Drying device for heating sludge and fecal material at high speed by rotating inner and outer double kettles and energy balls

A high-speed heating and drying device technology, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, water/sewage treatment, etc. The effect of high efficiency and compact structure of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described in conjunction with the following examples.

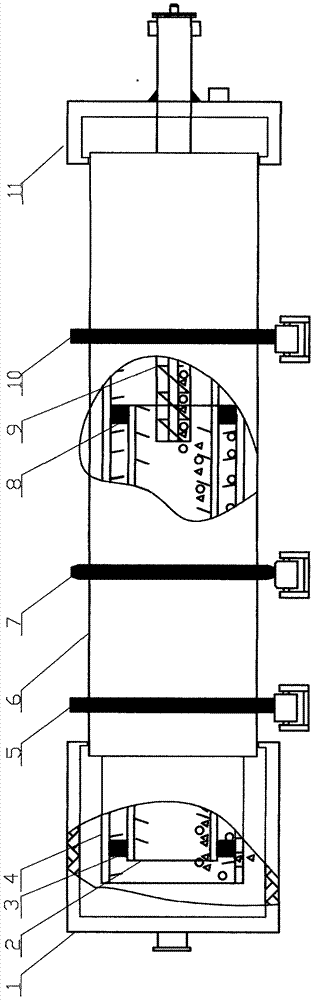

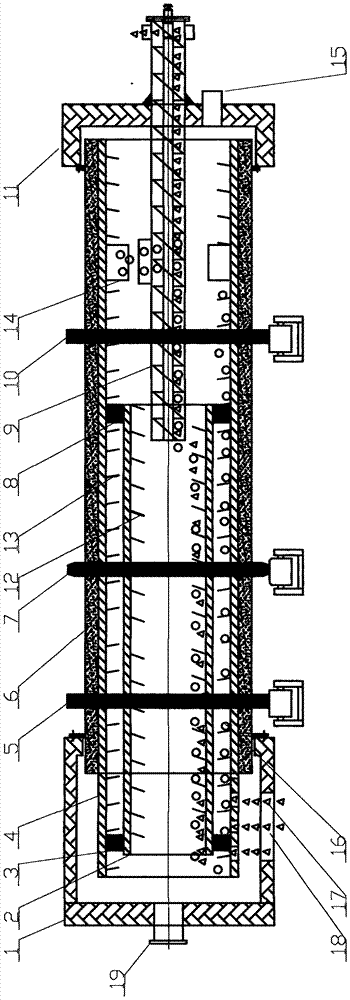

[0022] A kind of drying device for rotating inner and outer double kettles and energy balls to heat sludge and dung at high speed in this embodiment consists of a fume hood (1), an inner kettle (2), a support plate (3), an outer kettle (4), a support Wheel one (5), insulation cover (6), transmission wheel (7), support plate two (8), feeder (9), supporting wheel two (10), sealing sleeve (11), consist of: inner The kettle (2) is connected and welded to the inner side of the outer kettle (4) through the first support plate (3) and the second support plate (8); It is filled with heat-insulating material; a supporting wheel (5), a transmission wheel (7), and a supporting wheel (10) are respectively arranged outside the heat-insulating cover (6); smoke hoods (1 ), the sealing sleeve (11) and anastomosing contact; the feeder (9) is fixed on the sealing sleeve (11) middle part and stretche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com