Porous material loaded multi-metal composite Fenton-like catalyst and preparation method and application thereof

A porous material and multi-metal technology, applied in the field of composite Fenton-like catalysts, can solve problems such as complex preparation process, unfavorable application, poor catalyst stability, etc., achieve high specific surface area, and broaden the effect of pH limit range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of multi-metal composite type Fenton catalyst supported by porous material, its steps are:

[0036] (1) Prepare a mixed solution of iron sulfate and nickel chloride with a concentration of 1mol / L, in which the molar ratio of iron salt to nickel salt is 1:1, and soak activated alumina particles with a particle size of 3-5 mm in the mixed solution for 12 hours , dried at 80°C for 5 hours after filtering;

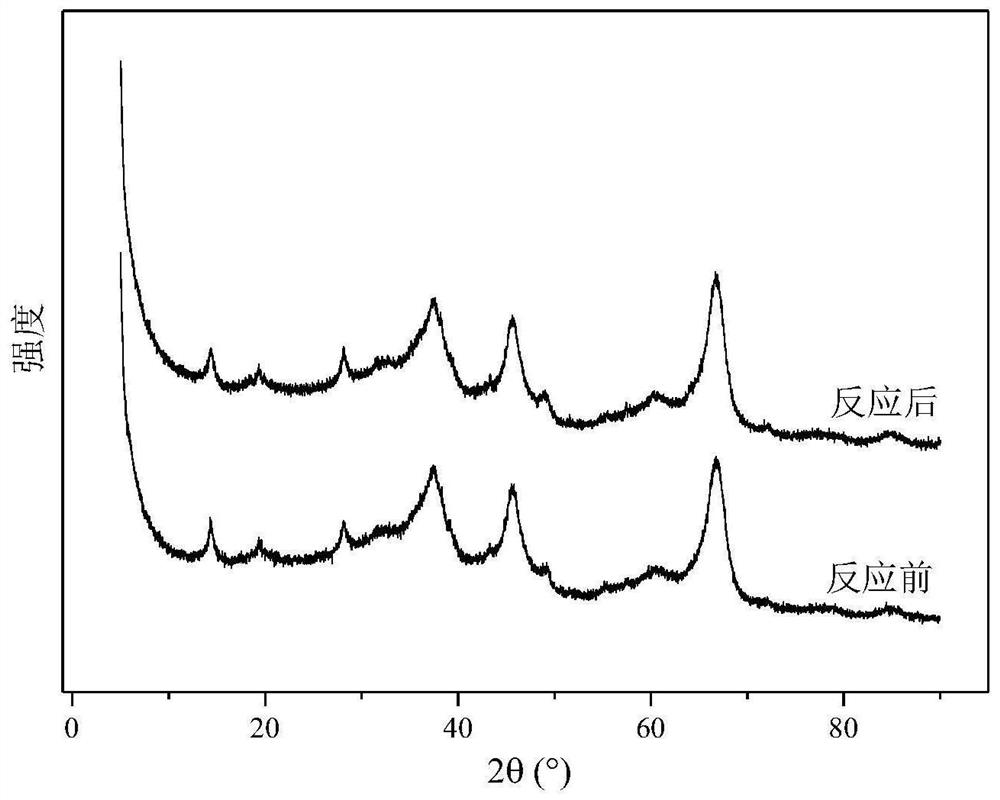

[0037] (2) Roast the product obtained from the above drying at 500°C for 5 hours, take it out and let it cool to room temperature for later use. figure 1 For the XRD spectrum of the compound type Fenton catalyst prepared in this embodiment, as can be seen from the figure, the diffraction peak of the compound type Fenton catalyst prepared in this embodiment is similar to that of Fe 2 o 3 The characteristic peaks of , NiO are consistent, and there is no significant difference before and after the reaction, indicating that the consumption of ...

Embodiment 2

[0040] A kind of preparation method of multi-metal composite type Fenton catalyst supported by porous material, its steps are:

[0041] (1) Prepare a mixed solution of ferric nitrate and manganese chloride with a concentration of 0.1mol / L, in which the molar ratio of iron salt to manganese salt is 0.8:0.2, and soak activated alumina particles with a particle size of 2 to 3 mm in the mixed solution 12h, after filtering, dry at 80°C for 5 hours;

[0042] (2) The above-mentioned dried product was roasted at 300° C. for 5 hours, and then taken out and allowed to cool to room temperature for later use.

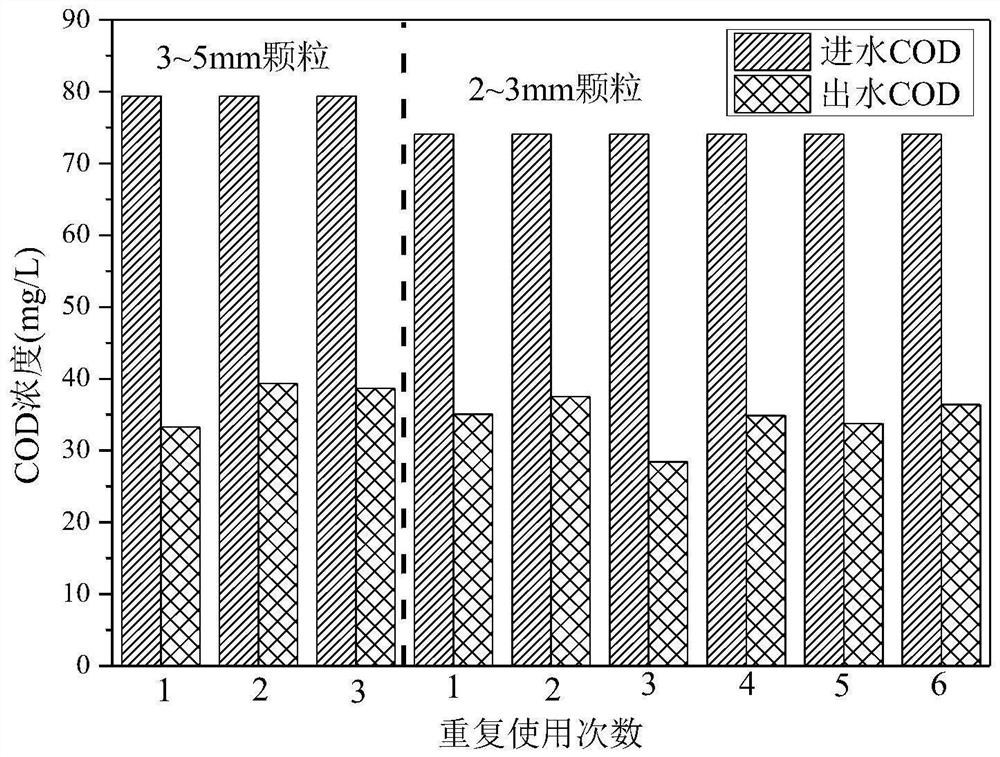

[0043] Fenton-like catalytic degradation of landfill leachate experiment: Take 100g of composite Fenton-like catalyst and place it in a 500mL conical flask, add 300mL of landfill leachate with initial pH adjusted to 3, add 100mg / L hydrogen peroxide, and take samples at regular intervals to measure COD Concentration, repeated use results see image 3 , it can be seen from the figu...

Embodiment 3

[0045] A kind of preparation method of multi-metal composite type Fenton catalyst supported by porous material, its steps are:

[0046] (1) Prepare a mixed solution of ferric nitrate, nickel chloride and copper chloride with a concentration of 0.5mol / L. The molar ratio of ferric nitrate, nickel chloride and copper chloride is 0.7:0.2:0.1, impregnating the molecular sieve with the mixed solution Soak in water for 15 hours, filter and dry at 80°C for 5 hours;

[0047] (2) Roast the above-mentioned dried product at 400° C. for 5 hours, take it out and let it cool to room temperature for later use.

[0048] Fenton-like catalytic degradation of landfill leachate experiment: take 100 g of the composite Fenton-like catalyst prepared in this example and place it in a 500 mL Erlenmeyer flask, add 300 mL of landfill leachate whose initial pH was adjusted to 5, add 100 mg / L hydrogen peroxide, and Take a sample for a certain period of time to measure the COD concentration, and see the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com