 8-9, carrying out cooling and filtering to obtain a filter cake, and subjecting the filter cake to washing, recrystallization and drying so as to obtain the product. The method provided by the invention has the advantages of simple process, high yield, safety and environmental protection, low cost, and easy realization of industrial production.

Owner:JUHUA GROUP TECH CENT +1

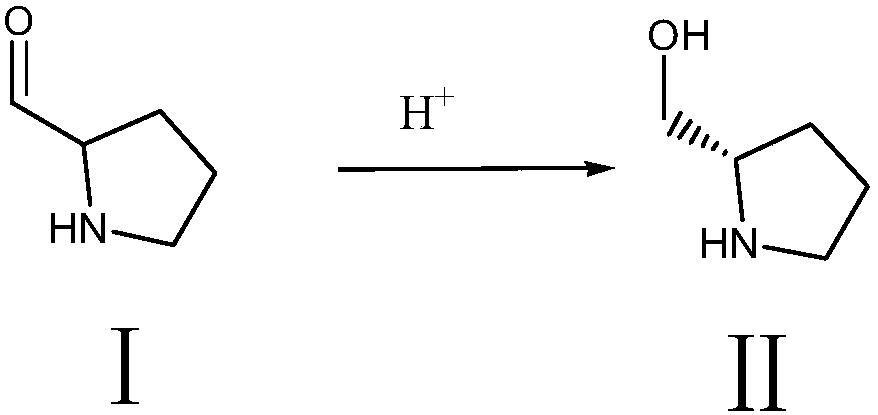

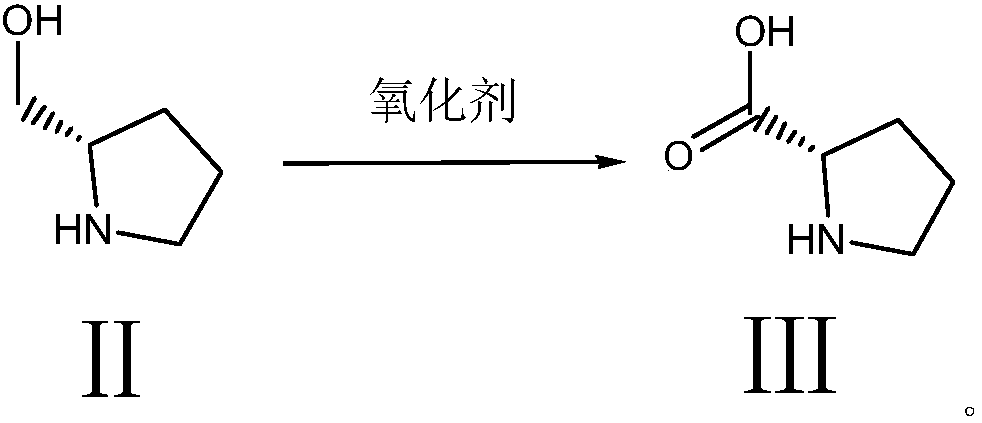

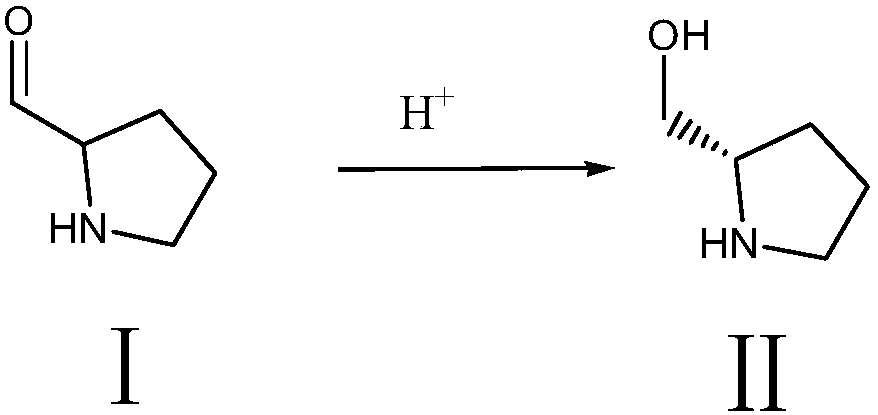

Method for synthesizing D-proline

The invention belongs to the technical field of synthesis of chiral organic compounds, and especially relates to a method for synthesizing D-proline. The method comprises the following steps: taking pyrrolidine-2-carbaldehyde, dissolving the pyrrolidine-2-carbaldehyde in an organic solvent, adding a catalyst and an organic alkali potassium t-butoxide, and carrying out an asymmetric catalysis hydrogenation reaction to obtain an intermediate II; and carrying out an oxidation reaction on the intermediate II and an oxidant to obtain the product D-proline III. The method for synthesizing D-prolinehas the following advantages: the use amount of the catalyst is small, and the catalyst can be used repeatedly, so the cost is saved; the solvent used in the synthesis process is a common solvent, sothe method has the characteristics of low cost, non-toxicity, no pollution, greenness and environmental protection; and the synthesis method has a simple process, the yield in the invention is higherthan the yield in the prior art, and the optical purity of the obtained product is high, so the method is suitable for industrial production.

Owner:NANJING REDWOOD FINE CHEM CO LTD

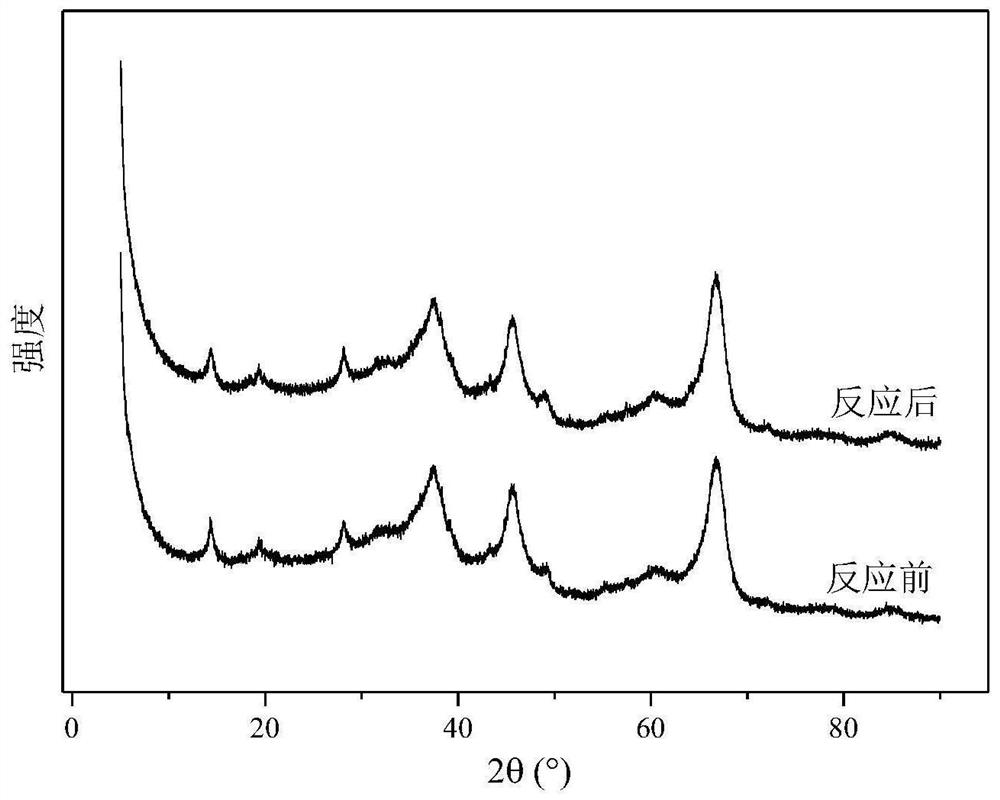

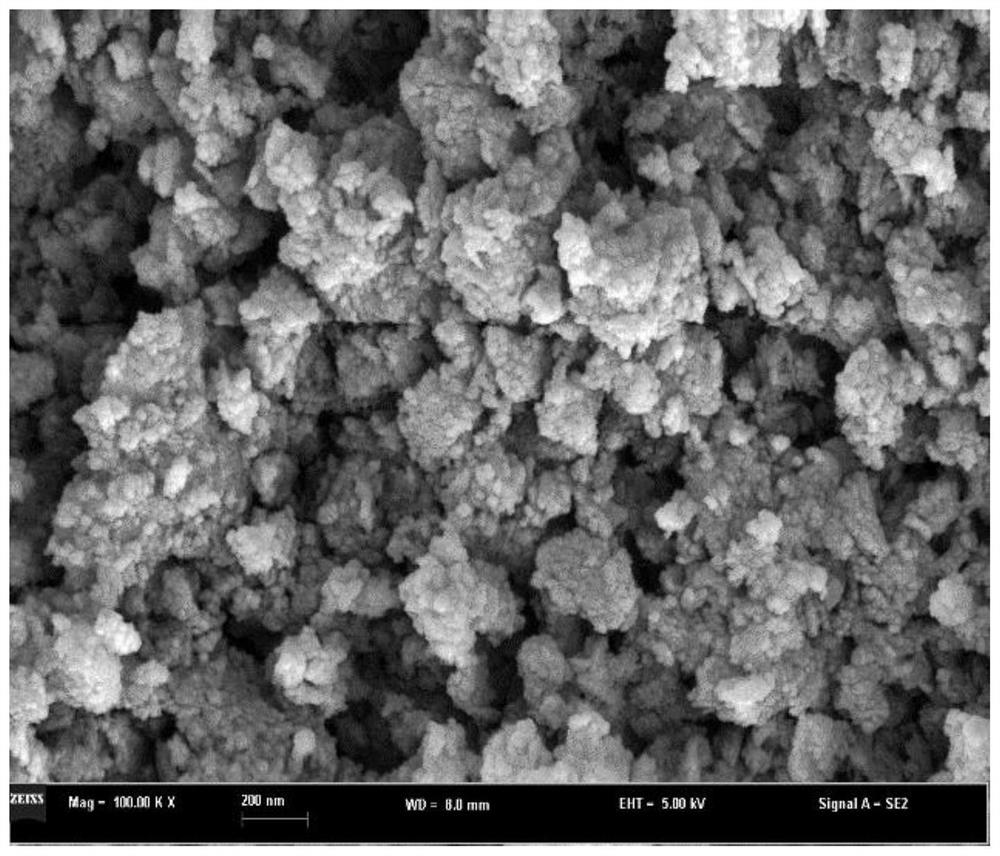

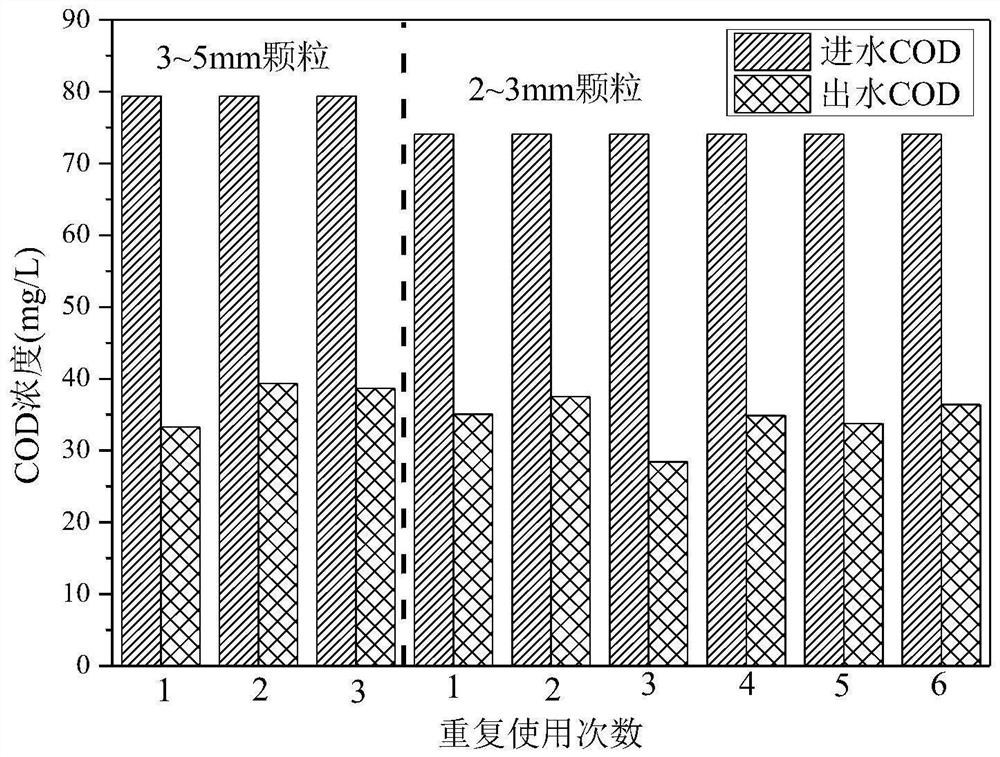

Porous material loaded multi-metal composite Fenton-like catalyst and preparation method and application thereof

PendingCN114011416AContinuous stable catalysisLarge specific surface areaMolecular sieve catalystsWater treatment compoundsPtru catalystHydroxyl radical

The invention relates to the technical field of composite Fenton-like catalysts, in particular to a porous material loaded multi-metal composite Fenton-like catalyst and a preparation method and application thereof. The porous material loaded multi-metal composite Fenton-like catalyst comprises a porous material and metal oxide loaded on the porous material, and the metal oxide comprises ferric oxide and at least one transition metal oxide; in the metal oxide, the molar percentage of ferric oxide is 50%-80%. The porous material loaded multi-metal composite Fenton-like catalyst has a relatively high specific surface area through the structural characteristics of the porous material, so that more effective catalytic reaction contact surfaces are exposed, and more adsorption sites and catalytic active sites are provided; iron ions released by the catalyst can synergistically participate and promote double oxidation to generate hydroxyl radicals, so that the reaction process is accelerated; the amount of hydrogen peroxide and the amount of the catalyst needed to be added in the reaction process are small, and the catalyst can continuously and stably play a catalytic role.

Owner:HUBEI JUNJI WATER TREATMENT

Synthetic method of L-nicotine with optical activity

PendingCN113896713AHigh optical purityImprove efficiencyOrganic chemistry methodsPtru catalystSilica gel

L-nicotine with optical activity is synthesized by adopting a one-pot method, an intermediate-L-nornicotine with optical activity is obtained from myosmine in a reduction system with hydrogen as a reducing agent and a chiral ligand / iridium metal catalyst, L-nornicotine is not subjected to post-treatment and is subjected to an aminomethylation reaction through a pyrrole ring, alkali is added into a product to adjust the pH value to 12-13.5, extracting is conducted with an organic solvent, separating, drying and concentrating are conducted to obtain a crude product, and silica gel column chromatography is conducted to obtain a high-purity product, namely the final product, namely the L-nicotine. According to the method, asymmetric hydrogenation of the myosmine is a key step of the method, the asymmetric hydrogenation reaction is catalyzed by an iridium-phosphorus oxazoline catalyst, the key intermediate L-nornicotine can be obtained at a high ee value, and the target product L-nicotine is obtained through an aminomethylation reaction and a one-pot method without subsequent purification treatment. According to the present invention, the method has advantages of low cost, stable operation and high purity.

Owner:云南萃精生物科技有限责任公司

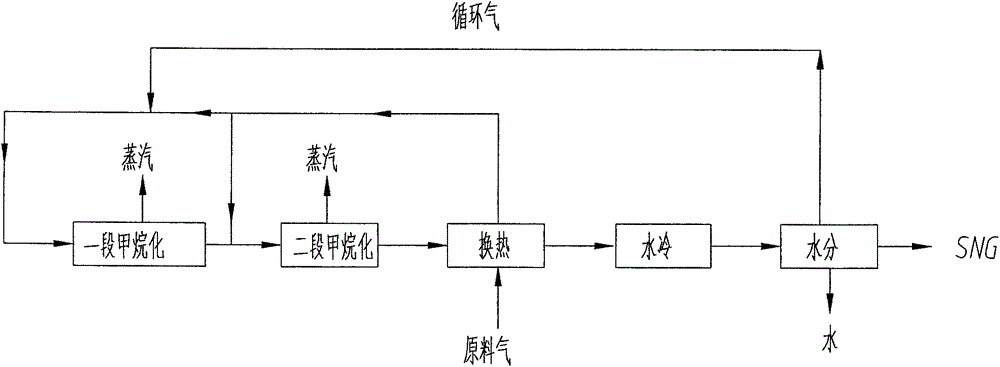

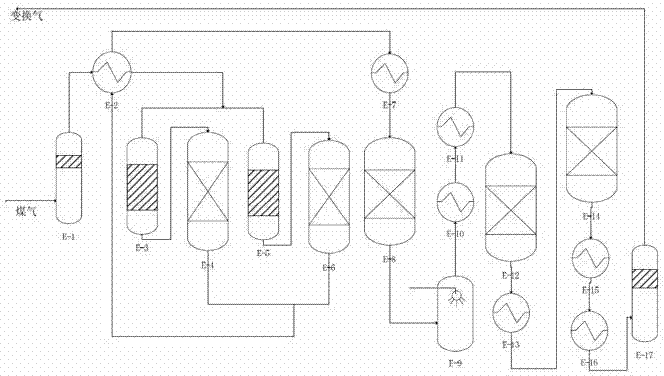

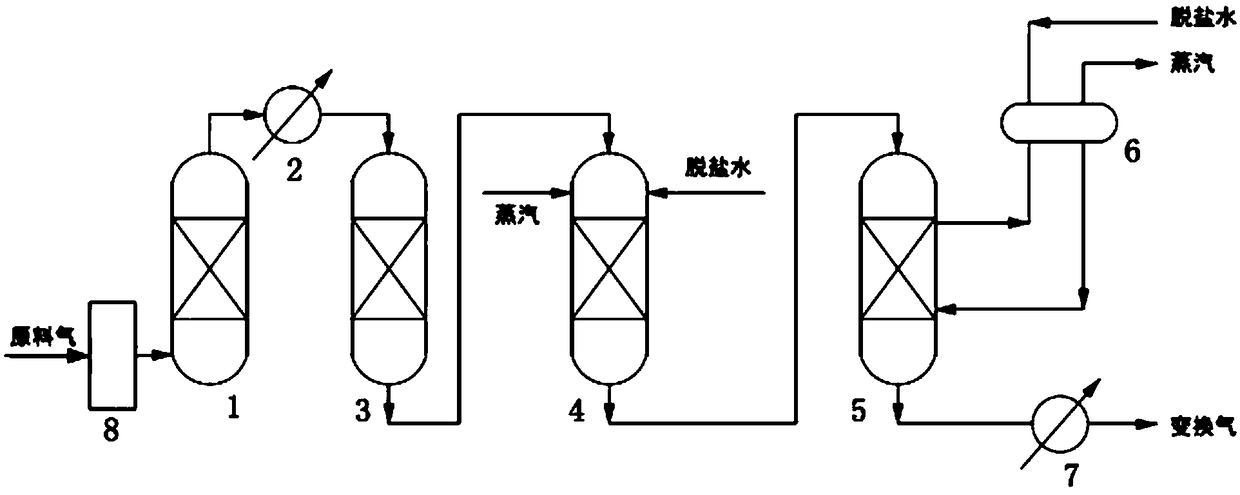

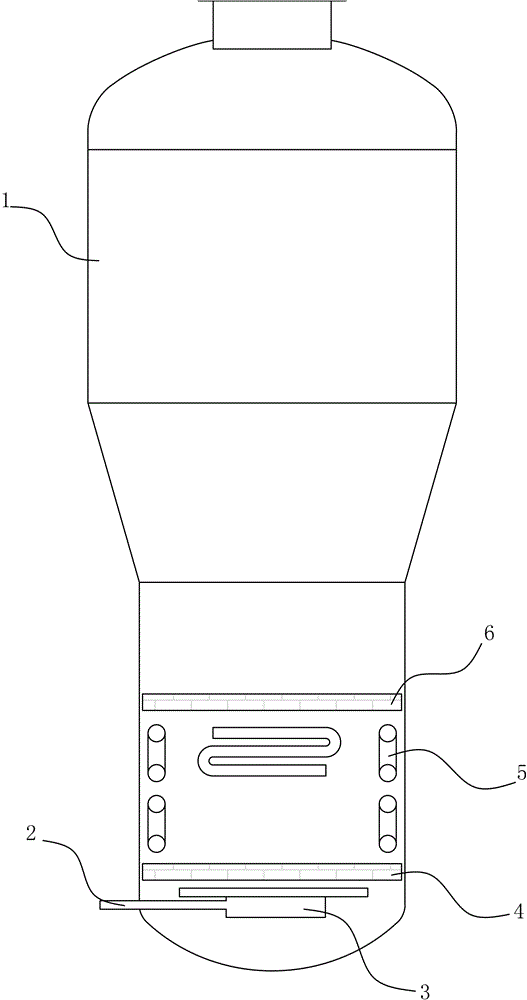

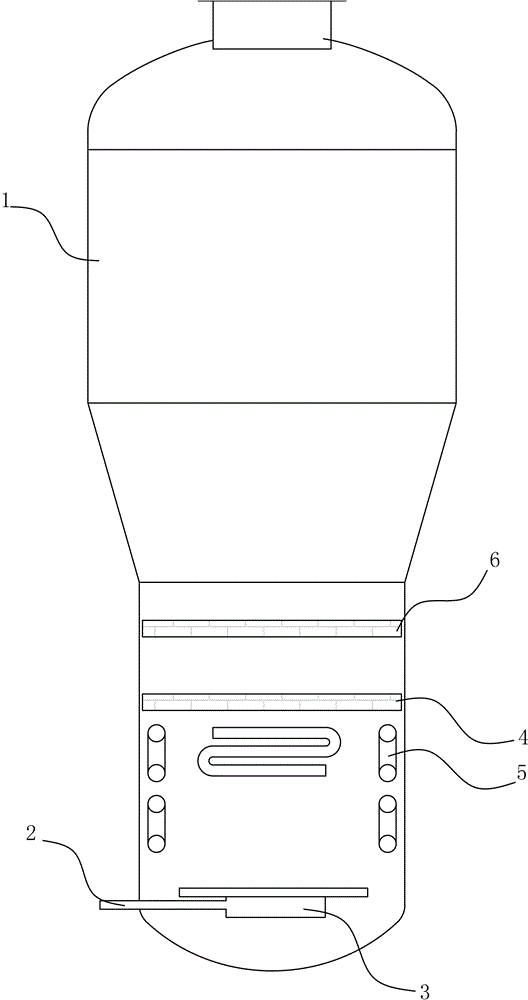

Methanation method and device for preparation of synthetic natural gas

The invention discloses a methanation method and device for preparation of synthetic natural gas. The method comprises that raw material gas subjected to catalyst poison purification removal enters into a first methanation reactor and undergoes a methanation reaction with most of H2 and CO, and the reaction gas enters into a second methanation reactor and undergoes a methanation reaction with the rest of H2 and CO so that dry gas subjected to methanation has CH4 content greater than 93% and a calorific value greater than 33MJ / M<3>. The invention also discloses a device for implementation of the method. The high-efficiency energy-saving compact large-scale natural gas methanation preparation technology and device are especially suitable for the conditions that many ammonia synthesis factories need coal gasification and purification low pressure apparatuses and ammonia synthesis middle / high pressure apparatuses. Middle and small scale ammonia synthesis factory high-pressure compressor and high-pressure synthesis device in China can be transformed into an artificial natural gas synthesis device so that a large amount of investment is saved. The technology and device have important effects.

Owner:杭州林达化工技术工程有限公司

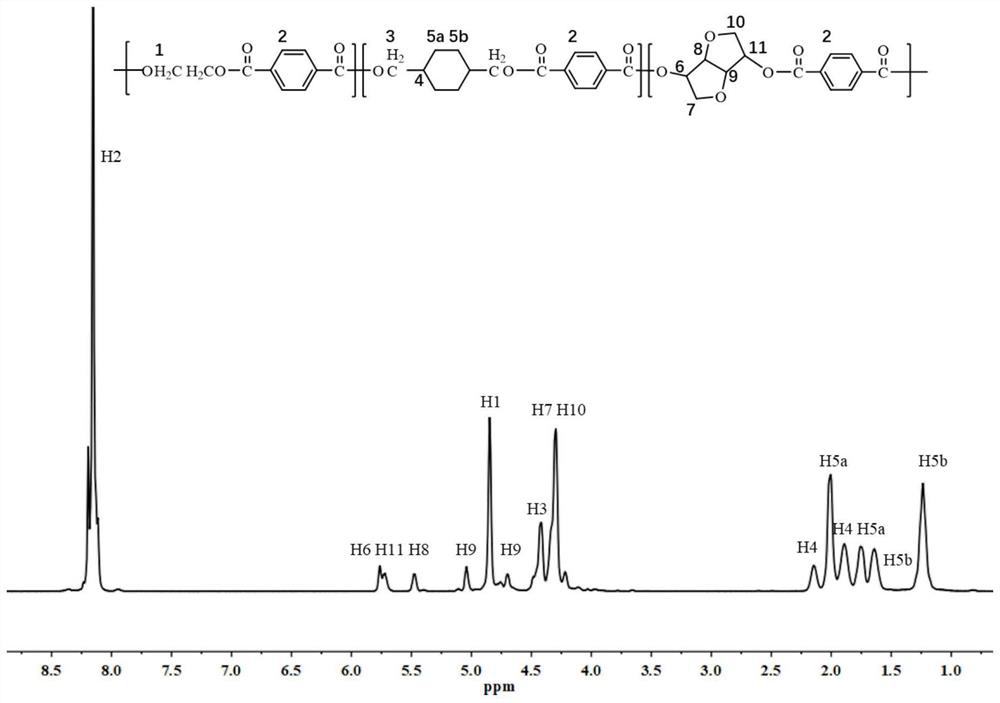

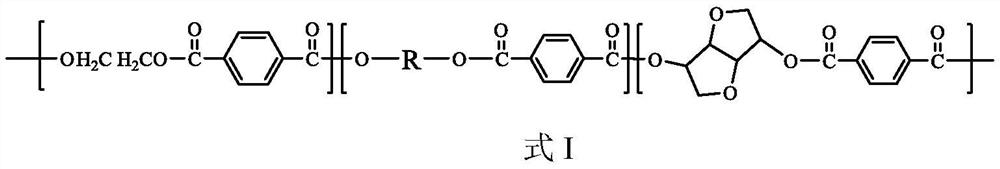

1, 4; 3, 6-diglycidyl hexanehexol modified PET polyester and semi-continuous preparation method thereof

The invention discloses a 1,4; 3, 6-diglycidyl hexanehexol modified PET polyester and a semi-continuous preparation method thereof, and monomers of the modified PET polyester comprise (a) terephthalic acid, (b) ethylene glycol, and (c) 1, 4; 3, 6-dihexanediol or mixtures thereof, and (d) aliphatic and / or alicyclic dihydric alcohol. The method comprises the following steps: preparing a certain amount of terephthalic acid glycol ester in a first esterification kettle, then continuously adding mixed terephthalic acid and glycol slurry into the first esterification kettle at a certain flow rate for reaction, and intermittently discharging reaction products into a second esterification kettle, and adding the modified monomer / ester exchange catalyst into the second esterification kettle for esterification / ester exchange reaction to obtain a prepolymer, discharging all the prepolymer into a polycondensation kettle, adding a polycondensation catalyst, and carrying out melt polycondensation to obtain a final polymer. The method provided by the invention overcomes the problems of low reaction activity, low conversion rate and high production cost of bio-based monomers, avoids the problem of metal residues, and is beneficial to realization of industrial production.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Process for gas phase reactions

ActiveCN1989092BLow costLess amount of catalystOrganic compound preparationHydroxy compound preparationPtru catalystFluid phase

Owner:JOHNSON MATTHEY DAVY TECH LTD

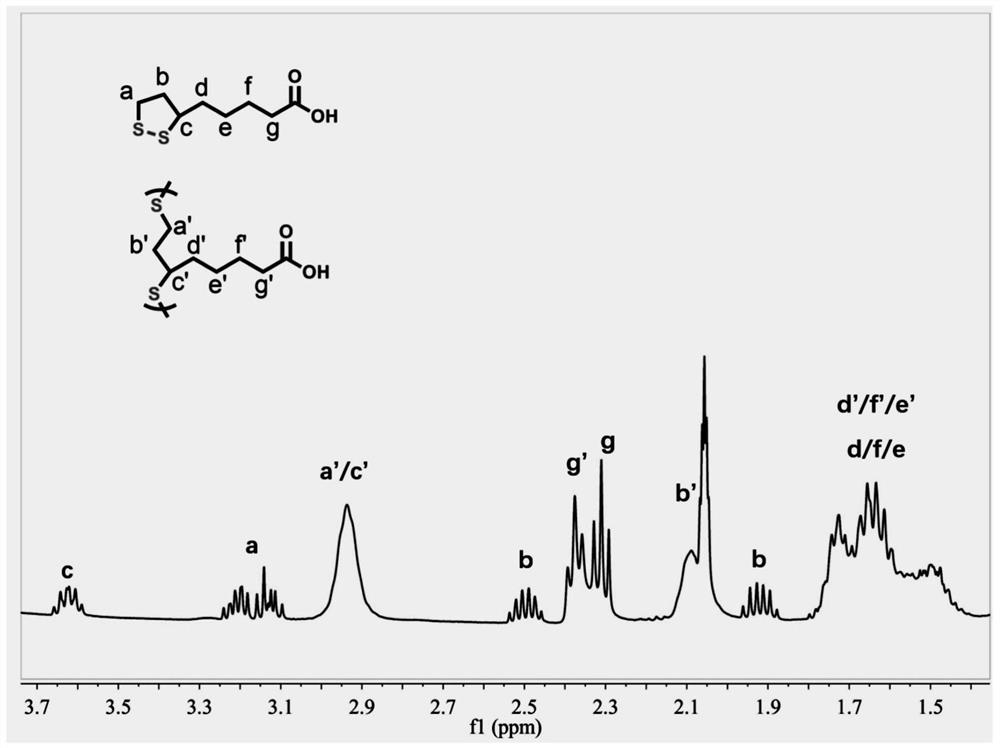

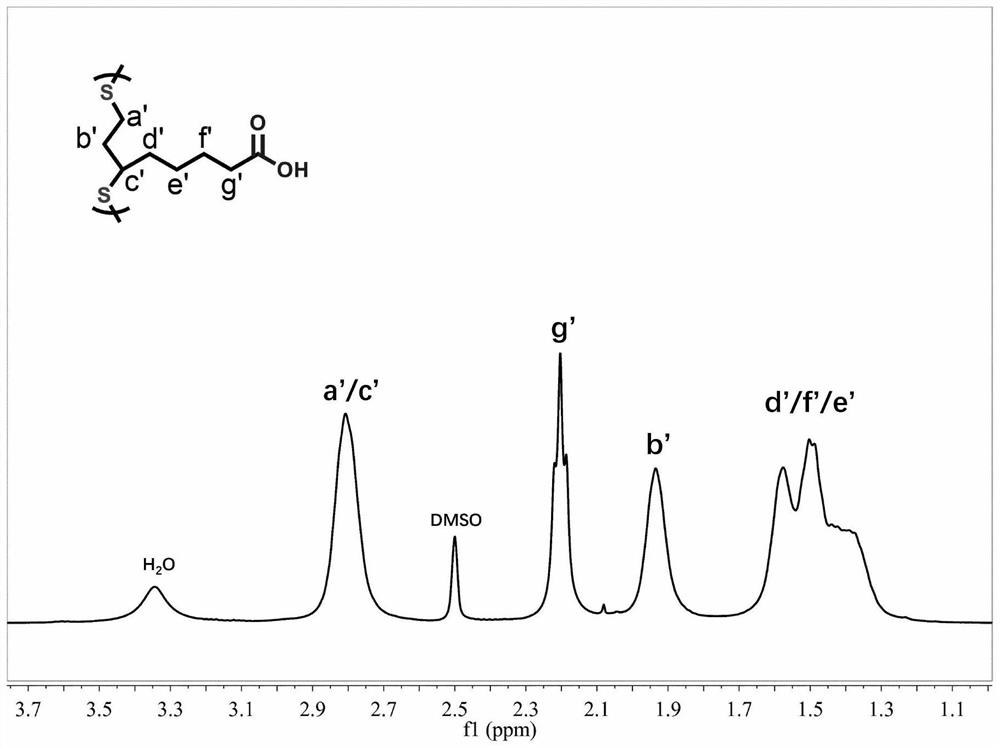

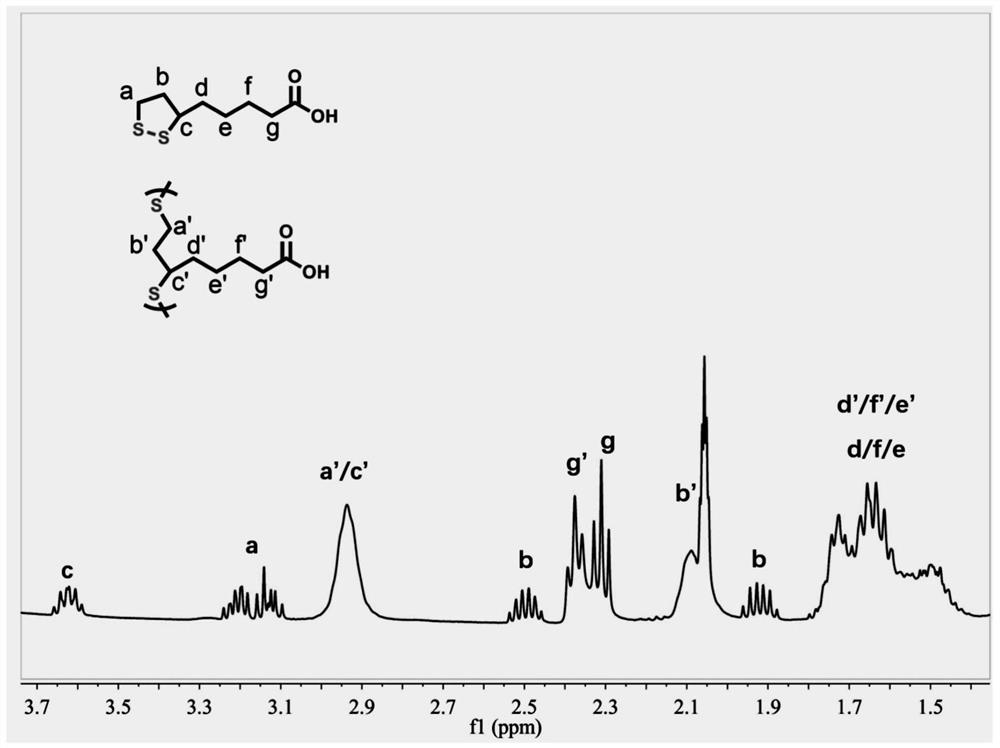

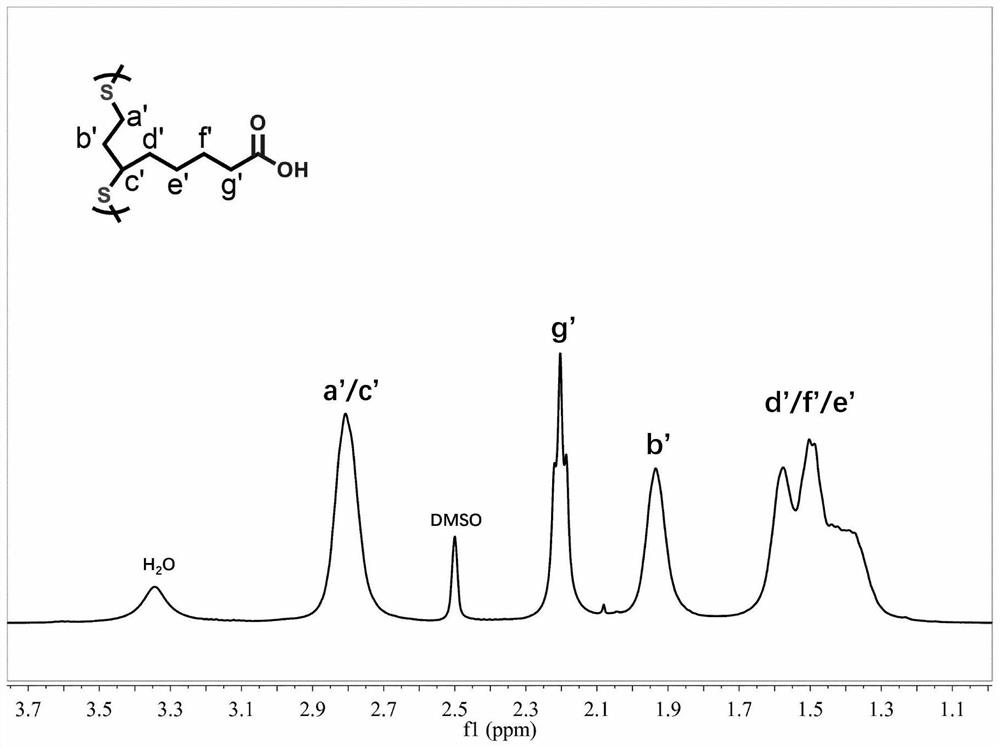

Preparation method of polymer of lipoic acid compound

ActiveCN113214482AFast and efficient ring-opening polymerizationMild reaction conditionsOrganic solventCatalytic method

The invention discloses a preparation method of a polymer of a lipoic acid compound. The preparation method is selected from a solvent-free direct hot-melting catalytic polymerization method or a room-temperature solution catalytic polymerization method. The catalyst used in the method is wide in source, easy to prepare and low in price, catalysis methods are diversified, the process is simple, metal ions are not contained, efficient catalysis can be achieved only through a trace amount of catalyst, and practical industrial feasibility is achieved; catalytic polymerization can be carried out under the condition that no solvent is directly heated and melted, and catalytic polymerization can also be carried out in a solution under the room temperature condition; the direct hot melting catalysis method does not need any organic solvent, has the advantages of rapid catalysis process, mild conditions, simple and safe operation, high atom utilization rate and no three wastes, and meets the green chemical requirements; according to the room-temperature solution catalysis method, heating and complex conditions are not needed, and efficient catalytic polymerization under the room-temperature condition can be achieved by adding a trace amount of catalyst into a monomer solution.

Owner:EAST CHINA UNIV OF SCI & TECH

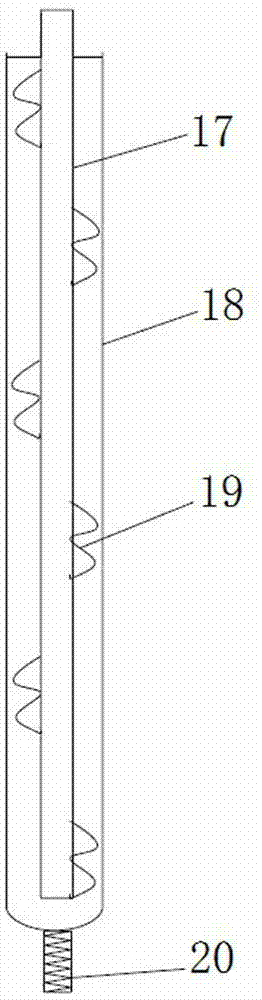

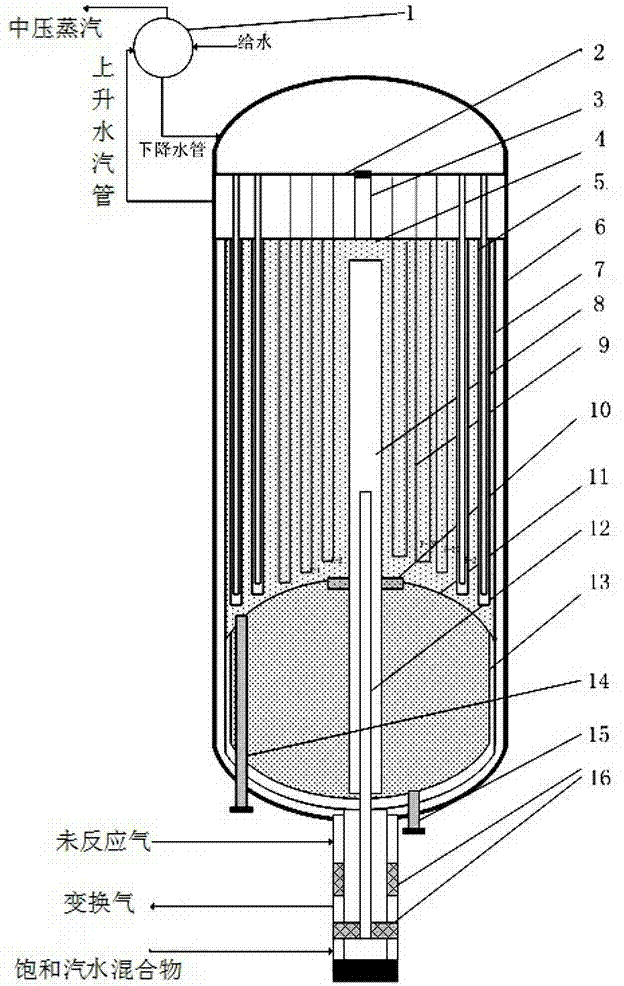

High-CO high-conversion-rate isothermal shift reactor

ActiveCN103435006BStable temperatureReduce the temperatureHydrogenEnergy inputNuclear engineeringSpray nozzle

An isothermal carbon monoxide (CO) shift reactor having high CO conversion and the process technology comprises the outside pressure vessel; the catalyst unit; tipper and lower tube sheets welded with water tubes and bottom tee joints; the said outside pressure vessel has seal heads at the upper and lower ends; the said vessel has a water chamber and a steam chamber at the upper section. The catalyst unit comprises the upper catalyst bed with water tubes. There is a central pipe that is located in the said vessel, of which the upper end is located in the upper catalyst bed while the lower end is located in the lower catalyst bed; the said bottom tee joint has an inlet for feed gas, outlet for reacted shift gas and inlet for steam-water mixture; the said central pipe is installed with spray nozzle for steam-water mixture; the said reactor is applicable for process technologies for feed and effluent gas having different CO contents. Low temperature, high CO feed content, high shift conversion and low system pressure drop are direct results of this disclosure.

Owner:HUNAN ANCHUN ADVANCED TECH

Method for preparing dichloroacetic acid by selective dechlorination of trichloroacetic acid

ActiveCN108658756AUniform concentrationSelective advantageOrganic compound preparationCarboxylic compound preparationGas phaseFixed bed

The invention discloses a method for preparing dichloroacetic acid by selective dechlorination of trichloroacetic acid. According to the method, a fixed bed catalytic reactor is adopted to convert thetrichloroacetic acid into the dichloroacetic acid with the conversion rate being greater than 99.5% and the selectivity being greater than 98%, and the balance comprises monochloroacetic acid and acetic acid. A catalyst is a precious metal catalyst supported by coal-based activated carbon; a trichloroacetic acid solution and hydrogen are preheated to reach the reaction temperature, enter from thetop of the reactor, and contact with the catalyst from top to bottom, and a hydrodechlorination reaction occurs; a gas replenishing port is disposed on the outer wall of the reactor; the hydrogen iscontinuously replenished during the reaction, so that the hydrogen concentration in the reactor is maintained at 10% to 40%; liquid phase and gas phase products produced are discharged from the bottomof the reactor; and the liquid phase products are distilled to obtain high-purity dichloroacetic acid products after condensation and gas-liquid separation.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

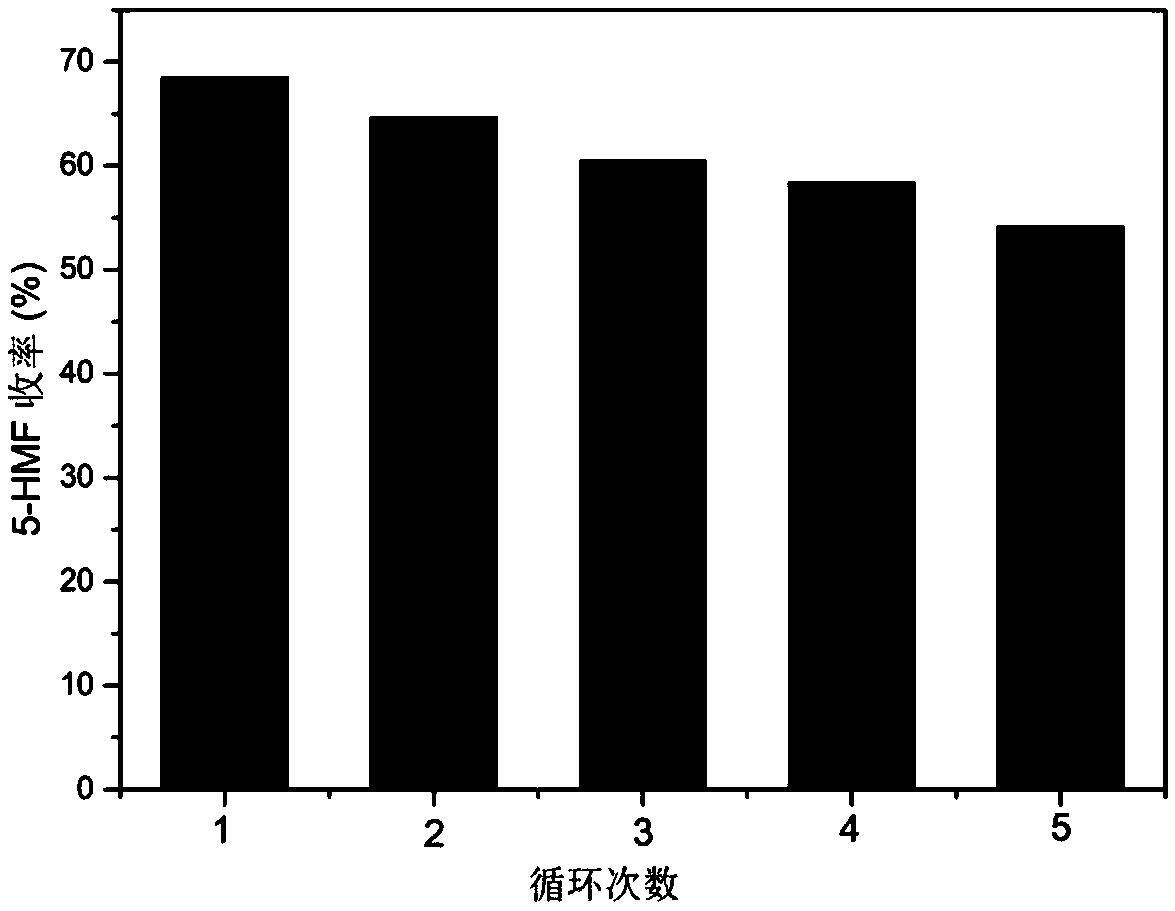

Method for synthesizing 5-hydroxymethylfurfural

InactiveCN109485622ALess amount of catalystReduce manufacturing costOrganic chemistryChemical recyclingRecyclable catalystFiber

The invention provides a method for synthesizing 5-hydroxymethylfurfural, and belongs to the technical field of 5-hydroxymethylfurfural preparation. The method comprises the following steps: adding cellobiose, dissolvent saturated saline solution, methyl isobutyl ketone and niobium modified montmorillonite catalyst into a pressure bottle reactor, reacting in a constant-temperature oil bath, and performing dehydration reaction at a certain temperature with a stirring device in the reactor; cooling the temperature of the mixture to room temperature after reaction is completed, performing suctionfiltration, standing and layering the filtrate, and putting 5-hydroxymethylfurfural in dissolvent; taking the solid catalyst obtained in suction filtration for reacting in next cycle. The method hasthe advantages of low cost, simplicity in operation, small corrosion on equipment, recyclable catalyst, and high product yield reaching more than 60 percent.

Owner:BEIJING UNIV OF CHEM TECH

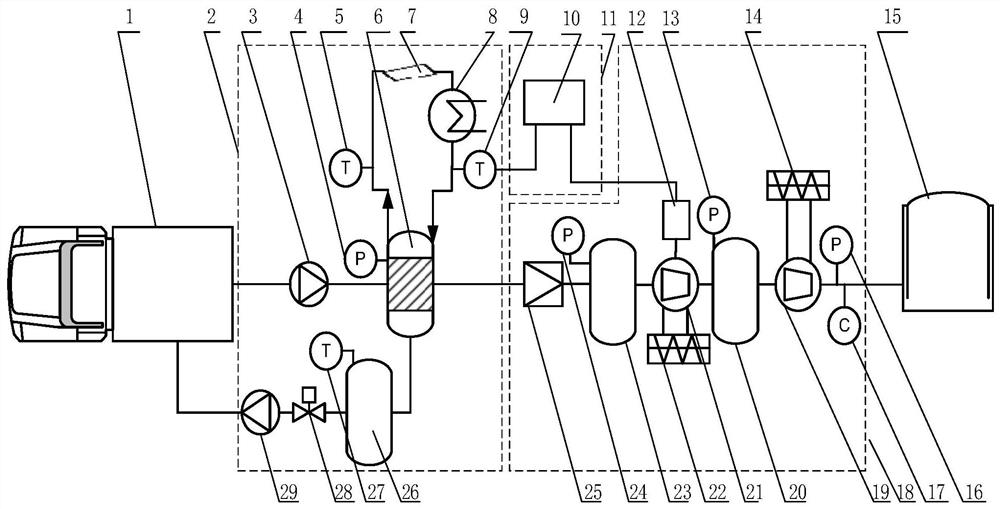

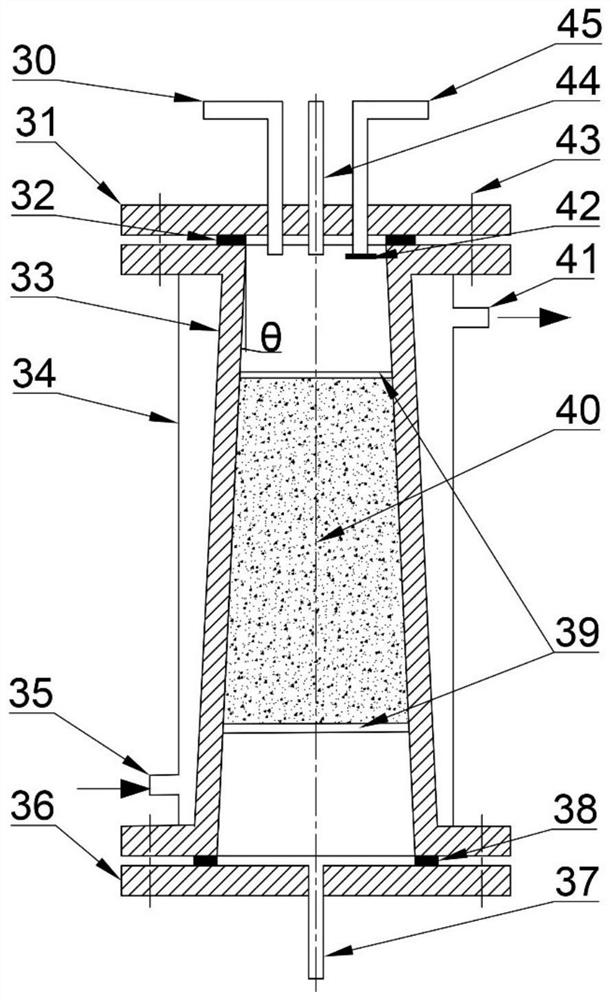

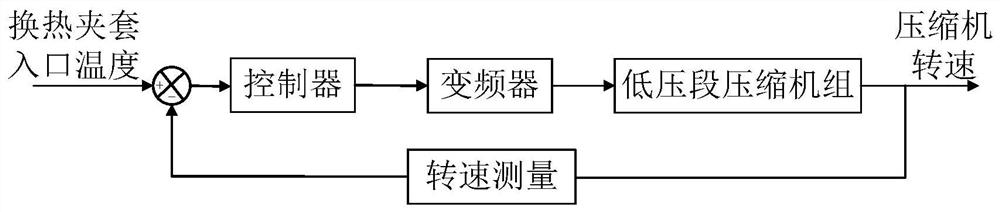

High-pressure gaseous hydrogen refueling station fuel supplementing device for hydrogen transportation of organic liquid hydrogen storage material

PendingCN112125278AExpanding Hydrogen SourcesAchieve convergenceHydrogen separation using solid contactPipeline systemsThermodynamicsHeat management

The invention discloses a high-pressure gaseous hydrogen refueling station fuel supplementing device for hydrogen transportation of an organic liquid hydrogen storage material, and belongs to the field of hydrogen energy storage and transportation. The high-pressure gaseous hydrogen refueling station fuel supplementing device comprises a hydrogen transport tanker, a hydrogen desorption module, a hydrogen pressurization module and a control module; a hydrogen-rich organic liquid hydrogen storage material in the hydrogen transport tanker releases low-pressure hydrogen through the hydrogen desorption module, and the low-pressure hydrogen is increased to the pressure of a high-pressure gaseous hydrogen refueling station through the hydrogen pressurization module and enters the high-pressure gaseous hydrogen refueling station; hydrogen can be provided for the high-pressure gaseous hydrogen refueling station through mutual cooperation of the hydrogen transportation tank car, the hydrogen desorption module, the hydrogen pressurization module and the control module. According to the device, connection between hydrogen transportation with an organic liquid hydrogen storage material and thehigh-pressure gaseous hydrogen refueling station is achieved, good heat management is provided for the desorption reactor, the purposes of high efficiency and energy conservation are achieved, hydrogen away from a hydrogen using place can be utilized in a centralized mode, the hydrogen source of the high-pressure gaseous hydrogen refueling station is expanded, and large-scale use and development of hydrogen energy are facilitated.

Owner:陕西集智氢源科技有限公司

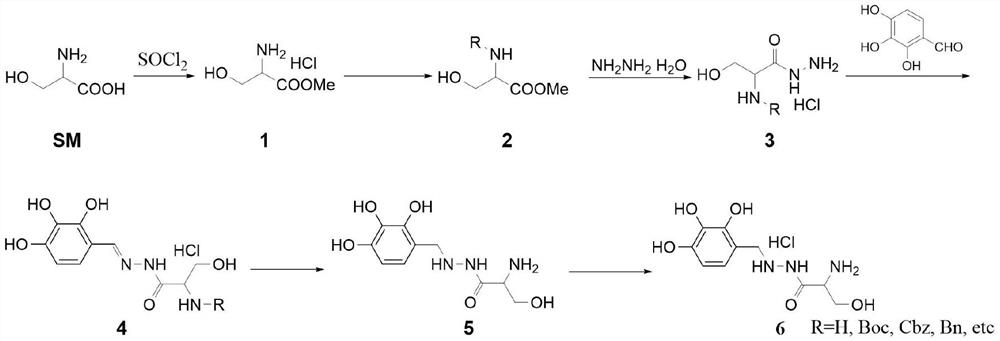

Method for synthesizing benserazide hydrochloride by utilizing fixed bed hydrogenation equipment

PendingCN112876379AReduce dosageEasy to purifyCarbamic acid derivatives preparationOrganic compound preparationPtru catalystBenserazide

The invention discloses a method for synthesizing benserazide hydrochloride by using fixed bed hydrogenation equipment, which is characterized in that a compound 1 reacts with an amino protective agent to carry out an amino protection reaction, so that the subsequent purification is easy, and the dosage of hydrazine hydrate in the synthesis method is small; according to the method, fixed bed hydrogenation equipment is used for synthesis, a fixed bed reactor is filled with a solid catalyst or a solid to realize a heterogeneous reaction process, the catalyst in the fixed bed reactor is relatively fixed, a reaction liquid flows through a bed layer, and the reaction liquid flows through the bed layer by adjusting the flow rate and the reaction pressure; qualified products can be obtained after reaction liquid flows out of the fixed bed, continuous production can be achieved, product deterioration caused by long-time contact of the products and the catalyst can be avoided, the same amount of products can be produced due to continuous production, the reactor size can be very small, the safety problem caused by high-pressure reaction is greatly reduced, the amount of the catalyst used in the reaction is less, and the production cost is reduced.

Owner:HEFEI LIFEON PHARMA

Terpene resin environment-friendly production technology

The invention discloses a terpene resin environment-friendly production technology. The production technology includes the steps that methylbenzene is added into a retort, and the temperature of the methylbenzene is reduced to -5-0 DEG C; turpentine and aluminum chloride are added into the methylbenzene, the raw material adding process lasts for 4-5 hours, and reaction is kept for a certain period of time after raw materials are added and lasts for 4-5 hours; after polymerization reaction is completed, semi-finished terpene resin can be filtered through a filtering screen plate at the bottom of the retort, screen meshes in the filtering screen plate are of a long strip shape, the distance between the screen meshes ranges from 0.05 mm to 0.3 mm, the semi-finished terpene resin enters in the next step of process through the screen meshes, and aluminum chloride is left in the retort for being used for secondary production and is repeatedly used; the filtered semi-finished terpene resin is washed through water; distillation and impurity removal are carried out on the semi-finished terpene resin to obtain finished terpene resin. The technology aims to solve the problems that catalysts are wasted in an existing terpene resin production process, a lot of acid waste water is generated and treatment cost is high.

Owner:广东星光脂胶科技股份有限公司

Silicomanganese furnace tail gas isothermal and sulfur-free transformation technology and system

InactiveCN109264666ARealize industrializationImprove heat recovery efficiencyHydrogenChemical industryHigh concentrationSulfur

The invention relates to a tail gas isothermal and sulfur-free transformation technology and system. The technology comprises the following step of desulfurization treatment, and in specific cases, the tail gas being subjected to dust removing and compressing is directly desulfurized. The system comprises a pre-treatment device and a fine desulfurization device. The input end of the pre-treatmentdevice is used for being directly connected with a tail gas generation device so as to receive the tail gas generated by the tail gas generation device and conducting dust removing treatment of the tail gas. The input end of the fine desulfurization device is directly connected with the output end of the pre-treatment device and used for directly receiving and desulfurizing the tail gas treated bythe pre-treatment device. The silicomanganese furnace tail gas isothermal and sulfur-free transformation technology and system solve the problems including that a catalyst conducts over reduction ortemperature runaway under a low steam-gas ratio, the high concentration CO is prone to being partly sintered when the original impetus is transformed, the technological procedure is complex, the number of the equipment is large, the life of the catalyst is short, the system resistance is high, and the occupation area is large in the prior art, thoroughly change the transformation technique of a traditional coal chemical industry, and effectively improve the heat recycling efficiency of the device.

Owner:鄂尔多斯市瀚博科技有限公司

A kind of reduction prepares the method for triphenylphosphine

ActiveCN108409785BReduce dosageImprove stabilityGroup 5/15 element organic compoundsPolymer sciencePtru catalyst

The invention provides a method for preparing triphenylphosphine in a reducing manner. Phenylphosphonicdichloride or chlorodiphenylphosphine is used as a reducing agent, and raw materials are low in price and easily obtained; under the effect of a catalyst, the phenylphosphonicdichloride or chlorodiphenylphosphine and triphenylphosphine oxide are subjected to reducing reaction, stabilities of phosphine oxygen double bonds in the triphenylphosphine oxide and oxidation products (phenylphosphonic dichloride or diphenylphosphinyl chloride) of a reducing agent are different, the stabilities of thedouble bonds of the phenylphosphonic dichloride and the diphenylphosphinyl chloride are good, the double bonds of the triphenylphosphine oxide are broken under the effect of the catalyst, the double bonds of the formed phenylphosphonic dichloride and the formed diphenylphosphinyl chloride are not easily damaged by the catalyst, and therefore, triphenylphosphine can be obtained under gentle conditions; the oxidation products (the phenylphosphonic dichloride or the diphenylphosphinyl chloride) of the reducing agent are important organic synthesis intermediate (such as synthesis of organic phosphate); and moreover, the amount of the catalyst required in the method is small, and the catalysis efficiency is high.

Owner:江苏富比亚化学品有限公司

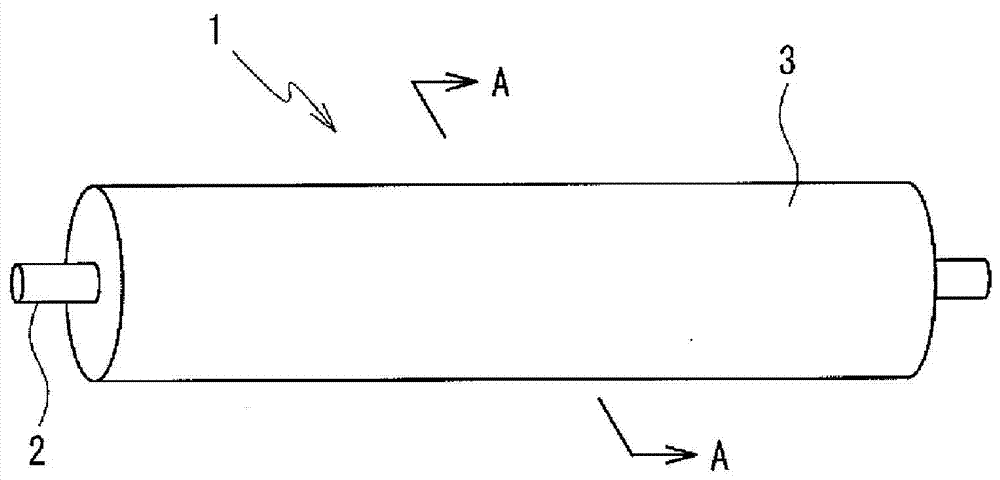

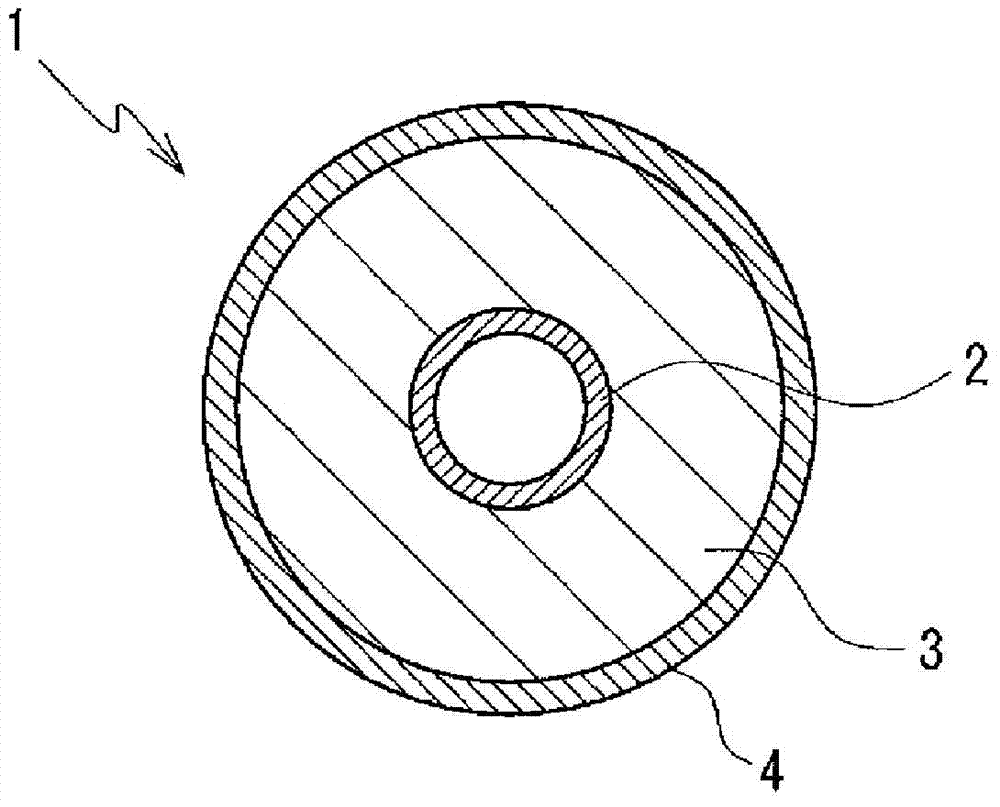

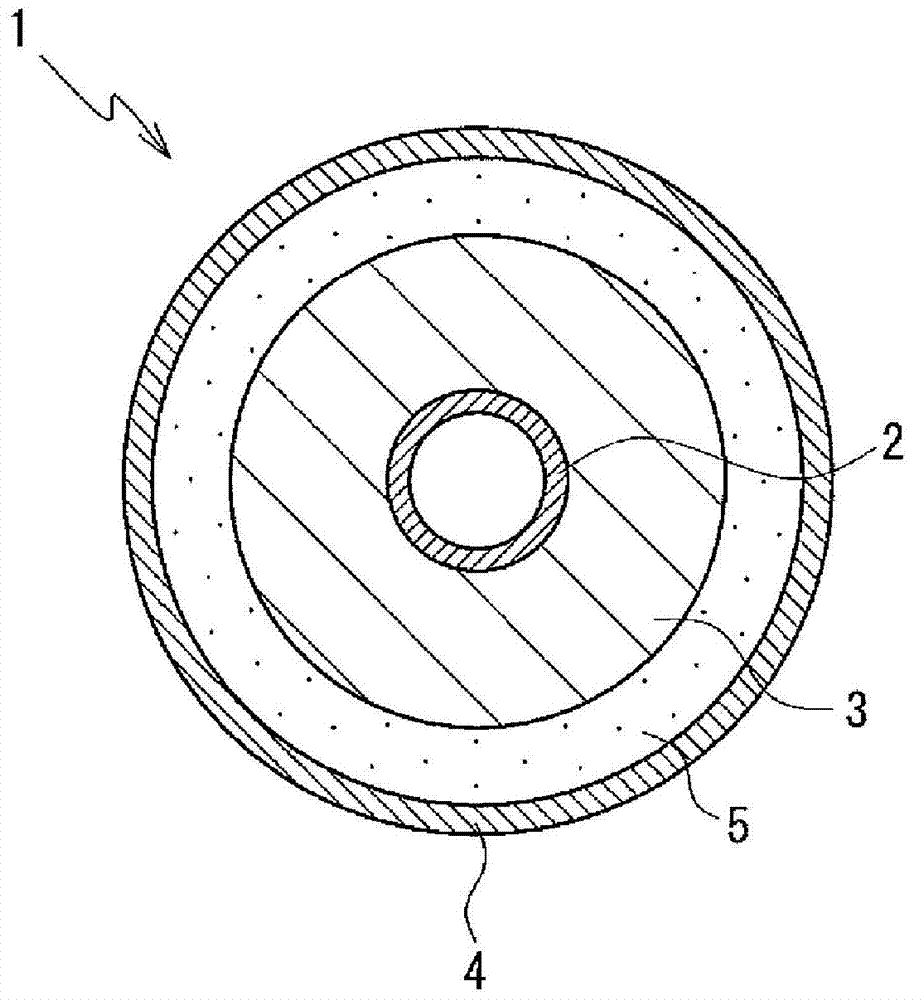

Conductive composition for electrophotographic apparatuses and conductive roll for electrophotographic apparatuses using same

ActiveCN104769506ALow resistanceImprove cationicityNon-conductive material with dispersed conductive materialElectrographic process apparatusIonChemistry

Provided are: a conductive composition for electrophotographic apparatuses, which is capable of reducing the resistance even in cases where an ion conductive agent is used; and a conductive roll for electrophotographic apparatuses. A conductive roll (1) is configured using a conductive composition, which contains a polar polymer and a quaternary ammonium salt represented by formula (1) and serving as a conductivity-imparting agent, in at least one of a base layer (3), a surface layer (4) and an intermediate layer (5), said layers being formed around a shaft body (2). In formula (1), each of R1-R3 represents a C1-C14 alkyl group; R4 represents a methacrylate group or an acrylate group; X- represents an anion, which is bistrifluoromethane sulfonimide, triflate or fluorosulfonyl imide; and A represents an alkylene group.

Owner:TOKAI RUBBER IND LTD

Hardenable compositions based on silylated polyurethanes

InactiveCN102037039BIncrease the degree of cross-linkingFast crosslinkingPolyureas/polyurethane adhesivesSilyleneIndium

The invention relates to a method for producing cross-linkable formulations. In a first step of the method, at least one α,ω-difunctional organic polymer of formula (1) X-A-X (1) is converted into organyloxysilyl-terminated polymers P1, using organofunctional silanes of formula (2) Y—R—Si—(R1)m(—OR2)3m (2), in the presence of catalysts (A) selected from the group consisting of potassium, iron, indium, zinc, bismuth and copper compounds. In said formulae, R is a bivalent, optionally substituted hydrocarbon group which comprises between 1 and 12 carbon atoms and can be interrupted with heteroatoms, R1 and R2 are the same or different, monovalent, optionally substituted hydrocarbon groups which comprise between 1 and 12 carbon atoms and can be interrupted with heteroatoms, A is bivalent, optionally substituted hydrocarbon group which comprises at least 6 carbon atoms and can be interrupted with heteroatoms, m is equal to 0, 1 or 2, X is a hydroxyl group and Y is an isocyanate group, or X is an isocyanate group and Y is a hydroxyl group or a primary or secondary amino group. In a second step, the polymers P1 obtained in the first step are mixed with a silane condensation catalyst (B) selected from the group consisting of compounds of elements of the third main group and / or fourth secondary group and heterocyclic organic amines, amine complexes of the element compounds, or the mixtures thereof. Optionally, said mixture is mixed with other substances (C). The formulations do not contain organic tin compounds, and are suitable for using as adhesives, sealants, or coating agents.

Owner:HENKEL KGAA

A kind of preparation method of the polymer of lipoic acid compound

ActiveCN113214482BFast and efficient ring-opening polymerizationMild reaction conditionsOrganic solventCatalytic method

The invention discloses a method for preparing a polymer of lipoic acid compounds, which is selected from solvent-free direct hot-melt catalytic polymerization or room temperature solution catalytic polymerization; the catalyst used in the method of the invention has a wide range of sources, is easy to prepare, and is inexpensive. Inexpensive, diverse catalytic methods and simple process, no metal ions, only a small amount of catalyst is needed to achieve high-efficiency catalysis, and has practical industrial feasibility; it can catalyze polymerization under the condition of direct heating and melting without solvent, or at room temperature Catalytic polymerization in the solution under the environment; the direct hot melt catalytic method does not need any organic solvent, the catalytic process is rapid, the conditions are mild, the operation is simple and safe, the utilization rate of atoms is high, and there is no three wastes, which meets the requirements of green chemistry; the room temperature solution catalytic method does not need heating and complicated High-efficiency catalytic polymerization at room temperature can be achieved by adding a small amount of catalyst to the monomer solution.

Owner:EAST CHINA UNIV OF SCI & TECH

Improved DMTO reactor

InactiveCN104815594AReduce disturbanceCatalyst concentration decreasedChemical/physical processesPtru catalystPhysical chemistry

The invention discloses an improved DMTO reactor. According to the invention, by means of arrangement of a grating in a dense-phase bed layer zone of the DMTO reactor, entrainment amount of a catalyst is reduced and the concentration of the catalyst in a dilute-phase bed layer is reduced, so that a secondary reaction is reduced. Meanwhile, bubbles are reduced in size so that the disturbance on the bed layers is reduced when the bubbles are broken, so that the bed layers are more stable and reduced in backmixing. By means of the technical scheme, selectivity of methanol to olefin is increased, thereby increasing the yield of olefin.

Owner:宁波富德能源有限公司

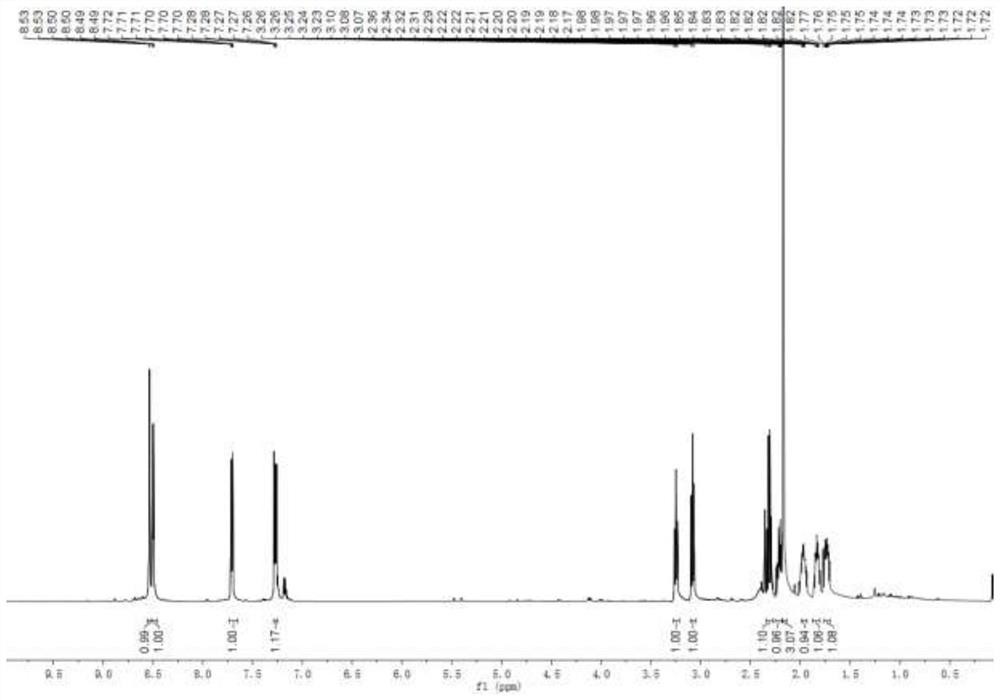

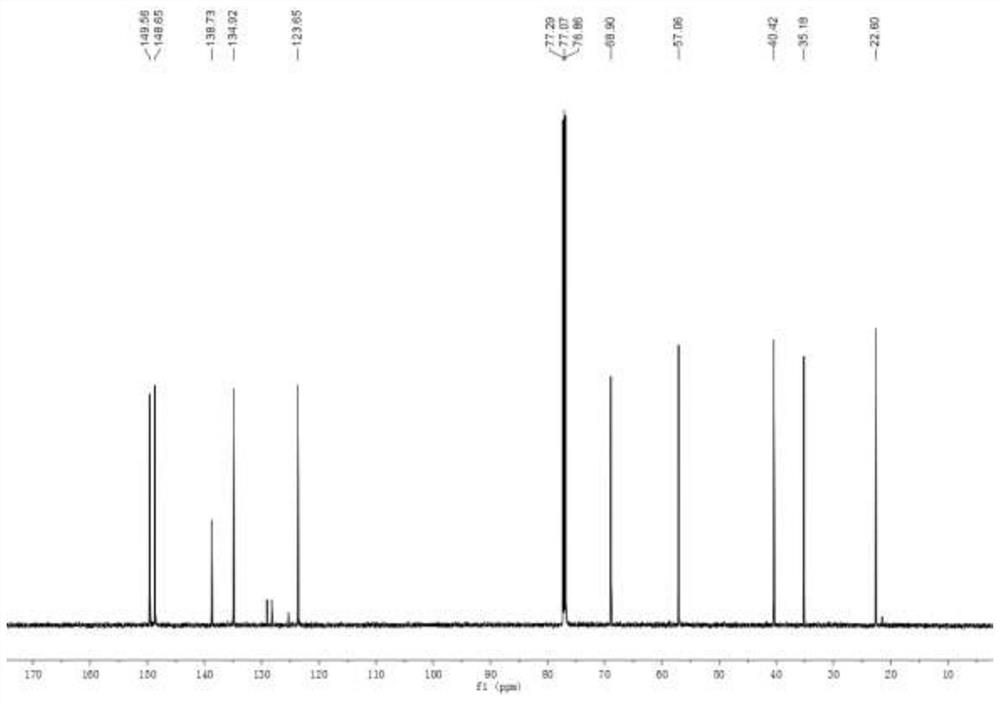

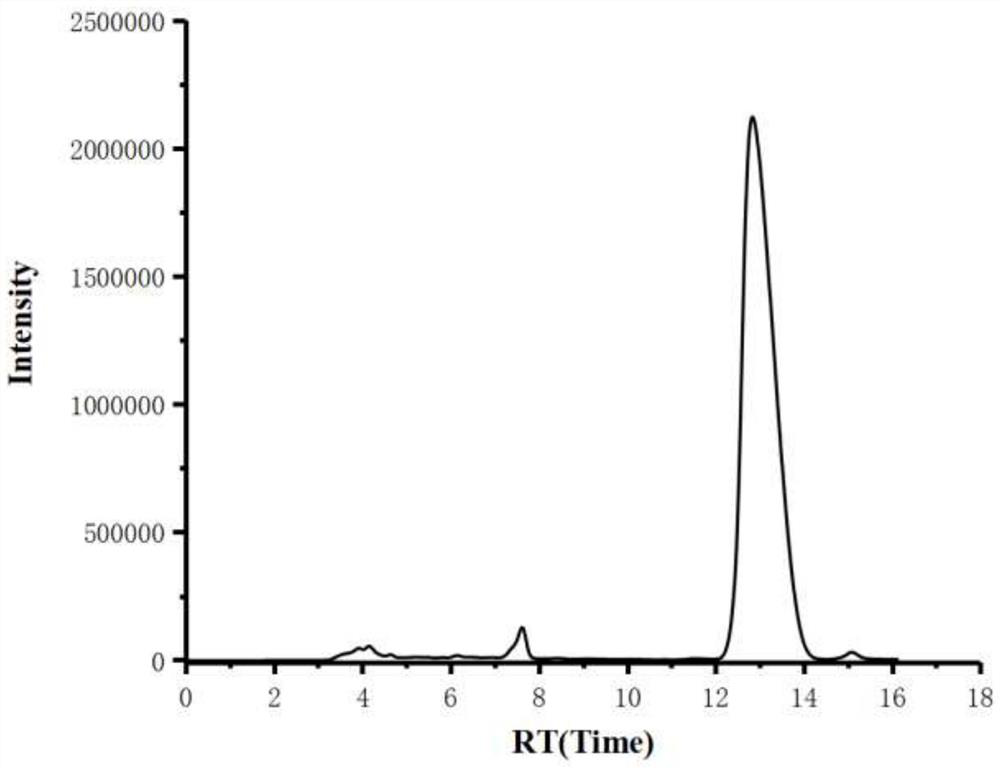

Cyclopenta[c]chromene compound and preparation method thereof

ActiveCN108774207BEasy to getHigh yieldOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystCombinatorial chemistry

The invention discloses a cyclopentadiene [c] chromene compound and a preparation method thereof. The cationic rare earth compound [Ln(CH 3 EN) 9 ] 3+ [(AlCl 4 ) 3 ] 3– •CH 3 CN is a catalyst, 2-naphthylthiol is a promoter, and catalyzes the reaction of chalcone compounds to prepare products; Ln in the catalyst represents positive trivalent rare earth metal ions, selected from one of La, Nd, Sm, Gd, and Yb. In this method, raw material is easy to obtain, and reaction process is simple, and the consumption of catalyst is few; Catalyst has universal applicability to multiple substituted 2-hydroxychalcones, and the obtained cyclopentadien[c]chromene compound has no See the report; the catalyst synthesis method is simple and easy to obtain; the yield of the target product is high, up to 85%.

Owner:ZHANGJIAGANG INST OF IND TECH SOOCHOW UNIV +1

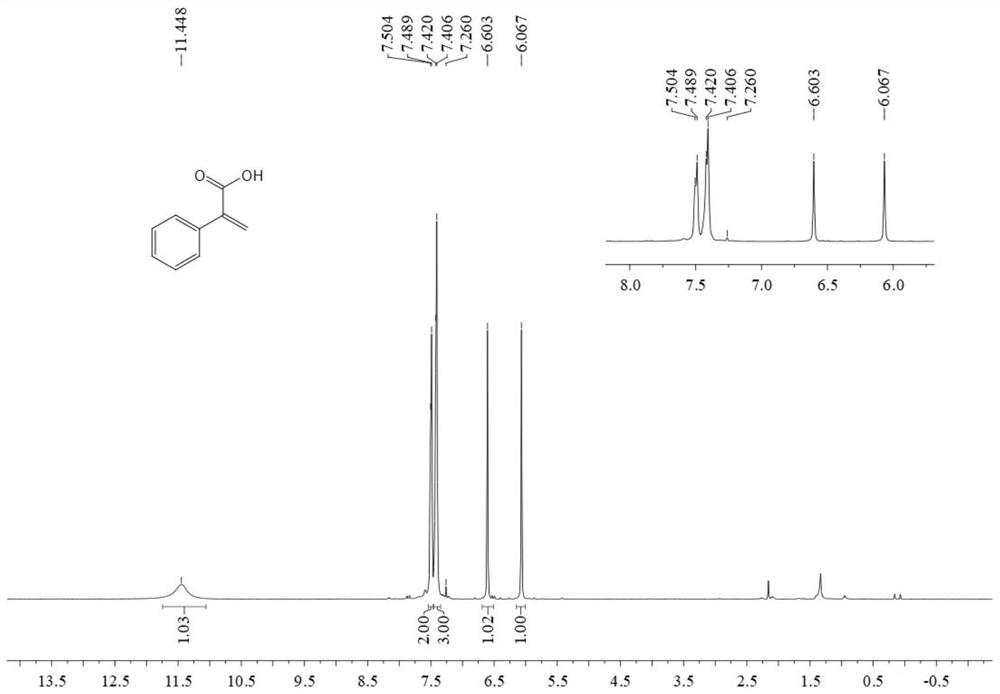

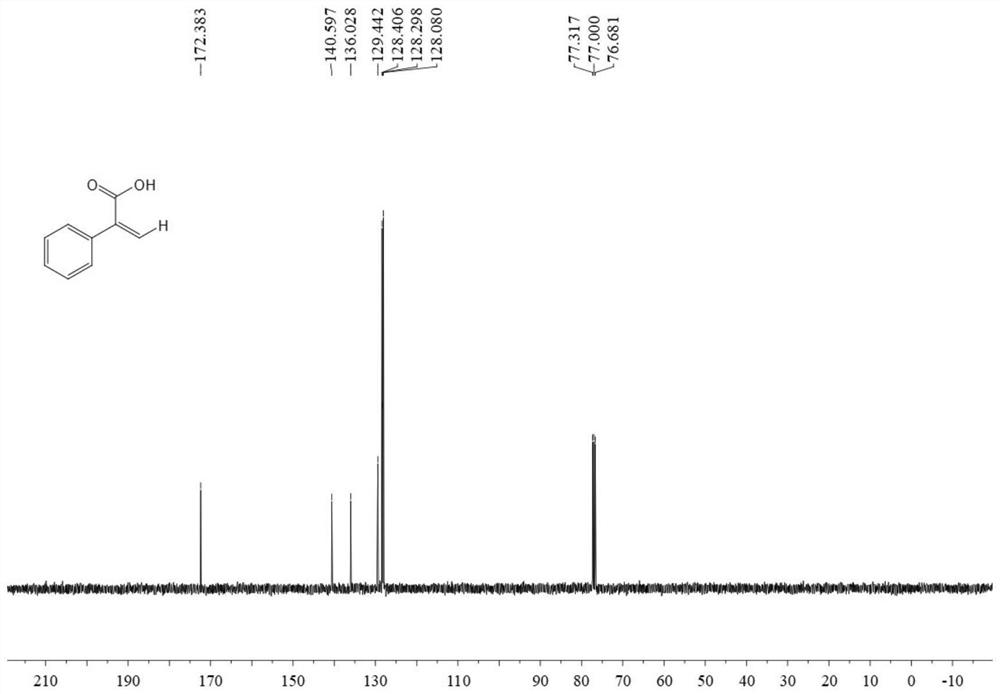

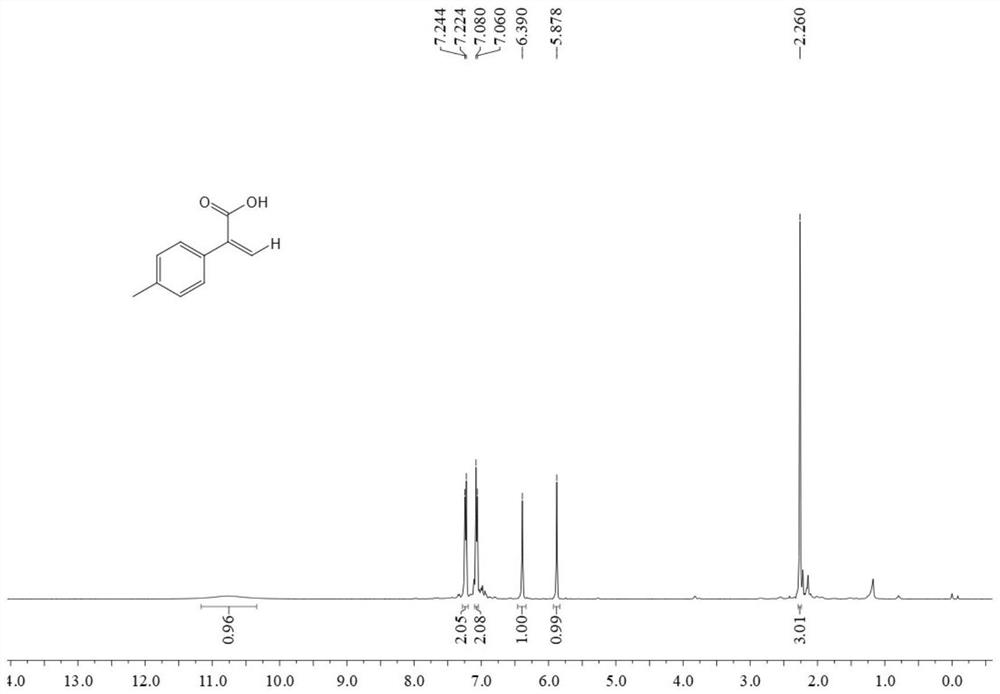

A kind of palladium catalyst carbon dioxide and the method for synthesizing α-acrylic acid compound of alkyne

ActiveCN111039773BHigh yieldAtom economy is highOrganic compound preparationCarboxylic compound preparationPtru catalystOrganic synthesis

The invention belongs to the technical field of organic synthesis, and discloses a palladium-catalyzed method for synthesizing α-acrylic acid compounds from carbon dioxide and alkynes. In a high-pressure reactor, add alkyne compound, palladium salt catalyst, alkali, bisphosphine ligand, silane reducing agent and solvent, pass in carbon dioxide, stir and react at 60-120°C, the reaction solution is washed and extracted with water, separated and purified, α-Acrylic acid compounds are obtained. The invention uses palladium salt as catalyst and bisphosphine ligand as ligand, and has the characteristics of high yield, single selectivity, wide substrate applicability and the like. In addition, the reaction uses alkyne compounds and carbon dioxide as raw materials, which has the advantages of simple and easy-to-obtain raw materials, simple operation, and high atom economy.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Cyclopenta[c]chromene compound and preparation method thereof Cyclopenta[c]chromene compound and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/05c5308e-9e50-4a01-b4ca-d925fbc8fd3d/DEST_PATH_IMAGE001.png)

![Cyclopenta[c]chromene compound and preparation method thereof Cyclopenta[c]chromene compound and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/05c5308e-9e50-4a01-b4ca-d925fbc8fd3d/DEST_PATH_IMAGE003.png)

![Cyclopenta[c]chromene compound and preparation method thereof Cyclopenta[c]chromene compound and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/05c5308e-9e50-4a01-b4ca-d925fbc8fd3d/DEST_PATH_IMAGE019.png)