High-performance concrete slurry-shaped admixture mixed by CaCO3 having multi-scale particle sizes

A high-performance concrete and admixture technology, applied in the field of concrete admixtures, can solve the problems of low compressive strength and insufficient structural strength, and achieve the effects of good compatibility, good nucleation effect, and improved material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

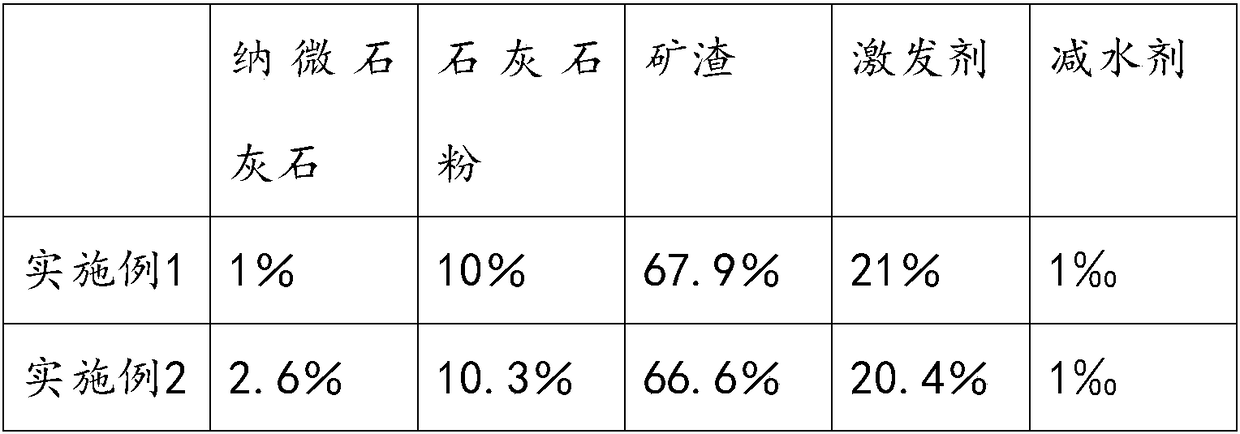

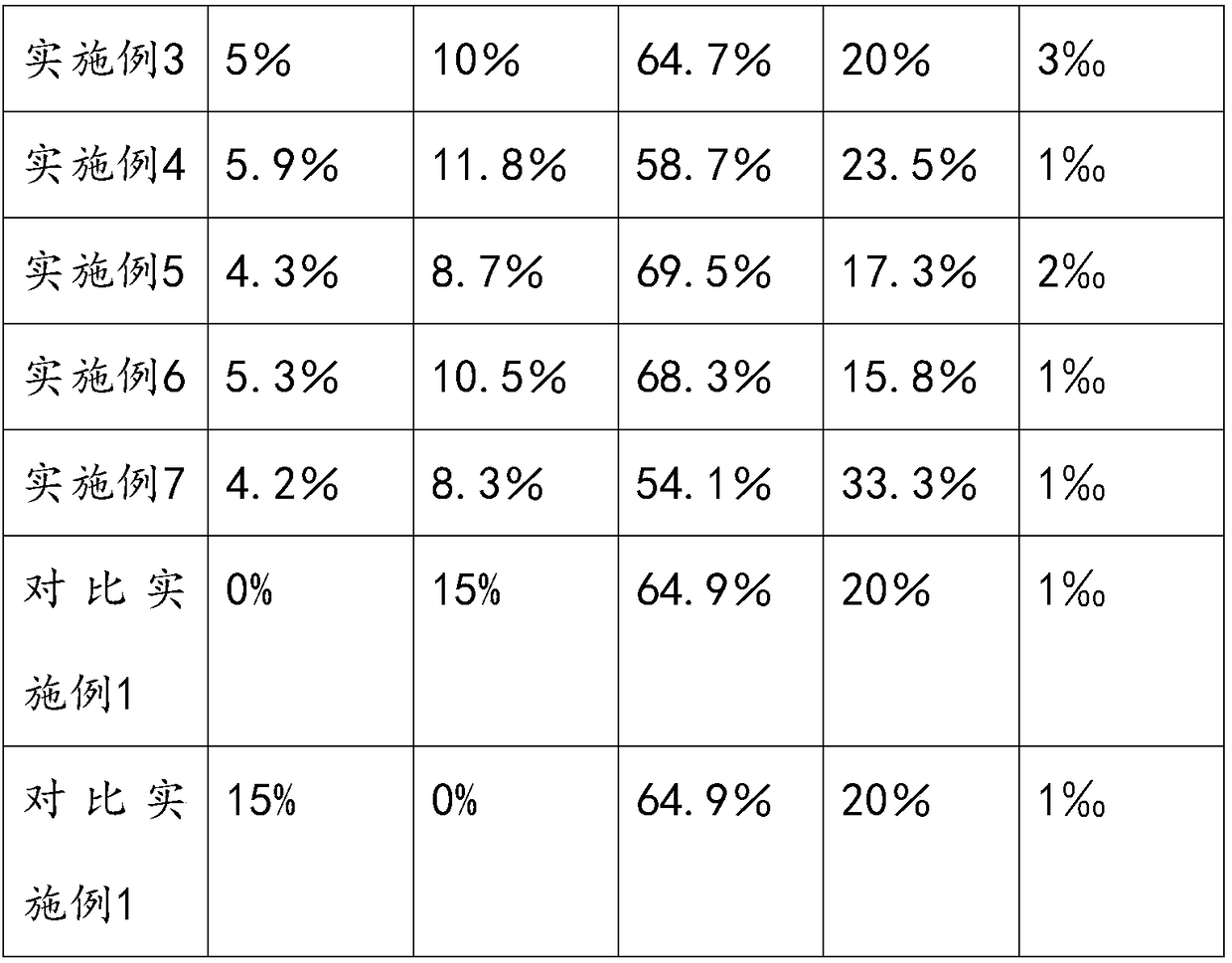

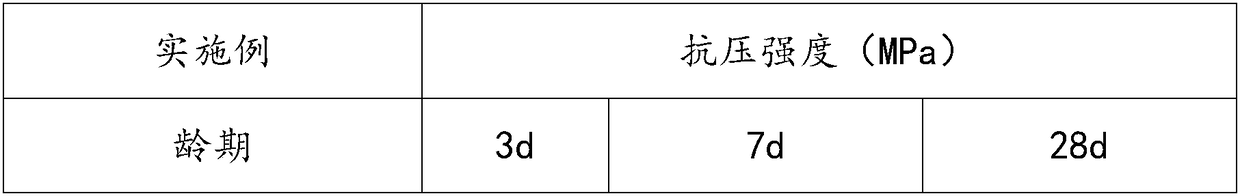

Examples

Embodiment Construction

[0022] Process example:

[0023] Nano-micro limestone: add water to the limestone powder and send it to a wet mill for grinding to obtain a slurry with a median particle size of 2μm-1μm and a median size of less than 0.3μm. The mass ratio of the two is 3-1:1 ;

[0024] Ultra-fine slag: Add water to the slag and send it to a wet mill to grind until the median diameter is 4μm-8μm;

[0025] Limestone powder: add water to the limestone powder and send it to a wet mill to grind until the median particle size is 9-13 μm to obtain limestone slurry;

[0026] Composite activator: Add water to the electrolytic manganese slag and carbide slag and send them to a wet mill to grind until the median particle size is 9-13 μm to obtain a composite activator slurry;

[0027] All wet-milled raw materials and water reducer can be directly mixed evenly or sent to the wet mill again to make slurry admixture. The mass fraction of slurry in the slurry admixture is controlled at 20%-60%. For the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com