Calcium-carbonate-supported nucleating agent used for poly(lactic acid) crystallization and preparation method thereof

The technology of a crystal nucleating agent and calcium carbonate is applied to the crystal nucleating agent of polylactic acid, the crystal nucleating agent of calcium carbonate supported polylactic acid and its preparation field, and can solve the problems of low efficiency, uneven dispersion and high cost, Achieve the effect of improving nucleation efficiency, avoiding poor toughness and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 In the reactor, the nano-calcium carbonate is dispersed in acetone or chloroform, and then mixed with phenylphosphonic acid in the following ratios of 5:1, 10:1, 20:1 and 40:1, at room temperature Stir and react for 4 hours, then centrifuge, and filter to obtain a white precipitate; wash the precipitate with acetone or chloroform respectively to remove unreacted phenylphosphonic acid, dry the precipitate, and phenylphosphonic acid and calcium carbonate react to form phenyl Calcium phosphate (PPCA) was loaded on the surface of calcium carbonate as an active ingredient to obtain calcium carbonate-loaded polylactic acid crystallization nucleating agents, respectively.

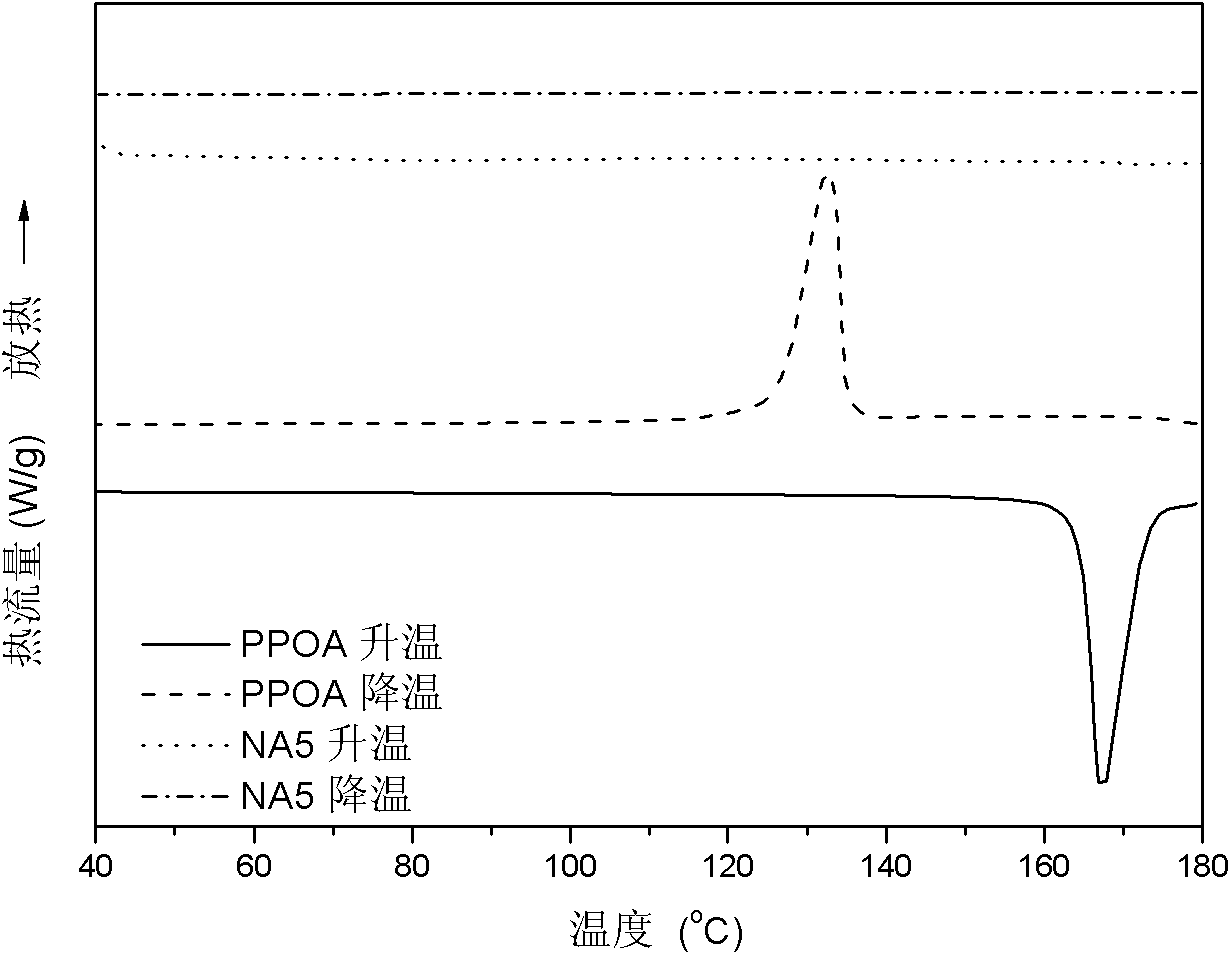

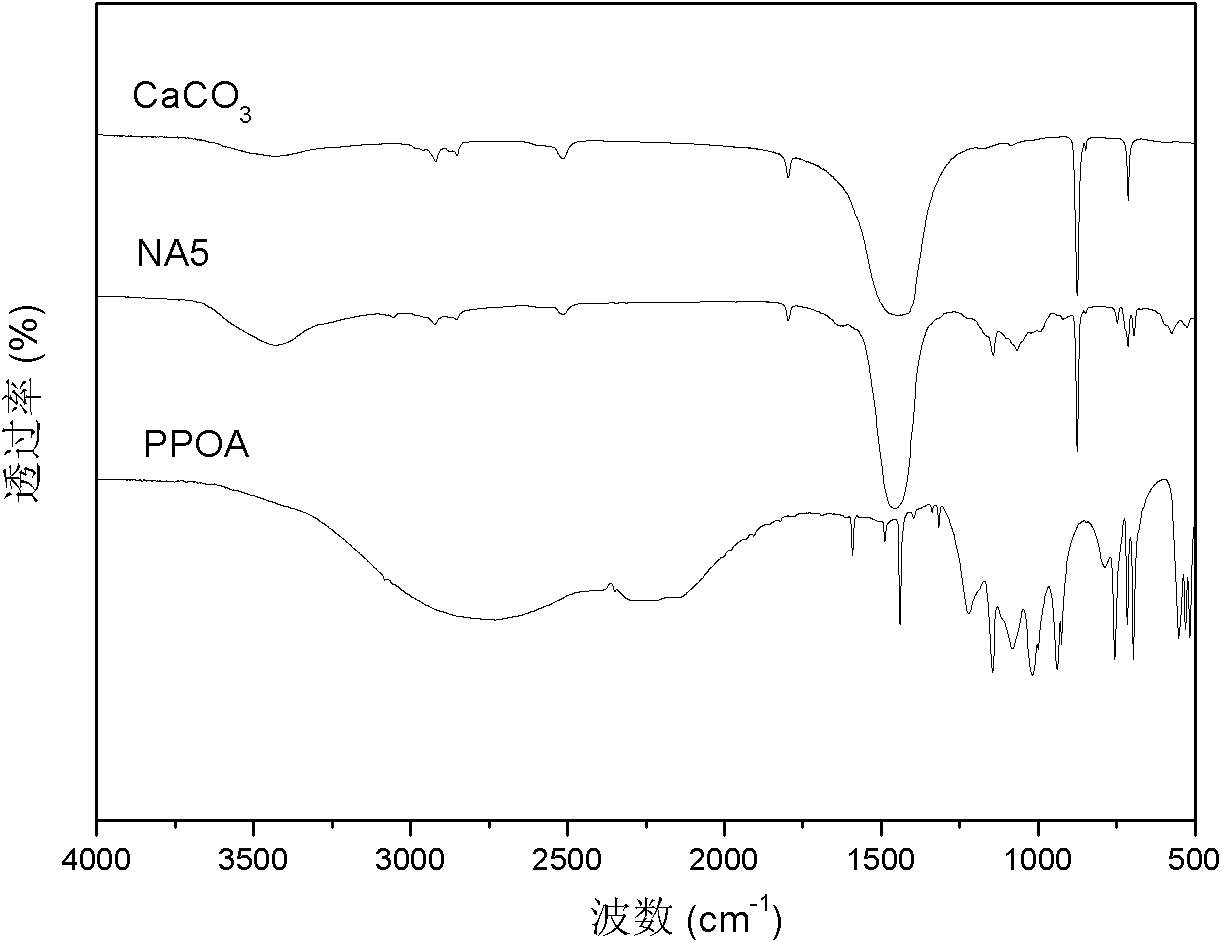

[0024] figure 1 and figure 2 It shows that phenylphosphonic acid reacts with nano-calcium carbonate to generate calcium phenylphosphonate, which is a supported nucleating agent loaded on the surface of nano-calcium carbonate.

[0025] A kind of usage of calcium carbonate loaded polylactic acid...

Embodiment 2

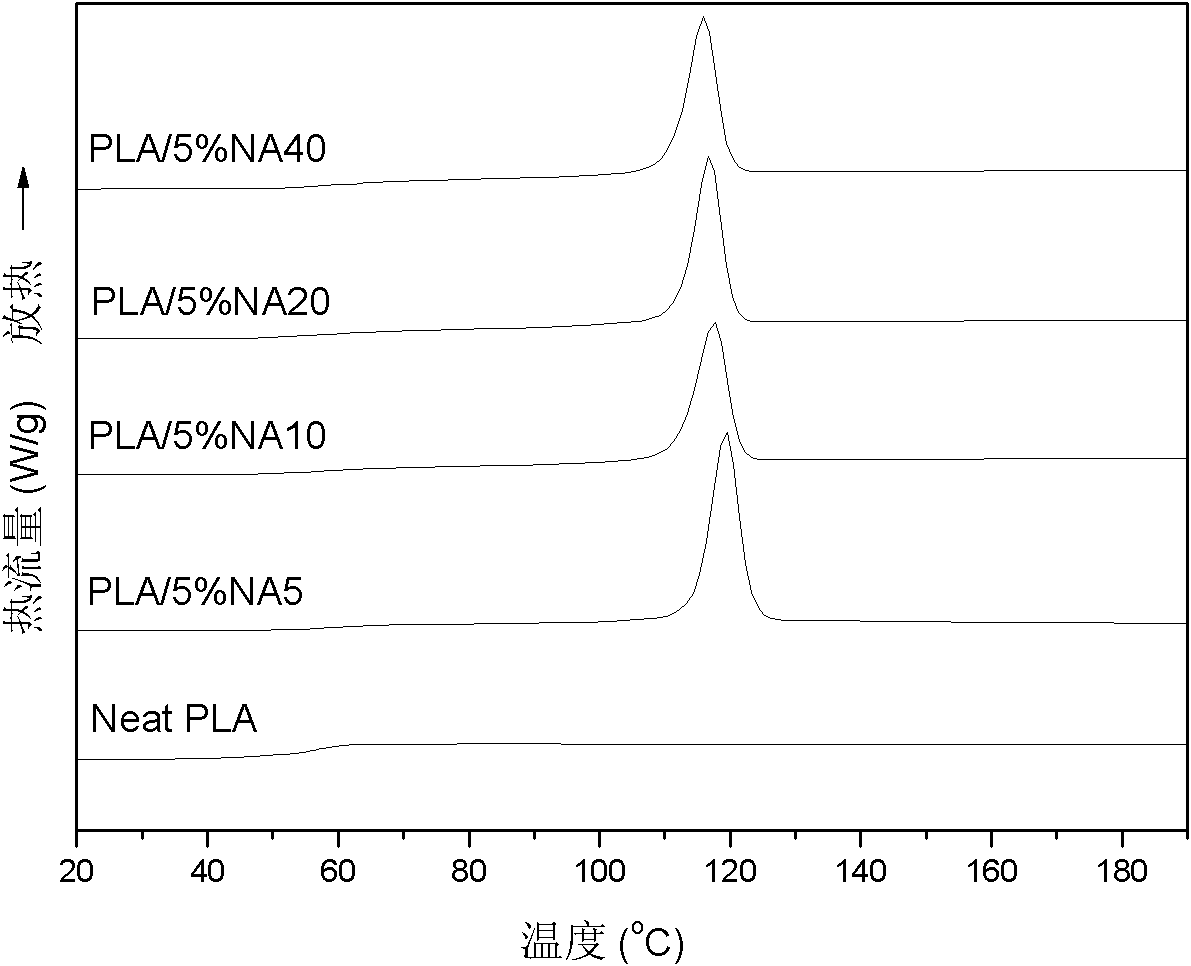

[0029] Embodiment 2 The calcium carbonate-loaded polylactic acid crystallization nucleating agent prepared in Example 1 of the present invention is compared with nano-calcium carbonate and calcium phenylphosphonate as nucleating agents, and differential scanning calorimetry is carried out to the nucleating ability of polylactic acid ( DSC) detection.

[0030] The DSC test method is: under the protection of nitrogen, rise from room temperature to 190°C at 50°C / min, stay for 2 minutes to eliminate the heat history, and then quickly cool down to the isothermal crystallization temperature at 45°C / min, where the isothermal crystallization temperature is set to 130°C and 140°C, isothermal crystallization at 130°C and 140°C respectively, test the half-crystallization time t 0.5 . The test results are shown in Table 1.

[0031] From Table 1, it can be concluded that although nano-calcium carbonate and calcium phenylphosphonate have all played a nucleating effect on polylactic acid a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com