Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

124results about How to "Good nucleation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A water tree-resistant polyolefin cable material and a preparation method thereof

ActiveCN103289162AShorten the lengthExcellent water tree resistancePlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

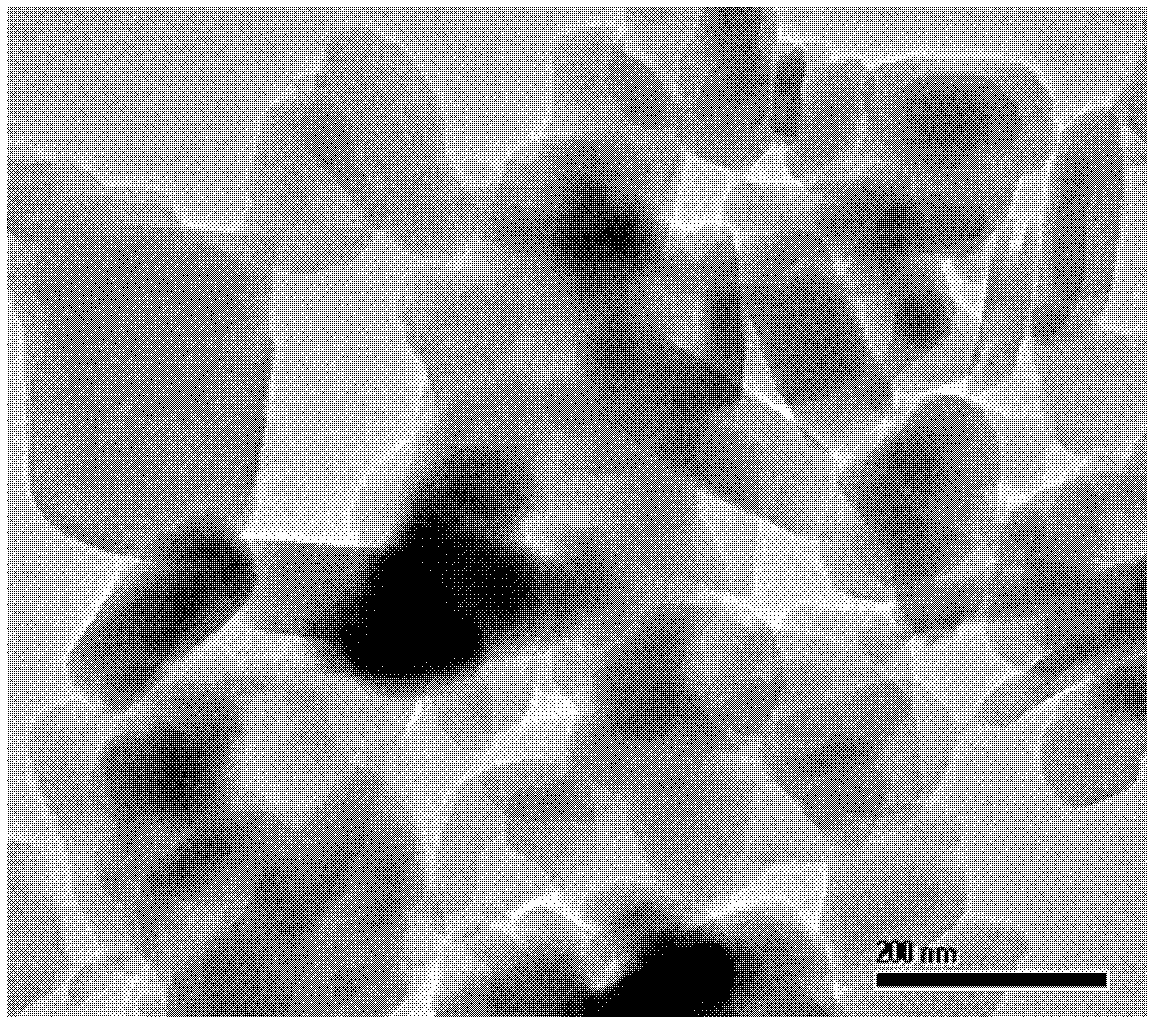

The invention discloses a water tree-resistant polyolefin cable material and a preparation method thereof. The water tree-resistant polyolefin cable material comprises, by mass, 70 to 95 parts of low density polyethylene, 5 to 30 parts of water tree resistant masterbatch, 1 to 2 parts of a crosslinking agent, 0.3 to 0.5 parts of a crosslinking coagent, 1 to 2 parts of an antioxidant, and 0.1 to 0.5 parts of a rheology modifier. Porous particles in the prepared water tree-resistant polyolefin cable material have adsorption characteristics, so that a more uniform distribution of water is obtained, water will not gather to be droplets, the probability of water tree growth is reduced by 50% or more than that of a conventional cross-linked polyethylene cable material, and the water tree-resistant polyolefin cable material of the invention has excellent water tree resistance; an elastic modulus ratio increases by 30% than that of a conventional cross-linked polyethylene cable material, so the water tree-resistant polyolefin cable material of the invention has excellent mechanical strength and toughness; and the water tree-resistant polyolefin cable material of the invention meet electrical performance standards of chemically cross-linked polyethylene insulation materials used for medium / low-voltage cable, etc., and has good processability.

Owner:XI AN JIAOTONG UNIV

Polyformaldehyde composition and preparation method thereof

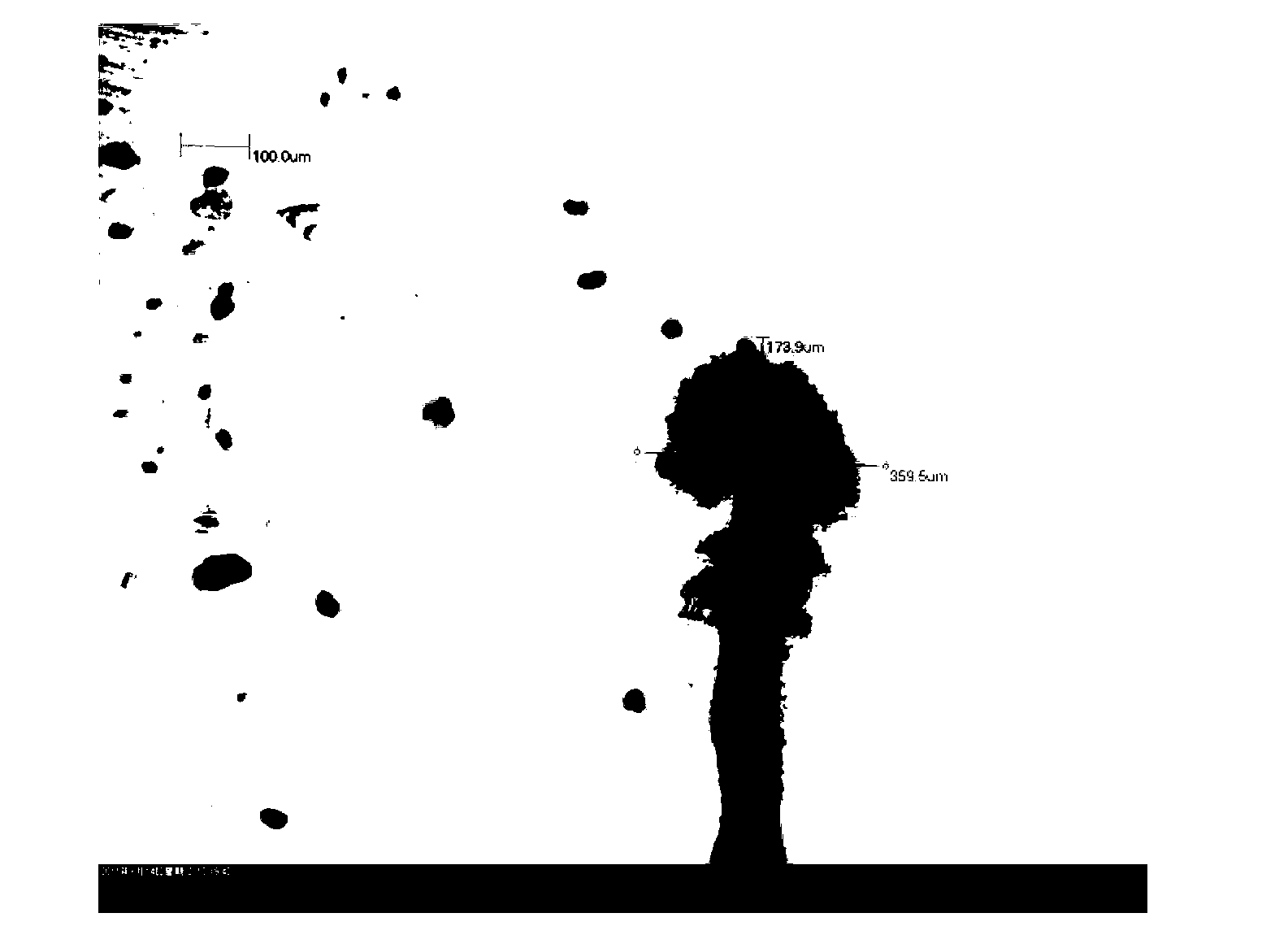

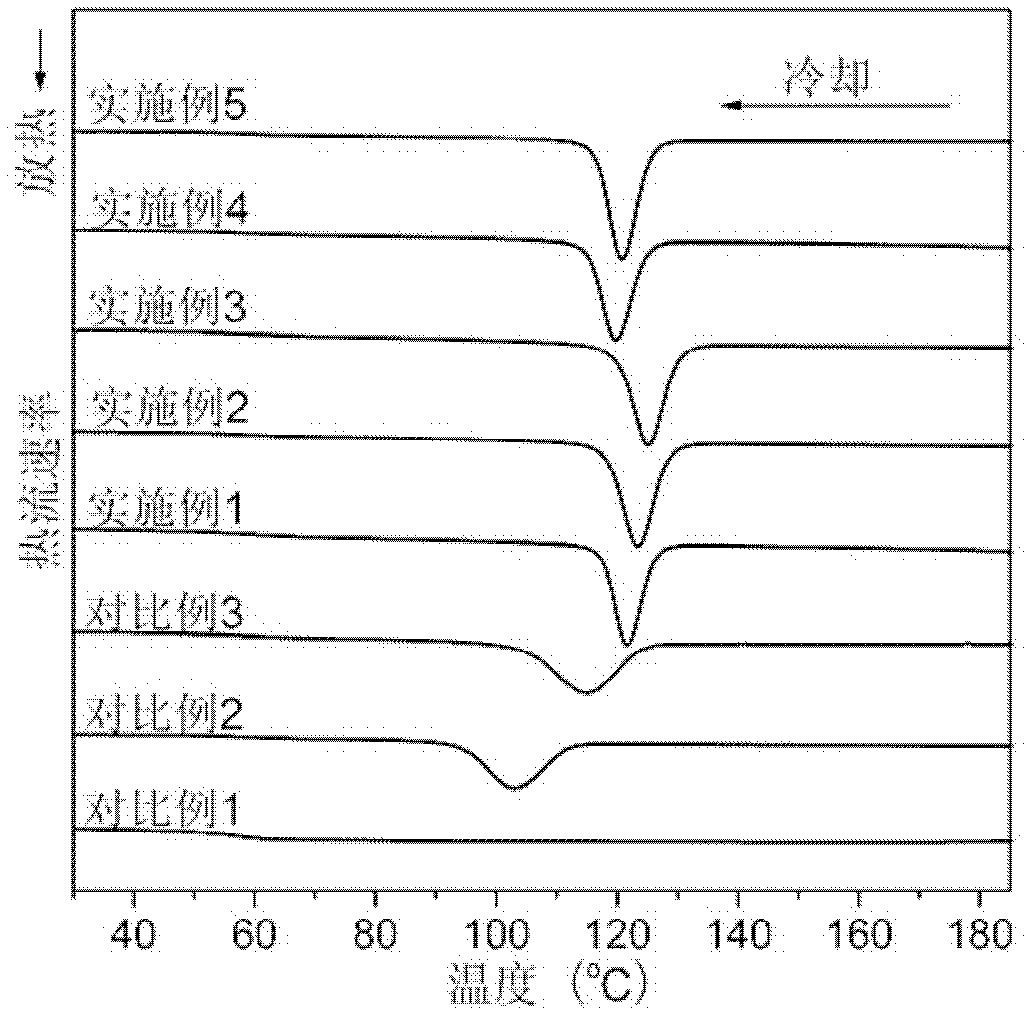

The invention discloses a polyformaldehyde composition and a preparation method thereof. The polyformaldehyde composition contains by part of weight: 100 parts of acetal resins, 0.01-2 parts of oxidation inhibitors, 0.01-2 parts of formaldehyde catching agents, 0.01-2 parts of formic acid catching agents and 0.01-5 parts of crosslinking acetal resins. Compared with the prior art, the crosslinking acetal resins serve as nucleating agents and are obvious in nucleating effects, and a great number of crystal nucleuses are formed before crystallization of the acetal resins, so that crystallization of the acetal resin is induced, the number of the crystal nucleuses is improved, crystallization degree and temperature are improved, sphaerocrystal dimension is lowered, and accordingly crystallization structure of the acetal resin is improved. Further, due to the fact that the adding amount of the crosslinking acetal resins is small, and bad influence on mechanical property, thermal performance and surface morphology of the polyformaldehyde composition is avoided. Experiment results prove that the sphaerocrystal dimension of the polyformaldehyde composition is about 40 mu m, and the polyformaldehyde composition has good crystalline structure and good mechanical property.

Owner:YUNNAN YUNTIANHUA

Biodegradable material containing aliphatic polycarbonate, and preparation method and application thereof

The invention relates to a biodegradable material containing aliphatic polycarbonate, and a preparation method and an application thereof. The biodegradable material is obtained by the following steps of mixing 20-90 parts by weight of aliphatic polycarbonate, 10-80 parts by weight of aliphatic polyester, 0.01-1 part by weight of an organic peroxide, 0.05-1 part by weight of a cross-linking agent, 3-15 parts by weight of a compatilizer, 0.3-5 parts by weight of a plasticizer, 0.1-5 parts by weight of a heat stabilizer and 0.01-1 part by weight of an auxiliary agent uniformly; adding the above mixture in a double-screw extruder for melt blending, stretching the blended mixture into strips; pelletizing the strips to obtain granular mixing resin slices; and vacuum drying the slices and removing water from the slices. The biodegradable material can be used for preparing completely biodegradable film which has various excellent performances of conventional films, can keep relatively good transparency, has relatively high tensile strength, can provide high toughness and tearing strength, and has good thermal stability, etc.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Totally degradable foam buffer packaging material and its manufacturing method

The invention provides a complete biodegradable foam cushioning packing material and method for preparation, characterized in that starch over 80% content is used as base-material, ultra-fine polyvinyl alcohol is used as film forming intensifier, water is used as foaming agent, and core forming agent and flow modifier are added, wherein the mixture is amalgamated through blending homogeneous machine and fed into reverse-flighted screw extrusion machine for one-shot extrusion forming. The product can be used to substitute polystyrene foam for filling with no requirement on shapes.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Cellulose nano fiber/polylactic acid composite material and preparation method thereof

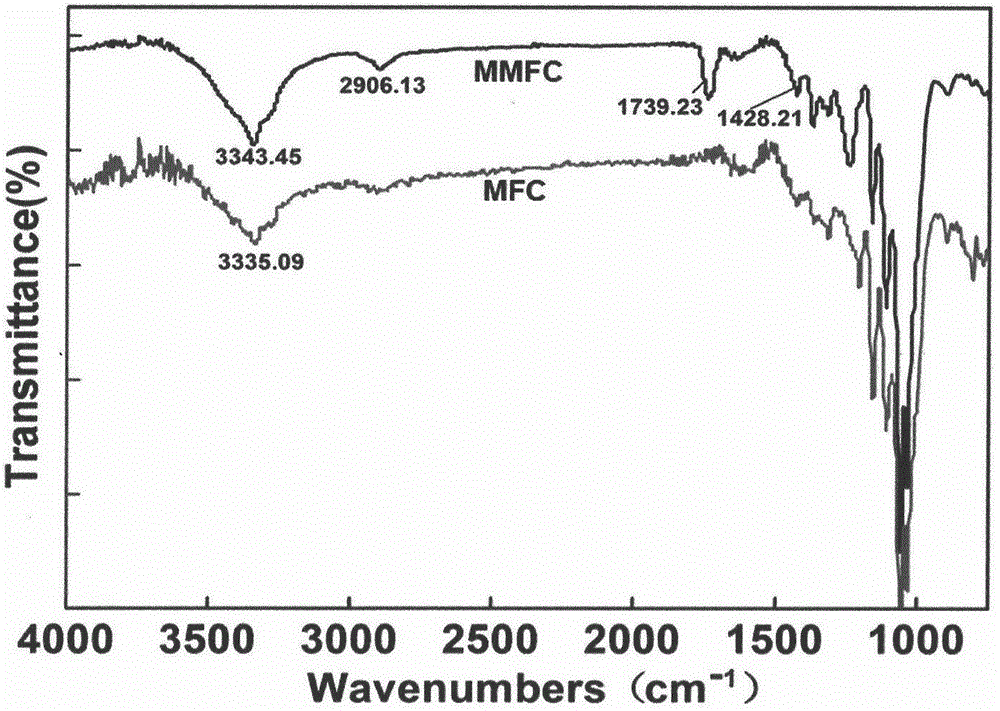

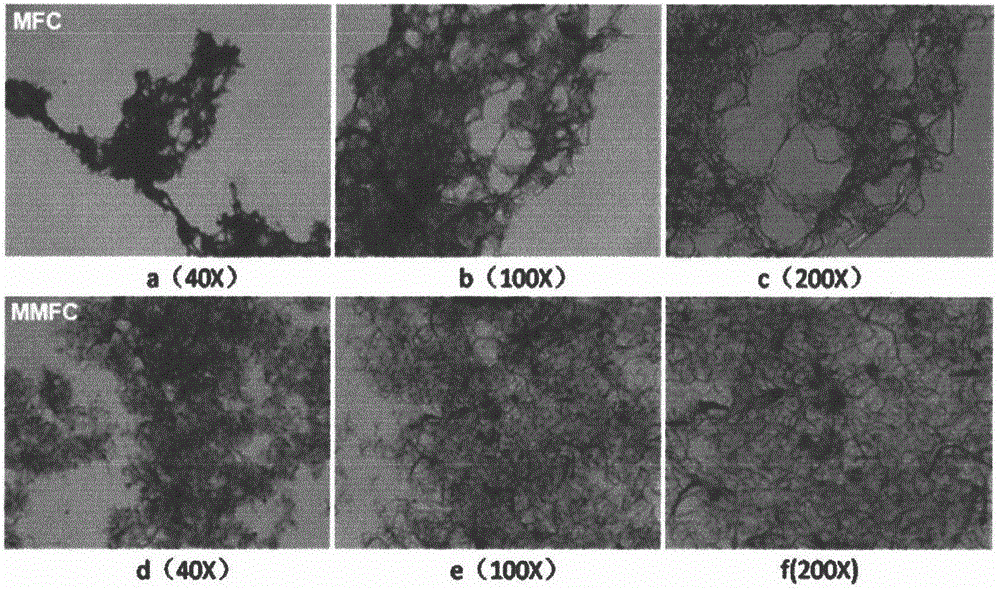

The invention discloses a cellulose nano fiber / polylactic acid composite material and a preparation method thereof. The cellulose nano fiber / polylactic acid composite material comprises the following components in percentage by weight: 60-99 wt% of polylactic acid, 1-40 wt% of cellulose nano fiber and 0.1-40 wt% of other aids. The preparation method comprises the following steps: dewatering a cellulose nano fiber primary pulp by using an organic solvent, replacing acetone with a methylbenzene solvent, adding acetic anhydride and pyridine to react, finally adding polylactic acid to obtain a mixed solution, and drying to obtain the cellulose nano fiber / polylactic acid composite material. The cellulose nano fibers are pretreated to enhance the dispersity; and the treated cellulose nano fibers are subjected to solution blending with the polylactic acid to prepare the cellulose nano fiber / polylactic acid composite material. The composite material can be directly used after being pulverized, or can be used as a reinforcing master batch to be compounded with the polylactic acid by melt extrusion, injection molding and the like to prepare the cellulose-nano-fiber-reinforced polylactic acid composite material with lower fiber content, higher mechanical strength and higher crystallization speed.

Owner:JIANGSU SUPLA BIOPLASTICS CO LTD

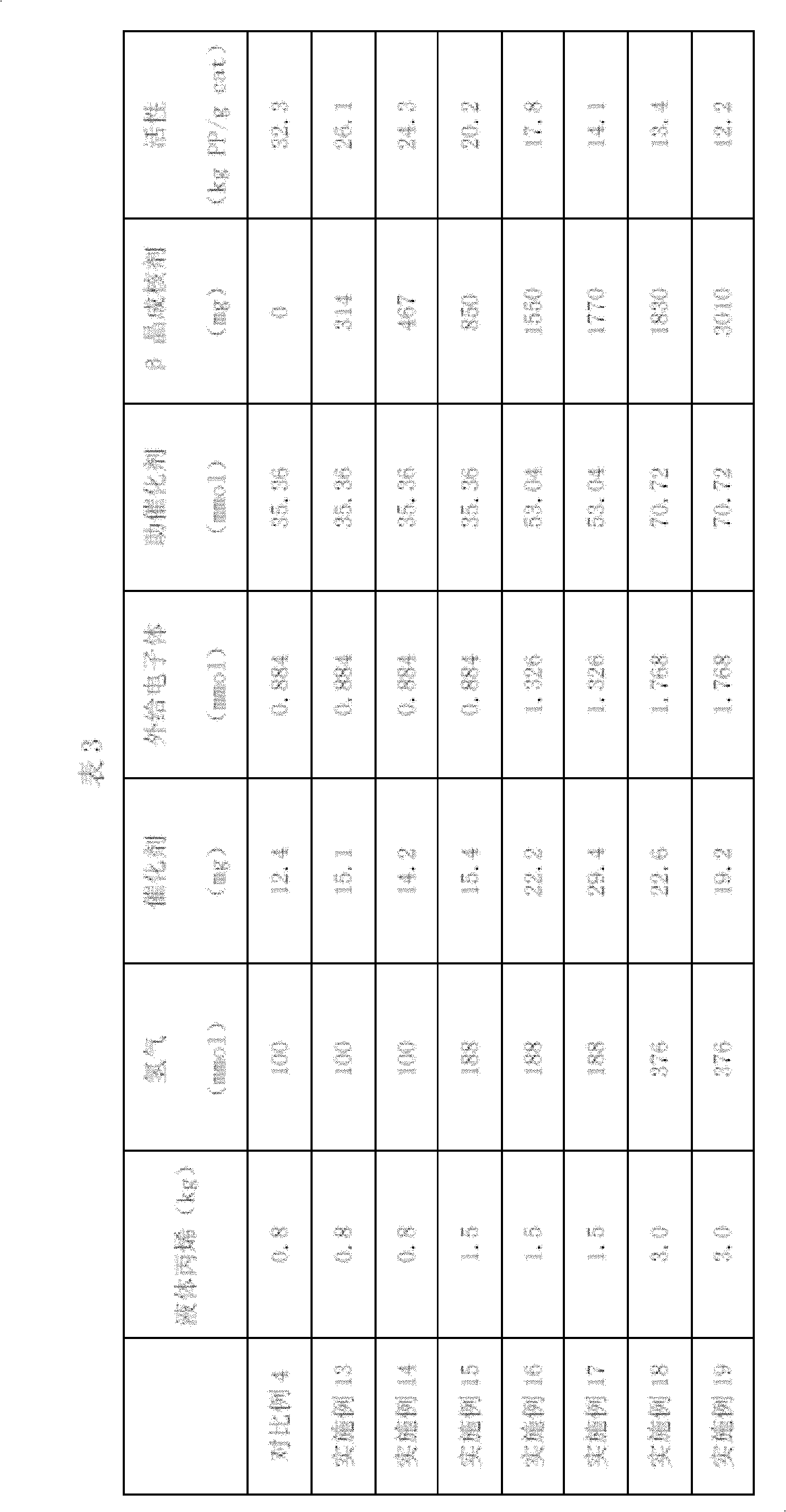

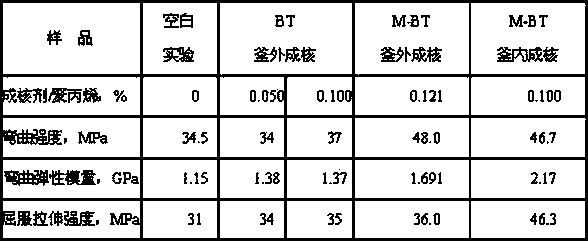

Preparation method of beta crystalline form polypropylene resin

ActiveCN102603941AEfficient manufacturingImprove impact resistanceBulk chemical productionPolymer scienceZiegler–Natta catalyst

The invention relates to a preparation method of a beta crystalline polypropylene resin. The method comprises: adding a dry polypropylene beta crystalline form nucleating agent into a bulk polymerization reaction kettle or a slurry polymerization reaction kettle loaded with propylene, utilizing the Ziegler-Natta catalyst system to catalyze propylene for its bulk polymerization or slurry polymerization, thus obtaining composite powder of polypropylene and the polypropylene beta crystalline form nucleating agent; subjecting the obtained composite powder directly to heating and melting treatment or extrusion pelletization by an extruder, thus obtaining the beta crystalline form polypropylene resin. The beta crystalline form polypropylene resin prepared by the method of the invention has obvious advantages in terms of impact resistance, flexural strength, flexural modulus, tensile yield strength and heat resistance, etc., and particularly, the substantial enhancement of the impact resistance can make the beta crystalline form polypropylene resin prepared in the kettle applied in high-end application fields such as automobiles, batteries and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Efficient polylactic acid nucleating agent, and preparation method and application thereof

ActiveCN102584567AEasy to prepareImprove securityCarboxylic acid salt preparationCITRATE ESTERHeat resistance

The invention discloses an efficient polylactic acid nucleating agent, and a preparation method and application thereof and belongs to the technical field of crystallization and modification of polylactic acid. The prepared nucleating agent is a lamellar submicron zinc citrate complex, and is generated by heating zinc salt and citric acid in a mixed solution of water and ethanol and performing reflux reaction. A small amount of the nucleating agent and polylactic acid are mixed in advance and then are fused, blended and molded so as to obtain a polylactic acid product which is highly crystallized and has excellent heat resistance. The prepared nucleating agent has high safety for a human body and an obvious nucleating effect; and a process is simple and environment-friendly, the problems of low crystallization rate and heat resistance of the polylactic acid are solved, the forming processability of the polylactic acid product is improved, and a production cycle is shortened.

Owner:新倍斯(杭州)材料科技有限公司

Regulating nucleation method during crystallization of nickel-cobalt-manganese precursor

ActiveCN109422297AParticle size distribution controlControlled nucleation method is simple and efficientCell electrodesSecondary cellsManganesePhysical chemistry

The invention discloses a regulating nucleation method during crystallization of a nickel-cobalt-manganese precursor. The method comprises the following steps: (1) adding a nickel-cobalt-manganese salt solution, an ammonia solution and an alkali solution into a closed reaction kettle containing a base liquid for a reaction; and (2) monitoring D50 and span values of particles generated in the reaction kettle; when the span value is smaller than 1, adding a nucleation feeding liquid to the reaction kettle, performing continuous stirring for the reaction, and monitoring the span value of the particles generated in the reaction kettle continuously; when the span value reaches a preset value, stopping adding the nucleation feeding liquid; and after the span value is lower than the preset value,adding the nucleation feeding liquid to the reaction kettle again, terminating the reaction until the D50 and span values of the particles generated in the reaction kettle reach a target particle size and the preset value separately, collecting materials, and then performing subsequent treatment so as to obtain the nickel-cobalt-manganese precursor, wherein the nucleation feeding liquid is a mixed solution of the nickel-cobalt-manganese salt solution and the ammonia solution, and span = (D90-D10) / D50.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

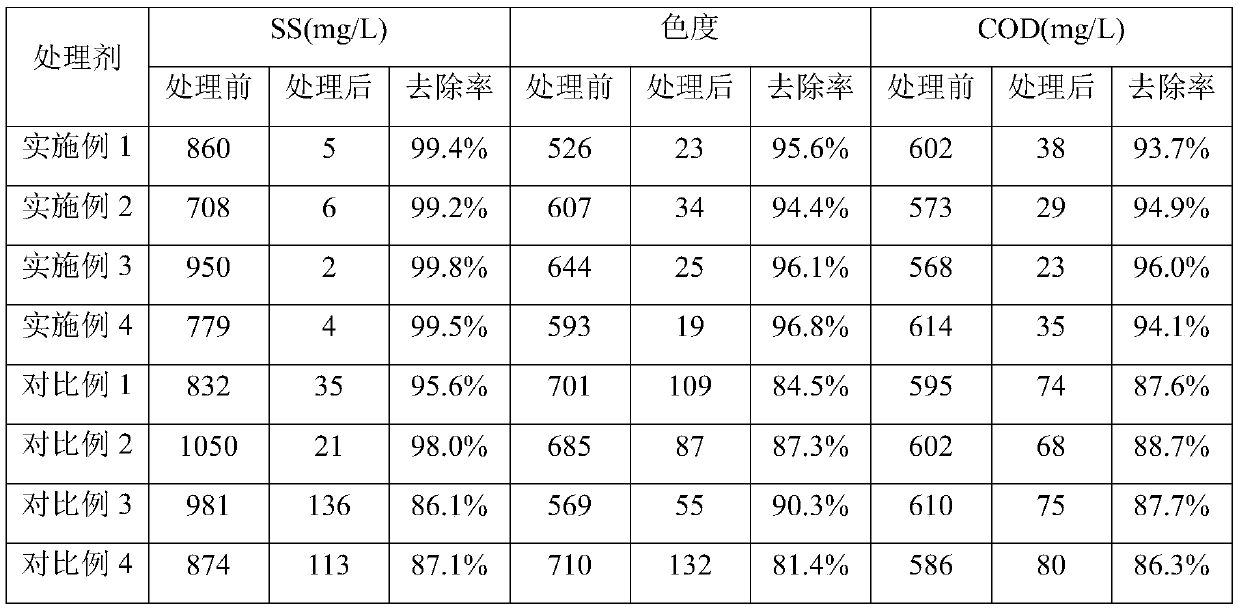

Composite flocculant for treating printing and dyeing wastewater

ActiveCN109734145AGood nucleation effectRealize separation and removalWater contaminantsWaste water treatment from textile industryFiberPolyvinyl alcohol

The invention discloses a composite flocculant for treating printing and dyeing wastewater. The composite flocculant for treating the printing and dyeing wastewater is prepared from the following rawmaterials in parts by weight: 15-25 parts of activated carbon fibers, 4-11 parts of acrylamide, 2-9 parts of sodium carboxymethyl cellulose, 5-17 parts of polyvinyl alcohol, 3-6 parts of a crosslinking agent, 0.003-0.006 part of an initiator, 3-5 parts of a polyethyleneimine-cellulose composite material, 10-15 parts of starch xanthate and 25-36 parts of modified bentonite. The composite flocculantprovided by the invention does not contain components which are complicated, have radiation and easily cause secondary pollution, all the used raw materials are natural, environment-friendly, low inprice and easy to obtain, the preparation method is simple, the feeding amount is small, the composite flocculant has multiple effects of flocculation sedimentation, adsorption decolorization, deodorization and the like, the sedimentation rate is high, the removal rates of organic matters, dye molecules and heavy metals are high, the structure and properties are stable, and the application range is wide.

Owner:XINXIANG UNIV

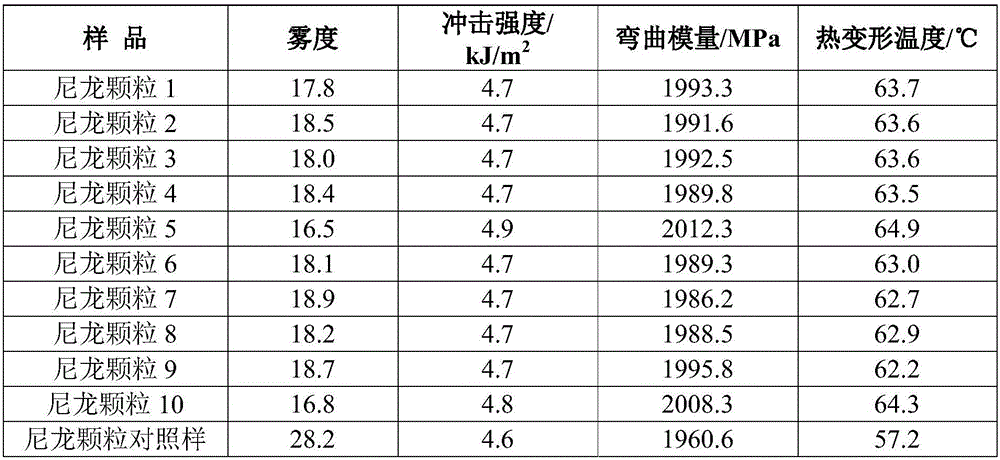

Preparation method of medical polylactic acid modified calcium phosphate bone cement composite 3D printing material

ActiveCN108295302AHigh mechanical strengthBoth mechanical strengthTissue regenerationProsthesisCalcium biphosphateRare earth

The invention relates to the technical field of 3D printing materials, in particular to a preparation method of a medical polylactic acid modified calcium phosphate bone cement composite 3D printing material. The preparation method of the medical polylactic acid modified calcium phosphate bone cement composite 3D printing material comprises steps as follows: S1, preparation of modified hectorite;S2, preparation of rare earth modified calcium phosphate powder; S3, preparation of the medical polylactic acid modified calcium phosphate bone cement composite 3D printing material. The composite obtained with the preparation method of the medical polylactic acid modified calcium phosphate bone cement composite 3D printing material has excellent printing performance and outstanding application performance, has the advantages of excellent mechanical strength, mechanical performance and compressive strength and has the mechanical strength of inorganic calcium phosphate materials and flexibilityof polymer polylactic acid materials, and besides, the preparation process is simpler and lower in production cost.

Owner:ZHONGSHAN POLYTECHNIC

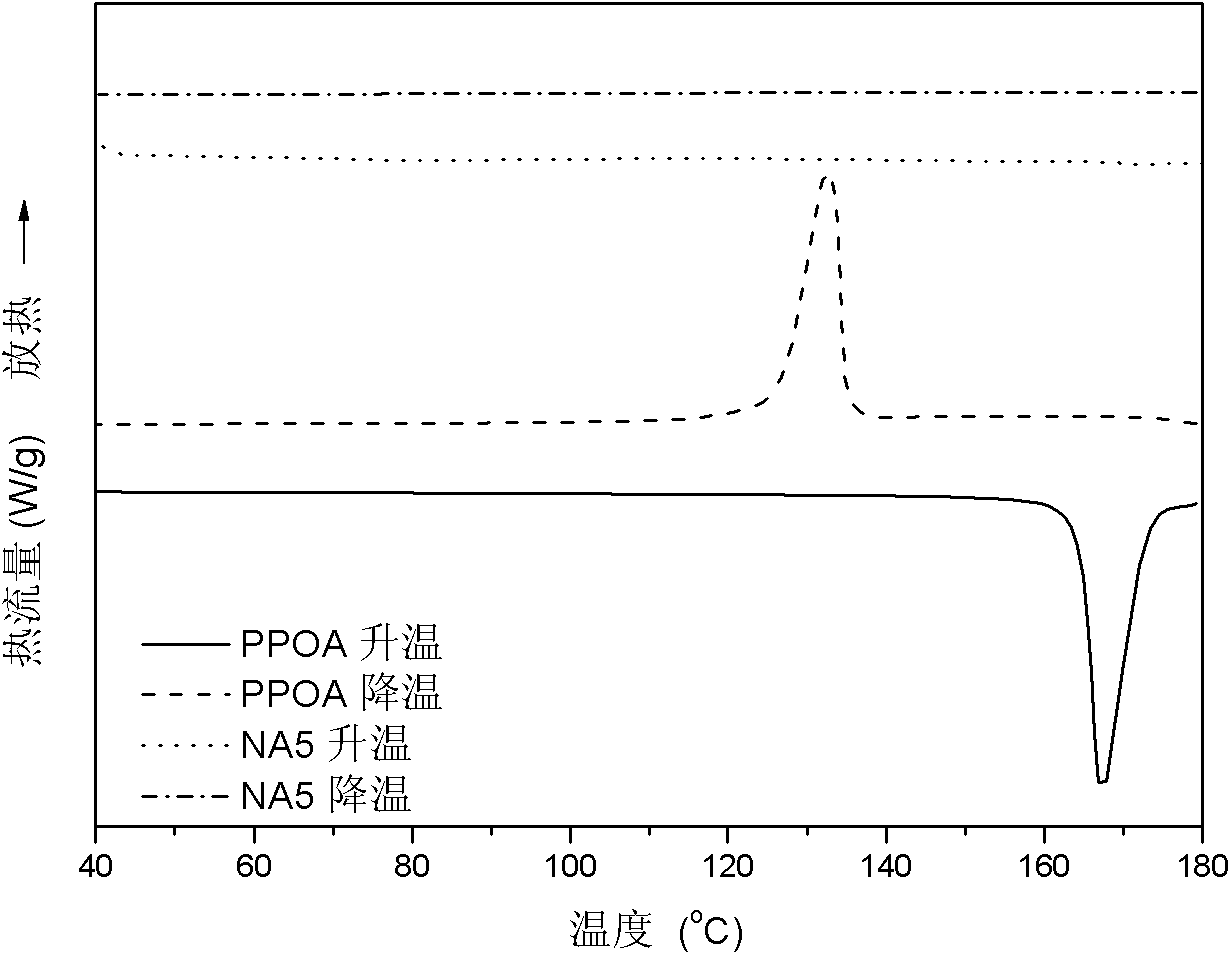

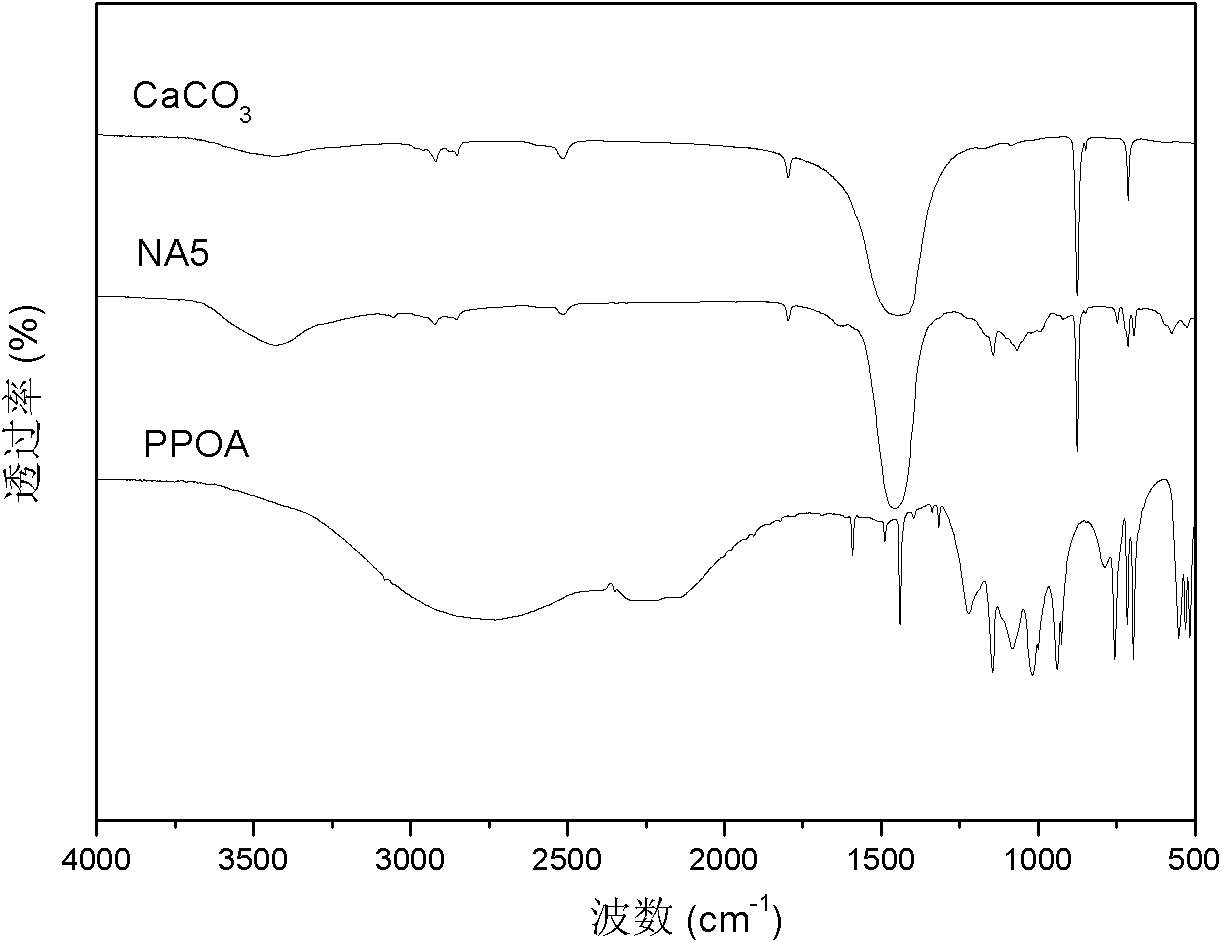

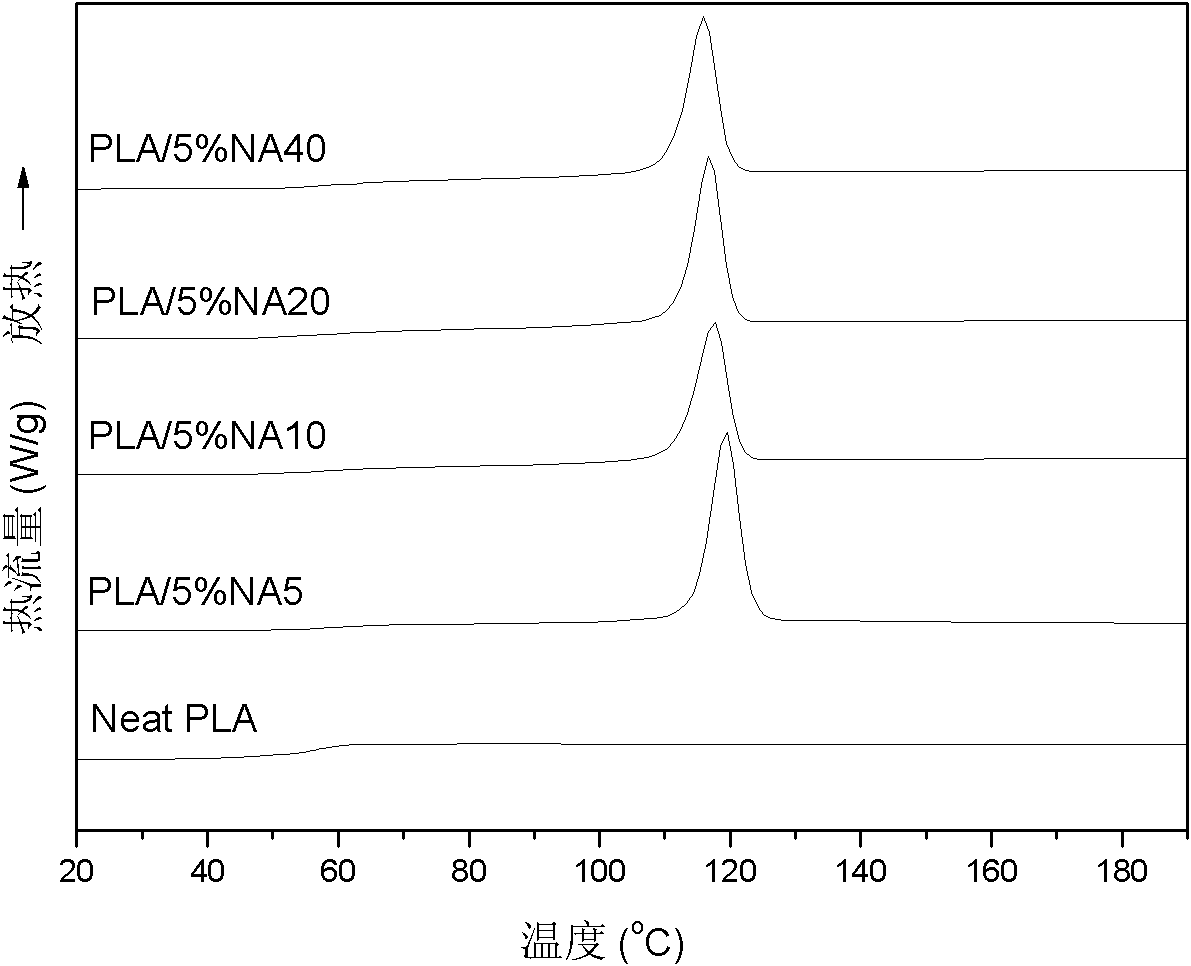

Calcium-carbonate-supported nucleating agent used for poly(lactic acid) crystallization and preparation method thereof

The invention discloses a calcium-carbonate-supported nucleating agent used for poly(lactic acid) crystallization and a preparation method thereof. The nucleating agent comprises the following composition formula: calcium carbonate and phenylphosphonic acid at a weight ratio of (5-40): 1, wherein calcium phenylphosphate generated by reaction of phenylphosphonic acid and calcium carbonate is used as an active ingredient and loaded on the surface of calcium carbonate, and phenyl phosphonic acid has a structural formula shown in the invention, in the formula, R1 and R2, the same or different, represent hydrogen atom, C1-10 alkyl or C1-10 alkoxycarbonyl. The nucleating agent can increase the effective nucleation sites formed by the high-degree dispersion of calcium phenylphosphate on the surface of calcium carbonate, thereby increasing nucleation efficiency as well as strengthening and toughening poly(lactic acid), avoiding the problem that poly(lactic acid) has poor toughness caused by non-supported nucleating agents, and facilitating the wide application of poly(lactic acid). The nucleating agent has a simple preparation method, low consumption of phenylphosphonic acid and significantly low cost.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

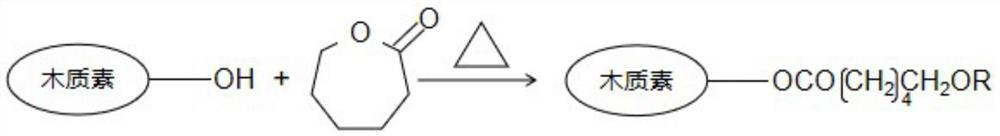

Lignin-based biodegradable polymer composite film and preparation method thereof

The invention discloses a lignin-based biodegradable polymer composite film which is prepared from the following raw materials in parts by weight: 100 parts of a biodegradable polymer material, 5-30 parts of lignin and 0.2-6 part of caprolactone. The invention also provides a preparation method of the lignin-based biodegradable polymer composite film. The preparation method has the advantages thatthe prepared lignin-based biodegradable polymer composite film is high in tensile strength and tear strength, resistant to ultraviolet radiation, flame-retardant, simple in preparation process, low-carbon, environment-friendly, high in production efficiency and easy to industrialize.

Owner:HUAIHUA UNIV

Ureas nucleating agent-containing polylactic acid composite and preparation method thereof

InactiveCN102634180ARaw materials are easy to getSimple and fast responseHeat resistancePolyethylene glycol

The invention discloses ureas nucleating agent-containing polylactic acid composite and a preparation method of the ureas nucleating agent-containing polylactic acid composite. The ureas nucleating agent-containing polylactic acid composite consists of polylactic acid, ureas nucleating agent or polylactic acid, ureas nucleating agent and plasticizer, wherein the weight of the nucleating agent is 0.1-5% of that of the polylactic acid, the plasticizer is tributyl citrate, acetyl tributyl citrate, polyethylene glycol or the mixture of the tributyl citrate, the acetyl tributyl citrate and the polyethylene glycol, and the weight of the plasticizer is 5-20% of that of the polylactic acid. The nucleating agent contains one or two urea bond(s), and is obtained by reacting unitary or binary secondary amine or primary amine, ramification of the unitary or binary secondary amine or the primary amine with mono-isocyanate or diisocyanate. The nucleating agent has the characteristics of being simple in preparation, easy for industrialization, high-efficiency, and low in price, is used for the polylactic resin, the crystallization of the polylactic acid can be intensively promoted due to the heterogeneous nucleation effect, the crystalline grain of the polylactic acid can be refined, and the heat resistance and the mechanical property of the polylactic acid can be improved. The nucleating agent is coupled with the plasticizer, so that the plasticity and the toughness of the polylactic acid can be further improved, and the application range of the composite can be widened.

Owner:ZHEJIANG UNIV

Ludox graft-modified organic phosphate nucleator preparation method

The invention discloses a ludox graft-modified organic phosphate nucleator preparation method, which includes steps of adding 2,2'-methylene-di(4, 6-Di-tert-butylphenol) phosphorus acyl chloride solution into lodox, and then extracting, filtering and drying the mixture to obtain white powder which is ludox graft-modified organic phosphate nucleator after sufficient reaction. Compared with the prior art, the ludox graft-modified organic phosphate nucleator has the advantages that under the action of steric hinderance, dispersity of the ludox graft-modified organic phosphate nucleator in plastics including polyethylene, polypropylene and the like is increased, crystallizing temperature is also increased and haze is reduced. Further, The ludox graft-modified organic phosphate nucleator has better mechnical performance and has better nucleating effect as compared with existing commonly-used NA-11 and NA21 nucleator.

Owner:贵州省复合改性聚合物材料工程技术研究中心

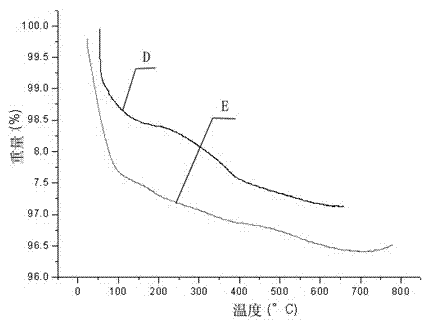

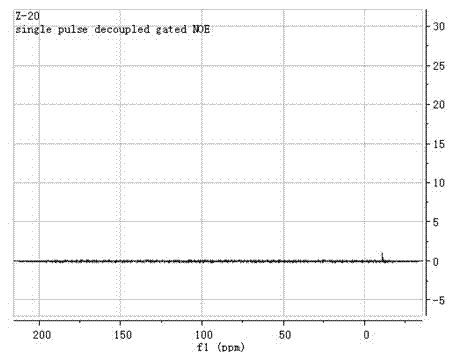

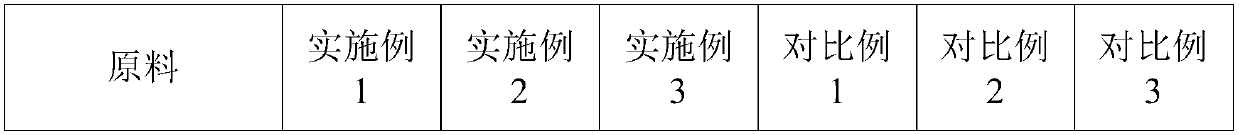

High-anti-impact, high-rigidity and high-shrinking rate polypropylene modified material and preparation method thereof

The invention provides a high-anti-impact, high-rigidity and high-shrinking rate polypropylene modified material and a preparation method thereof. The material includes, by weight, 40-90 parts of polypropylene resin, 5-30 parts of spherical silicon, 5-15 parts of a toughener, 0.1-2 parts of a nucleating agent, 0.2-0.4 parts of a main anti-oxygen agent and 0.2-0.4 parts of an assistant anti-oxygenagent. By selecting the proper polypropylene resin, elastomer and inorganic filler, the material is improved in both anti-impact strength and shrinking rate, so that the material is guaranteed in sizeand physical properties in a product with large mold-opening shrinking rate.

Owner:TIANJIN KINGFA NEW MATERIAL

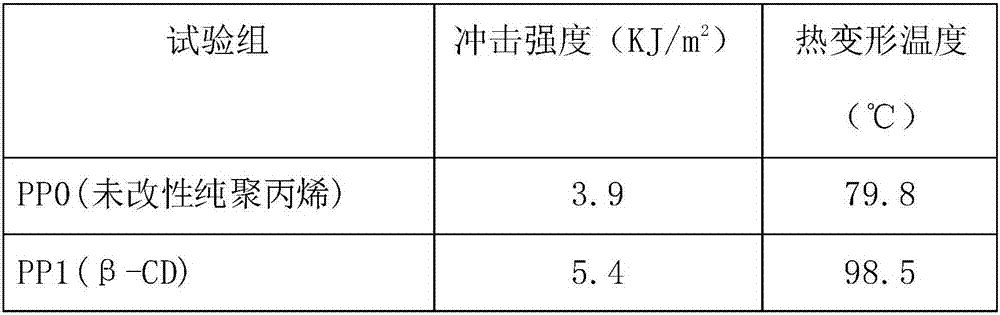

Modified polypropylene plastic and preparation method thereof

The invention relates to a modified polypropylene plastic and a preparation method thereof. Raw materials of the modified polypropylene plastic comprise isotatic polypropylene and a composite nucleating agent; the composite nucleating agent consists of an inclusion complex of cyclodextrin and a derivative thereof and a synergist, and the synergist is suberate. Compared with a common polypropylene plastic, the modified polypropylene plastic has obvious advantages on properties such as impact resistance, and meanwhile has the advantages of simplicity in preparation, high production efficiency and the like.

Owner:深圳市磐汩新材料有限公司

Composite alterant for nickel aluminum molybdenum-silicon iron alloy loaded nano-aluminum-silicon oxide ball milling cast iron and preparation method thereof

The invention relates to an alterant for ball milling cast iron, in particular to the composite alterant for the nickel aluminum molybdenum-silicon iron alloy loaded nano-aluminum-silicon oxide ball milling cast iron and a preparation method thereof. The alterant is prepared from the following raw materials, by weight, of 2-3 parts of nano-alumina, 1-2 parts of potassium fluoborate, 2-3 parts of nickel powder, 1-2 parts of aluminum powder, 1-2 parts of molybdenum powder, 0.2-0.4 part of oxidized graphene, 1-2 parts of nano silica, 3-5 parts of expanded graphite powder, 1-2 parts of monazite micro powder, 4-5 parts of ferrosilicon powder with the silicon content being 45%, 0.3-0.4 part of magnesium aluminosilicate, 20-25 parts of ethanol aqueous solutions with the concentration being 5%-10% and 0.4-0.5 part of an addition agent. Nano composite powder bodies and a nickel aluminum molybdenum-silicon iron alloy which are loaded by expanded graphite powder are bonded and loaded mutually to prepare the composite alterant with stable performance. The alterant is stable in high temperature, the nucleating effect is good, and graphite spheroidization is stable and durable. According to the alterant, the graphitizing process is facilitated, the structural organization is improved, strength and abrasion resisting are further improved, and compared with a traditional alterant, using is more convenient and faster, and the additional production cost is reduced.

Owner:徐世云

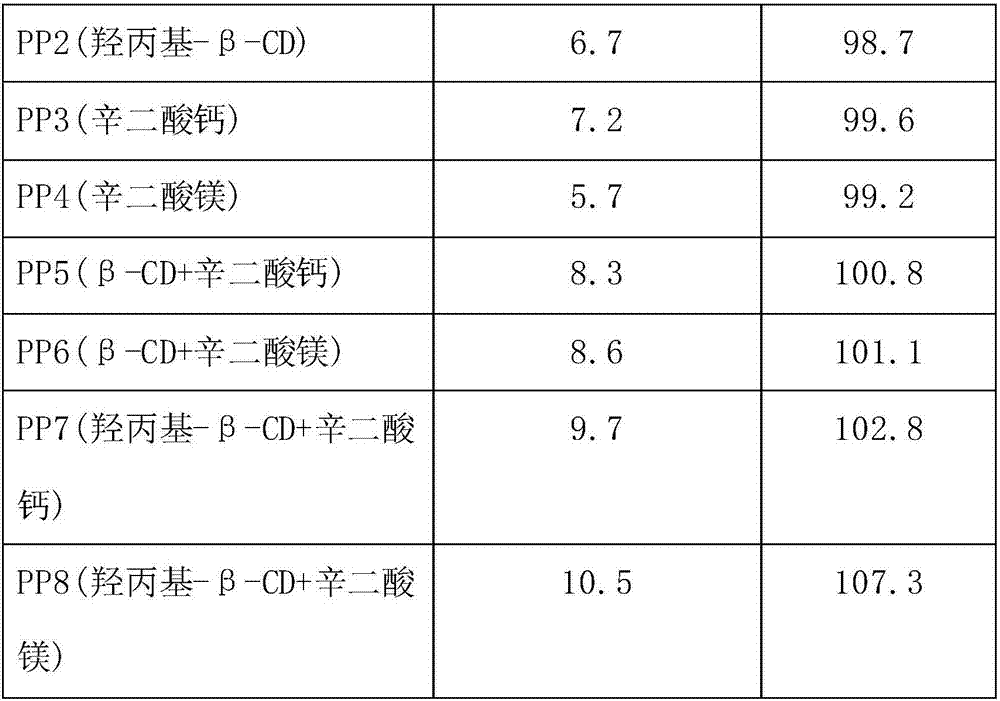

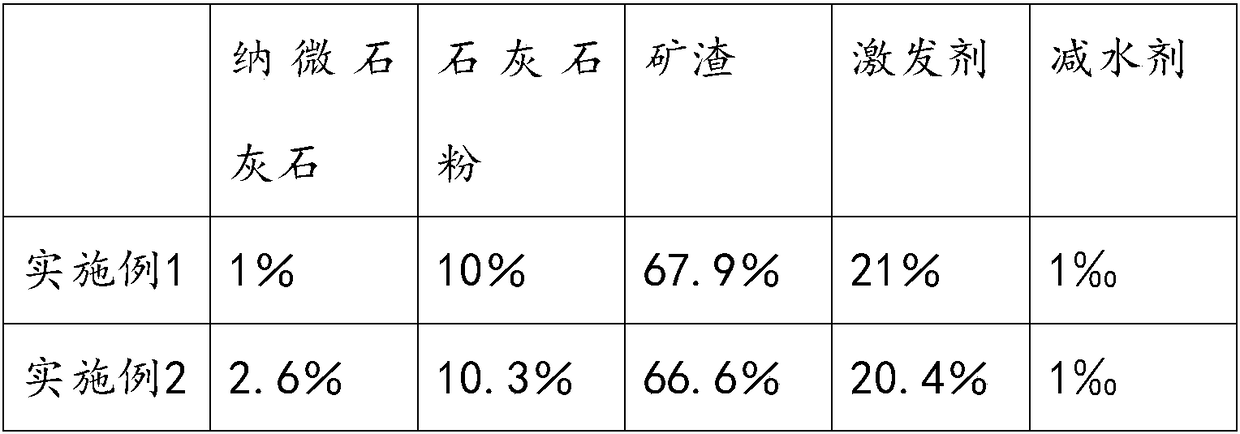

High-performance concrete slurry-shaped admixture mixed by CaCO3 having multi-scale particle sizes

The invention discloses a high-performance concrete slurry-shaped admixture mixed by CaCO3 having multi-scale particle sizes. The admixture solves the problems that current high-performance concrete has high costs and a large number of unhydrated cement particles exist, and the working performance is improved. The dry slurry-shaped admixture comprises the following components in percentages by weight: 1%-5% of nano micro limestone, 5%-20% of limestone powder, 50%-80% of ultrafine mineral slag, 5%-40% of a composite activator, and 0.1%-0.3% of a water reducing agent, wherein the total percentage is 100%; and water is added into each component, wet grinding is performed, uniform mixing is performed, and therefore the slurry-shaped admixture is obtained, wherein each component is controlled to meet the following grading requirements after wet grinding is performed: the nano micro limestone is composed of slurry with two particle size ranges including a median particle diameter of 2-1 [mu]m and a median particle diameter of less than 0.3 [mu]m; the ultrafine mineral slag has a median particle diameter of 4-8 [mu]m; and the composite activator and the limestone powder separately have amedian particle diameter of 9-13 [mu]m. The admixture disclosed by the invention has simple components and low production costs, and fully utilizes mineral slag; and slurry produced by the admixture has the advantages of high fluidity, good dispersibility, no shrinkage, micro expansion and early strength.

Owner:HUBEI UNIV OF TECH

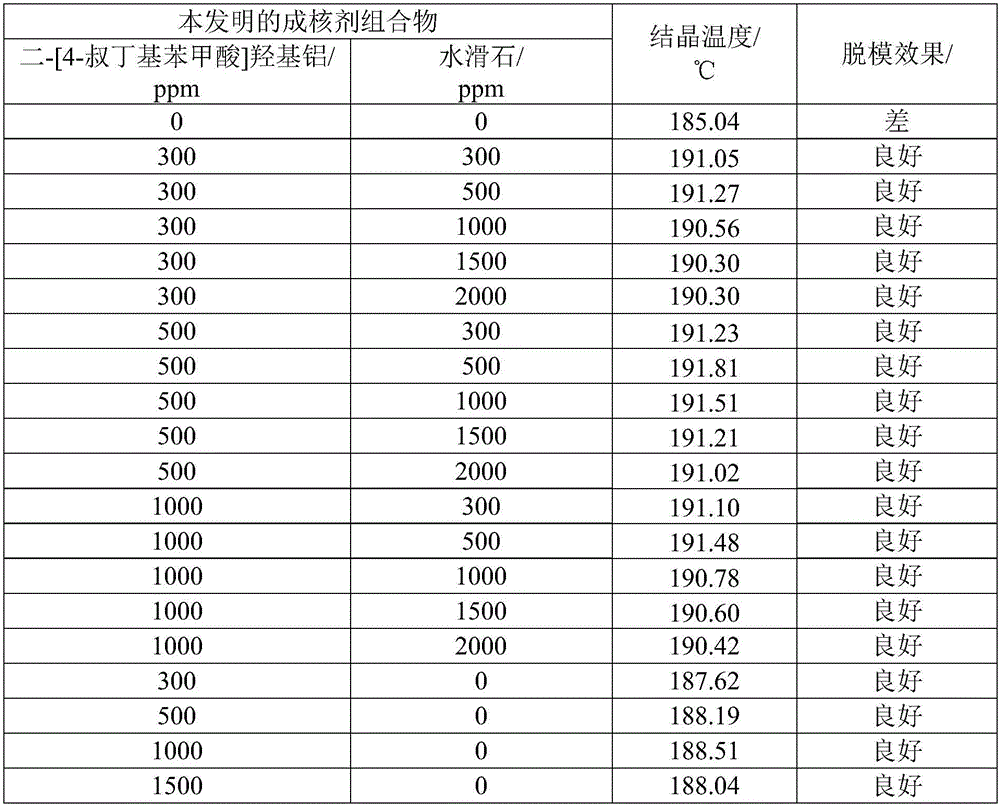

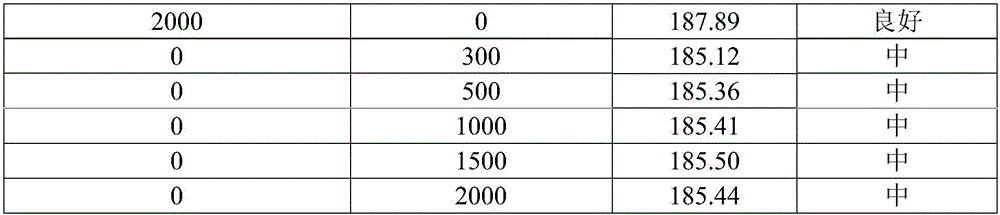

Hydrotalcite-containing stiffening nucleating agent composition

ActiveCN105754142AGive full play to the functional advantagesImprove processing thermal stabilityBenzoic acidThermoplastic

The invention relates to a hydrotalcite-containing stiffening nucleating agent composition and also relates to a thermoplastic plastic containing the nucleating agent composition and particularly relates to nylon containing the nucleating agent composition. The nucleating agent composition contains di-[4-tert-butyl benzoic acid]hydroxyl aluminium in a weight ratio of (5:1)-(1:5). The nucleating agent composition has a better nucleating effect, and the obtained nylon product has high tensile and bending strength, low loss of impact strength, good heat resistance and the like. By adopting the nucleating agent provided by the invention, the demoulding property in the nylon processing process is improved, the injection moulding cycle is shortened, and the production efficiency is improved; and moreover, the dimensional stability of the product is higher, the shrinkage is reduced, and the mechanical properties, product transparency and heat-resistance temperature of the product are improved.

Owner:GCH TECH

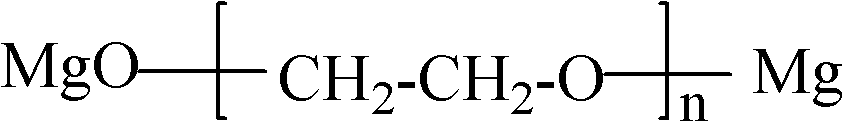

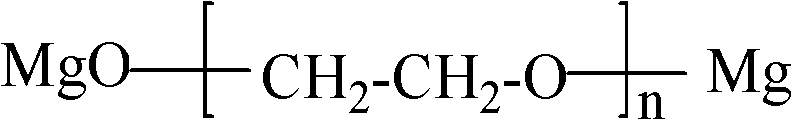

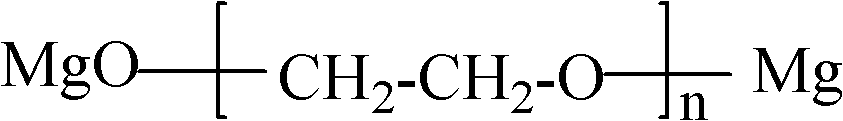

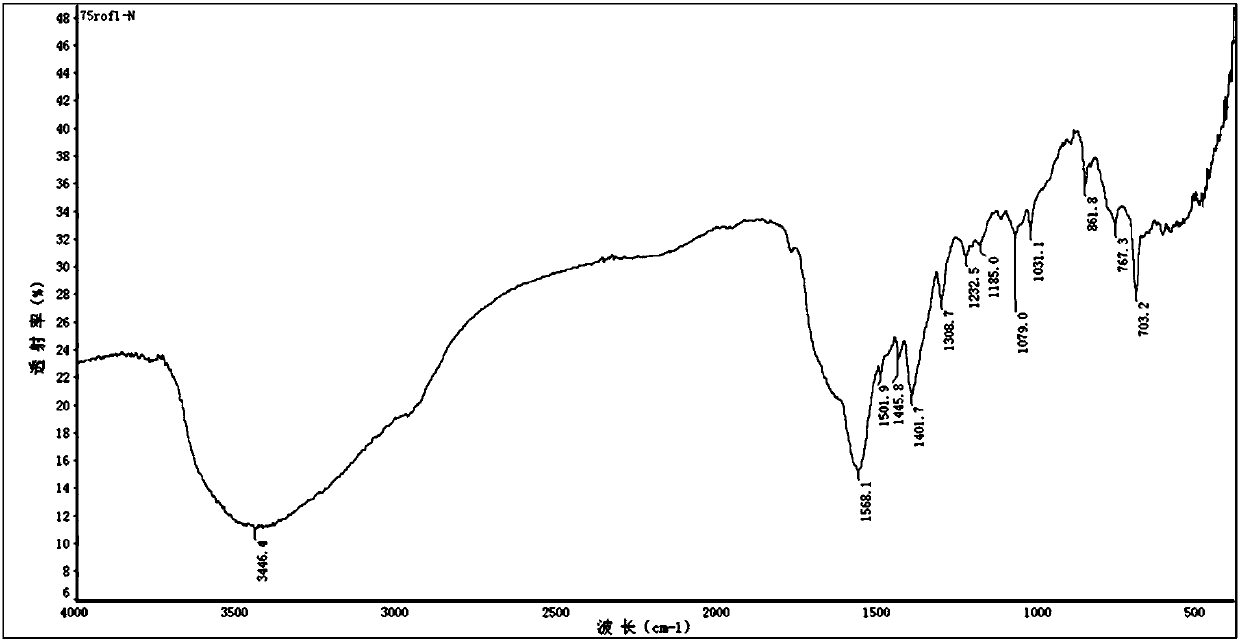

Polyethylene glycol magnesium and preparation method and application thereof

InactiveCN102491883AGood nucleation effectHigh crystallinityOrganic chemistryOrganic compound preparationChemical structurePolyethylene terephthalate glycol

The invention relates to polyethylene glycol magnesium and a preparation method and application thereof. The chemical structure of the polyethylene glycol magnesium is shown in the specification. The preparation method for the polyethylene glycol magnesium comprises the following steps of: mixing polyethylene glycol and magnesium, heating and carrying out a reaction on the mixture, and continuously removing steam produced during the reaction to promote the generation of products; and removing residual water and residual polyethylene glycol from a reactant solution by using a vacuum pressure-reduction distillation process, taking a final product out and cooling, crystallizing at room temperature and leaching, washing and drying, and finally obtaining white crystalline particles which are the polyethylene glycol magnesium. A polyethylene terephthalate (PET) nucleating agent is provided, and is smelted and mixed with PET during squeezing of a screw, so that the flexibility of a PET chain section is improved, and the glass transition temperature and the cold crystallization temperature of the PET are reduced; furthermore, the dispersion activation capacity of the PET chain section is reduced, so that the PET chain section does dispersive motion towards the surface of a crystal nucleus, and is arranged neatly; and therefore, a function of accelerating the PET crystallization rate is realized.

Owner:DONGHUA UNIV

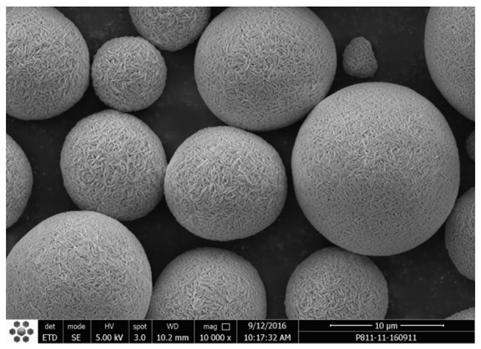

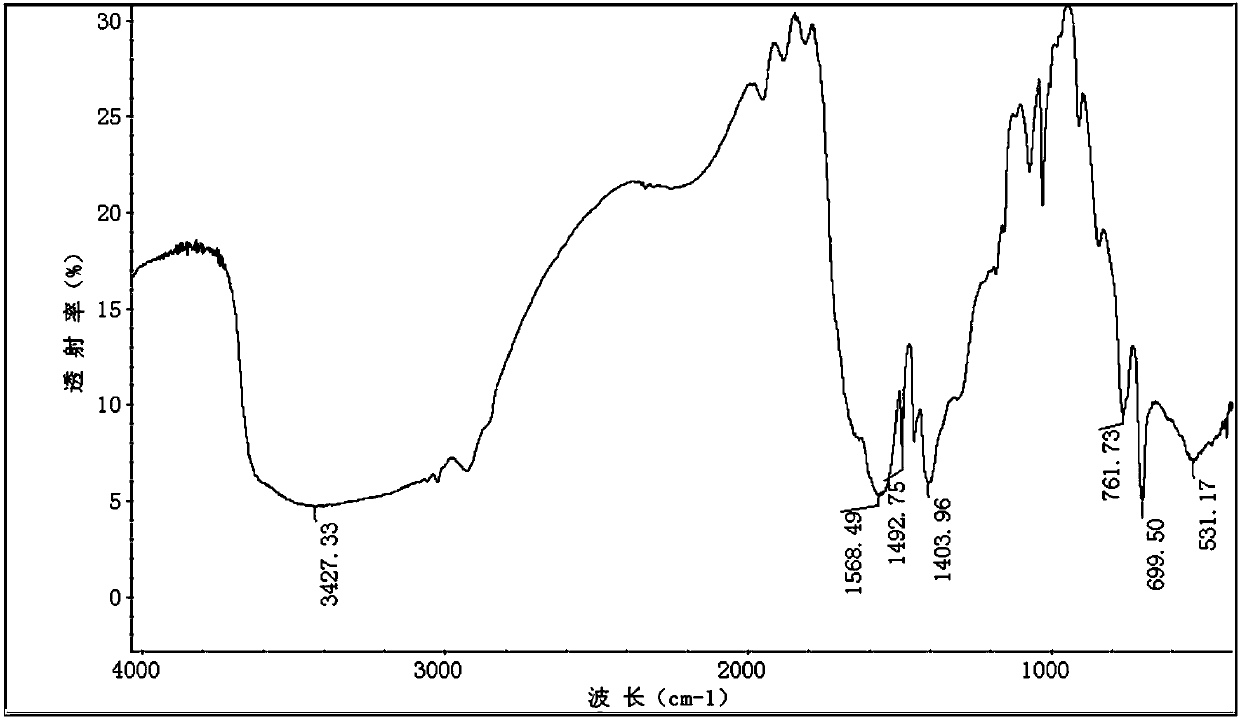

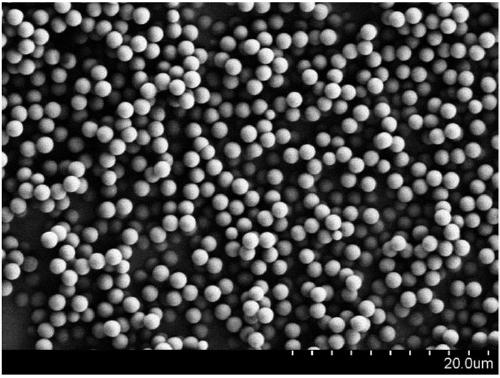

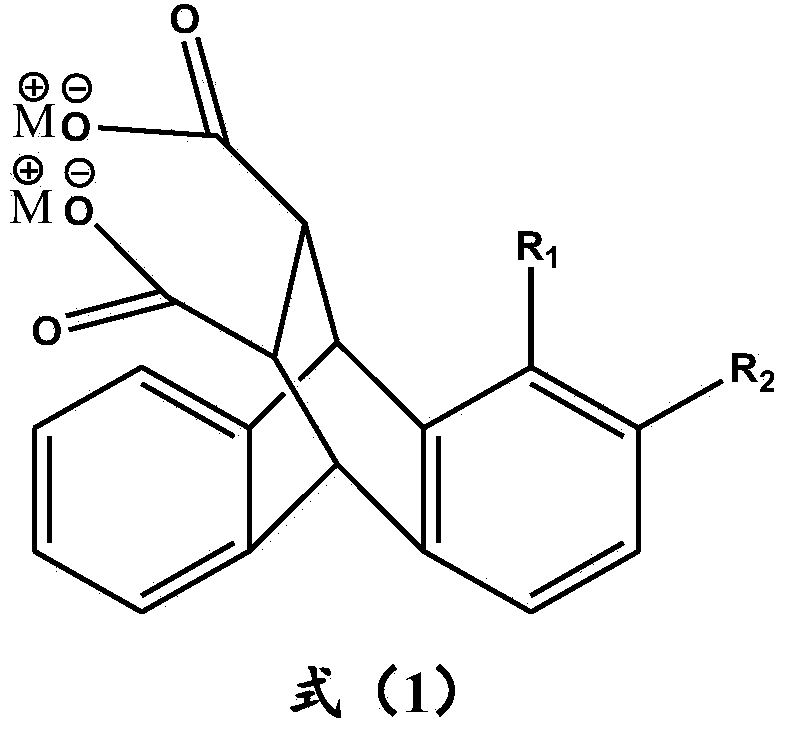

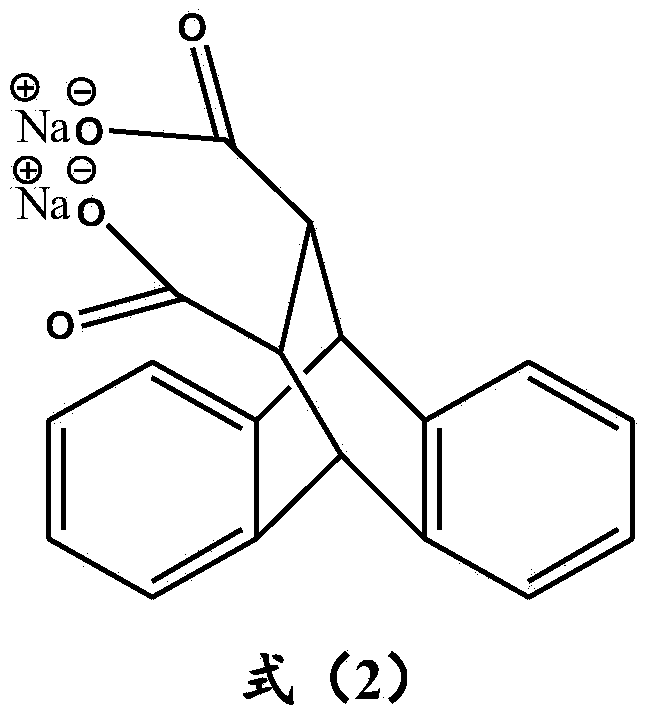

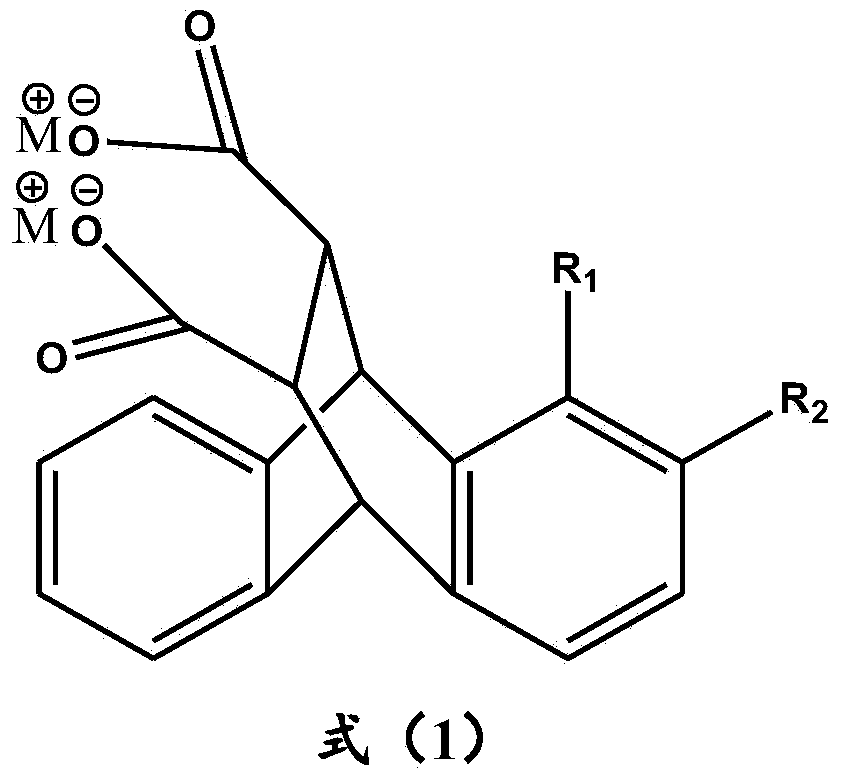

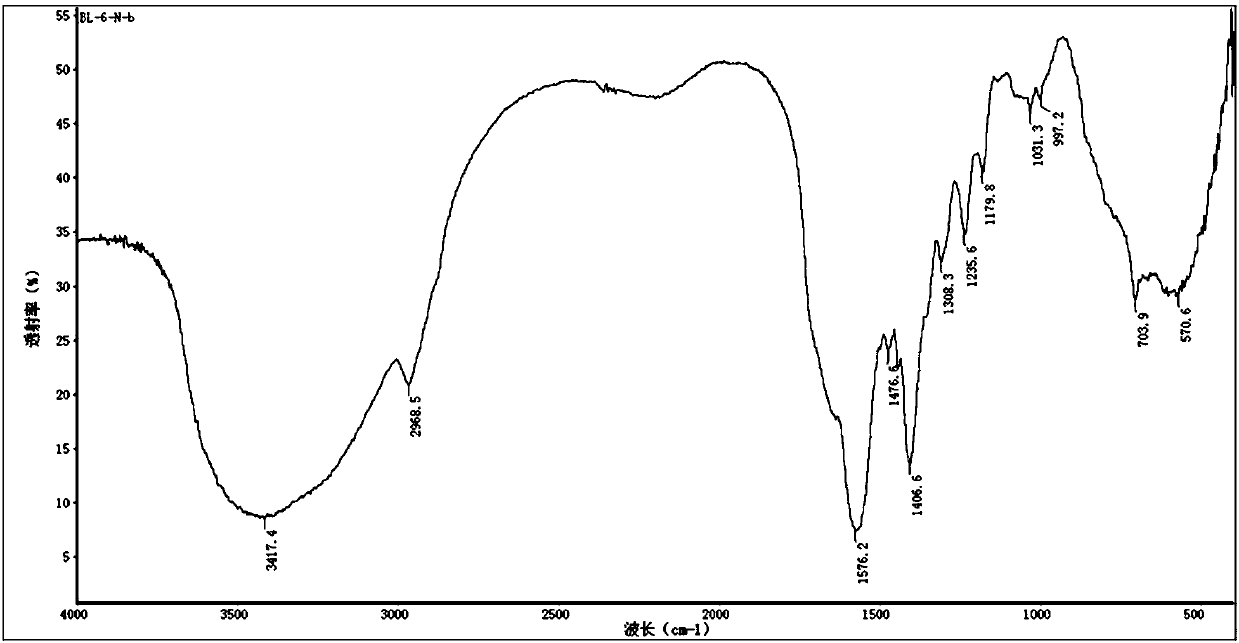

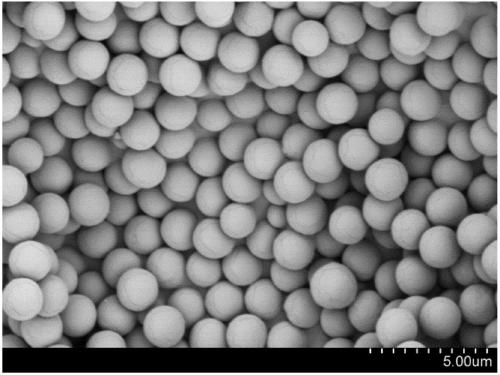

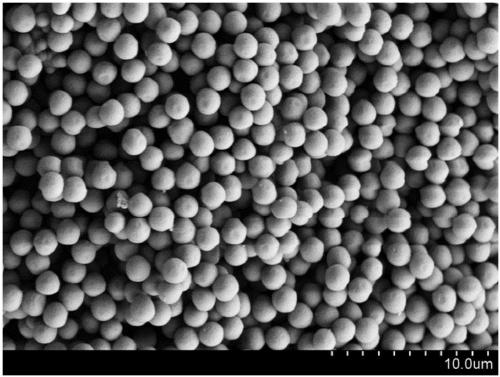

Microspheric ionomer having crosslinking structure, and preparation method and application thereof

The invention relates to the field of high molecular materials and discloses a microspheric ionomer having a crosslinking structure, and a preparation method and an application thereof. The ionomer contains a structural unit A represented as the formula (1), a structural unit B represented as the formula (2), and a crosslinking structure supplied by a crosslinker. The M1 and M2 are independently hydrogen or metal cations, R being hydrogen or methyl group. The invention also discloses a method of preparing the ionomer and the ionomer prepared by the method, wherein the method includes contacting maleic anhydride, a monomer B which supplies the structural unit B represented as the formula (2), and the crosslinker for a reaction; and mixing the reaction product with alkali in the presence ofwater for salinization. The invention also discloses an application of the ionomer, as a nucleating agent, for modifying PET. The ionomer has excellent nucleating effect on the PET, is simple in preparation method and is green and environment-friendly.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for toughening heat-resistant modified polylactic acid with plant-base composite environment-friendly modifier

The invention relates to a method for toughening heat-resistant modified polylactic acid with a plant-base composite environment-friendly modifier, which comprises the following steps: removing water from the raw material vegetable oil; proportionally adding polybasic acid / acid anhydride and a nucleating agent, and heating to 140-160 DEG C in an N2 atmosphere to react for 2-8 hours; adding a certain amount of dehydrated lactic acid or lactide, continuing reacting at 140-160 DEG C in the N2 atmosphere for 1-2 hours, heating to 170-190 DEG C to react for 2-10 hours, and vacuumizing the system; and extruding the prepared plant-base environment-friendly modifier polymer and polylactic acid by an equidirectional double screw extruder, blending, drawing, cooling with water, granulating, and drying to obtain the modified polylactic acid granules. Compared with the prior art, the modified polylactic acid granules have the advantages of no toxicity or harm, no harm to the environment and human health and favorable compatibility, and can be completely biodegraded. Besides, the polylactic acid modified by the modifier has favorable heat resistance.

Owner:SHANGHAI JIAO TONG UNIV

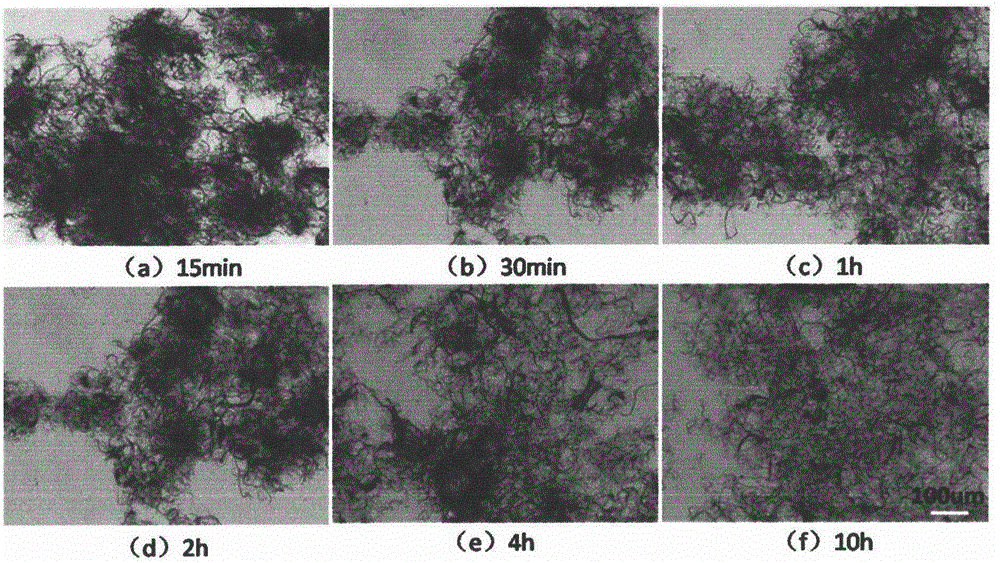

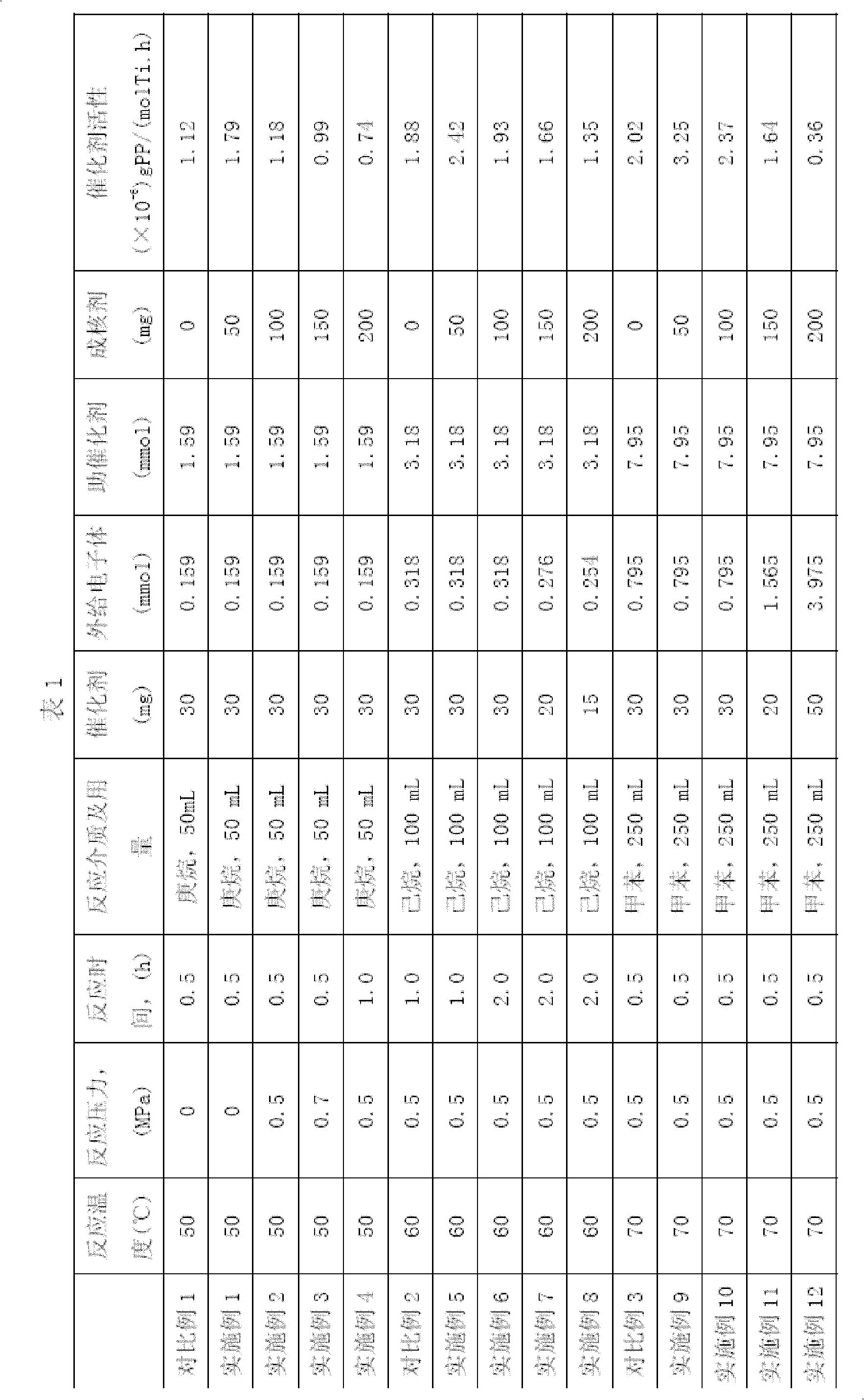

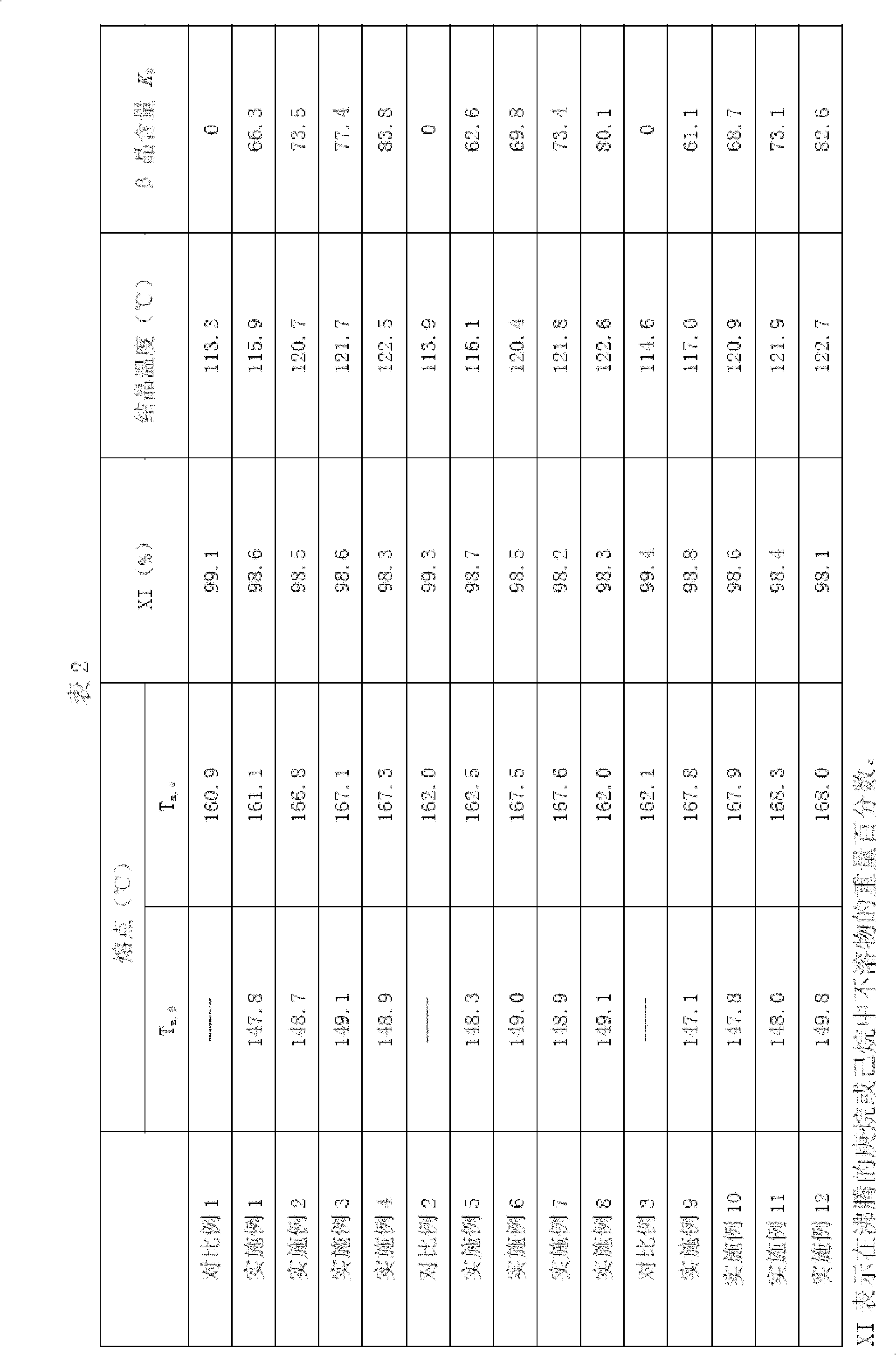

Nucleating agent modifying and preparing method of high-performance polypropylene

ActiveCN103724464AImprove performanceCatalytic activity does not decreaseElectron donorBULK ACTIVE INGREDIENT

The invention provides a nucleating agent modifying and preparing method of high-performance polypropylene. The method, under a circumstance of not changing polymerization conditions, can modify a nucleating agent or adopt special feeding ways to shield deactivated components after poisoning of a catalyst, so that active ingredients of the nucleating agent are completely released in reaction nucleating and polymerizing processes to the greatest extent; functional group of the modified nucleating agent is free from adverse effect on activity of a main catalyst and free from reaction with a catalyst promoter and an electron donor, so that catalytic activity is basically not reduced, and the modified polypropylene is excellent in performance and obvious in nucleating action in a kettle; the prepared polypropylene is high in comprehensive performance.

Owner:NINGXIA BAOTA PETROCHEM SCI & TECH IND DEV

Poly1-butylene nucleating agent composition and application thereof

The invention discloses a poly1-butylene nucleating agent composition. The poly1-butylene nucleating agent composition comprises 9,10-dihydro-9,10-ethylene-anthracene-11,12-disodium salt (DHEAS) and derivatives thereof. By adopting the poly1-butylene nucleating agent composition, the nucleating capability can be improved well, a glass transition temperature of poly1-butylene is increased, and the poly1-butylene nucleating agent composition has the advantages of low usage amount, low cost, simple preparation technology and the like, so that the poly1-butylene nucleating agent composition is an ideal poly1-butylene nucleating agent. The structural formula of the poly1-butylene nucleating agent composition is described in the specification.

Owner:INST OF CHEM CHINESE ACAD OF SCI

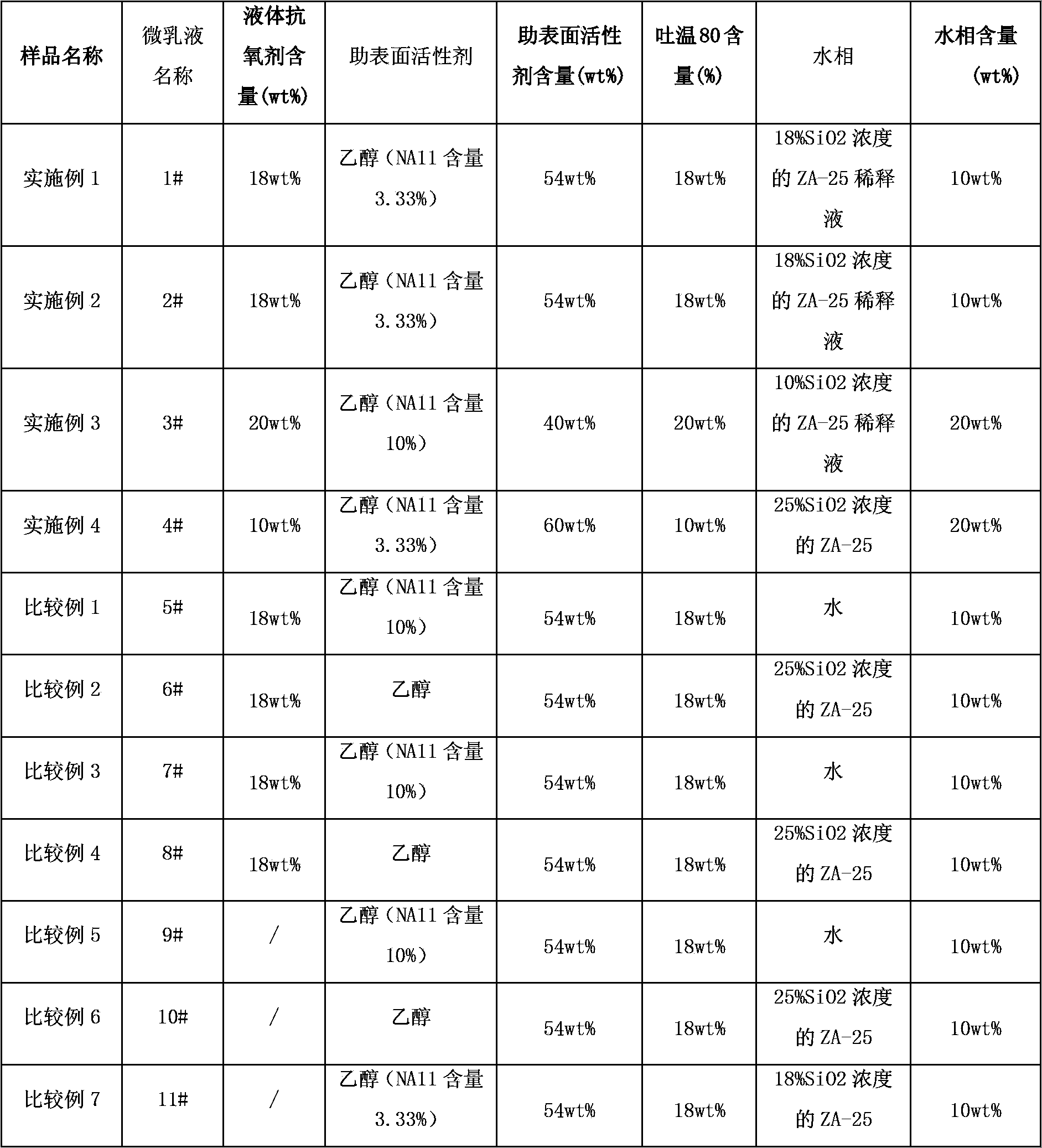

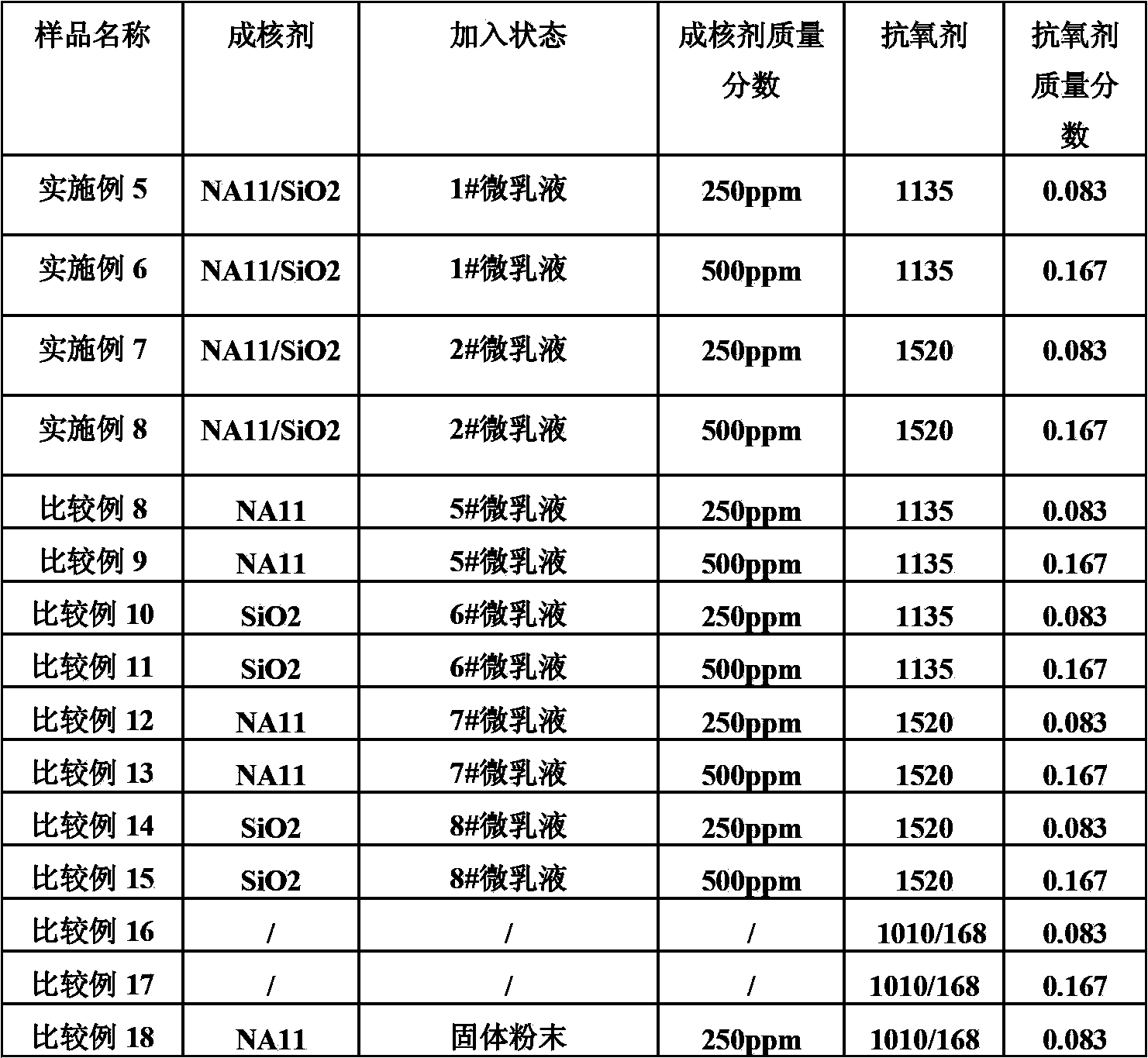

Modified polypropylene resin and preparation method thereof

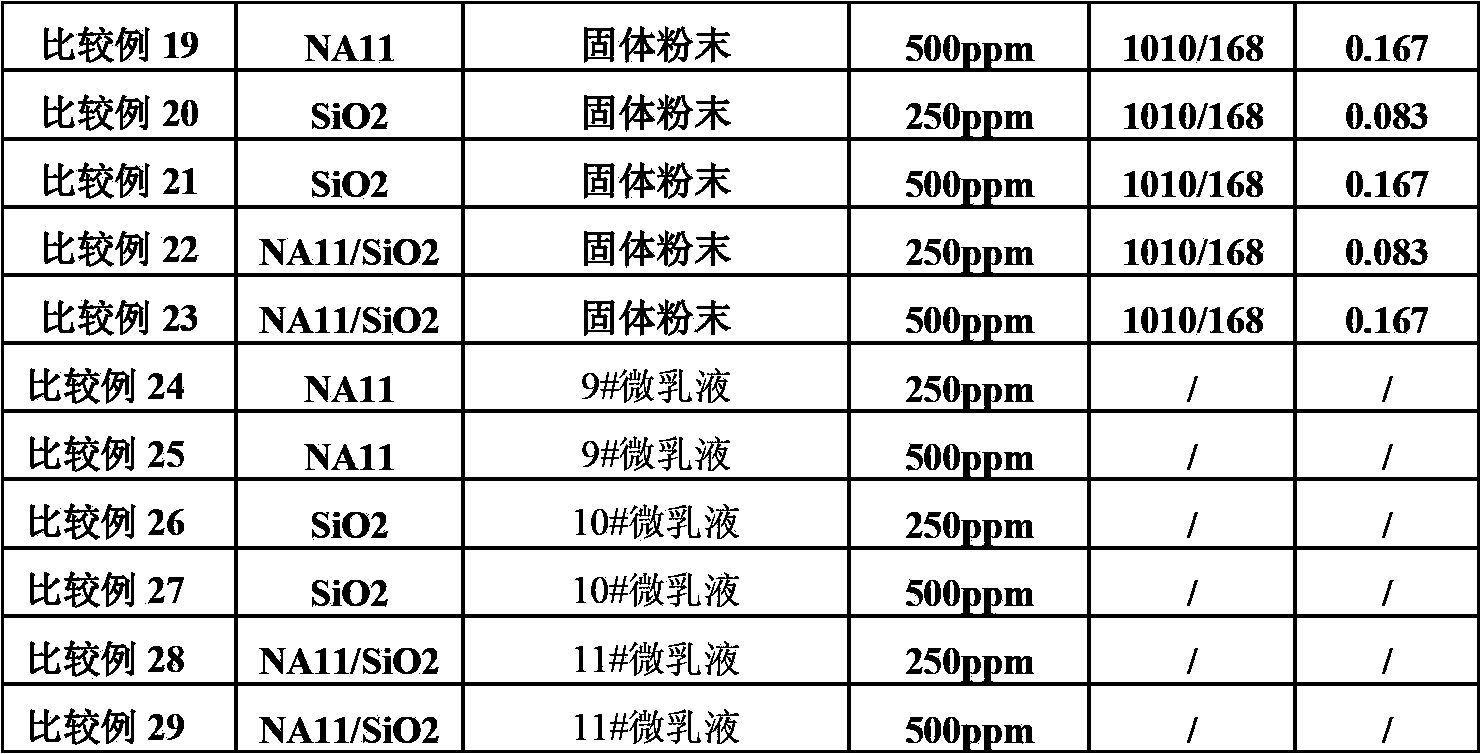

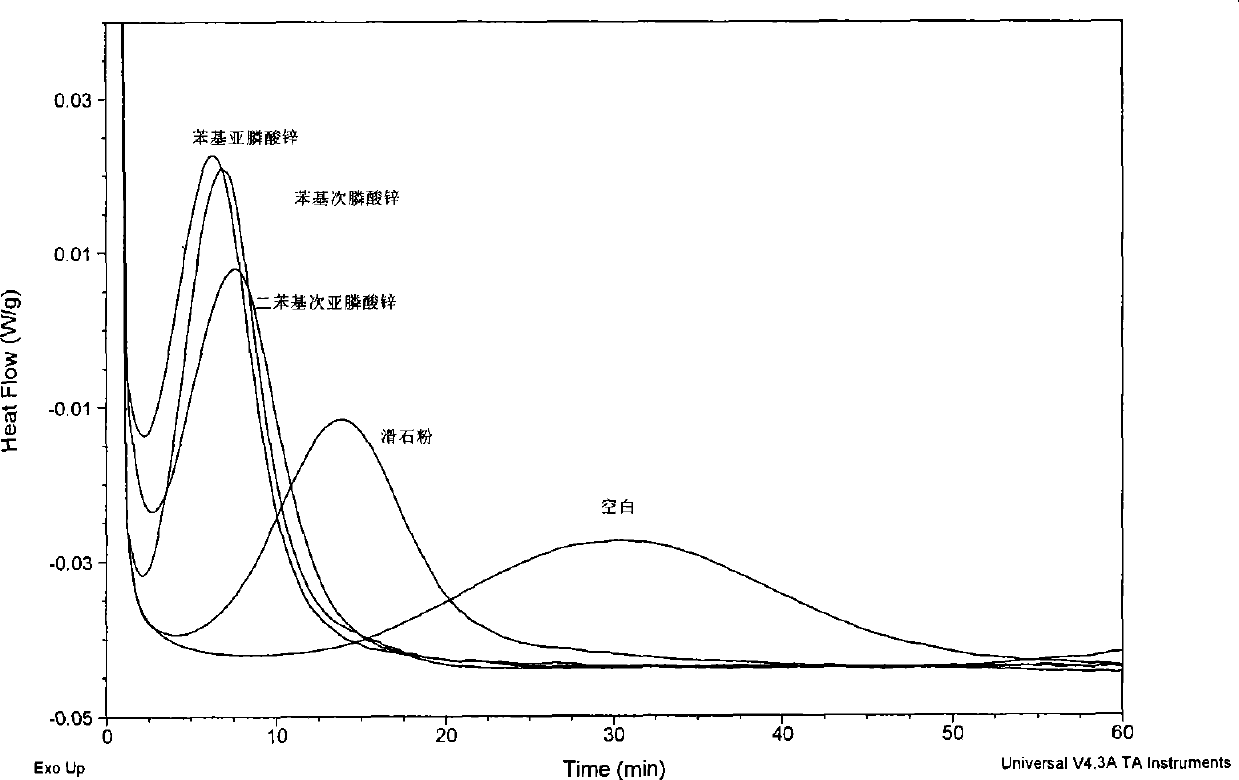

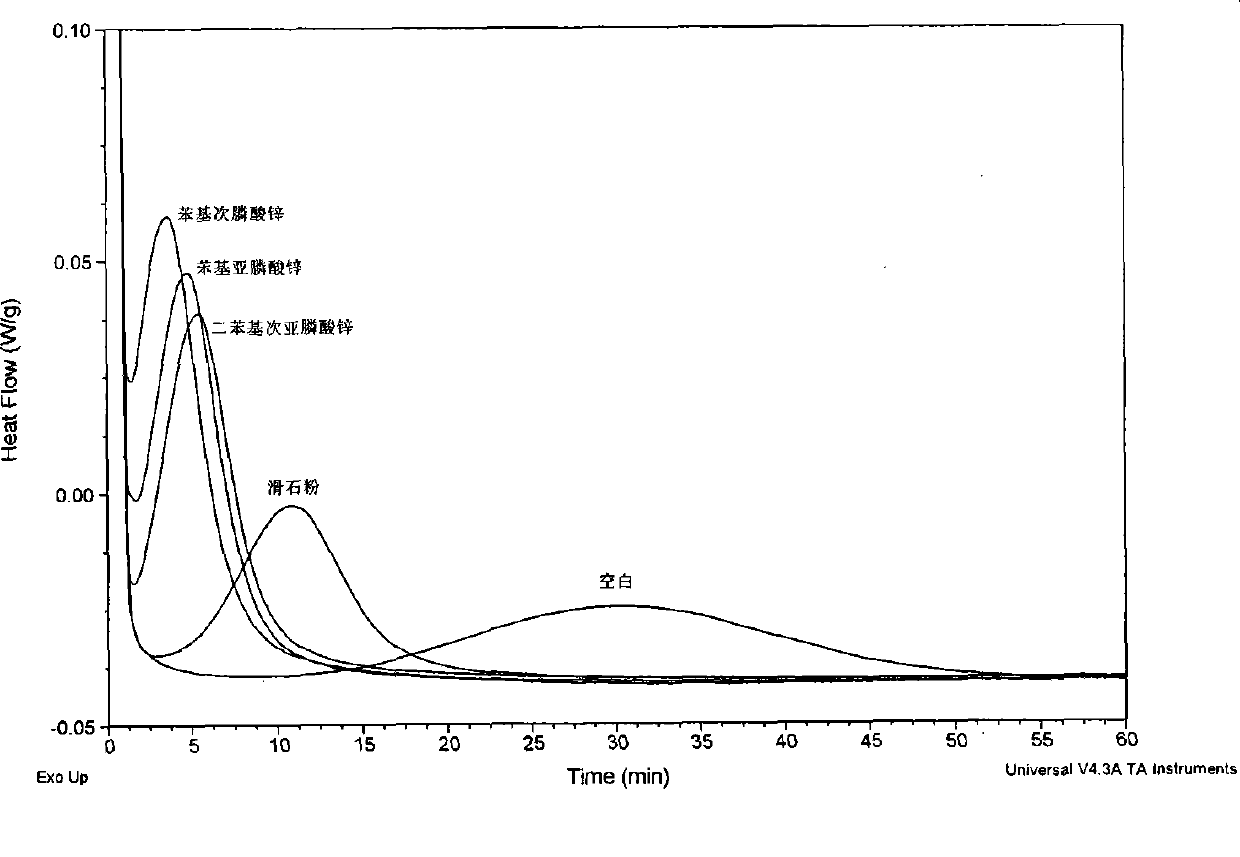

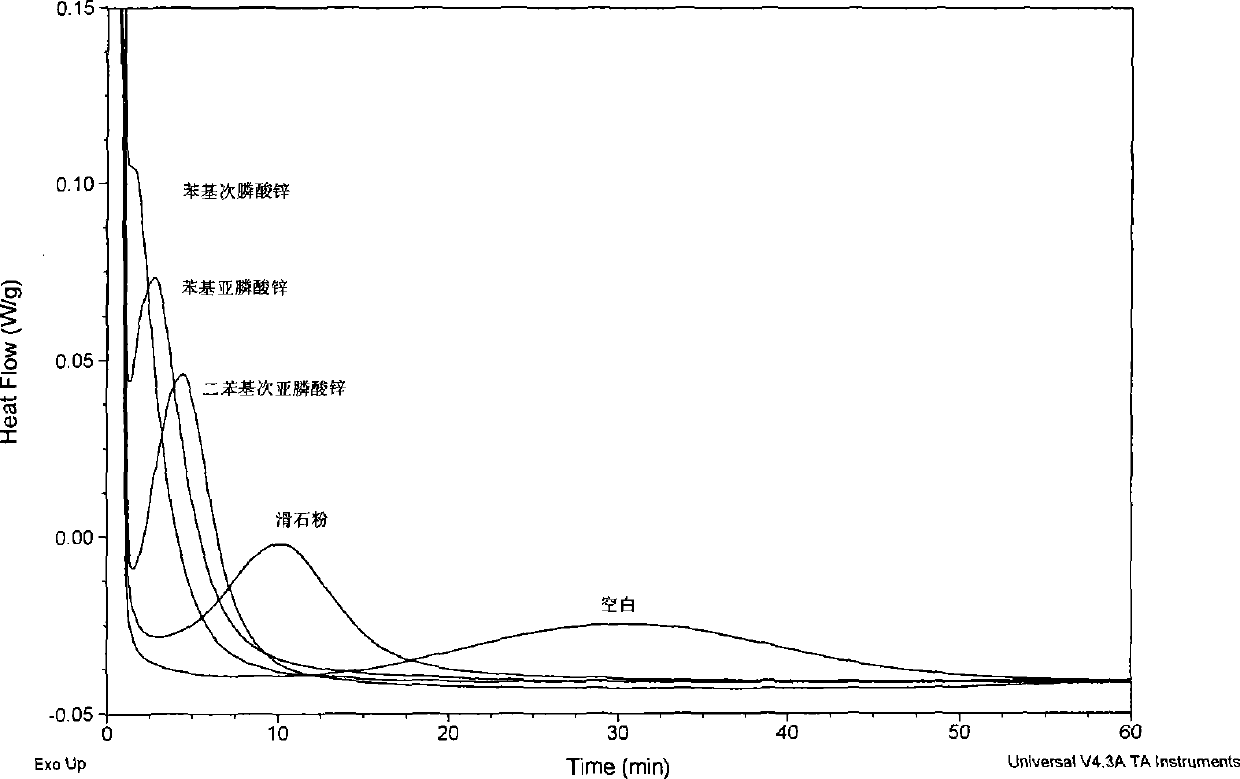

The invention discloses a modified polypropylene resin and a preparation method thereof. The modified polypropylene resin comprises polypropylene resin and a modification assistant and the polypropylene resin and the modification assistant are mixed. The modification assistant is a microemulsion of a liquid anti-oxidant and a binary composite nucleating agent. The binary composite nucleating agent comprises silica and 2,2'-methylene-di(4,6-di-n-butylphenol)phosphoric acid sodium and a weight ratio of silica to 2,2'-methylene-di(4,6-di-n-butylphenol)phosphoric acid sodium is in a range of 95: 5 to 5: 95. The preparation method comprises that the above ingredients are subjected to melt blending according the above use amount ratio so that the modified polypropylene resin is obtained. The modified polypropylene resin has obviously improved polypropylene crystallinity and greatly improved mechanical properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rapid nucleating agent of polylactic resin

The invention provides a nucleater for a polylactic resin, which belongs to the technical field of novel materials. The nucleater is phosphorous compound metal salt with reduction function, and the phosphorous compound metal salt is one or a mixture of phosphonous compound metal salt containing trivalent phosphor or phosphorus hydrogen bonds, phosphinous compound metal salt and phosphinic compound metal salt. The nucleater can promote growth of crystals and reduce the dimension of the crystals, and simultaneously has good nucleation effect, quick crystallization speed and strong antioxygenic property, heat resistance and hydrolytic resistance.

Owner:ZHEJIANG HISUN BIOMATERIALS +1

Soft high-temperature-resistant polypropylene foam material and preparation method thereof

The invention discloses a soft high-temperature-resistant polypropylene foam material and a preparation method thereof. The soft high-temperature-resistant polypropylene foam material comprises 100 parts of co-polypropylene resin, 10-20 parts of polyolefin block copolymer resin, 5-15 parts of high-density polyethylene resin, 1-3 parts of low-molecular-weight polytetrafluoroethylene and 1-4 parts of a foaming agent. The method comprises the following steps of: melting and mixing copolymerized polypropylene resin, polyolefin block copolymer resin, high-density polyethylene resin, a foaming agentand low-molecular-weight polytetrafluoroethylene, and extruding from an extruder to obtain a sheet; and sequentially feeding the cross-linked sheet into a preheating section, a foaming section and acooling shaping section of equipment for foaming to obtain the foam material. The soft high-temperature-resistant polypropylene foam material is low in compression set and low in compression strength,so that the foam material is soft enough; meanwhile, under the high-temperature condition, the heat-resistant dimension change rate (transverse / longitudinal) reaches -0.8% / -1.4%, and the foam material has both softness and heat resistance.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

Device and method for efficiently removing fine particulate matters by temperature and humidity regulation and control

ActiveCN111068451AGuarantee unimpededAvoid dust accumulationCombination devicesGas treatmentElectrocoagulationFlue gas

The invention discloses a device and a method for efficiently removing fine particulate matters through temperature and humidity regulation and control. A box body structure with the same cross section structure size is adopted; the main body channels are arranged in series in a manner that flow channel center lines coincide; efficient removal of the particles with large and small particle sizes is achieved step by step in a regional mode through the forms of front-stage negative direct current pre-dedusting, primary flue gas temperature and humidity regulation and control, acoustoelectric coupling coagulation, secondary flue gas temperature and humidity regulation and control and rear-stage negative direct current dedusting in combination with gravity settling, filtering and trapping effects, condensation nucleation effects and acoustoelectric coupling effects for enhancing the collision coagulation effect of the fine particles. Local regulation and control of the flue gas temperatureand step-by-step humidification of the humidity are achieved through the series connection effect of the two-stage flue gas temperature and humidity regulation and control dust collection areas and the coupling effect of acoustic agglomeration and pulse electrocoagulation; meanwhile, the partition electrocoagulation effect of particulate matter with different particle sizes is achieved, and the trapping and removing effect of fine particulate matter is enhanced through the ash removal and dust collection effects of the movable grid plate and the movable electrode plate, and the removing efficiency of the fine particulate matter is high.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

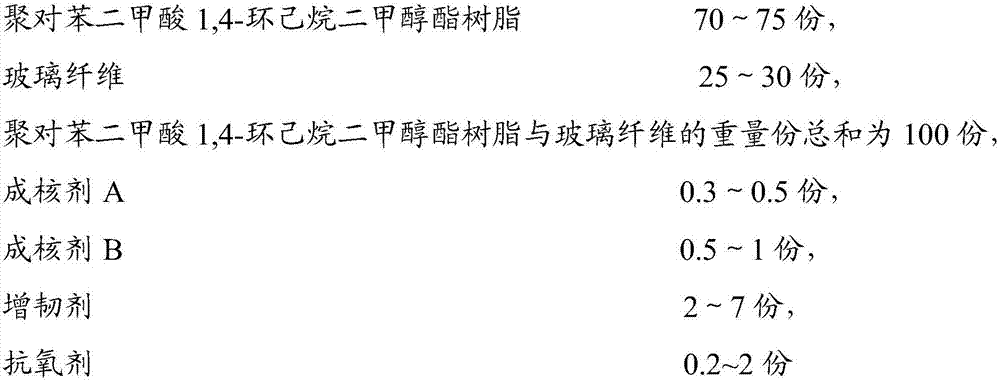

Polyester composition and preparation method thereof

The invention relates to a polyester composition and a preparation method thereof; the polyester composition is prepared from poly-1,4-cyclohexane dimethylene terephthalate (PCT) resin, glass fiber, nucleating agent A, nucleating agent B, a flexibilizer, an antioxidant, a lubricant and an additive. The poly-1,4-cyclohexane dimethylene terephthalate (PCT) resin has number-average molecular weight of 25000 to 30000; the nucleating agent A is sodium carboxylate organic small-molecular nucleating agent, having molecular weight of 100-200 g / mol; the nucleating agent B is an ionic polymer salt nucleating agent. The polyester composition has higher crystallizing rate so that a material takes short time to form, time cost of product processing is saved, crystallizing rate is largely increased, and the comprehensive properties of the material, such as impact property, bending performance, and thermal deformation temperature tolerance, can be better improved.

Owner:SINOPLAST NEW MATERIAL

Microspheric ionomer having crosslinking structure, and preparation method and application thereof

The invention relates to the field of high molecular materials and discloses a microspheric ionomer having crosslinking structure, and a preparation method and an application thereof. The preparationmethod includes: (1) in an organic solvent, contacting maleic anhydride and a first part of a monomer M in the presence of a first part of an initiator for a reaction, then introducing a solution containing a crosslinker to continuously perform the reaction, wherein the solution contains the crosslinker, optionally a second part of the monomer M, and optionally a second part of the initiator, andthe monomer M is supplied by a C4 and / or a C5 compound; (2) performing salinization, in the presence of water, on the product in the step (1) by contacting with alkali. The invention also discloses anapplication of the ionomer as a nucleating agent for modification of PET. The ionomer has excellent nucleating effect on PET. The preparation method is simple, green and environment-friendly.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com