1, 4; 3, 6-diglycidyl hexanehexol modified PET polyester and semi-continuous preparation method thereof

A modified technology of hexanehexanol, which is applied in the field of 1 and 4, and can solve the problems of low conversion rate, low catalyst dosage and low reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

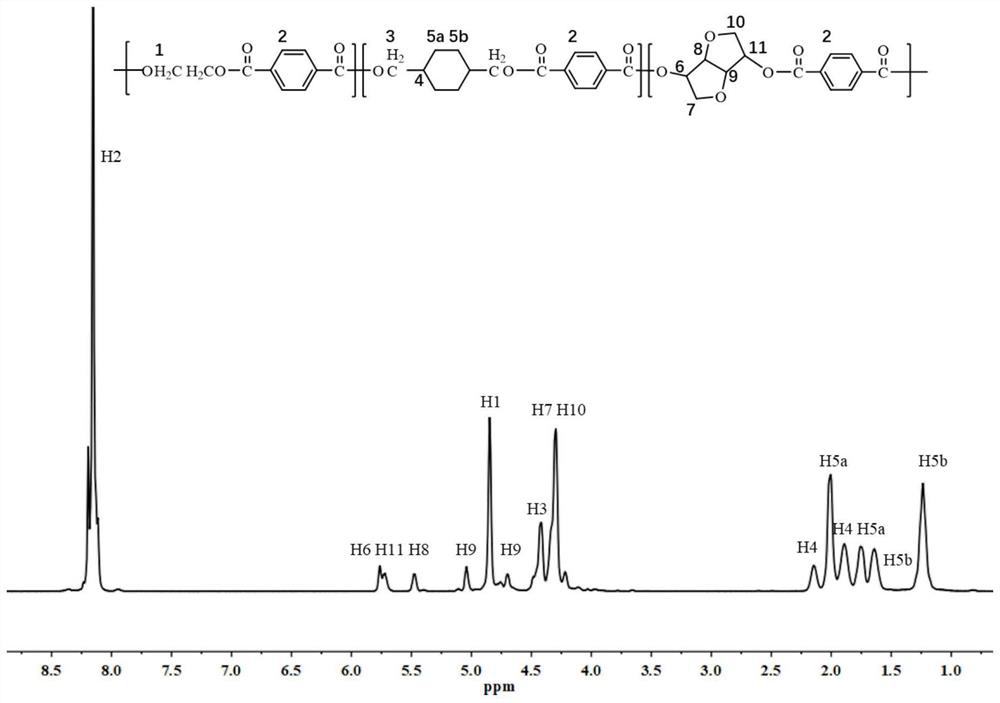

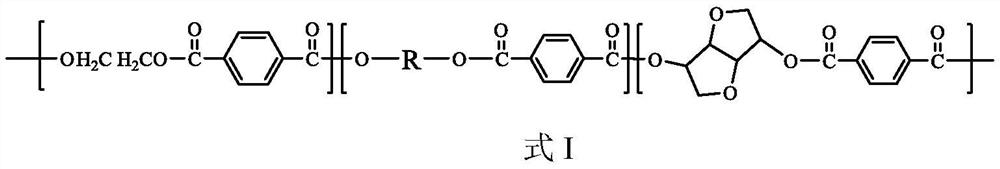

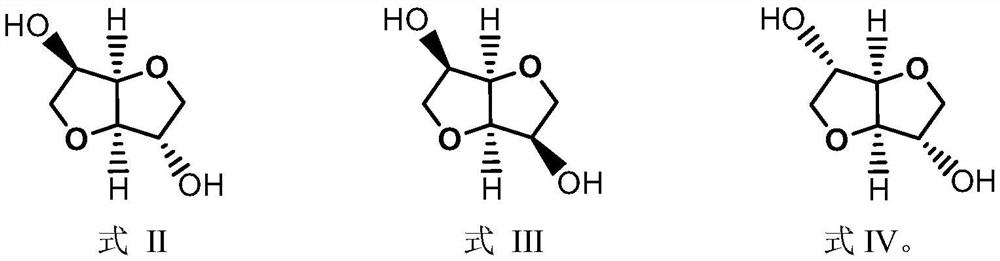

[0045] Embodiment 1 Semi-continuous method efficiently prepares high heat-resistant high-performance (terephthalic acid-isosorbide-ethylene glycol-1,4-cyclohexanedimethanol) copolyester

[0046] (1) Under the protection of nitrogen atmosphere, in the first esterification kettle, add 24.9kg (150mol) terephthalic acid, 18.6kg (300mol) ethylene glycol (the molar ratio of terephthalic acid and ethylene glycol is 1 : 2), pressurized to 300kPa, stirred and reacted at 240° C. for 3 hours, and distilled out the by-product water produced by the reaction. After the by-product water is all evaporated, the reaction is complete, and the esterified product of terephthalic acid and ethylene glycol is obtained; 2 / 3 of the esterified product is discharged into the second esterification kettle, and 16.6kg (100mol) of terephthalic acid and 12.4kg (200mol) ethylene glycol mixture is fed into the first esterification kettle at a speed of 10kg / min to continue the esterification reaction with the re...

Embodiment 2

[0051] Example 2 Semi-continuous method for efficiently preparing high heat-resistant high-performance (terephthalic acid-isosorbide-ethylene glycol-1,3-cyclohexanedimethanol) copolyester

[0052] (1) Under the protection of nitrogen atmosphere, in the first esterification kettle, add 24.9kg (150mol) terephthalic acid, 23.25kg (375mol) ethylene glycol (the mol ratio of terephthalic acid and ethylene glycol is 1 : 2.5), pressurized to 300kPa, stirred and reacted at 245°C for 4 hours, and distilled out the by-product water produced by the reaction. After the by-product water is all evaporated, the reaction is complete, and the esterified product of terephthalic acid and ethylene glycol is obtained; 2 / 3 of the esterified product is discharged into the second esterification kettle, and 16.6kg (100mol) of terephthalic acid and 15.5kg (250mol) of ethylene glycol mixture was fed into the first esterification kettle at a rate of 10kg / min to continue the esterification reaction with th...

Embodiment 3

[0056] Example 3 Semi-continuous method efficiently prepares high heat-resistant high-performance (terephthalic acid-isosorbide-ethylene glycol-1,4-cyclohexanediol) copolyester

[0057] (1) Under the protection of nitrogen atmosphere, in the first esterification kettle, add 24.9kg (150mol) terephthalic acid, 13.95kg (225mol) ethylene glycol (the molar ratio of terephthalic acid and ethylene glycol is 1 : 1.5), pressurized to 280kPa, stirred and reacted at 250°C for 3.5 hours, and distilled off the by-product water produced by the reaction. After the by-product water is all evaporated, the reaction is complete, and the esterified product of terephthalic acid and ethylene glycol is obtained; 2 / 3 of the esterified product is discharged into the second esterification kettle, and 16.6kg (100mol) of terephthalic acid and 9.3kg (150mol) of ethylene glycol mixture was fed into the first esterification kettle at a rate of 10kg / min to continue the esterification reaction with the remain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com