Preparation method of bifunctional Pickering emulsion catalyst

A functional and catalyst technology, applied in the field of preparation of dual-functional Pickering emulsion catalysts, can solve the problems of long reaction time, large amount of catalyst and high reaction temperature, and achieves the effects of simple operation, low preparation cost and optimized reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

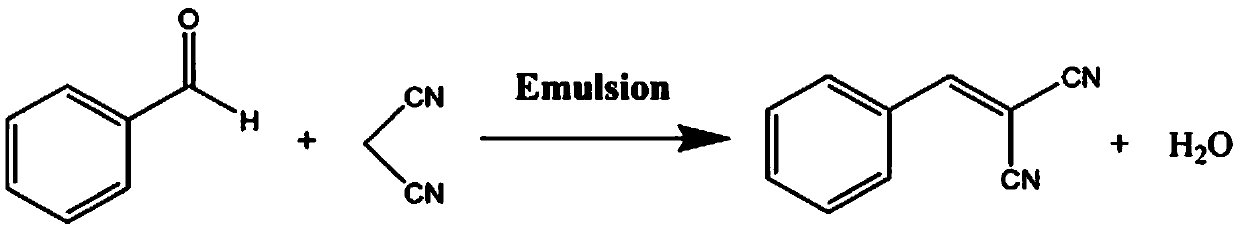

[0030] A preparation method of a dual-functional Pickering emulsion catalyst, using a dual-functionalized graphene oxide material, benzaldehyde and solvent water to form a Pickering emulsion with more superior properties, and using the dual-functional emulsion catalyst to catalyze benzaldehyde at room temperature Knoevenagel condensation reaction with malononitrile.

[0031] The method is carried out according to the following steps:

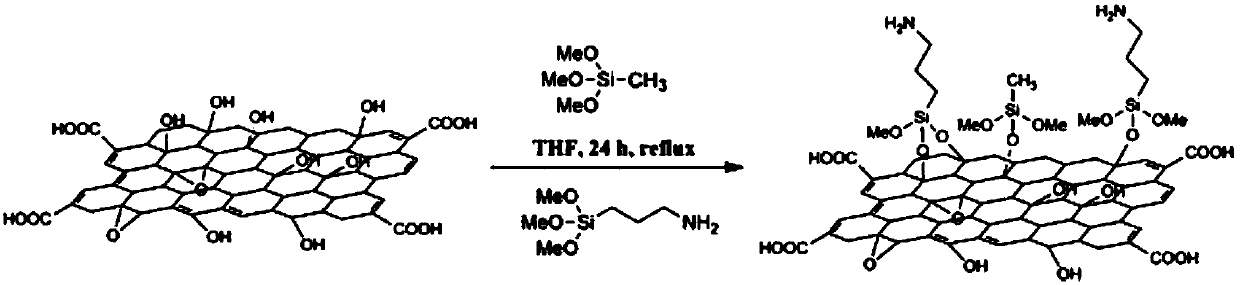

[0032](1) Weigh 0.2g of graphite oxide into a round-bottomed flask containing 100mL of tetrahydrofuran (THF) solution, then dropwise add 1.8g of 3-aminopropyltrimethoxysilane (APTMS) and 0.2g of 3-methyltrimethoxysilane Oxysilane (MTMS), followed by ultrasound three times (180W, 60Hz), each time for 30min, with an interval of 5min. Put the solution in the bottle under N 2 Under the protection of the atmosphere, reflux and stir at 70°C for 24h, then filter and wash with absolute ethanol several times, and finally vacuum-dry at 50°C for 6h to ob...

Embodiment 2

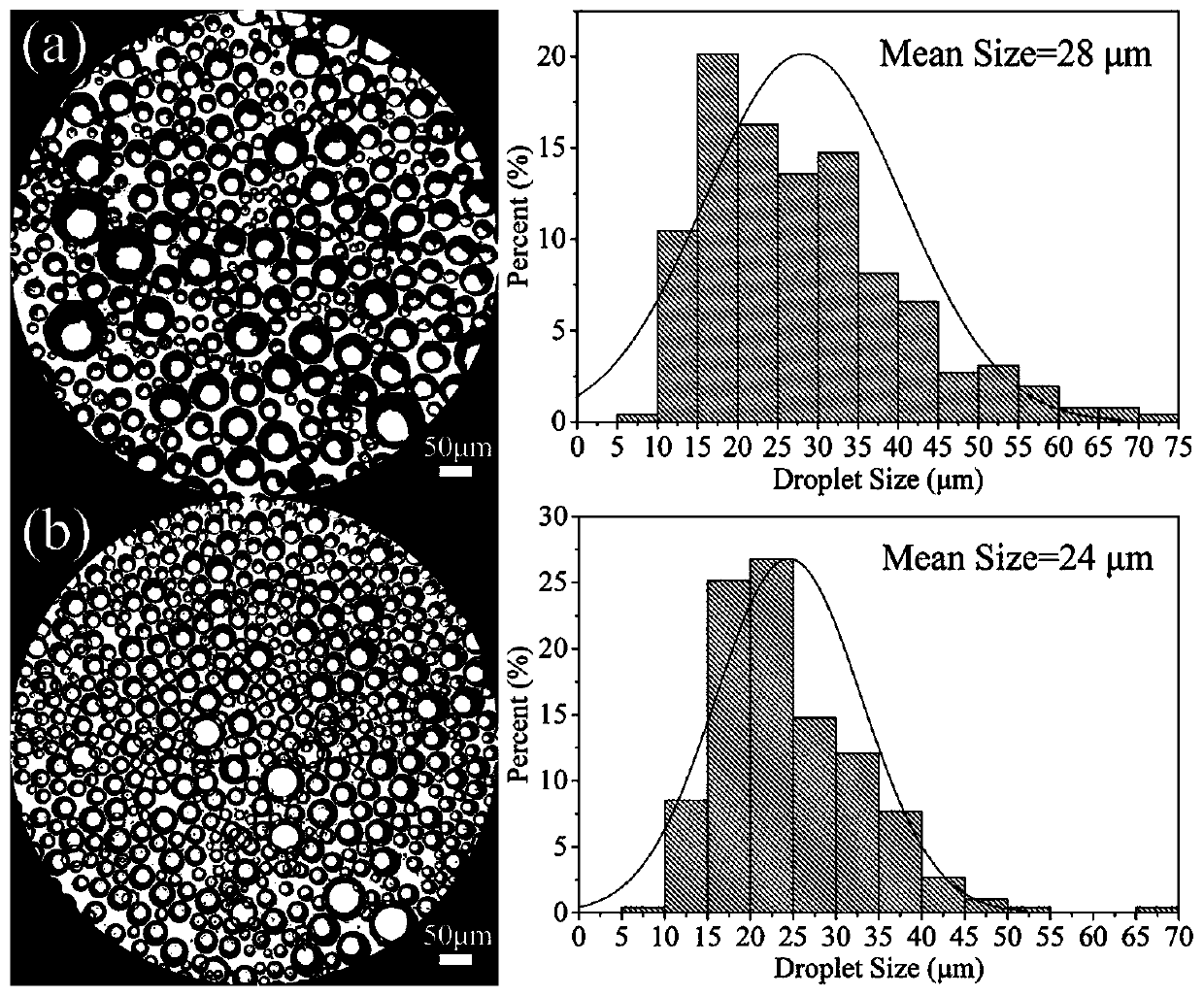

[0036] Weigh 0.2g of graphite oxide and add it to a round-bottomed flask containing 100mL of THF solution, then dropwise add 1.8g of 3-aminopropyltrimethoxysilane and 0.2g of 3-methyltrimethoxysilane, then sonicate three times (180W , 60Hz), 30 minutes each time, with an interval of 5 minutes in between. Next, put the bottle solution in N 2 Under the protection of atmosphere, reflux and stir at 70°C for 24h, then filter and wash with absolute ethanol for several times, and finally vacuum-dry at 50°C for 6h to obtain bifunctional graphene oxide. Then weigh 20mg of bifunctional graphene oxide and add it to a 50mL round bottom flask, then add 3mL of water and 1.5mL of benzaldehyde, then sonicate for 5min (180W, 60Hz), and mechanically stir at 800rpm for 5min after sonication to prepare Bifunctional Pickering emulsion catalyst, denoted as Emulsion 1.

Embodiment 3

[0038] Weigh 0.2g of graphite oxide and add it to a round-bottomed flask containing 100mL of THF solution, then dropwise add 1.8g of 3-aminopropyltrimethoxysilane and 0.2g of 3-methyltrimethoxysilane, then sonicate three times (180W , 60Hz), 30 minutes each time, with an interval of 5 minutes in between. Next, put the bottle solution in N 2 Under the protection of atmosphere, reflux and stir at 70°C for 24h, then filter and wash with absolute ethanol for several times, and finally vacuum-dry at 50°C for 6h to obtain bifunctional graphene oxide. Then weigh 20mg of bifunctional graphene oxide and add it to a 50mL round bottom flask, then add 4mL of water and 1.5mL of benzaldehyde, then sonicate for 5min (180W, 60Hz), and mechanically stir at 800rpm for 5min after sonication to prepare Bifunctional Pickering emulsion catalyst, denoted as Emulsion 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com