Lignin-based biodegradable polymer composite film and preparation method thereof

A composite material film and polymer material technology, applied in the field of lignin-based biodegradable polymer composite material film and its preparation, can solve the problems of easy combustion, high price, low strength, etc. The effect of uniform and sufficient nucleation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

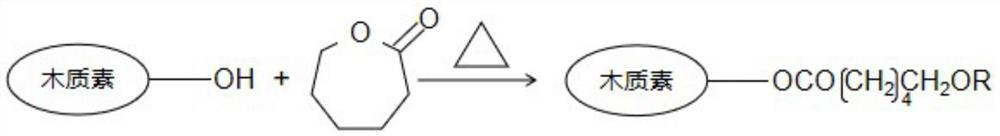

Method used

Image

Examples

Embodiment 1

[0028] After 25 parts of lignin are air-pulverized to a particle size of 0.2 μm-8 μm, they are stirred and mixed with 5 parts of caprolactone in a high-speed mixer at 90°C for 20 minutes, then cooled to room temperature to obtain caprolactone-grafted lignin ( Lignin-PCL); Lignin-PCL is mixed with 100 parts of butylene adipate and butylene terephthalate copolymer (PBAT) to obtain a precursor, and the resulting precursor is extruded through a twin-screw The lignin / PBAT composite material is obtained by machine melt blending extrusion and granulation; the lignin / PBAT composite material is blown upward by a blow molding machine to obtain a lignin / PBAT composite material film. The first zone of the twin-screw extruder is 100°C, the second zone is 120°C, the third zone is 140°C, the fourth zone is 150°C, the fifth zone is 160°C, the sixth zone is 165°C, the head is 165°C, the screw speed is 100rpm; the first zone of the blow molding machine is 120°C ℃, the second zone is 140°C, the ...

Embodiment 2

[0030] After 20 parts of lignin is air-pulverized to a particle size of 0.2 μm-8 μm, it is stirred and mixed with 2 parts of caprolactone in a high-speed mixer at 85°C for 30 minutes, then cooled to room temperature to obtain caprolactone-grafted lignin ( Lignin-PCL); Lignin-PCL is mixed with 100 parts of polylactic acid (PLLA) to obtain a precursor, and the obtained precursor is melt blended and extruded by a twin-screw extruder, and pelletized to obtain a lignin / PLLA composite material; The lignin / PLLA composite material is blow-molded upward through a blow molding machine to obtain a lignin / PLLA composite material film. The first zone of the twin-screw extruder is 120°C, the second zone is 140°C, the third zone is 150°C, the fourth zone is 160°C, the fifth zone is 170°C, the sixth zone is 175°C, the head is 175°C, the screw speed is 120rpm; the first zone of the blow molding machine is 120°C ℃, the second zone is 150°C, the third zone is 170°C, the fourth zone is 180°C, and...

Embodiment 3

[0032] After 10 parts of lignin is air-pulverized to a particle size of 0.2 μm-8 μm, it is stirred and mixed with 2 parts of caprolactone in a high-speed mixer at 90°C for 10 minutes, then cooled to room temperature to obtain caprolactone-grafted lignin ( Lignin-PCL); Lignin-PCL is mixed with 100 parts of polybutylene succinate (PBS) to obtain a precursor, and the obtained precursor is melt-blended and extruded by a twin-screw extruder, and pelletized to obtain a wood The lignin / PBS composite material; the lignin / PBS composite material is blow-molded upwards through a blow molding machine to obtain a lignin / PBS composite material film. The first zone of the twin-screw extruder is 90°C, the second zone is 100°C, the third zone is 110°C, the fourth zone is 120°C, the fifth zone is 130°C, the sixth zone is 140°C, the head is 140°C, the screw speed is 100rpm; the first zone of the blow molding machine is 100°C ℃, the second zone is 120°C, the third zone is 140°C, the fourth zone i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com