Modified polypropylene plastic and preparation method thereof

A technology of polypropylene plastic and isotactic polypropylene, which is applied in the field of plastic materials and can solve problems such as poor toughness and anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

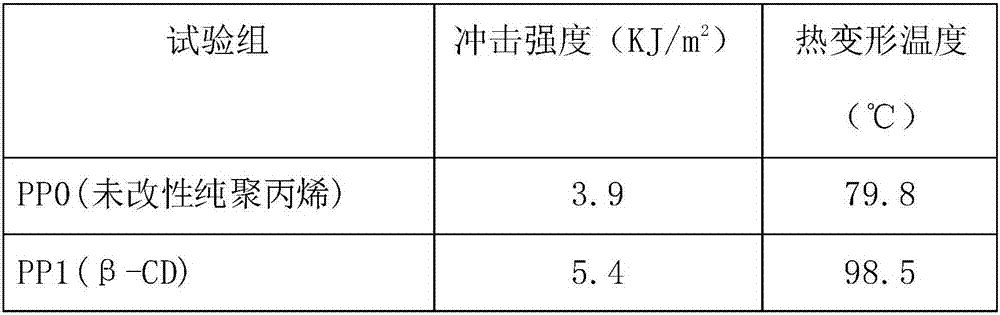

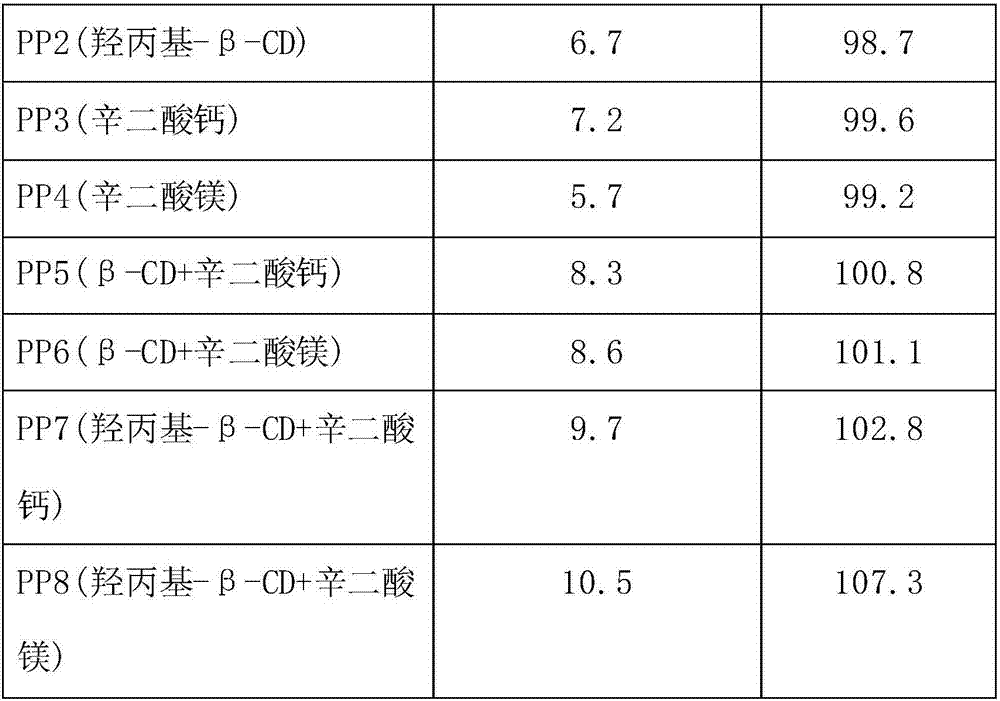

Examples

Embodiment 1

[0019] Embodiment 1 Preparation of isotactic polypropylene / β-cyclodextrin inclusion compound

[0020] Dissolve 0.02mol of isotactic polypropylene in 800ml of 1,2,4-trichlorobenzene, stir at 120°C under nitrogen atmosphere until clear, and take another 0.02mol of β-cyclodextrin and dissolve it in 80ml of dimethyl sulfoxide , the above-mentioned dimethyl sulfoxide solution was heated to 120° C. and then slowly added dropwise to the polypropylene solution. After the dropwise addition was completed, stirring was continued at 120° C. for 4 hours. After the reaction, the reaction solution was cooled to room temperature and continued to stir for 24 hours, and the reaction solution was filtered to obtain a precipitate. After the precipitate was washed with hot 1,2,4-trichlorobenzene solution, water and acetone in sequence, the washed precipitate was in Vacuum-dry at room temperature for 24 hours to obtain β-cyclodextrin inclusion compound wrapped with polypropylene.

Embodiment 2

[0021] Example 2 Preparation of isotactic polypropylene / hydroxypropyl-β-cyclodextrin inclusion compound

[0022] Dissolve 0.02mol of isotactic polypropylene in 800ml of 1,2,4-trichlorobenzene, stir at 120°C under a nitrogen atmosphere until clear, and dissolve another 0.02mol of hydroxypropyl-β-cyclodextrin in 80ml of dichlorobenzene In methyl sulfoxide, the above-mentioned dimethyl sulfoxide solution was heated to 120°C and then slowly added dropwise to the polypropylene solution. After the dropwise addition was completed, stirring was continued at 120°C for 4 hours. After the reaction, the reaction solution was cooled to room temperature and continued to stir for 24 hours, and the reaction solution was filtered to obtain a precipitate. After the precipitate was washed with hot 1,2,4-trichlorobenzene solution, water and acetone in sequence, the washed precipitate was in After vacuum drying at room temperature for 24 hours, the inclusion compound of hydroxypropyl-β-cyclodextri...

Embodiment 3

[0023] The preparation of embodiment 3 modified polypropylene PP1

[0024] 100 parts by weight of isotactic polypropylene and 0.2 parts by weight of the β-cyclodextrin inclusion compound prepared in Example 1 were stirred and mixed uniformly in a mixer, then extruded and pelletized at 185°C; after the pellets were dried, the Injection molding at a temperature of 200°C to obtain modified polypropylene PP1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com