High-anti-impact, high-rigidity and high-shrinking rate polypropylene modified material and preparation method thereof

A shrinkage, polypropylene technology, applied in the high shrinkage polypropylene modified material and its preparation, high impact and high rigidity field, can solve the problems affecting the impact performance or rigidity of the material, and achieve the improvement of shrinkage rate, wide applicability, high rigidity, etc. The effect of improving impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

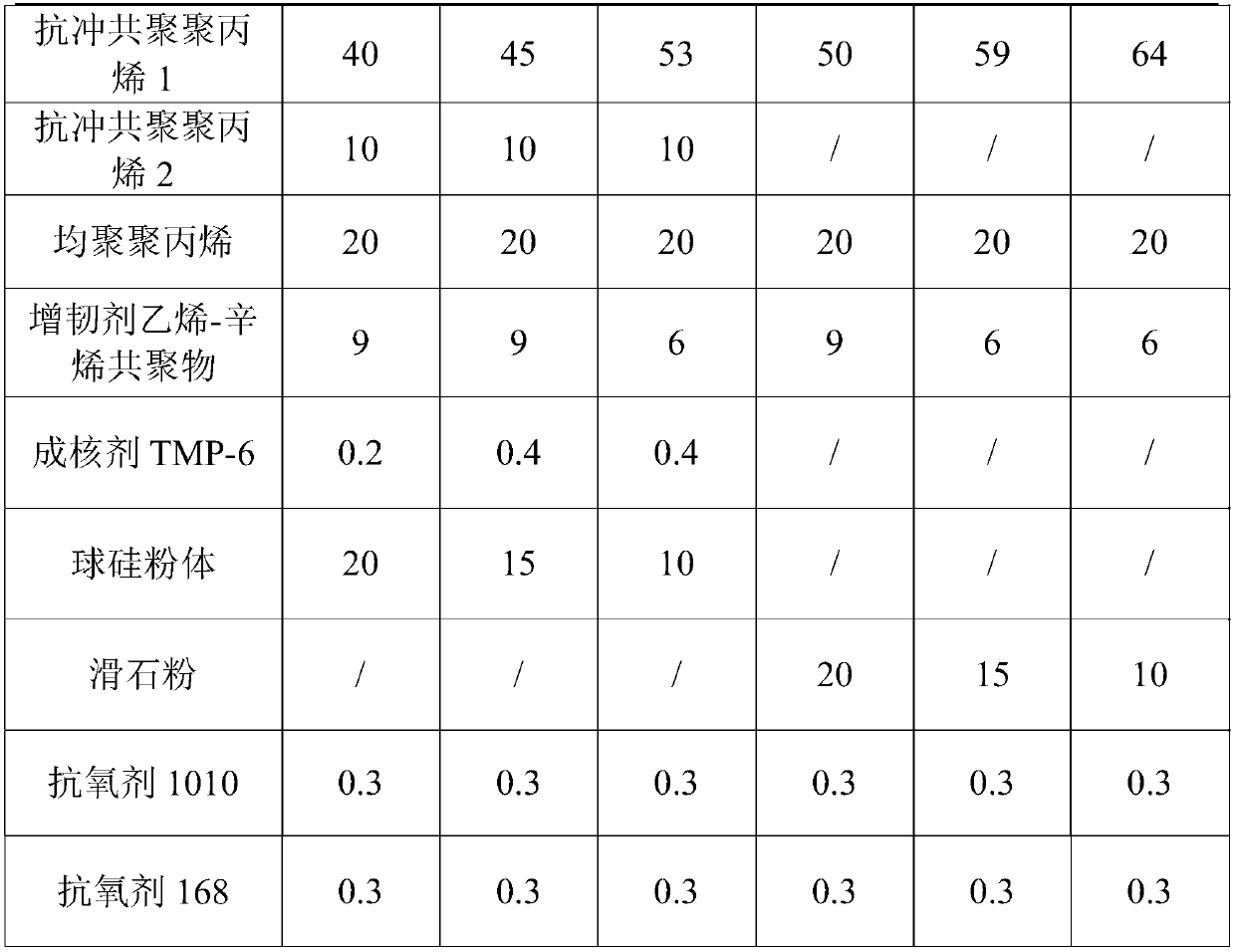

Embodiment 1

[0037] A high-impact, high-rigidity, high-shrinkage polypropylene modified material, including the following components in parts by weight: impact copolymer polypropylene 1 40.0 parts, impact copolymer polypropylene 2 10.0 parts, homopolypropylene 20.0 parts, Toughening agent (ethylene-octene copolymer) 9.0 parts, spherical silicon (spherical silicon powder) 20.0 parts, nucleating agent (TMP-6) 0.2 parts, antioxidant 1010 0.3 parts, antioxidant 168 0.3 parts.

[0038] The preparation method of the described high-impact, high-rigidity, high-shrinkage polypropylene modified material comprises the following steps:

[0039] (1) Weigh the polypropylene, spherical silicon, toughening agent, nucleating agent, primary antioxidant and auxiliary antioxidant of the formula, and mix them in a high-speed mixer (550r / min) for 2min, mix Uniformly, a premix is obtained.

[0040] (2) Add the premixed material into the main feeding port of the twin-screw extruder, perform melt extrusion, gra...

Embodiment 2

[0043]A high-impact, high-rigidity, high-shrinkage polypropylene modified material, including the following components in parts by weight: impact copolymer polypropylene 1 45.0 parts, impact copolymer polypropylene 2 10.0 parts, homopolypropylene 20.0 parts, Toughening agent (ethylene-octene copolymer) 9.0 parts, spherical silicon (spherical silicon powder) 15.0 parts, nucleating agent (TMP-6) 0.4 parts, antioxidant 1010 0.3 parts, antioxidant 168 0.3 parts.

[0044] The preparation method of the high-impact, high-rigidity, and high-shrinkage polypropylene modified material is the same as in Example 1, except that the conditions for melt extrusion are: the temperature in the first zone is 100°C, the temperature in the second zone is 200°C, and the temperature in the third zone is 200°C. The temperature is 215°C, the temperature in the fourth zone is 215°C, the temperature in the fifth zone is 225°C, the temperature in the sixth zone is 215°C, the temperature in the seventh zone...

Embodiment 3

[0046] A high-impact, high-rigidity, high-shrinkage polypropylene modified material, including the following components in parts by weight: impact copolymer polypropylene 1 53.0 parts, impact copolymer polypropylene 2 10.0 parts, homopolypropylene 20.0 parts, Toughening agent (ethylene-octene copolymer) 6.0 parts, spherical silicon (spherical silicon powder) 10.0 parts, nucleating agent (TMP-6) 0.4 parts, antioxidant 1010 0.3 parts, antioxidant 168 0.3 parts.

[0047] The preparation method of the high-impact, high-rigidity, and high-shrinkage polypropylene modified material is the same as in Example 1, except that the conditions for melt extrusion are: the temperature in the first zone is 115°C, the temperature in the second zone is 207°C, and the temperature in the third zone is 115°C. The temperature is 218°C, the temperature in the fourth zone is 220°C, the temperature in the fifth zone is 225°C, the temperature in the sixth zone is 215°C, the temperature in the seventh zon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com