White light LED and preparation method thereof

An LED chip, white light technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of uncontrolled quantum dot film morphology, poor color uniformity and optical consistency, low utilization rate of quantum dot film, etc. Improve optical consistency, improve color uniformity, save quantum dot material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

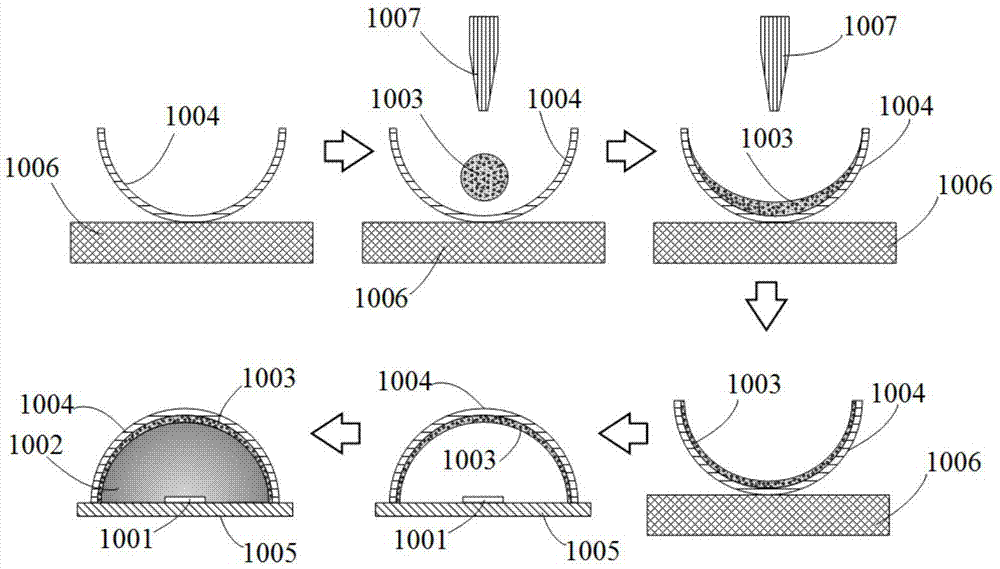

[0042] The preparation method of this white light LED comprises the following steps, such as figure 1 Shown:

[0043] S1. Coating quantum dot colloid with a volume of 10% to 77.5% of the volume of the transparent housing 1004 on the inner surface of the transparent housing 1004, or spot-coating on the top of the transparent housing 1004, Make it infiltrate the inner surface of the light-transmitting shell; wherein, the light transmittance of the light-transmitting shell is greater than 90%, and its shape is hemispherical, equi-polygonal, cylindrical or spherical, with a diameter of 0.3mm-1.0mm glue injection hole; the quantum dot colloid includes quantum dot particles with a mass fraction of 0.05%-1%, a polymer matrix with a mass fraction of 10%-50%, and a mass fraction of 49%-89.5% An organic solvent, the polymer matrix is one or more of polymethyl methacrylate, polycarbonate, polystyrene or silica gel, and the organic solvent is one of toluene, methylene chloride or chlor...

Embodiment 1

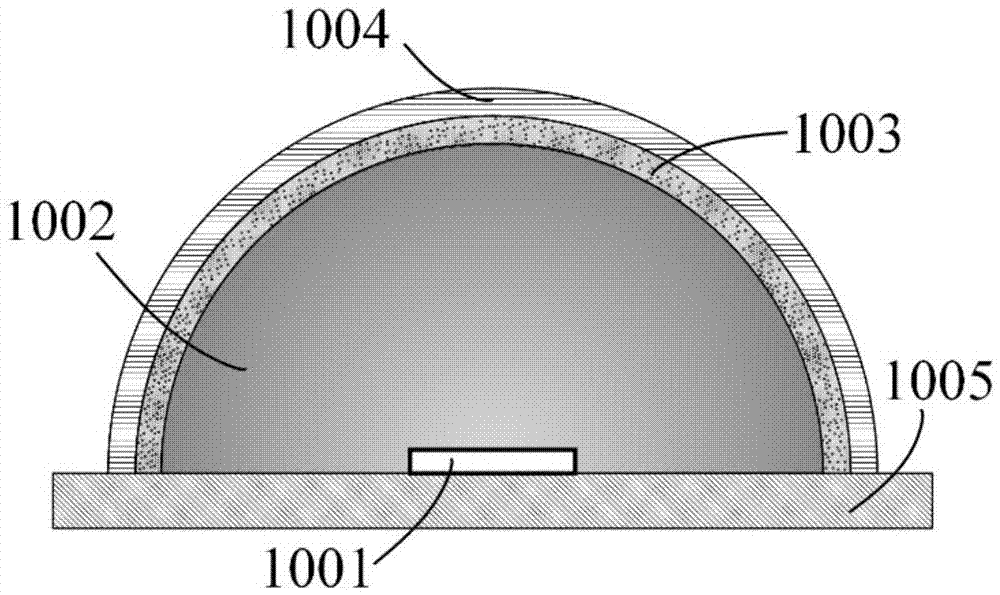

[0050] S1. This embodiment adopts a hemispherical curved surface mold with an inner surface radius of 3mm. The mold material is polycarbonate (PC), the light transmittance is 95%, and a glue injection hole with a diameter of about 0.3mm is opened on the top. The composition of quantum dots is CdSe / ZnS, the emission wavelength is 650nm, and the mass fraction of quantum dots is 0.1%. The organic solvent component is toluene, and the mass fraction is 87.5%. The polymer matrix component is PMMA with a mass fraction of 12.4%. First, place the curved surface mold 1004 with the opening facing upward on the constant temperature heating substrate 1006, heat the constant temperature heating substrate 1006 to 40°C, wait for 30 minutes and then the temperature of the curved surface mold is stable, and then use the dispensing equipment 1007 to dispense 15 μl of quantum dot glue 1003 On the inner surface of the curved surface mold 1004, the quantum dot colloid will wet the inner surface of...

Embodiment 2

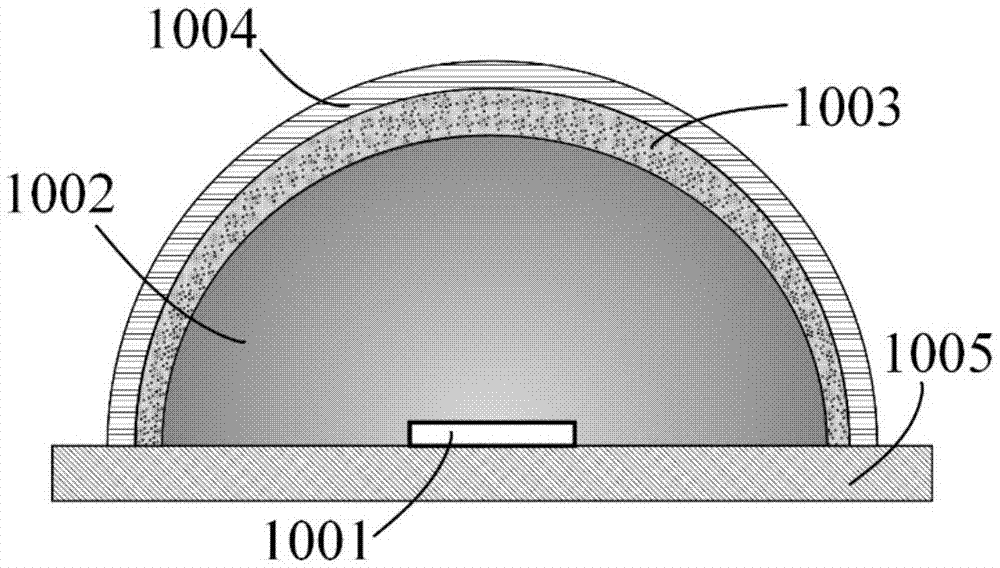

[0054] Repeat Example 1 with the same steps as described, the difference is that the CdSSe / ZnS quantum dots with a luminous wavelength of 650nm are used to replace the CdSe / ZnS quantum dots, the volume of the quantum dot colloid is 20 μl, and due to the large volume of the quantum dot colloid, the obtained The middle thickness of the film is about 0.9mm, and the edge thickness is about 0.7mm, such as image 3 As shown, this morphology is suitable for COB-packaged white light LEDs. Covering a nearly uniform quantum dot film on top of COB LEDs can match the luminous characteristics of the COB module, which is strong in the middle and weak at the edges, and obtain uniform spatial color and high color rendering index. Higher white LEDs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com