Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95results about How to "Increase the number of nuclei" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light gauge aluminum foil woolen produced with AL-Ti-C wire refiner and preparation method

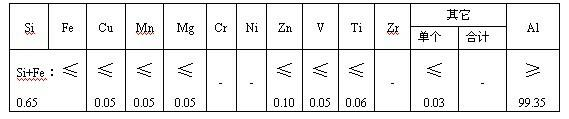

InactiveCN102181754AReduced responseLess rigidRoll mill control devicesMetal rolling arrangementsMaterials preparationFiltration

The invention relates to a light gauge aluminum foil woolen produced with AL-Ti-C wire refiner and a preparation method. The iron-silicon rate of the woolen ranges between 4.3-5.3. The process of the preparation technology is sequentially as follows: material preparation, batching, feeding, melting, stirring, primary refining of a smelting furnace, drossing, sampling, ingredient adjustment, secondary refining of the smelting surface, drossing, converter, primary refining in a holding furnace, intensified refining in the holding furnace, online addition of AL-Ti-C wire intermediate alloy refiner, Ar online degassing, filtration, continuous casting into 7.0-7.5mm cast rolling plates, cold rolling, high-temperature homogenizing annealing of a primary sheet strap, cold rolling, trimming of a rereeling machine, cold rolling, intermediate annealing of a secondary sheet strap, cold rolling to 0.26-0.32mm, trimming of the rereeling machine, and packaging. The cost is low, the quality is stable, the calendaring of the aluminum foil and grain refining are good in effect, and the probability of generating pinholes is low during production.

Owner:江阴新仁铝业科技有限公司

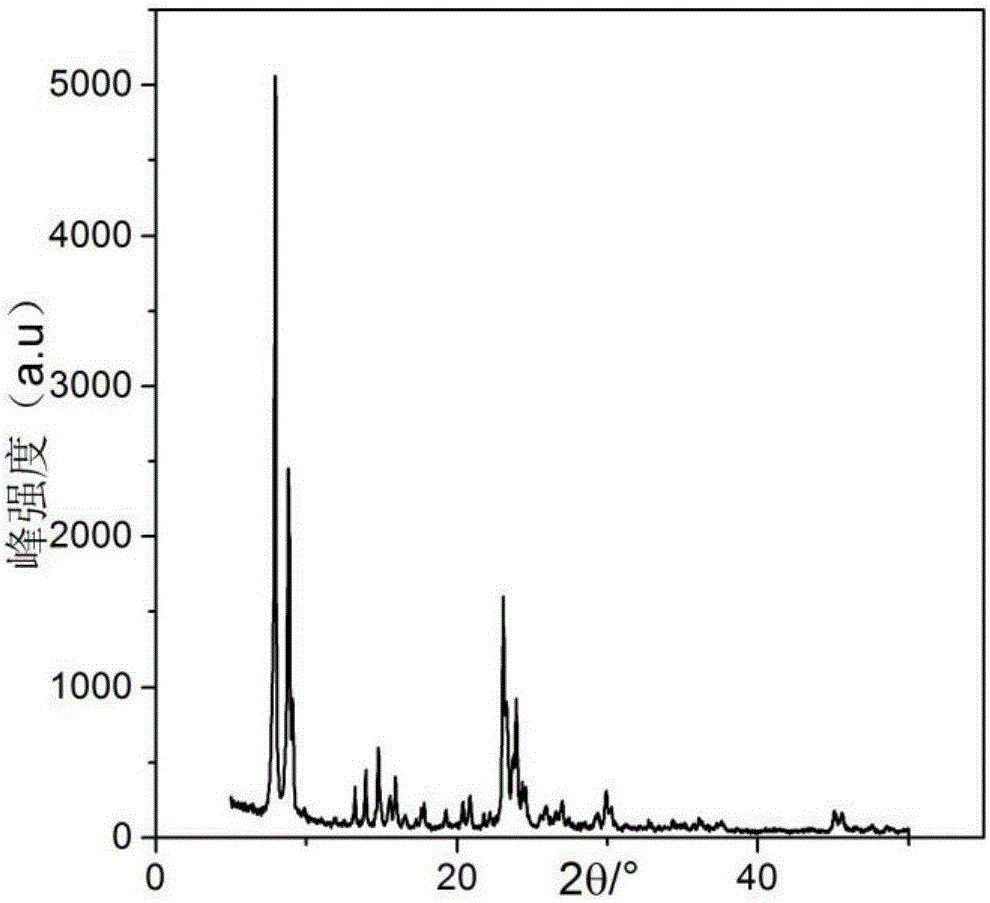

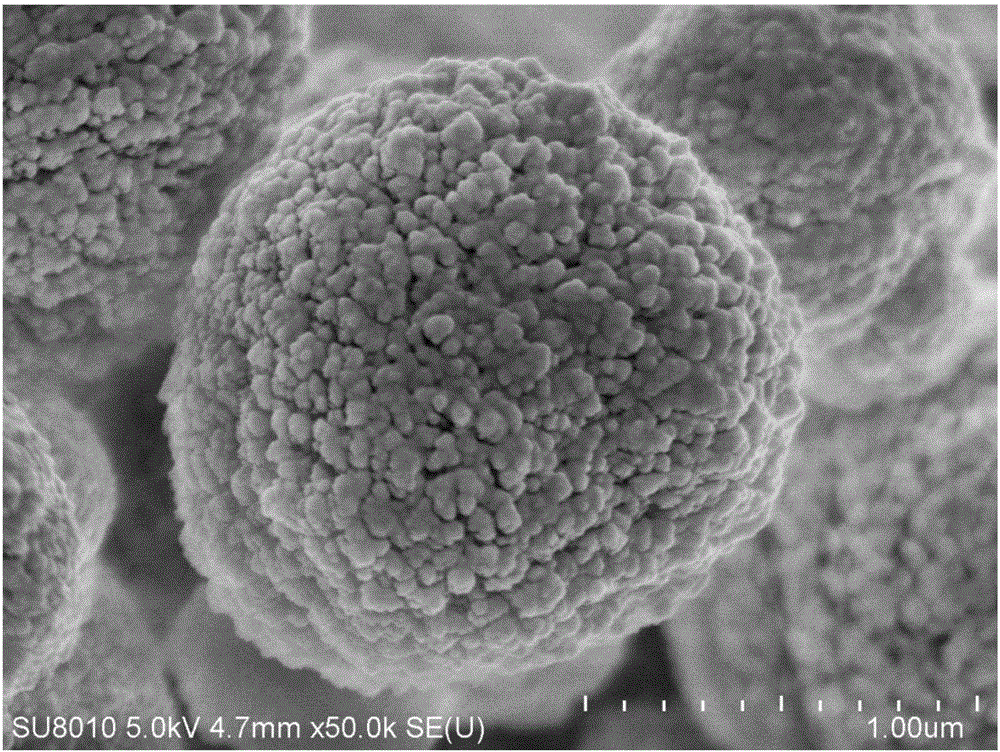

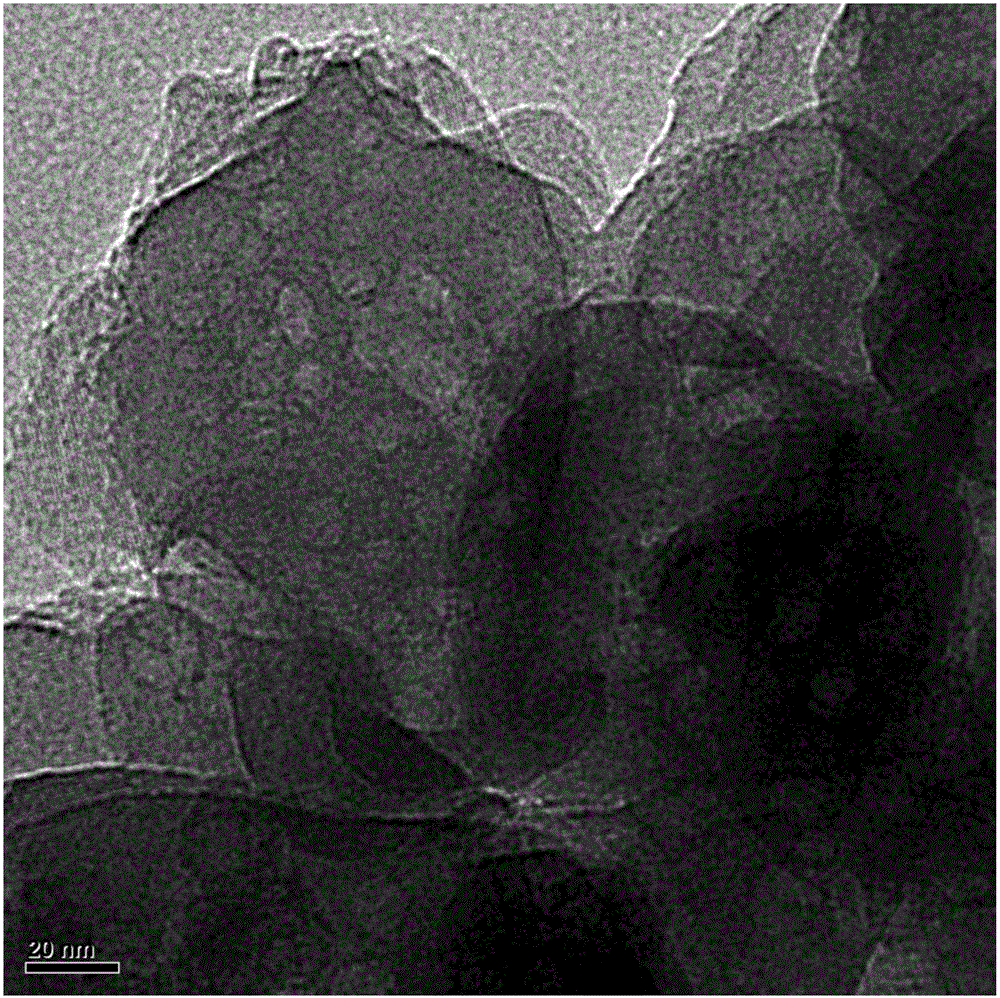

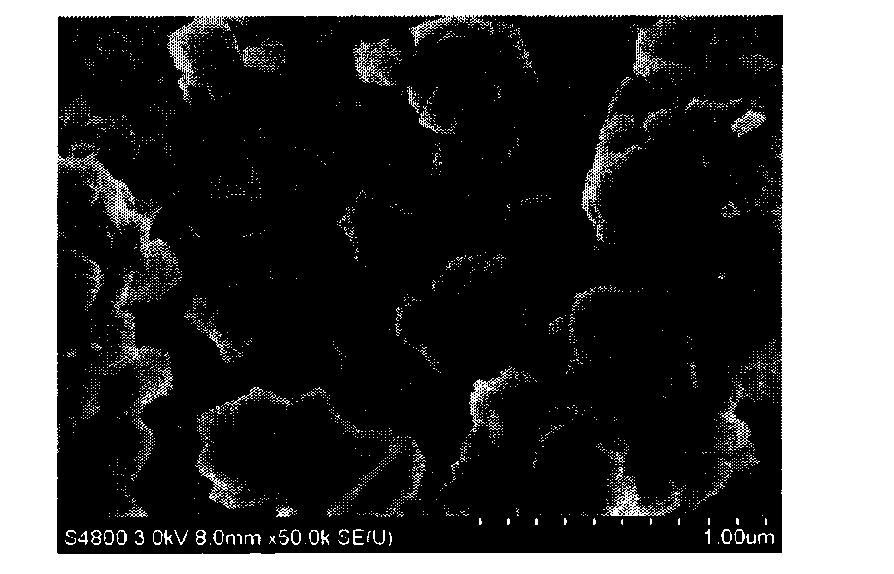

Multilevel structure ZSM-5 zeolite molecular sieve, as well as synthetic method and application thereof

ActiveCN106673008AImprove diffusion abilityHigh catalytic activityMolecular sieve catalystsOrganic compound preparationMolecular sieveSide reaction

The invention relates to a synthesized multilevel structure ZSM-5 zeolite molecular sieve with intracrystalline meso pores and intercrystalline meso pores, as well as a synthetic method and an application thereof. Except micropores of the zeolite structure, the multilevel structure ZSM-5 zeolite molecular sieve comprises the intracrystalline mesoporous and intercrystalline mesoporous structure, wherein primary nanometer crystal grain size is 40-500nm, and secondary accumulated particle size is 500nm-5[mu]m. The structure greatly improves diffusion performance and the catalyst activity of the molecular sieve, reduces possibility of generation of side reaction and carbon deposit, improves carbon accommodating capability of the molecular sieve catalyst, and prolongs life of the catalyst.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

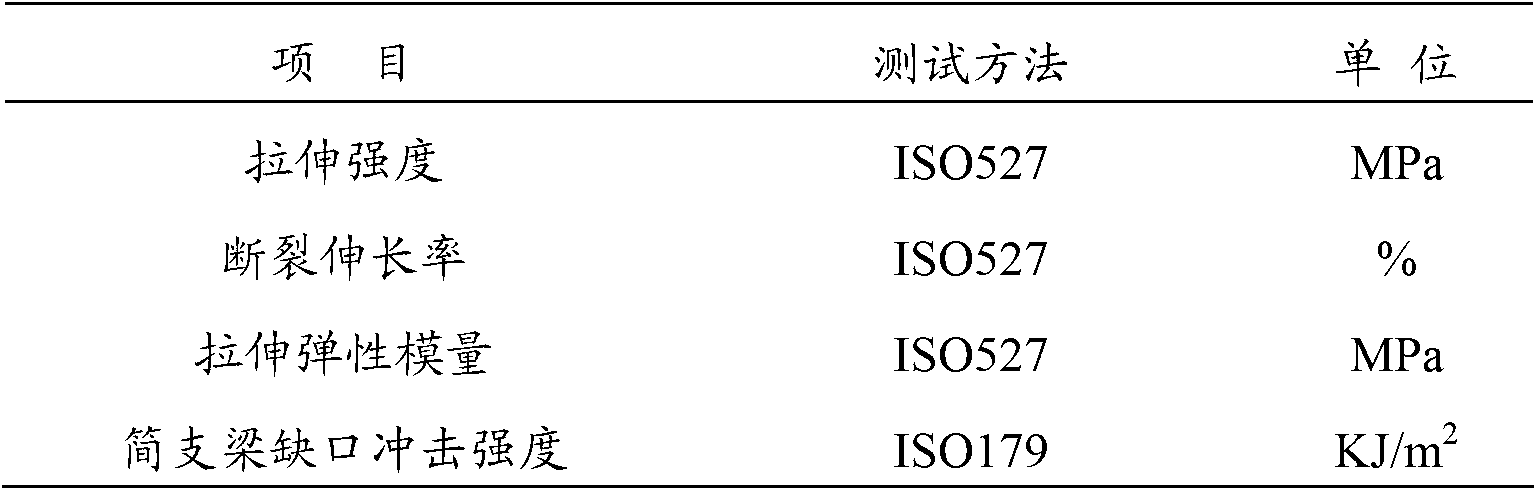

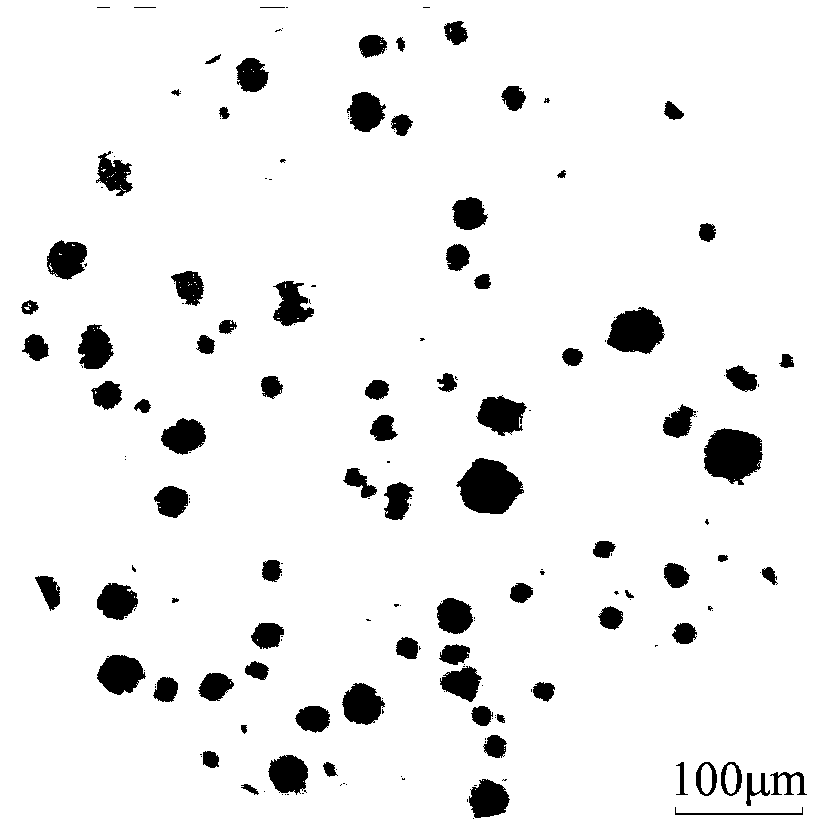

Polyformaldehyde composition and preparation method thereof

The invention discloses a polyformaldehyde composition and a preparation method thereof. The polyformaldehyde composition contains by part of weight: 100 parts of acetal resins, 0.01-2 parts of oxidation inhibitors, 0.01-2 parts of formaldehyde catching agents, 0.01-2 parts of formic acid catching agents and 0.01-5 parts of crosslinking acetal resins. Compared with the prior art, the crosslinking acetal resins serve as nucleating agents and are obvious in nucleating effects, and a great number of crystal nucleuses are formed before crystallization of the acetal resins, so that crystallization of the acetal resin is induced, the number of the crystal nucleuses is improved, crystallization degree and temperature are improved, sphaerocrystal dimension is lowered, and accordingly crystallization structure of the acetal resin is improved. Further, due to the fact that the adding amount of the crosslinking acetal resins is small, and bad influence on mechanical property, thermal performance and surface morphology of the polyformaldehyde composition is avoided. Experiment results prove that the sphaerocrystal dimension of the polyformaldehyde composition is about 40 mu m, and the polyformaldehyde composition has good crystalline structure and good mechanical property.

Owner:YUNNAN YUNTIANHUA

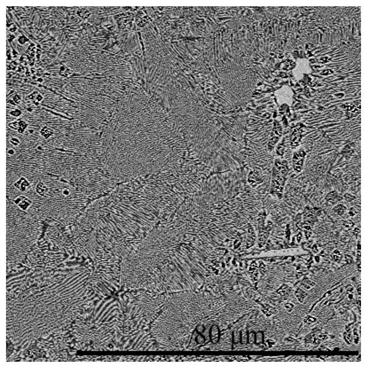

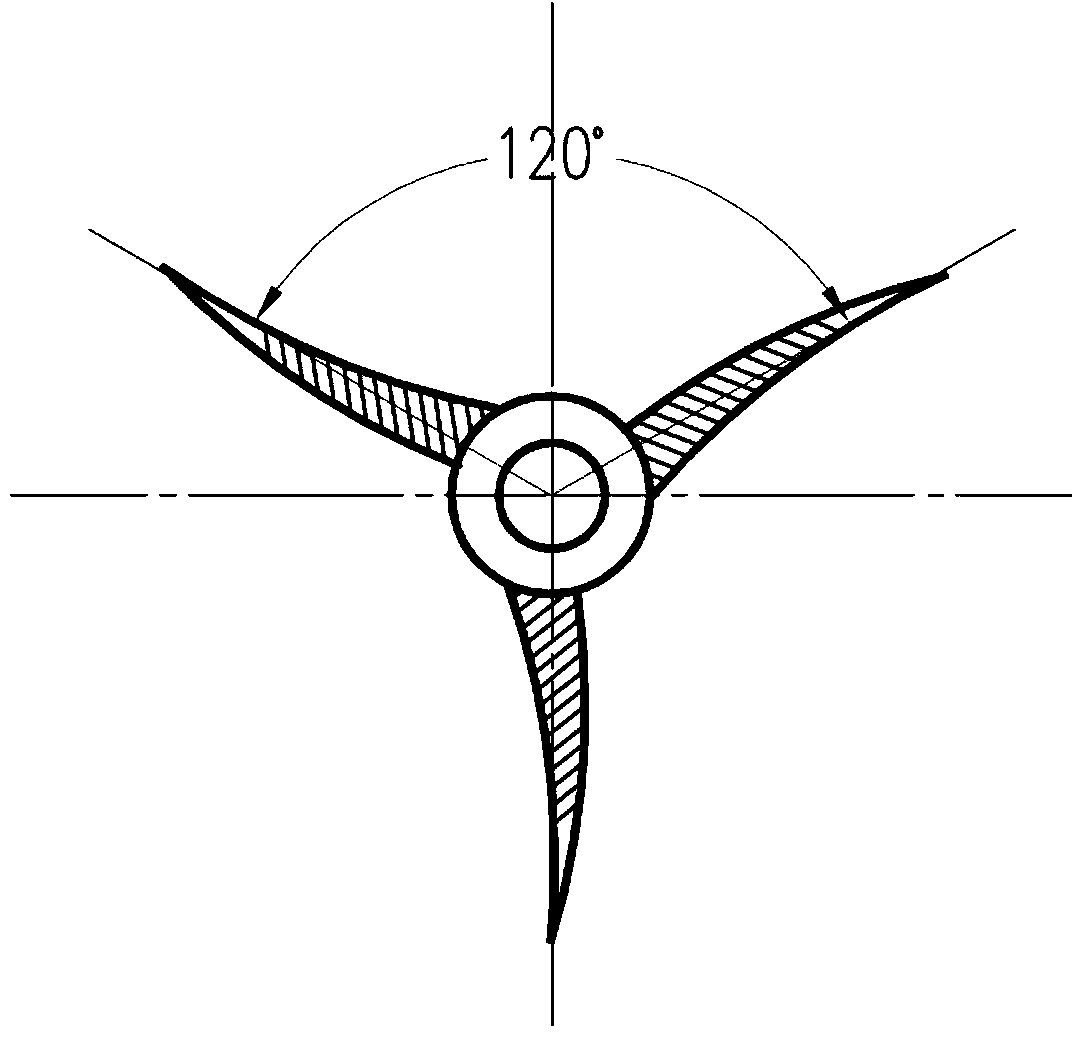

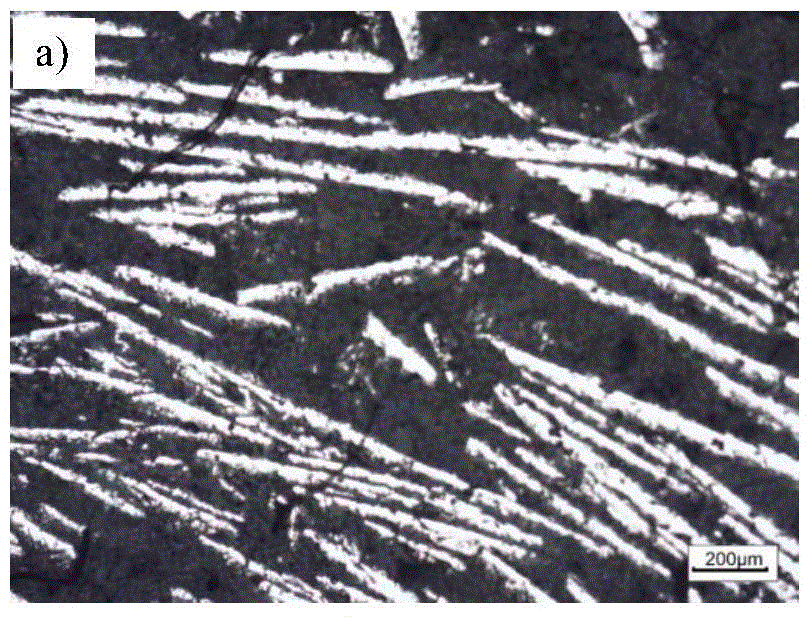

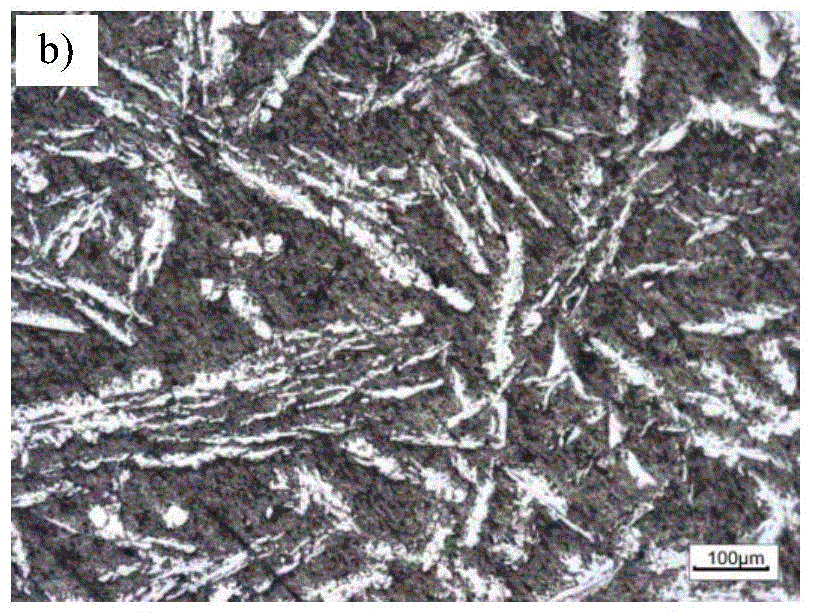

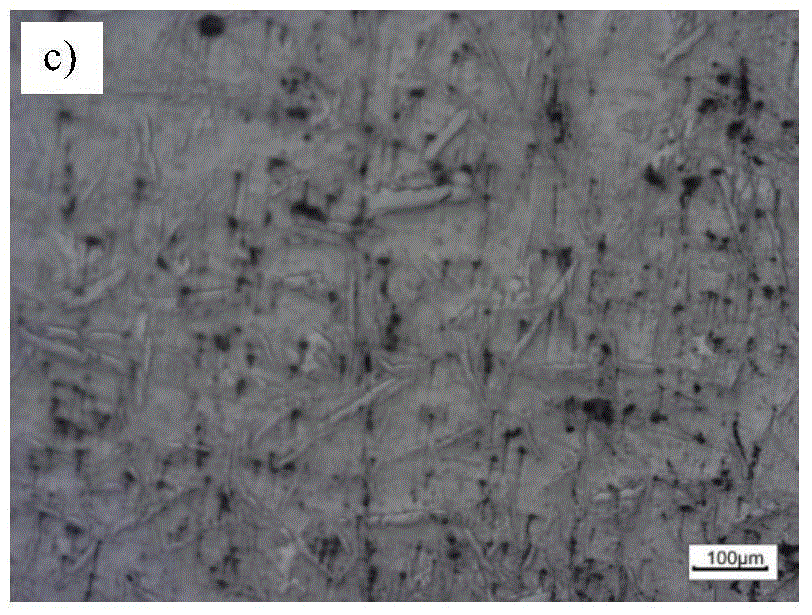

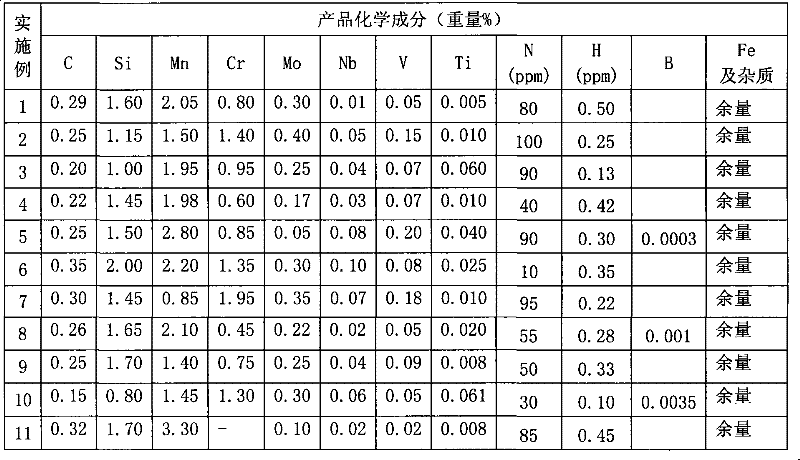

Hot rolled bainite steel rail and production process

The invention discloses a hot rolled bainitic steel rail and a production process. The hot rolled bainitic steel rail comprises the following chemical compositions in percentage by weight: 0.10 to 0.35 percent of C, 0.80 to 2.00 percent of Si, 0.80 to 3.30 percent of Mn, less than 2.00 percent of Cr, 0.0010 to 0.0100 percent of N, 0.01 to 0.10 percent of Nb, 0.02 to 0.2 percent of V, 0.005 to 0.06 percent of Ti, 0.10 to 0.40 percent of Mo, less than 0.00005 percent of H and the balance of Fe and inevitable impurities. The process is characterized in that: a hole pattern method is adopted for the rough rolling of the steel rail, a universal method is adopted for the precision rolling of the steel rail, the rolling interval of adjacent passes in the rough rolling is controlled to more than 5 seconds and not more than 35 seconds, and the steel rail after the rolling is naturally cooled in the air to room temperature. The production process limits the size of residual austnesite in M-A islands and between lath bainitic ferrite; the proportion of the lath bainitic ferrite is over 75 percent; comprehensive indexes of performance such as specific elongation and the like are improved; and the production process can be also applied to turnout bainitic steel rails and bainitic AT rails.

Owner:ANGANG STEEL CO LTD

Method for synthesizing kaolin microsphere in-situ crystallized product containing small crystal grain NaY molecular sieves

ActiveCN102019197APromote depolymerizationSmall grainMolecular sieve catalystsCatalyst activation/preparationMicrosphereSlurry

The invention relates to a method for synthesizing a kaolin microsphere in-situ crystallized product containing small crystal grain NaY molecular sieves. Kaolin is used as a raw material. The method comprises the following steps of: adding deionized water and sodium silicate or sodium pyrophosphate into the kaolin, mixing and slurrying, performing spray drying on the mixed slurry to prepare kaolin spray microspheres with particle diameters of 20 to 110 microns, roasting a part of the kaolin spray microspheres for 1 to 3 hours at the temperature of between 920 and 1,000 DEG C to obtain high-temperature roasted microspheres, and roasting the other part of the kaolin spray microspheres for 1 to 3 hours at the temperature of between 700 and 900 DEG C to obtain metakaolin microspheres; mixing the high-temperature roasted microspheres and the metakaolin microspheres in a mass ratio of 9:1-1:9, adding sodium silicate, directing agent, sodium hydroxide solution, deionized water and organic additive into the mixture, and crystallizing for 16 to 36 hours at the temperature of between 90 and 95 DEG C; and filtering, removing mother solution, and drying the filtrate to obtain the kaolin microsphere in-situ crystallized product containing NaY molecular sieve crystal grains of 200 to 400 nanometers.

Owner:PETROCHINA CO LTD +1

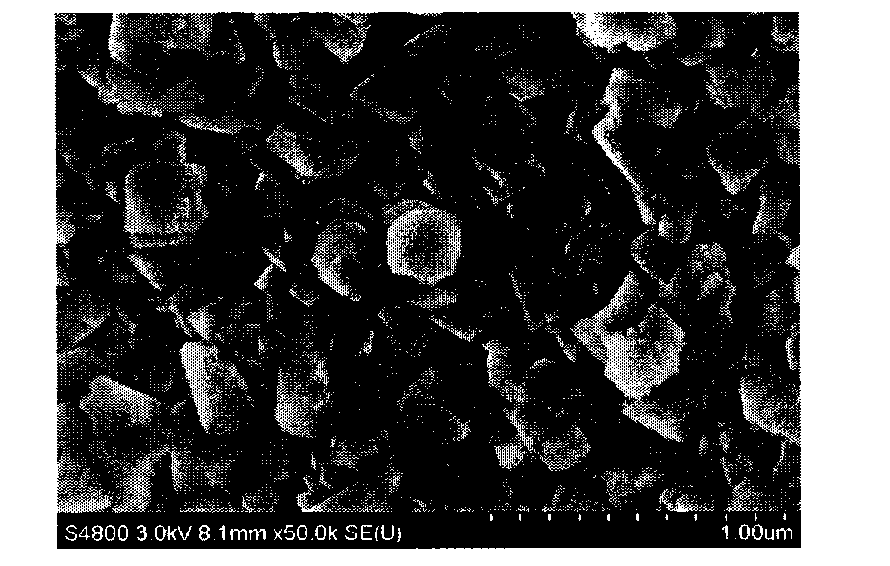

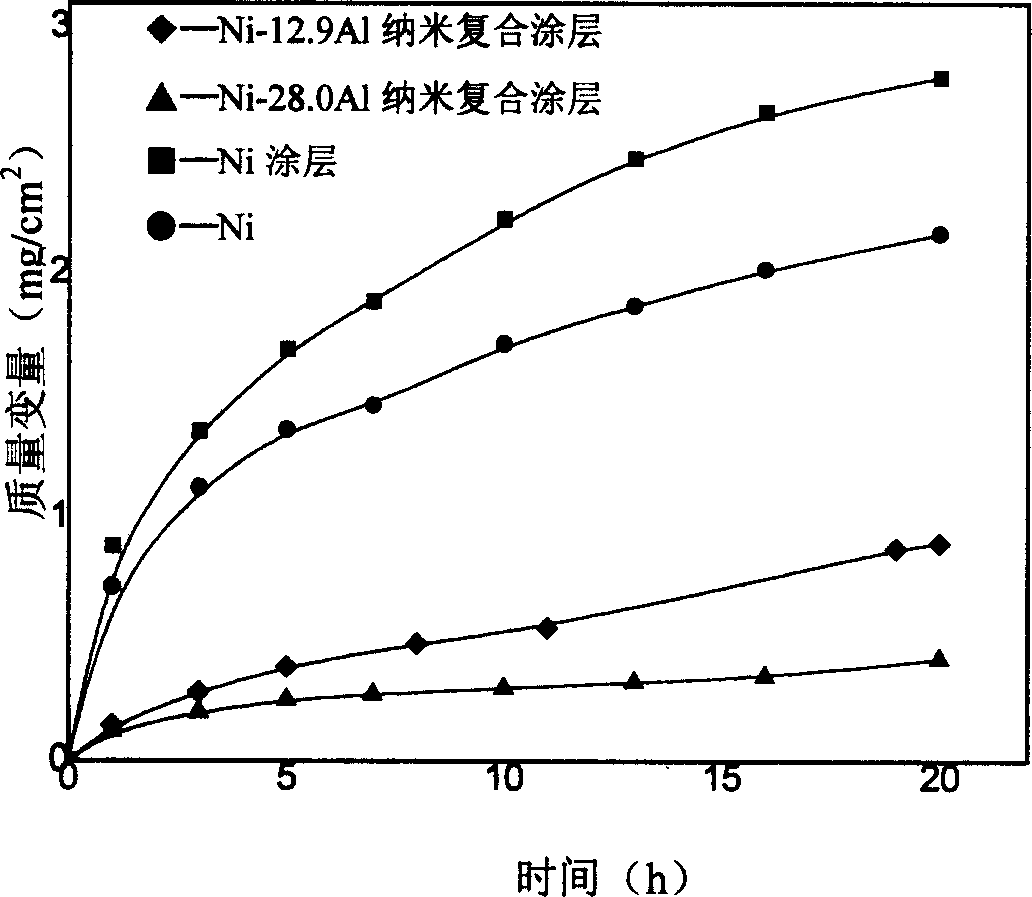

Thermal growth AL2O3 film type M A1 nano composite plating and producing process and application

InactiveCN1576398AIncrease the number of nucleiDiffusion fastElectrolytic coatingsGrown filmNanoparticle

The thermally grown Al2O3 film type M-Al nano composite coating consists of nano crystal M coating and nano metal Al grains dispersed in the coating, where M is Ni, Fe or Co. The Al content is 9.8-35 wt%, and M is the rest. The nano composite Ni-Al, Fe-Al or Co-Al coating is prepared through composite electroplating process to deposit metal M and Al coating on to the base material of Ni, Fe or Co, carbon steel or alloy steel. The present invention has the features of simple technological process, low cost, high and controllable compounded amount, compact coating, no need of vacuum diffusion treatment of the nano composite coating, direct thermally growth of protecting Al2O3 film, etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

As-cast high pearlite quantity and high vermicular rate vermicular graphite cast iron and preparation method thereof

ActiveCN108624807AEvenly distributedSimple preparation processProcess efficiency improvementCrack resistanceCreep rate

The invention discloses as-cast high pearlite quantity and high vermicular rate vermicular graphite cast iron and a preparation method thereof. The vermicular graphite cast iron is prepared from the following components by weight percent: 3.5-3.8% of C, 2.2-2.4% of Si, 0.8-1% of Mn, 0.2-0.4% of Cu, 0-0.4% of Mo, 0.08-0.1% of Sn, 0.2-0.4% of Cr, 0.2-0.5% of Ni, 0.05-0.1% of Nb, less than or equal to 0.06% of S, less than or equal to 0 .06% of P, and the balance of Fe and impurities introduced by raw materials. The vermicular graphite cast iron with a high creep rate (90-98%) is obtained by using an Mg-RE creeping method for controlling; furthermore, by means of micro-regulation of multiple alloy elements, the vermicular graphite cast iron with a high high pearlite quantity (90%-100%) can bestably obtained; the tensile strength of the vermicular graphite cast iron is greater than or equal to 500MPa, the elongation of the vermicular graphite cast iron is greater than or equal to 1.5%, Brinell hardness of the vermicular graphite cast iron is 230-260HBW, and the microhardness of pearlite is 300-320HV. The vermicular graphite cast iron provided by the invention has the characteristics of being good in mechanical properties, thermal fatigue resistance, thermal crack resistance and wear resistance under the extremely harsh working conditions; the preparation method is simple in control method and can stably produce castings with excellent comprehensive performance, thus being suitable for industrial mass production.

Owner:西安洪盛冶金科技有限公司

Refractory high-entropy alloy and forming method thereof

The invention relates to a refractory high-entropy alloy and a forming method thereof. The forming method comprises the steps of preparation of a refractory high-entropy alloy raw material, electromagnetic induction suspension smelting, high-frequency electromagnetic stirring of semi-solid slurry and die-casting forming. According to the method, suspension smelting, electromagnetic stirring and semi-solid forming are combined, the problem of serious component segregation commonly existing in high-entropy alloy is avoided, and a product with a fine and uniform microstructure and high density can be obtained.

Owner:苏州天峰动立合金科技有限公司

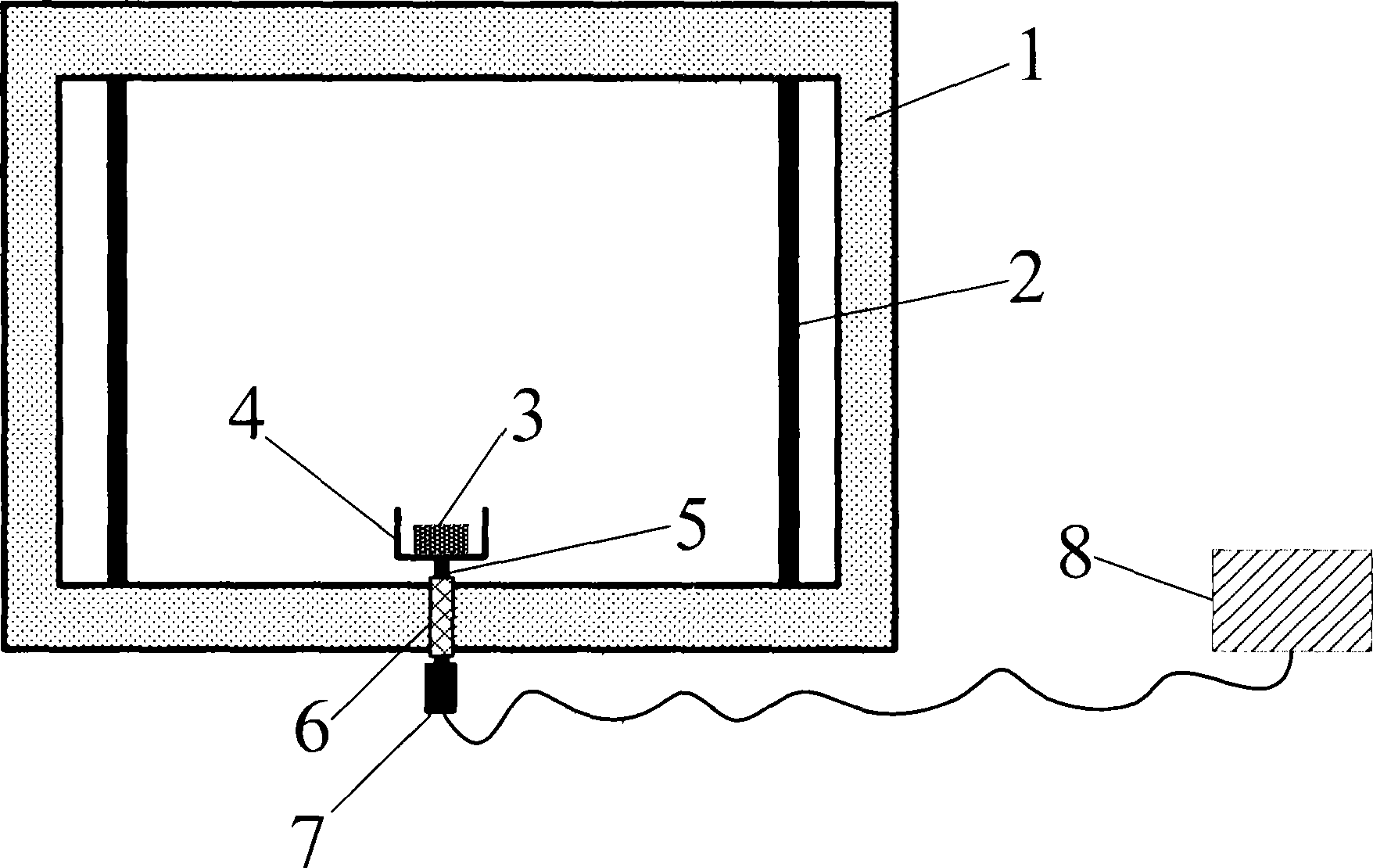

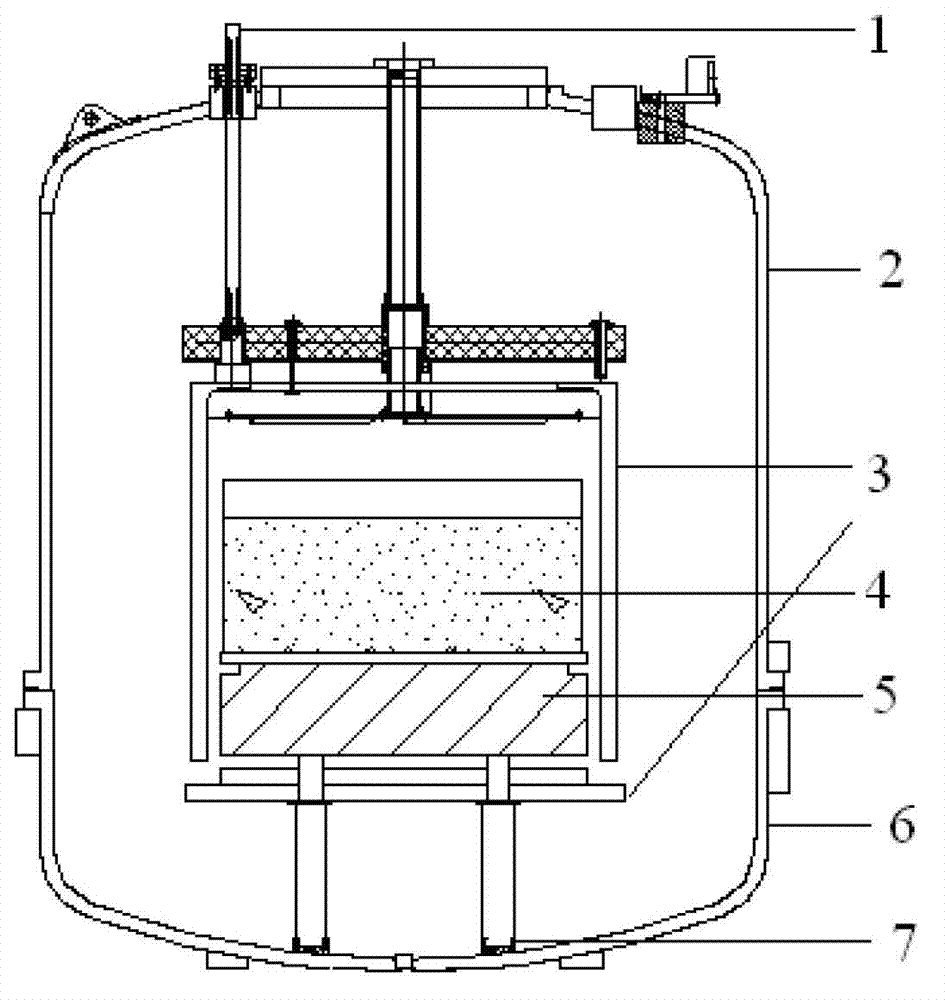

Ultrasonic-vibration activation-assisted sintering box-type resistance furnace

InactiveCN104180655AInhibit growthLarge grainCrucible furnacesParticulatesElectrical resistance and conductance

The invention provides an ultrasonic-vibration activation-assisted sintering box-type resistance furnace aiming at actual demands of research and development of new materials upon a sintering technology, inherent defects of the resistance furnace and the advantages of an ultrasonic technology. The ultrasonic-vibration activation-assisted sintering box-type resistance furnace comprises a furnace shell, a heating element, a furnace door, a crucible, an amplitude-change pole, an amplitude-change pole supporting frame, an ultrasonic generator and an ultrasonic transducer; ultrasonic power and loading time are controlled through the ultrasonic generator, electrical signals generated from the ultrasonic generator are converted into ultrasonic vibration through the ultrasonic transducer, the ultrasonic vibration transfers to-be-sintered samples through the amplitude-change pole and the crucible, the to-be-sintered samples are enabled to be in the ultrasonic vibration state during sintering, matter particulates of the to-be-sintered samples vibrate at a high speed under high temperature to promote crystal particulates of the to-be-sintered samples to evenly nucleate and grow up or evenly melt. By the arrangement, micro-structure of the massive sintering samples is evener and more compact, and powdery sintering samples can be more evenly dispersed.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Polycrystalline silicon ingot furnace and method for preparing polycrystalline silicon ingot with even and fine crystalline grains

InactiveCN103243392ASmall sizeIncrease the number of nucleiPolycrystalline material growthSingle crystal growth detailsMetallurgyIngot

The invention provides a polycrystalline silicon ingot furnace and a method for preparing a polycrystalline silicon ingot with even and fine crystalline grains. The polycrystalline silicon ingot furnace comprises a heat insulating cage lifting mechanism, an upper furnace body, a heat insulating cage, a crucible assembly, a directional coagulantion enhancement block, a lower furnace body, a support pillar and an ultrasonic generator, wherein the ultrasonic generator is arranged at the bottom of the outer wall of the lower furnace body, or on the side surface of the outer wall of the upper furnace body. The polycrystalline silicon ingot furnace and the method are characterized in that in the process of producing the polycrystalline silicon ingot, the ultrasonic generator is opened when the polycrystalline melt is in critical nucleation state, and the ultrasonic generator is closed in 1-20 min, and mechanical oscillation is introduced in initial stage of polycrystalline nucleation, so that the polycrystalline silicon ingot with even and fine in crystalline grains can be formed.

Owner:TIANJIN YINGLI NEW ENERGY RESOURCES

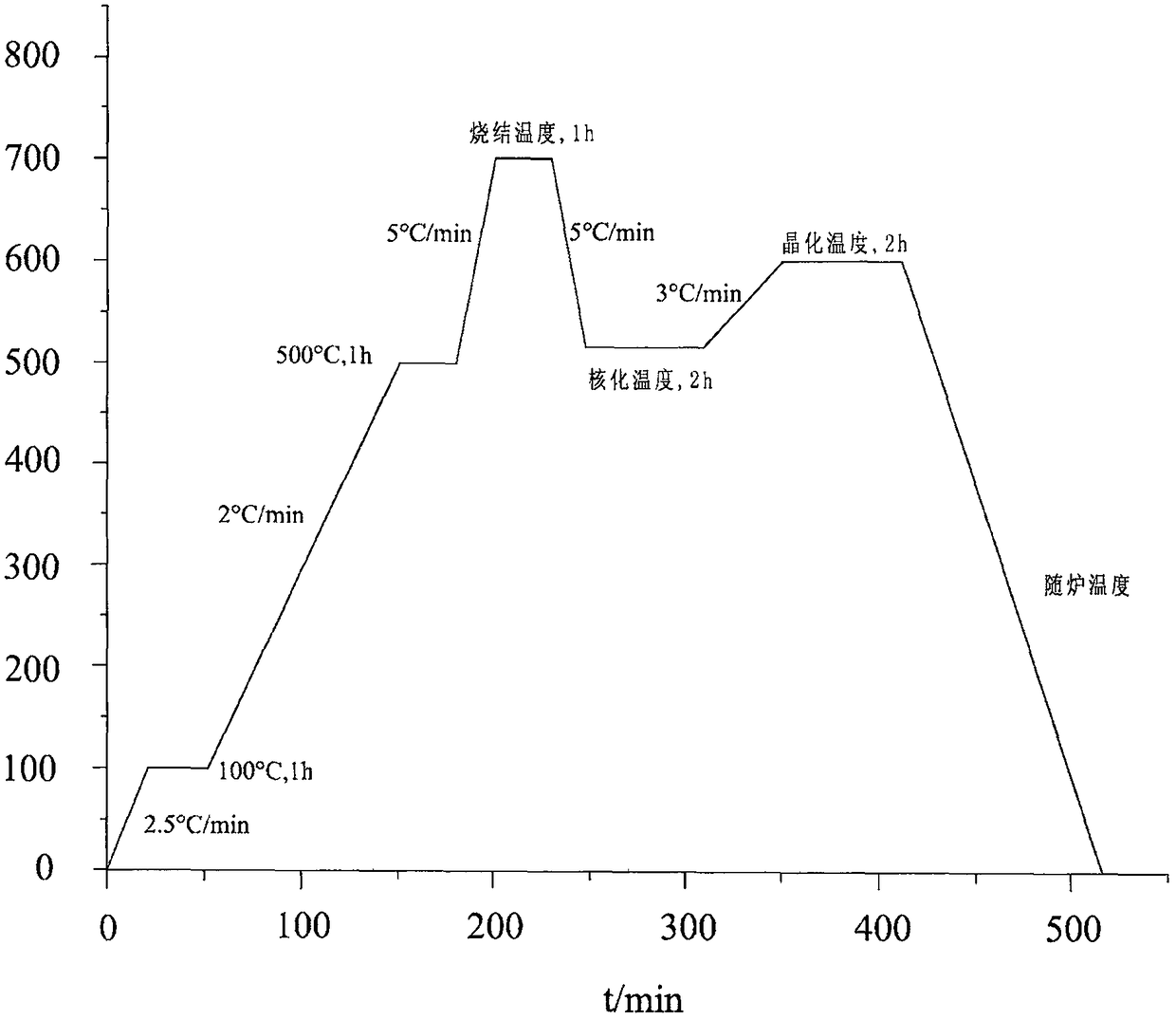

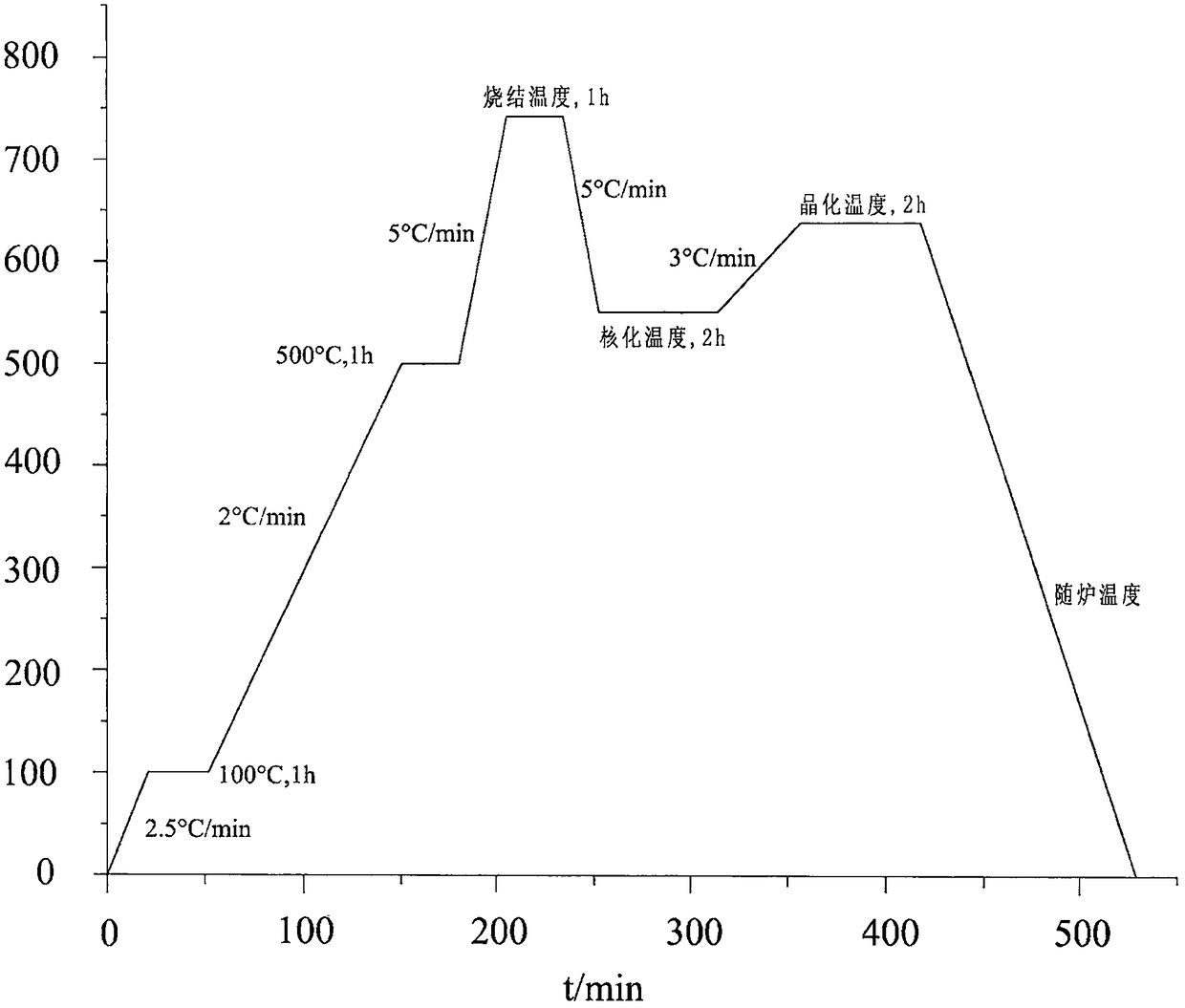

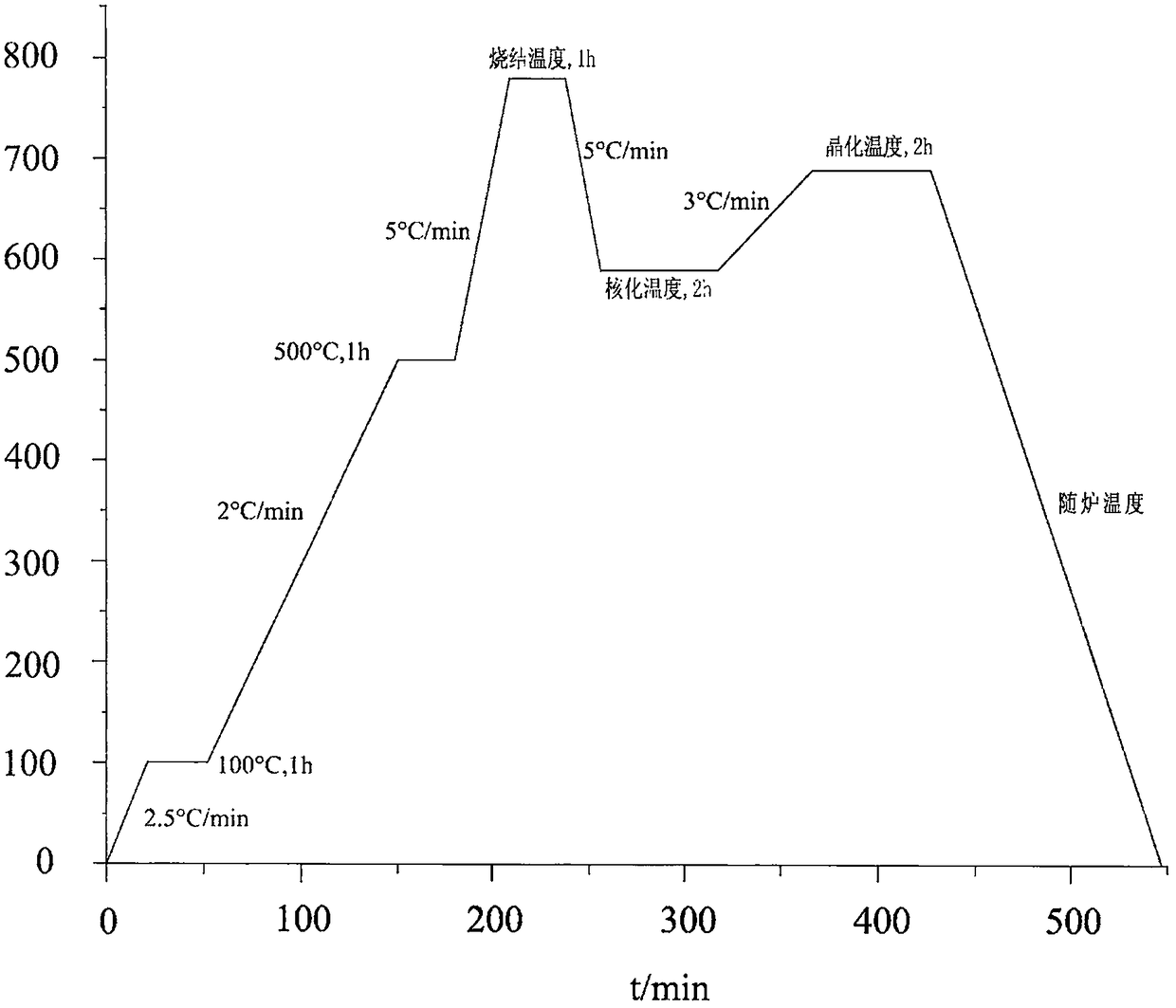

Ceramic microcrystal diamond wheel for grinding titanium alloy and preparation method thereof

InactiveCN108098602AIncrease the number of nucleiGuarantee the number of nucleiAbrasion apparatusGrinding devicesLiquid stateTitanium alloy

The invention discloses a grinding wheel for grinding titanium alloy and a preparation method thereof. The grinding wheel for grinding titanium alloy is prepared with the fallowing raw materials, by weight, 65 parts to 75 parts of cellular diamond abrasive materials, 20 parts to 30 parts of ceramic microcrystal bonding agents, 3 parts to 6 parts of temporary sticky patches, and 5 parts to 10 partsof pore-forming agents. According to the grinding wheel for grinding titanium alloy, and the preparation method thereof, the adopted ceramic microcrystal bonding agents provide advantages for improving the bonding strength, wear resistance, self-sharpening, cutting edges, grinding efficiency and heat dissipation performance of a grinding tool; the filling agents, namely refined naphthalene, generate uniform air holes after volatilizing due to the high temperature, and the heat dissipation performance of the grinding wheel is further improved; and additionally, because an isostatic press is adopted, pressure is transmitted in a liquid state, and the texture uniformity and the product stability of the grinding tool are improved.

Owner:郑州宏拓精密工具有限公司

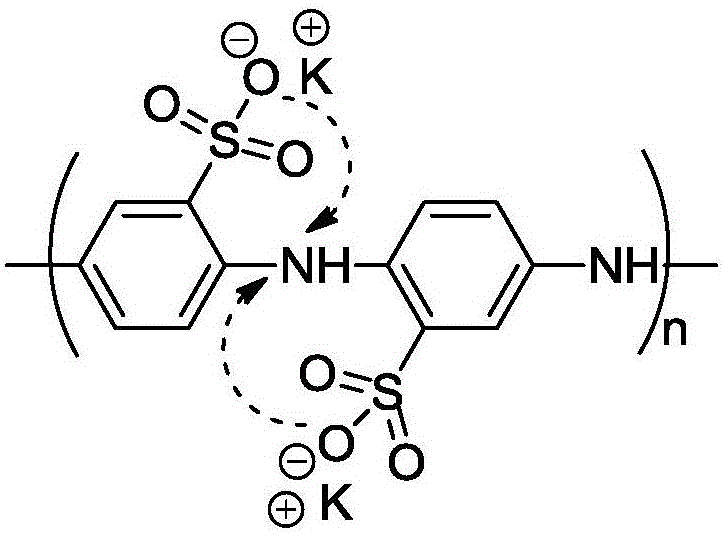

Battery cathode diachylon formulation high in utilization rate of active substance and preparation method of battery cathode diachylon formulation

The invention relates to a battery cathode diachylon formulation high in utilization rate of active substance and a preparation method of the battery cathode diachylon formulation and belongs to the technical field of lead-acid storage batteries. The the battery cathode diachylon formulation comprises dilute sulfuric acid of 1.38g / ml in density, deionized water, lignin Vanisperse AT, polyaniline potassium sulfonate PAN-K, nano hollow barium sulfate, acetylene black, emulsion carbon naotube Sus-CNT and lead powder. On the basis of a conventional cathode diachylon formulation, water-soluble PAN-K is adopted to completely replace conventional polyester staple fiber, nano hollow barium sulfate is adopted to completely replace conventional precipitated barium sulfate, and the emulsion carbon nanotube Sus-CNT is adopted to partly replace deionized water for paste mixing. On the premise that circulating life of a cathode produced by the formulation is not shortened, active substance utilization rate and charging receiving capability of the cathode are remarkably improved, and the battery cathode diachylon formulation is about to have great application and popularization prospect in the field of lowering weight of active substance of the cathode and lowering manufacturing cost of the lead-acid storage batteries.

Owner:CAMEL GRP HUAZHONG BATTERY

Confined vortex flow reactor and application thereof to preparation process of Me-SAPO-34 molecular sieve

ActiveCN104353404AEnhanced mixing processIncrease the frequency of collisionsChemical/physical/physico-chemical stationary reactorsMolecular-sieve and base-exchange phosphatesMolecular sieveChemical physics

The invention inventively provides a confined vortex flow reactor and application thereof to a preparation process of a Me-SAPO-34 molecular sieve. The confined vortex flow reactor comprises a multi-stage reaction channel with the shape similar to an apron, wherein the width of the multi-stage reaction channel decreases continuously or in a stepping way from the top to the bottom; two side surfaces forming the multi-stage reaction channel can move relatively. When the confined vortex flow reactor implements forcible mixing of particles in a molecular level, the time scale is reduced to a millisecond level, so that the Me-SAPO-34 molecular sieve structure with a more regular structure, a smaller size and narrower particle size distribution can be prepared; the confined vortex flow reactor is especially applicable to needs of industrial production of a catalyst.

Owner:CHINA TIANCHEN ENG +1

Refiner for aluminum alloy and preparation method

The invention provides a refiner for aluminum alloy and a preparation method. The refiner for the aluminum alloy comprises, by weight, the components of 4.5-5.5% of titanium, 0.2-0.4% of cerium, 0.6-1.8% of magnesium and the balance aluminum. The refining effects of two refiners of Al-5Ti and Al-5Ti-0.7Mg-0.3Ce on Ai-Si alloy are compared to find that the refining effect of the Al-5Ti-0.7Mg-0.3Ce is better than that of the Al-5Ti due to the fact that the size of Al3Ti in the Al-5Ti-0.7Mg-0.3Ce is obviously smaller than that of the Al-5Ti in the Al-5Ti-0.7Mg-0.3Ce, therefore, the quantity of heterogeneous nucleation is increased, and the refining effect is more obvious; in addition, an element Mg and rare earth elements are filled in the interface of an alpha-Al dendritic crystal and eutectic silicon, therefore, the growth of the alpha-Al dendritic crystal is prevented, the improvement of the refining effect is facilitated, and more remarkable, the improvement effect of the interaction effect of the element Mg and the rare earth elements for a refining structure is more obvious than that of a single rare earth element.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Crystallization accelerating agent for crystallization/semi-crystallization polyurethane and preparing method and application thereof

ActiveCN105778032AFast crystallizationHigh hardnessPolyureas/polyurethane adhesivesPolyesterAging resistance

The invention discloses a crystallization accelerating agent for crystallization / semi-crystallization polyurethane and a preparing method and application thereof.In the prior art, control over the crystallization morphology and the crystallization speed of the crystallization / semi-crystallization-type polyurethane does not exist, and the advantage of a crystallization / semi-crystallization polymer can not be most effectively developed.According to the crystallization accelerating agent, polyester diol serves as a structural body, and closed isocyanate serves as a potential reactive functional group.The crystallization accelerating agent is applied to the crystallization / semi-crystallization polyurethane, the crystallization speed can be increased, and the crystallization morphology can be improved; in the use process or the heat existing process, the potential closed isocyanate functional group can be further reacted with polyurethane resin or an active group on a contact base material, and hardness, strength and aging resistance are improved.

Owner:传化智联股份有限公司 +2

Hot rolled bainite steel rail and production process

The invention discloses a hot rolled bainitic steel rail and a production process. The hot rolled bainitic steel rail comprises the following chemical compositions in percentage by weight: 0.10 to 0.35 percent of C, 0.80 to 2.00 percent of Si, 0.80 to 3.30 percent of Mn, less than 2.00 percent of Cr, 0.0010 to 0.0100 percent of N, 0.01 to 0.10 percent of Nb, 0.02 to 0.2 percent of V, 0.005 to 0.06 percent of Ti, 0.10 to 0.40 percent of Mo, less than 0.00005 percent of H and the balance of Fe and inevitable impurities. The process is characterized in that: a hole pattern method is adopted for the rough rolling of the steel rail, a universal method is adopted for the precision rolling of the steel rail, the rolling interval of adjacent passes in the rough rolling is controlled to more than 5 seconds and not more than 35 seconds, and the steel rail after the rolling is naturally cooled in the air to room temperature. The production process limits the size of residual austnesite in M-A islands and between lath bainitic ferrite; the proportion of the lath bainitic ferrite is over 75 percent; comprehensive indexes of performance such as specific elongation and the like are improved; andthe production process can be also applied to turnout bainitic steel rails and bainitic AT rails.

Owner:ANGANG STEEL CO LTD

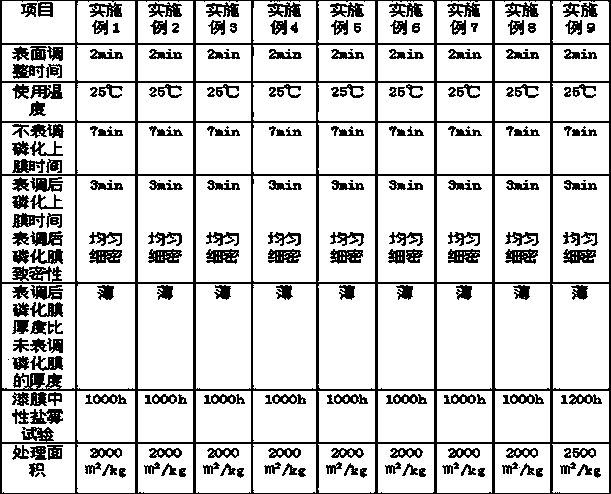

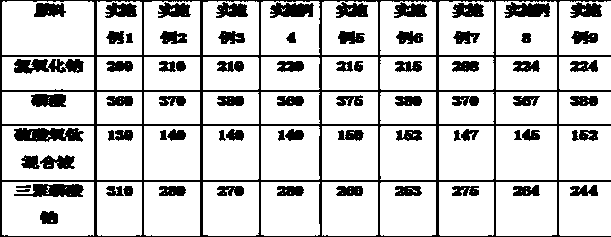

Colloid titanium surface conditioner and preparation method thereof

ActiveCN103741132AStrong anti-rust functionReduce rust return rateMetallic material coating processesPhosphatePhosphoric acid

The invention discloses a colloid titanium surface conditioner which is prepared from the following raw materials in parts by weight: 20-23 parts of sodium hydroxide, 36-40 parts of phosphoric acid, 13-16 parts of titanyl sulfate mixed liquid and 24-30 parts of sodium tripolyphosphate. By adopting the colloid titanium surface conditioner, a phosphate coating crystal is denser and more uniform, the adhesion and corrosion resistance are remarkably improved, all growth process of a conversion coating can be finished at relatively low temperature within relatively short time, the phosphating coating speed is particularly high, and complete lamination can be realized by 30 seconds of phosphating.

Owner:HUNAN JINYU CHEM

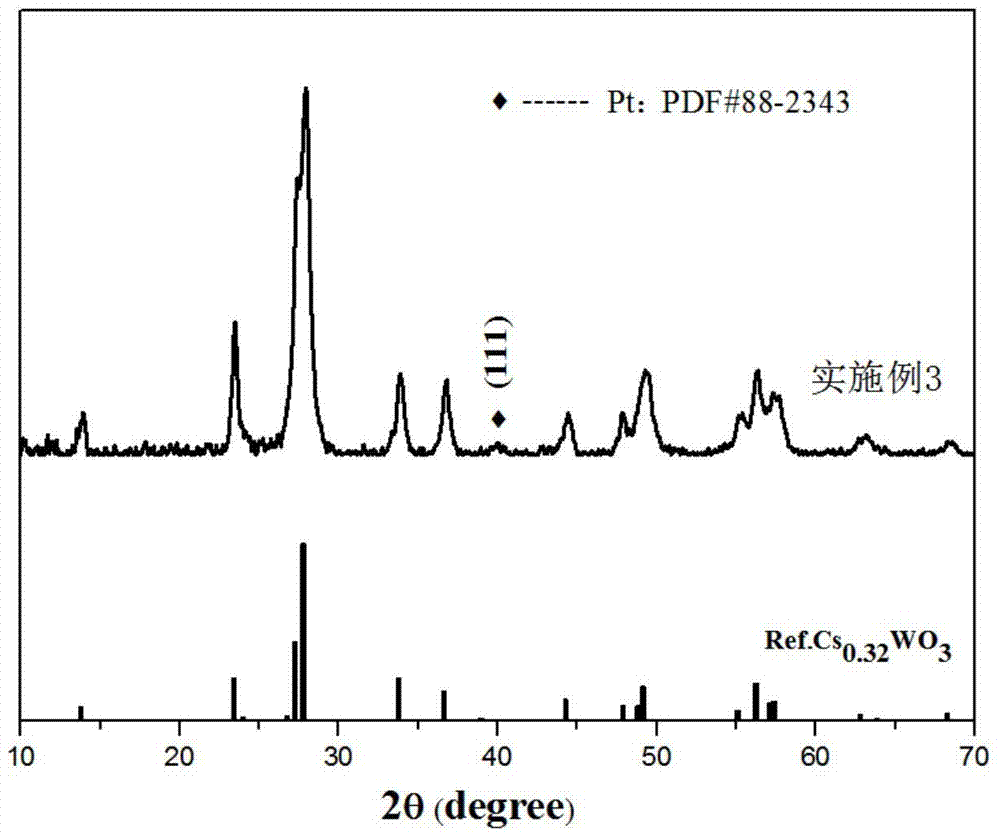

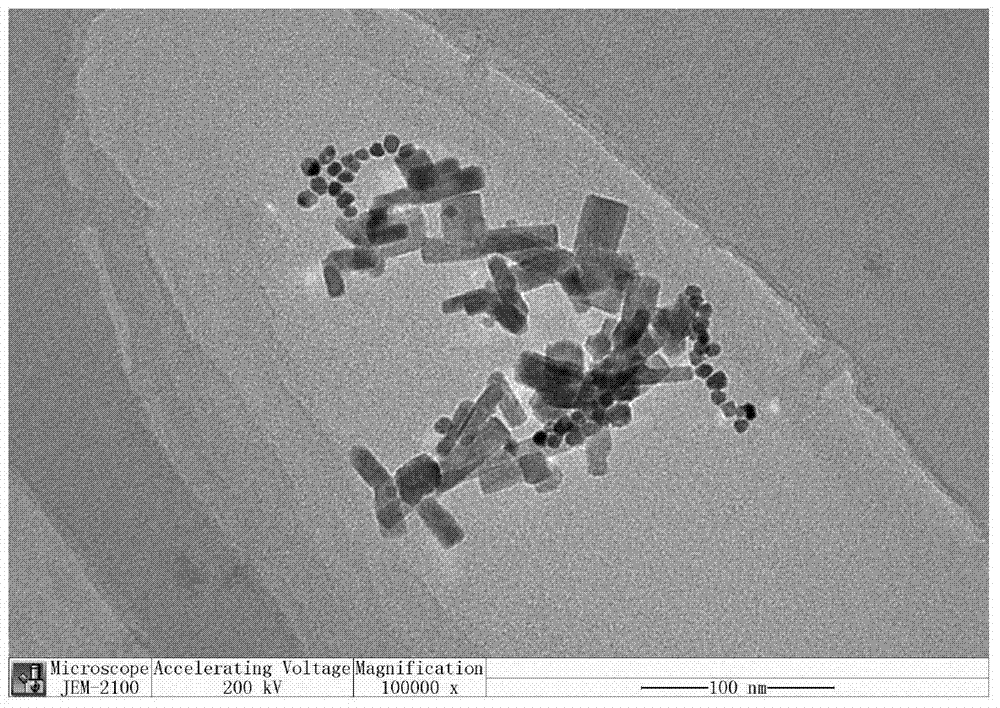

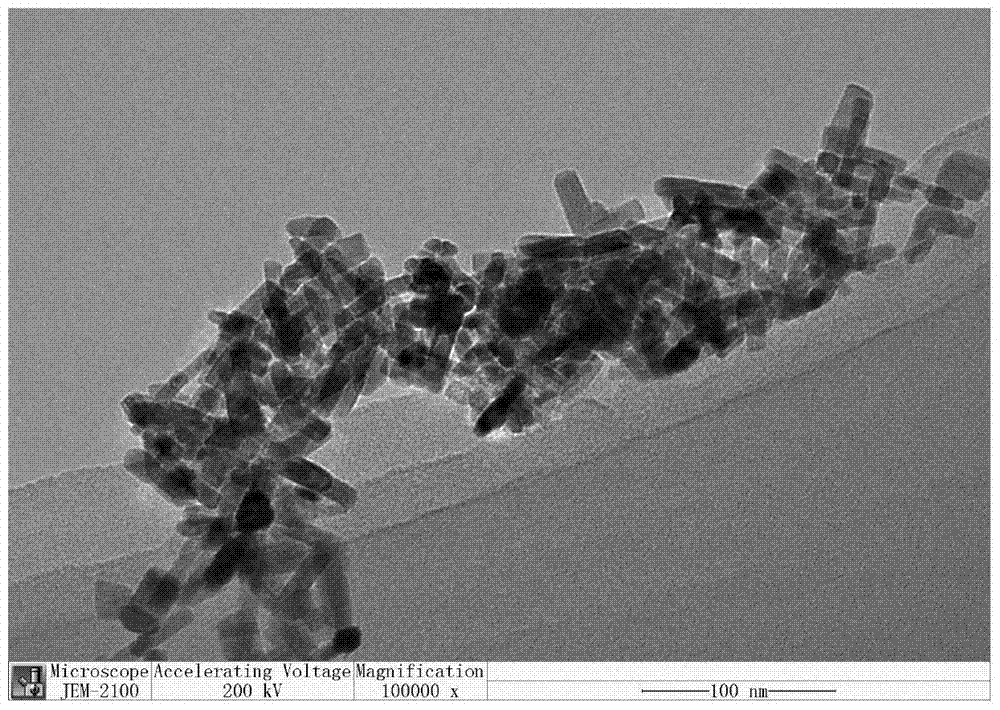

A kind of tungsten bronze nano short rod particles catalyzed and doped by variable valence metal and its preparation method

ActiveCN105668632BImprove visibilityIncrease the number of nucleiTungsten compoundsFiberMultifunctional nanoparticles

The invention provides a variable valency metal catalyzed and doped tungsten bronze Ax-MyWO3 nano-short rod particle and a preparation method thereof. The method consists of: firstly making solid colloidal tungstic acid as a tungsten source, mixing the tungsten source with an M source, an appropriate solvent and an inducing agent, adding a proper amount of a variable valency metal A salt, and carrying out thermal reaction to synthesize the variable valency metal catalyzed and doped tungsten bronze Ax-MyWO3 multifunctional nanoparticle. The synthesized Ax-MyWO3 nano-short rod particle has excellent visible light permeability and near-infrared shielding performance and photothermal conversion ability, can be widely used for preparation of glass transparent thermal insulation paint, transparent and heat insulation compounds, photothermal absorbing coatings, solar thermal collectors, solar water heater coatings, heating fiber and photothermal therapy nanoparticles, etc. At the same time, the synthesized variable valency metal catalyzed and doped tungsten bronze Ax-MyWO3 nano-short rod particle also has excellent photocatalysis ability, and can be widely applied to the photocatalytic degradation field of organic pollutants.

Owner:DALIAN POLYTECHNIC UNIVERSITY

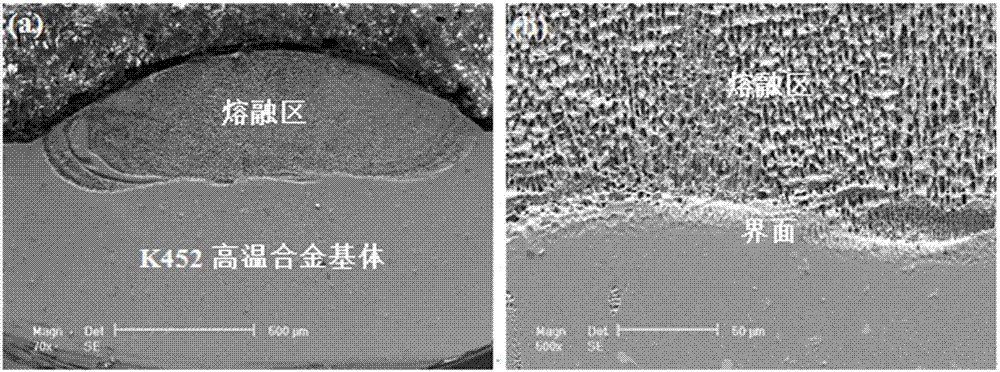

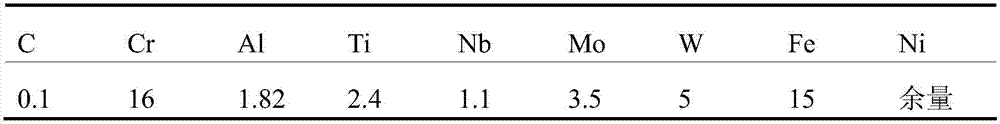

Nickel-based multi-component laser cladding powder and laser cladding method for powder

ActiveCN106884109AImprove wettabilityImprove high temperature ductilityMetallic material coating processesAlcoholCrack free

The invention relates to the field of laser cladding materials, and discloses nickel-based multi-component laser cladding powder. The powder comprises, by mass, 10-25% of Fe, 6-15% of Al, 1-5% of TiB2, 0.5-1.0% of Dy and the balance Ni. The invention further discloses a laser cladding method for the powder. The method comprises the steps that the nickel-based multi-component laser cladding powder and absolute ethyl alcohol are mixed, the surface of a cladding base material is evenly covered with the mixture, drying is carried out after roll pressing, a preformed layer is formed, and the cladding layer can be obtained through laser cladding. By means of the technology, the crack-free laser cladding layer can be obtained, the hardness is high, the cost is low, the fusion degree is improved, the strength and plasticity are ensured, and the powder is suitable for repair machining of various parts.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Modified inoculation core-spun yarn and preparation method thereof

The invention belongs to the technical field of material chemistry and specifically relates to a modified inoculation core-spun yarn and a preparation method thereof. The modified inoculation core-spun yarn is prepared from the following raw materials in percentage by mass: 60-90% of inoculation core-spun yarn, 10-20% of micron silicon carbide and 2-10% of nano silicon carbide. The modified inoculation core-spun yarn provided by the invention can increase the nucleation quantity, optimize the nodulizing process and improve the mechanical property of the casting.

Owner:HEFEI KAIER NANOMETER ENERGY & TECH

Chemical nickel plating solution with high corrosion resistance and stability on surface of aluminum alloy and preparation method and application thereof

ActiveCN111074250AImprove stabilityQuality improvementLiquid/solution decomposition chemical coatingButanedioic acidSodium phosphates

The invention discloses a chemical nickel plating solution with high corrosion resistance and stability on the surface of an aluminum alloy and a preparation method and application of the chemical nickel plating solution. The chemical nickel plating solution is composed of deionized water, main salt, a reducing agent, a complexing agent, a buffering agent, a stabilizer and a brightener. The main salt is nickel sulfate, the reducing agent is sodium hypophosphite, the complexing agent is composed of glycine and lactic acid, the buffering agent is composed of sodium tetraborate and succinic acid,the stabilizer is composed of cobalt nitrate and potassium iodide, and the brightener is polyethylene glycol. An environmental-friendly chemical nickel plating system with high corrosion resistance and high stability and a simple and efficient pretreatment process are developed, so that the process flow is simplified, the production cost is reduced, and the corrosion resistance of the aluminum alloy is greatly improved.

Owner:XI AN JIAOTONG UNIV

Modified spherified core-spun wire and preparation method thereof

The invention belongs to the technical field of material chemistry, and particularly relates to a modified spherified core-spun wire and a preparation method thereof. The modified spherified core-spunwire comprises, by mass part, 60 wt% to 90 wt% of spherified core-spun wires, 10 wt% to 20 wt% of micron silicon carbide and 2 wt% to 10 wt% of nano silicon carbide. According to the modified spherified core-spun wire and the preparation method thereof, the nucleation number of CADI can be increased, and the spherifying process can be optimized.

Owner:HEFEI KAIER NANOMETER ENERGY & TECH

Vibration-solidified low-stress lathe bed casting and casting method thereof

ActiveCN105945261AImprove surface qualityOvercome stomataFoundry mouldsFoundry coresLiquid metalCasting defect

The invention relates to a production method of a lathe bed casting and application, in particular to a vibration-solidified low-stress lathe bed casting and a casting method thereof. The casting method comprises the steps that a sand mould of the lathe bed casting is firstly manufactured; liquid metal is smelted and poured; and three-dimensional vibration solidification is performed. For three-dimensional vibration solidification, through a wavelet spectral analysis technology, after a casting mould cavity is filled with molten iron, a 10-200 Hz low-frequency three-dimensional resonance field is applied; when the molten iron is cooled to a temperature in the range of a Fe-C eutectic point+ / -50 DEG C, 200-2000 Hz high-frequency three-dimensional resonance is performed; the casting sand mould is subjected to still standing; a riser and a runner are cut off; and a flash is ground and removed. The low-frequency three-dimensional resonance field enables the mould cavity to be fully filled with the liquid metal, so that pores, impurity mingling, segregation, cavity shrinkage and other casting defects which often happen during a traditional casting process are overcome; by utilizing the high-frequency three-dimensional resonance, the supercooling degree of the molten iron is improved; solidification nucleation is facilitated; the number of nucleation is increased; and the structure refinement of crystals is facilitated. The casting method is simple in process, low in cost, simple for operation and wide in application range and is pollution-free; the quality of the casting can be obviously improved; and the residual stress of the casting is lowered.

Owner:SICHUAN JIANYANG HAITE

Carbonizer for continuously synthesizing calcium carbonate and production method of calcium carbonate

InactiveCN102295306BContinuous productionIncrease supersaturationCalcium/strontium/barium carbonatesNanotechnologyCalcium hydroxidePrecipitated calcium carbonate

The invention relates to a carbonizer for continuously synthesizing calcium carbonate and a production method of calcium carbonate, an input port of calcium hydroxide, an input port of carbon dioxide are provided on the body of the carbonizer, a discharge port is provided at the bottom of the carbonizer, the input port of calcium hydroxide and the input port of carbon dioxide are positioned at the top of the carbonizer body, the transverse trays with displacement from each other are uniformly arranged from the lower part to the bottom of two input ports in the body of the carbonizer, a layout of a S shape backflow baffle plate or a snaky shape backflow baffle plate is used between the adjacent trays. The calcium hydroxide slurry is a fluid suspension, and enables an equidirectional flow with carbon dioxide on the transverse trays between the trays, the calcium hydroxide slurry enters to the next tray from an outlet, three phases of gas, liquid and solid phase are reacted to generate precipitated calcium carbonate, the reacted material-carbonized boiled slurry is flowed out from the outlet of lower part of the reactor. The product has the advantages of adjustable particle size, narrow grain size distribution and stable quality, dispersibility, stability and alkali efflorescence are improved; the invention has the advantages of less equipment investment, short reaction time, less energy consumption, low cost, and the product enables continuous production.

Owner:连州市凯恩斯纳米材料有限公司

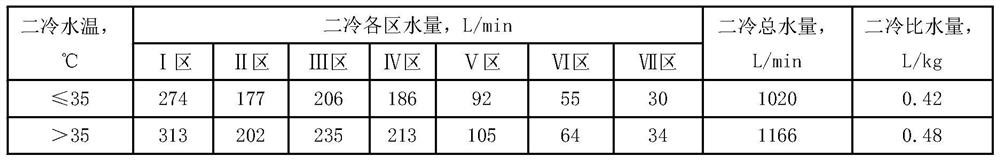

Method for improving flaw detection qualification rate of Q345C steel plate with specification of 14-30 mm

ActiveCN113005353AReduce segregationQuality improvementManufacturing convertersChemical compositionManganese

The invention provides a method for improving the flaw detection qualification rate of a Q345C steel plate with the specification of 14-30 mm, belongs to the technical field of medium-thickness steel plate production, and comprises a Q345C steel plate and a production method of the Q345C steel plate. The Q345C steel plate comprises the following chemical components of (unit, wt%) 0.15wt% to 0.18wt% of C, 0.20wt% to 0.40wt% of Si, 1.25wt% to 1.35wt% of Mn, P less than or equal to 0.025wt%, S less than or equal to 0.005wt%, 0.015wt% to 0.025wt% of Ti, 0.015wt% to 0.030wt% of Als and the balance Fe and residual elements. According to the method, in the production, the Q345C process technology is strictly controlled, the sulfur content and the manganese content of a finished product are strictly controlled; on the premise that the surface temperature of a casting blank is higher than the third brittleness temperature interval of steel by 900 DEG C or above when the casting blank is straightened, when the secondary cooling water temperature is lower than or equal to 35 DEG C, the secondary cooling specific water flow is controlled to be 0.42 L / kg, and when the secondary cooling water temperature is higher than 35 DEG C, the secondary cooling specific water flow is controlled to be 0.48 L / kg; and the casting blank is rolled after being cut and slowly cooled. Through the implementation of the method, the flaw detection qualification rate of the rolled Q345C steel plate with the specification of 14-30 mm is increased to 99.80% from 98.40%, and the qualification rate is increased.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

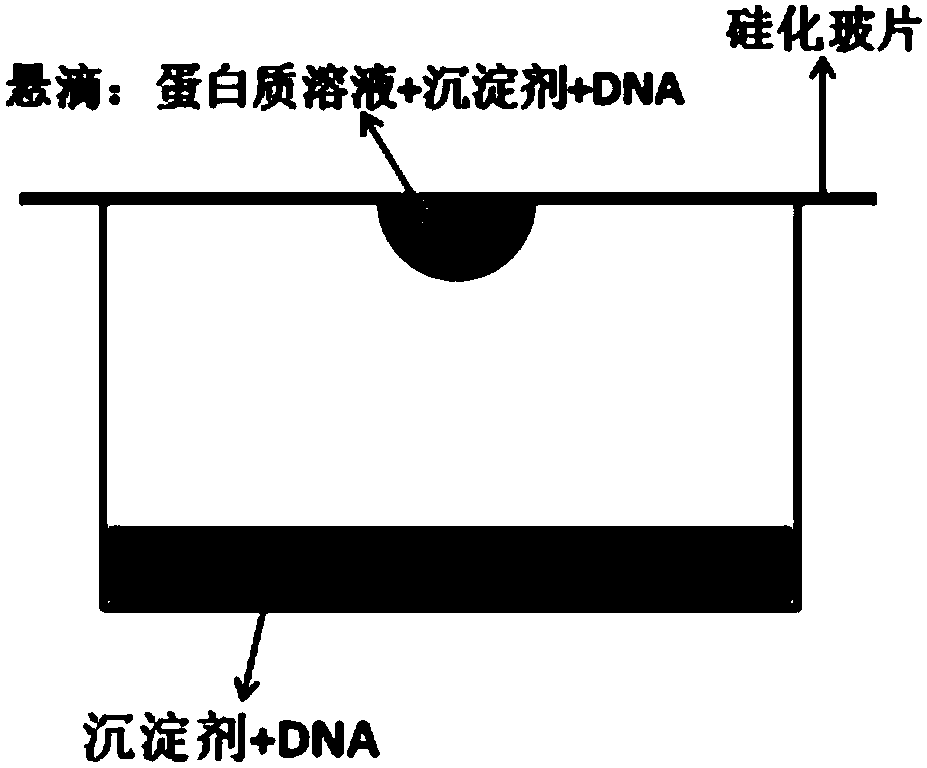

Use of deoxyribonucleic acid in promotion of protein crystallization and method for promoting protein crystallization

InactiveCN107814831AImprove the success rate of crystallizationMaintain biological activityPeptide preparation methodsChemistryProtein formation

The present invention discloses use of deoxyribonucleic acid in promoting of protein crystallization. The deoxyribonucleic acid can significantly increase the efficiency and success rate of the protein crystallization.

Owner:TSINGHUA UNIV

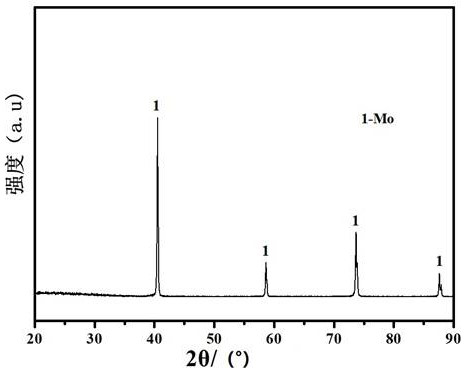

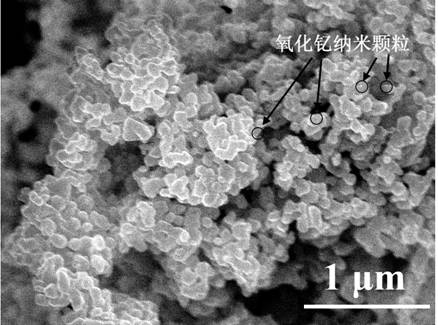

Preparation method and application of nano-molybdenum powder doped with yttrium oxide nano-particles

ActiveCN112207287AIncrease the number of nucleiGranularityNanotechnologyCarbon NanoparticlesYttrium(III) oxide

The invention discloses a preparation method of nano-molybdenum powder doped with yttrium oxide nano-particles. The preparation method comprises the following steps of 1, dispersing commercial micron-sized molybdenum trioxide and carbon nano-particles in a solution, and conducting drying by distillation to obtain composite powder; 2, spraying the ultrafine / nanometer yttrium salt liquid drops intothe composite powder, and conducting drying to obtain a yttrium salt-containing mixture; 3, carrying out segmented heat preservation and reduction on the yttrium salt-containing mixture to obtain ultrafine doped MoO2; and 4, conducting reduction on the ultrafine doped MoO2 by hydrogen to obtain nano-molybdenum powder doped with yttrium oxide nano-particles. The invention also provides an application of the nano-molybdenum powder doped with the yttrium oxide nanoparticles to sintering preparation of a nano-structure oxide dispersion strengthened molybdenum alloy. According to the preparation method, two-step reduction is combined with preparation of the composite powder, so that the nucleation number of a reduction product is increased, the granularity of the reduction product is refined, the granularity of the doping yttrium oxide nano-particles and molybdenum powder is regulated and controlled, and the raw material cost is reduced. The application method is simple and easy to implement.

Owner:西安稀有金属材料研究院有限公司

Rapid cooling solidification fine crystal device and welding method for thin plate NiTi alloy electron beam welding

InactiveCN111085766AIncrease contact areaReduce sliding frictionWelding/cutting auxillary devicesAuxillary welding devicesThin slabCrystallite

The invention discloses a rapid cooling solidification fine crystal device and welding method for thin plate NiTi alloy electron beam welding and relates to the technical field of welding. The rapid cooling solidification fine crystal device and welding method for thin plate NiTi alloy electron beam welding aim to solve the problem that after existing thin plate NiTi alloy electron beam welding, crystalline grains in a connector are coarse. The rapid cooling solidification fine crystal device comprises a pressing and grasping type fixture body, cooled red copper and a cooled red copper fastening mechanism; and the cooled red copper is arranged over the pressing and grasping type fixture body through the cooled red copper fastening mechanism. The welding method includes the steps of performing pretreatment on to-be-welded base metal, clamping the to-be-welded base metal, clamping the cooled red copper fastening mechanism, performing welding and performing cooling. The rapid cooling solidification fine crystal device and welding method for thin plate NiTi alloy electron beam welding are used for thin plate NiTi alloy electron beam welding.

Owner:HARBIN INST OF TECH

Modified nucleating agent and preparation method thereof

The invention belongs to the technical field of material chemistry, and particularly relates to a modified nucleating agent and a preparation method thereof. The modified nucleating agent is preparedfrom the following raw materials in percentage by mass: 60 to 90 weight percent of nucleating agents, 10 to 20 weight percent of micrometer silicon carbide and 2 to 10 weight percent of nanometer silicon carbide. The modified nucleating agent provided by the invention can increase the nucleation quantity of CADI (Carbonic Austempering Ductile Iron); the spheroidization process is optimized.

Owner:HEFEI KAIER NANOMETER ENERGY & TECH

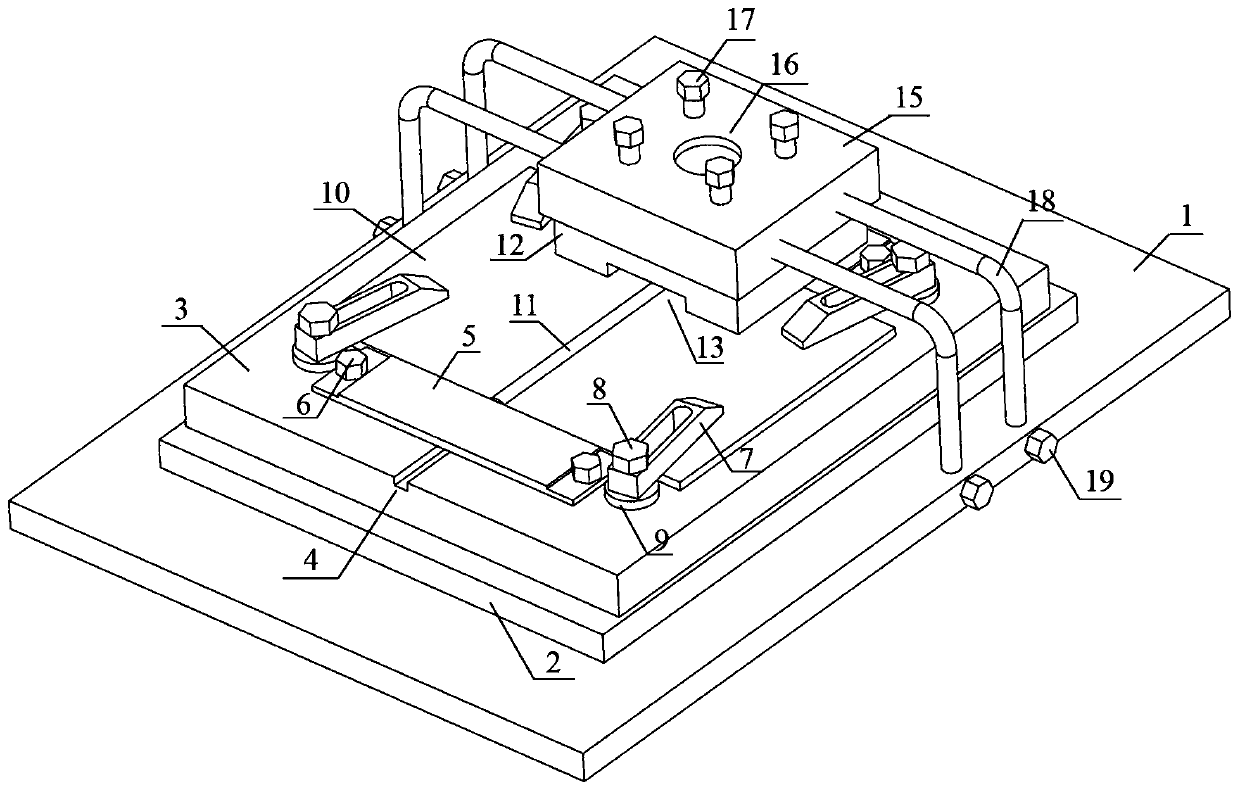

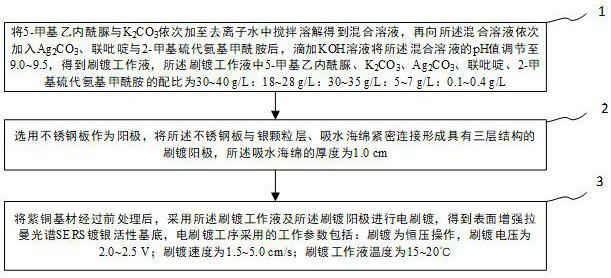

Brush plating-based surface enhanced Raman spectrum SERS silver-plated active substrate and preparation method thereof

InactiveCN112126954AEasy to useEasy to operateRaman scatteringElectrodesSurface-enhanced Raman spectroscopyPhotochemistry

The invention discloses a brush plating-based surface enhanced Raman spectrum SERS silver-plated active substrate and a preparation method thereof, and relates to the technical field of Raman spectrumdetection. The brush plating process is combined with the preparation process of the surface-enhanced Raman spectrum silver-plated active substrate, and the nucleation mechanism of silver crystal grains is converted into the instantaneous nucleation mechanism according to the preparation requirements of the surface of the surface-enhanced Raman spectrum silver-plated active substrate, that is a silver crystal nucleus generation accelerant is added into the prepared brush plating working solution, so that the nucleation quantity in unit time is increased, fine grains are facilitated to be achieved, and all of the best working parameters of the electric brush plating technology are further obtained; and the surface-enhanced Raman spectrum SERS silver-plated active substrate with nano-sizedsilver particles and good uniformity is prepared by a simple preparation process, so that the technical problems of poorer sensitivity and stability of a Raman spectrum metal active substrate in SERSdetection can be solved, and the technical effect of improving the sensitivity and stability of the Raman spectrum metal active substrate in SERS detection is achieved.

Owner:JIAXING UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com