A device utilizing rotary inner and outer kettles and energy balls and used for rapid sludge heating and manure material drying

A technology of high-speed heating and drying device, used in dewatering/drying/concentrating sludge treatment, etc., can solve the problems of secondary pollution, etc., and achieve the effect of less floor space, lower investment, and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

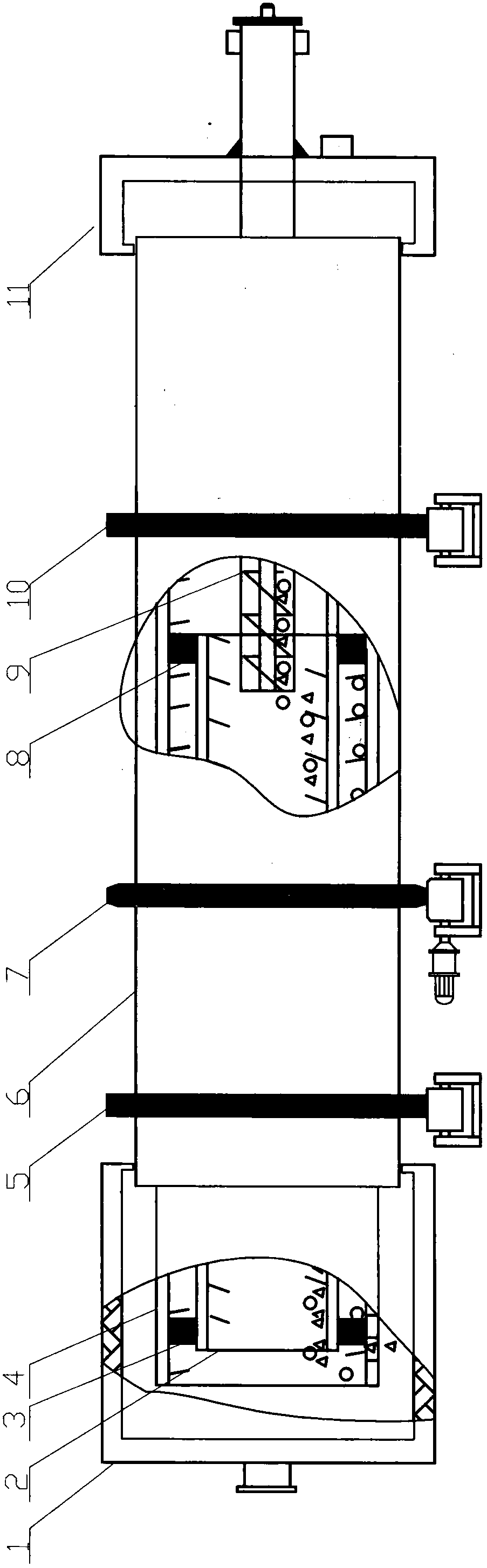

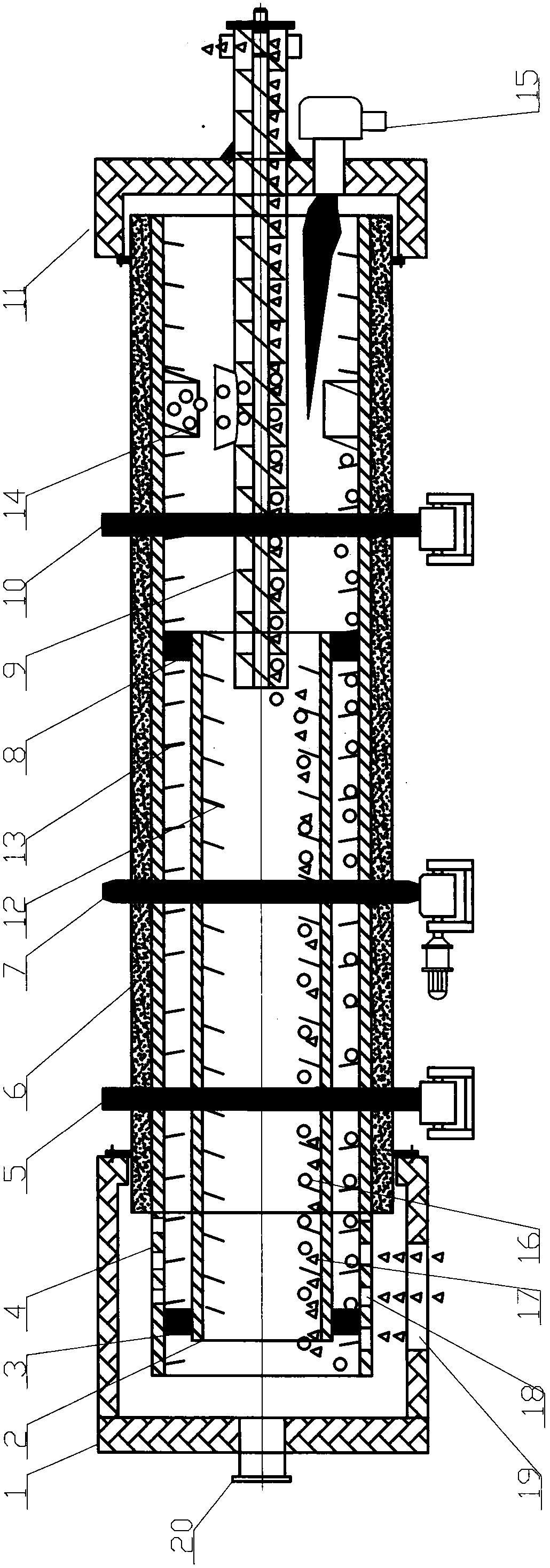

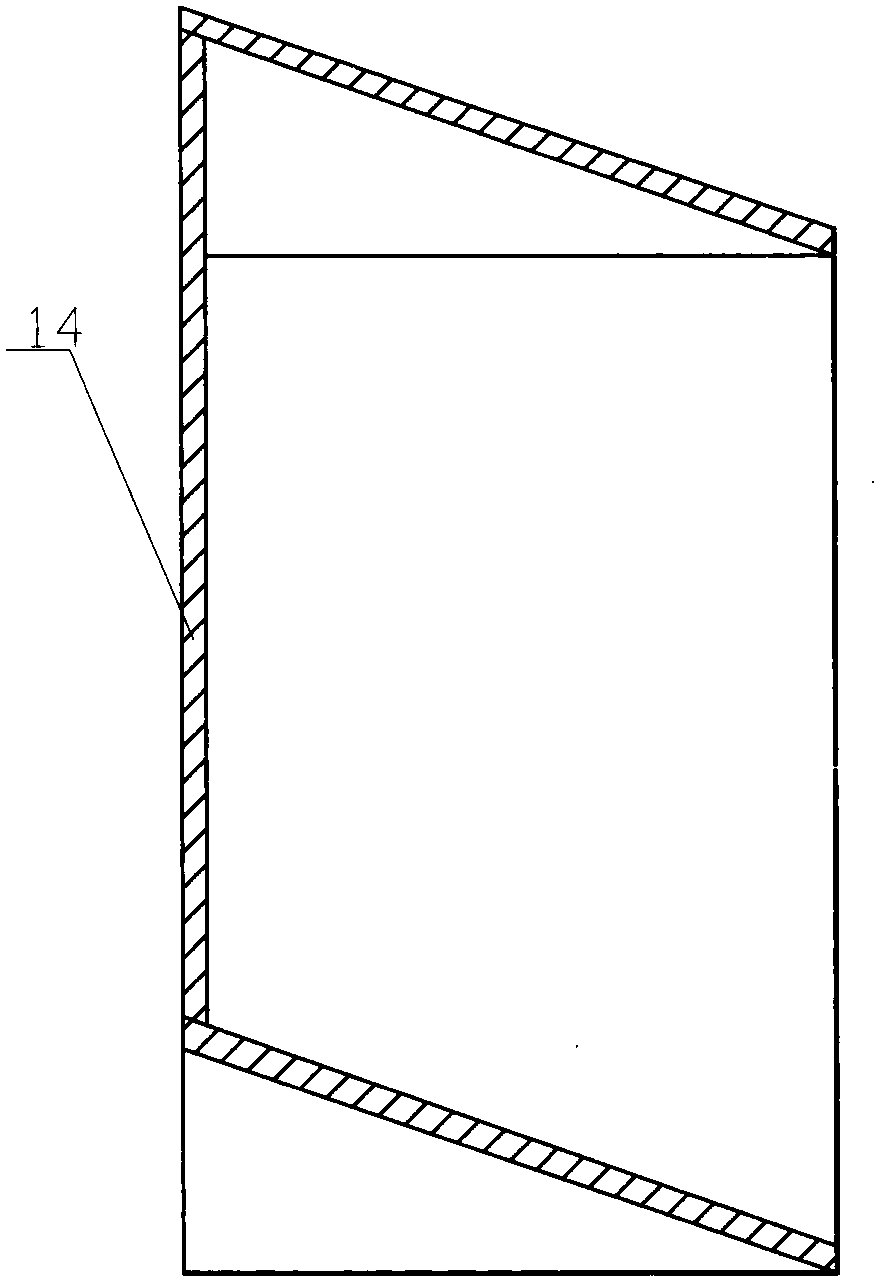

[0022] The present invention is further described in conjunction with the following examples.

[0023] The rotating inner and outer double kettle and the energy ball high-speed heating sludge and dung drying device of this embodiment consist of a fume hood (1), an inner kettle (2), a support plate (3), an outer kettle (4), and a supporting wheel (5), thermal insulation cover (6), transmission wheel (7), support plate two (8), feeder (9), supporting wheel two (10), seal sleeve (11) composition, wherein: inner kettle (2 ) is connected and welded to the inner side of the outer kettle (4) through the first support plate (3) and the second support plate (8); the outer kettle (4) is provided with an insulation cover (6) and is filled with insulation Material; supporting wheel one (5), driving wheel (7), supporting wheel two (10) are respectively provided outside the insulation cover (6), and the outer kettle ( 4) Rotate with the inner kettle (1); the two ends of the insulation cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com